Fast piling construction machine for soft soil road base

A technology for construction machinery and highways, applied in infrastructure engineering, sheet pile walls, buildings, etc., can solve the problems of easy cracking, inability to completely remove frozen soil, and large damage area, and achieve small damage area, easy removal, and convenience. take out effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

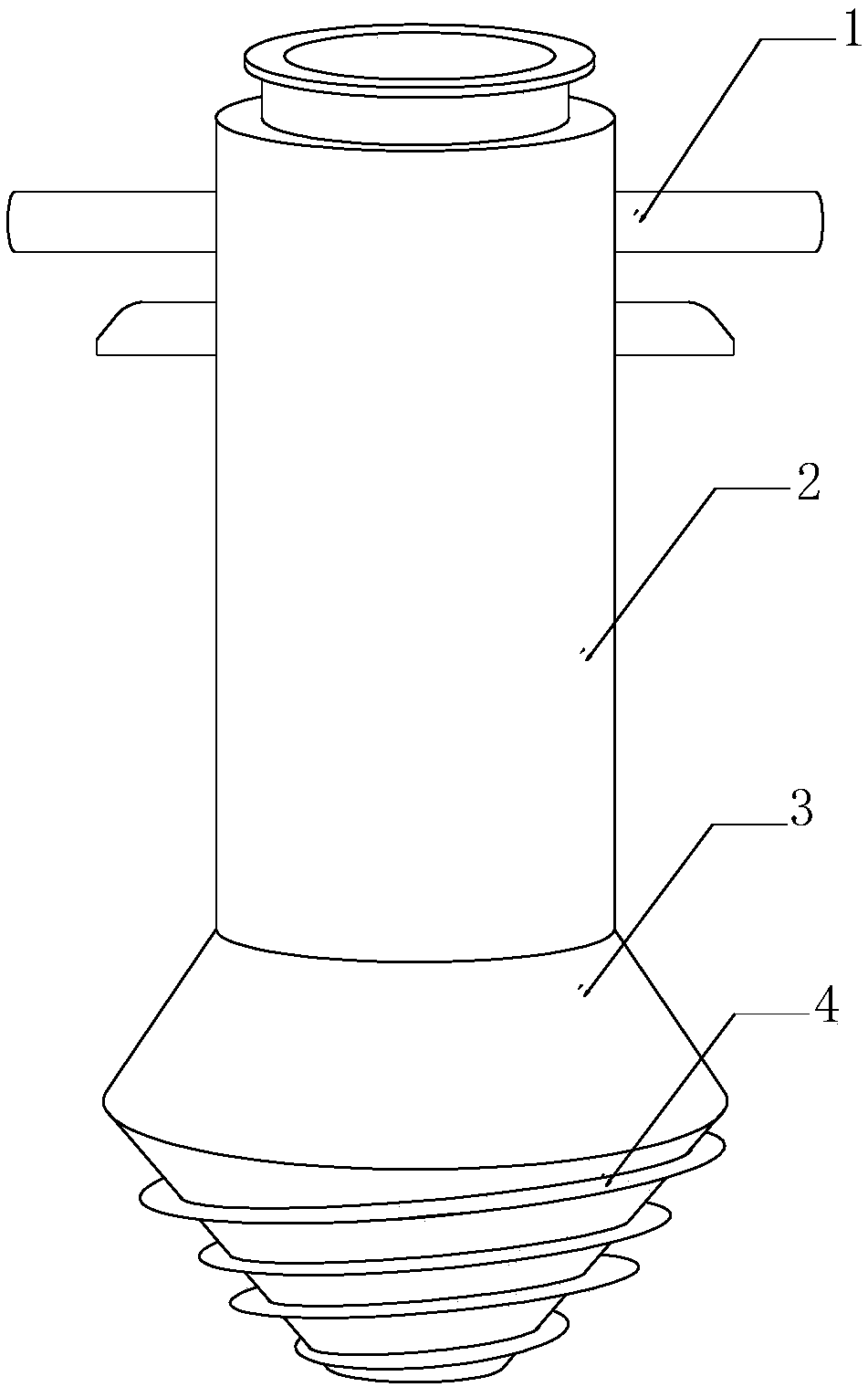

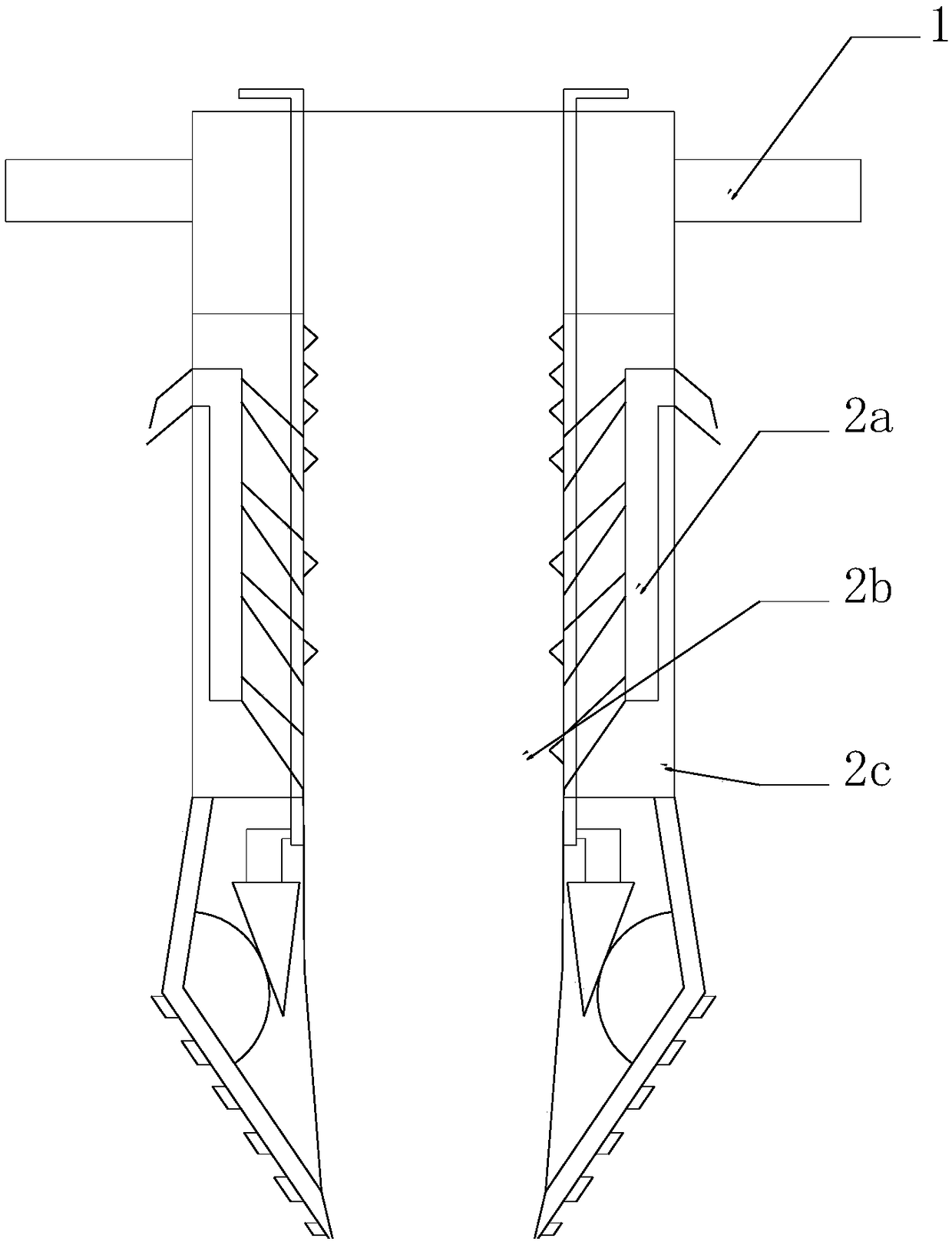

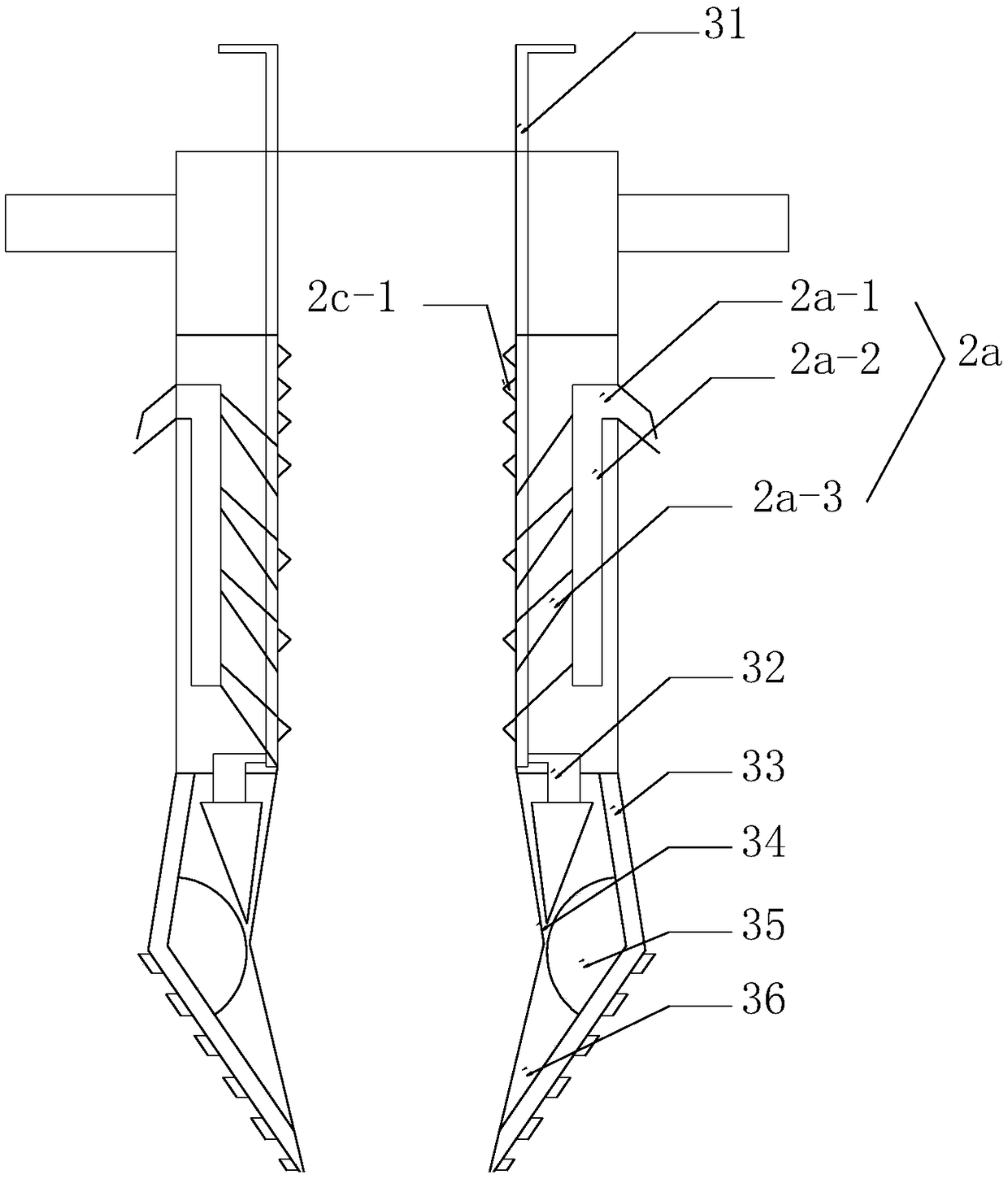

[0025] see Figure 1-Figure 3 , the present invention provides a quick piling construction machine for soft soil road base, its structure includes a parallel bar handshake 1, a main body 2, and a drill bit 3, the main body 2 is a cylindrical structure, and the bottom of the main body 2 is provided with a drill bit 3, which is opposite to the drill bit 3 The top of the main body 2 is provided with two mutually symmetrical parallel bar handshakes 1, and the parallel bar handshakes 1 and the main body 2 are welded horizontally.

[0026] The main body 2 is mainly composed of a drainage structure 2a, a soil chamber 2b and a housing 2c, the housing 2c and the parallel bar handshake 1 are fixed horizontally, the inner space of the housing 2c is the soil chamber 2b, and the housing 2c is provided with The inner and outer layers are double-layered and a drainage structure 2a is provided inside.

[0027] The drainage structure 2a is mainly composed of an oblique outlet pipe 2a-1, a mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com