Adjustable spanner

An adjustable wrench and wrench technology, applied in the field of hand tools, can solve the problems of hoarding dust, increasing the overall cost of the wrench, flying in, etc., and achieving the effect of reducing the area of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

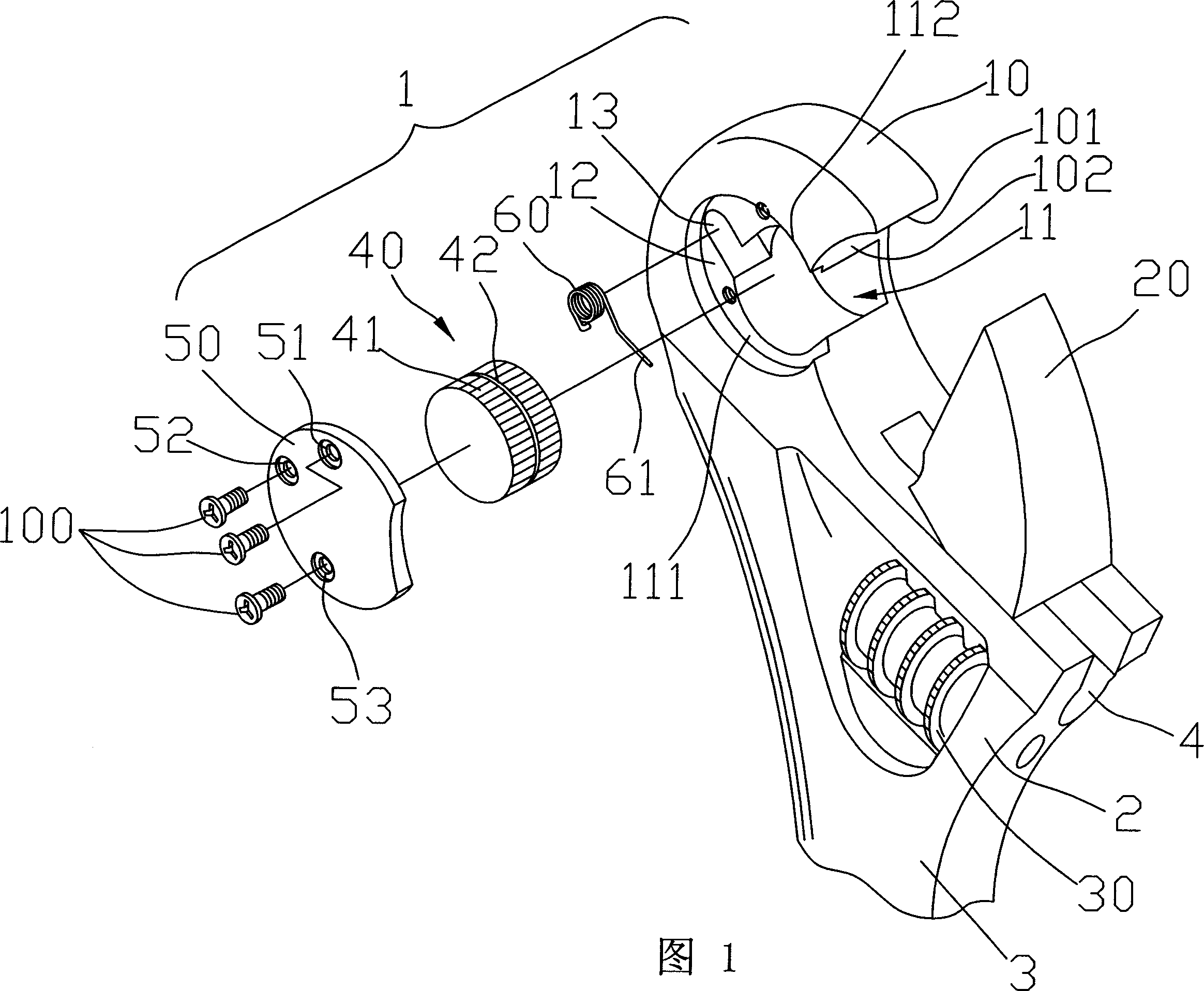

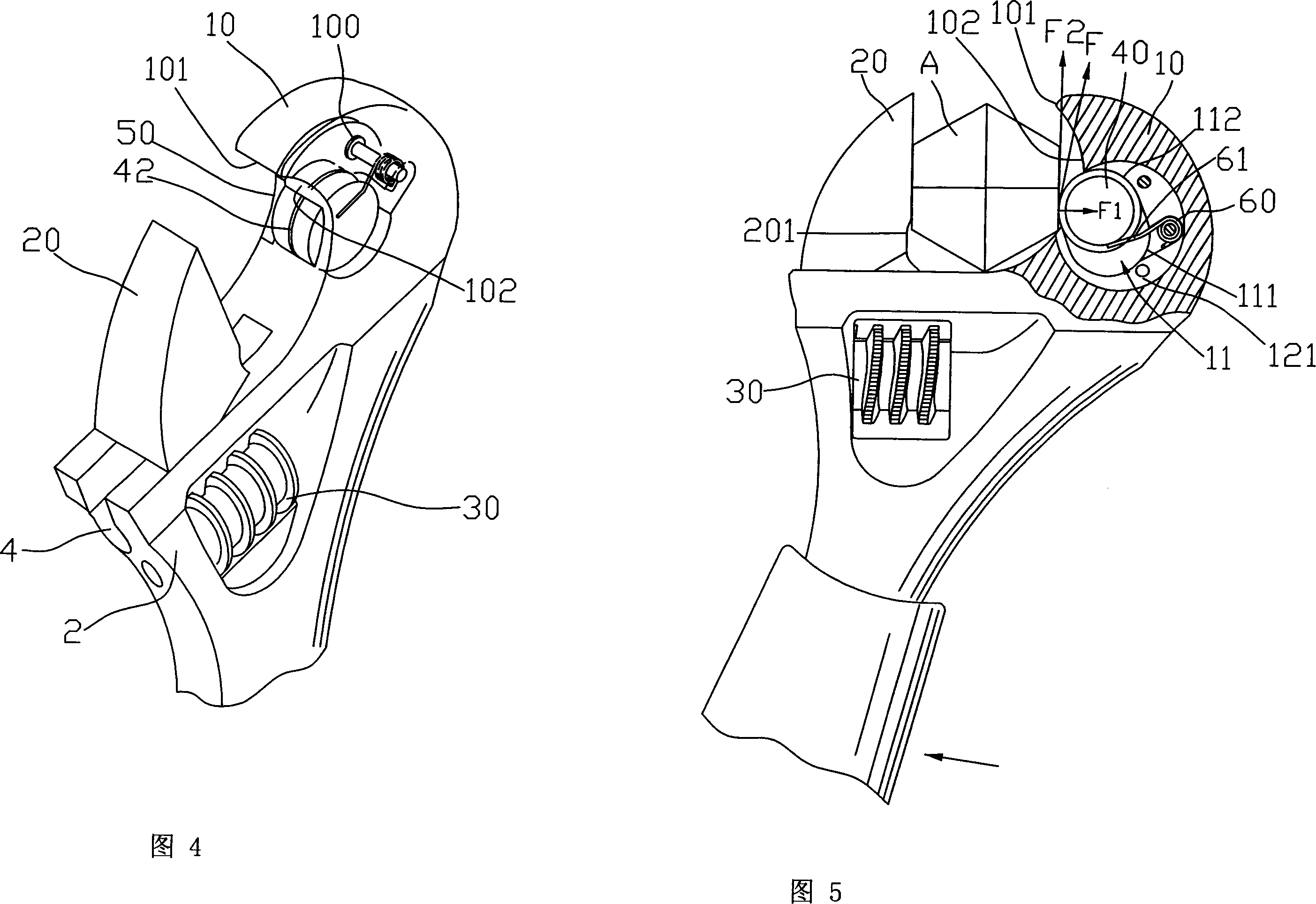

[0047] In Fig. 1-14, adjustable wrench 1 includes a head 2 and a handle 3, one end of head 2 has a fixed jaw 10, and the other end is provided with a chute 4 transversely for a movable jaw 20 to be laterally displaced. Combined, the movable jaw 20 achieves the purpose of lateral displacement through the adjusting worm 30 set at the intersection of the head 2 and the handle 3, and then controls the distance between the movable jaw 20 and the fixed jaw 10, and the upper and lower sections of the inner side of the movable jaw 20 respectively form a clip The holding section, the upper and lower holding sections are designed in a step-like shape, and a hole 201 is formed at the junction of the steps.

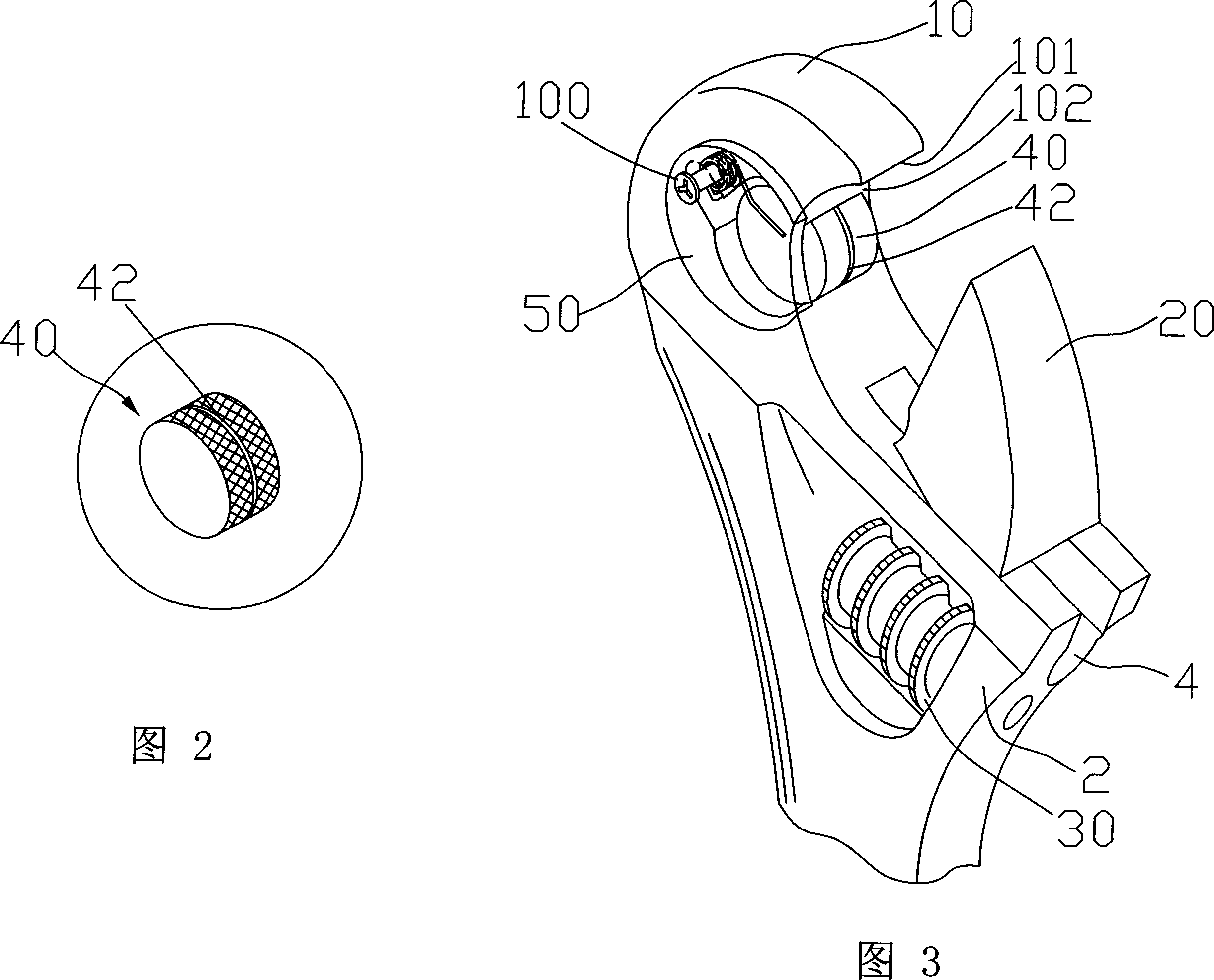

[0048]In addition, an end surface and an inner side of the fixed jaw 10 form a C-shaped chamber 11 with a narrower opening and a depth step edge 12, a driving roller 40 is arranged in the chamber 11, and the step edge 12 abuts against the cover piece 50 , to form a chamber 11 with on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com