Hill planter

A technology of hole sowing machine and planting hole, which is applied in the field of agricultural machinery, can solve the problems of large land damage area, artificial seedling replenishment, and large space occupation, and achieve the effects of small land damage area, continuous and rapid sowing, and reduced labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

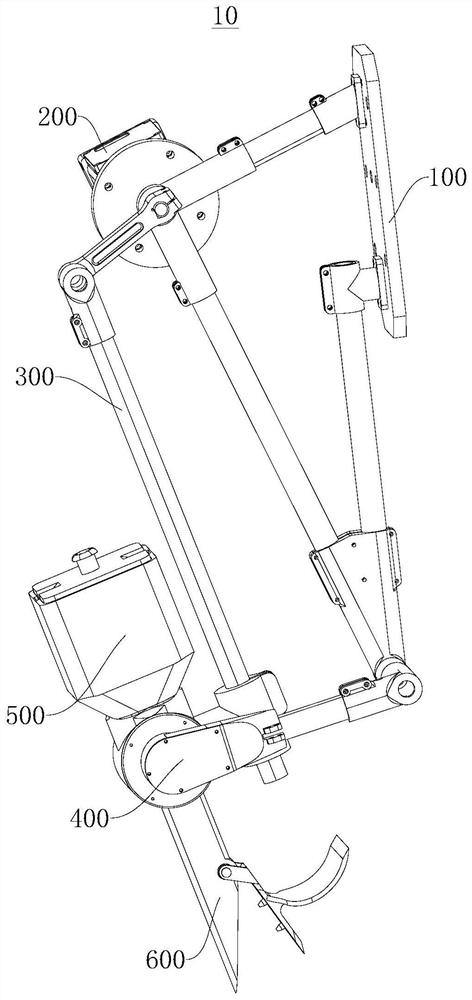

[0046] Please refer to figure 1 , the embodiment of the present invention provides a hole seeder 10 for sowing operations. It can not only achieve continuous and rapid sowing, but also intermittently mechanized seedling replenishment, which reduces labor costs, occupies a small space, and has a small area of land damage, ensuring crop yields.

[0047] It should be noted that the hole seeder 10 needs to cooperate with agricultural machinery (not shown) to carry out farming operations. The agricultural machinery is used to drive the hole seeder 10 to move forward. Realize the function of rapid sowing or mechanized seedling replenishment. Specifically, the agricultural machinery can be an unmanned vehicle, or a walking device that requires manual operation.

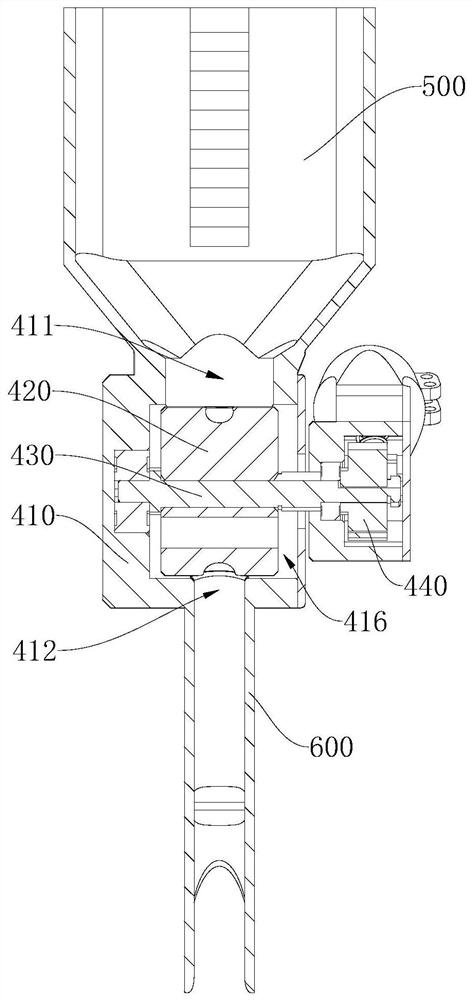

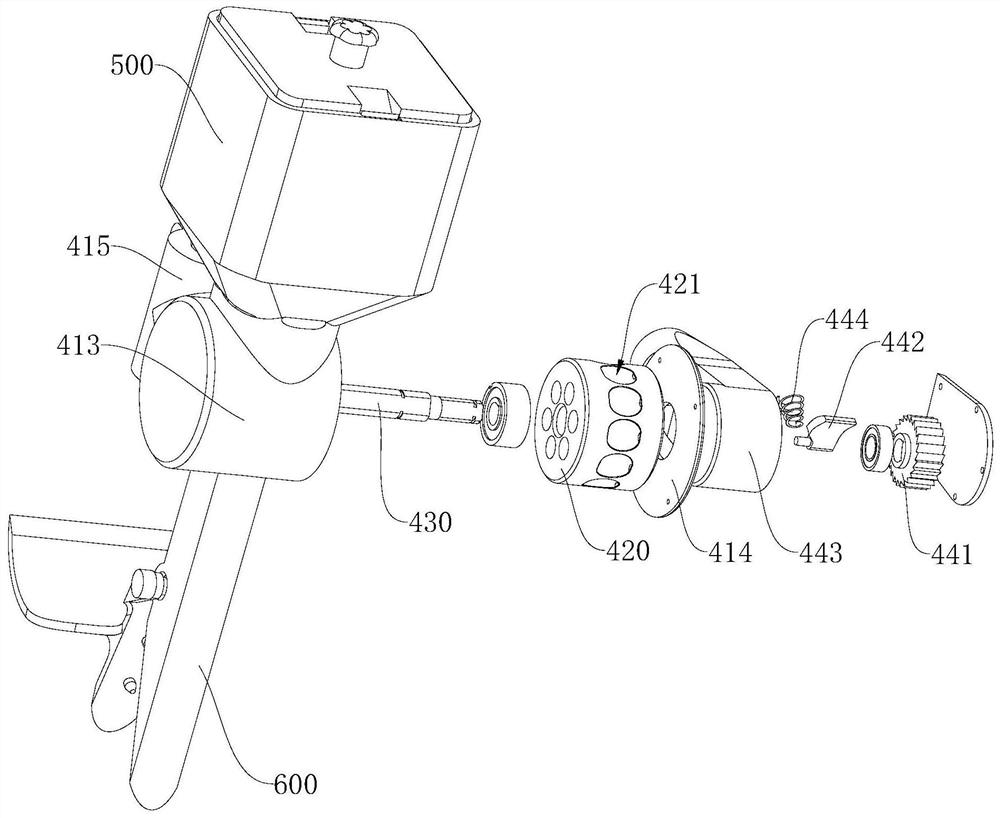

[0048] The hole seeder 10 includes a mounting frame 100 , a driving motor 200 , a connecting rod mechanism 300 , a feeding mechanism 400 , a material storage box 500 and a hole punching head 600 . The driving motor 200 ...

no. 2 example

[0090] Please refer to Figure 13 , the embodiment of the present invention provides a hole seeder 10. Compared with the first embodiment, the difference of this embodiment is that the connection mode between the case cover 520 and the clamping member 530 is different.

[0091] In this embodiment, the box cover 520 is provided with a sliding slot 522 , the clip 530 is provided with a sliding block 531 , and the sliding block 531 is slidably disposed in the sliding slot 522 . The sliding slot 522 can limit the sliding block 531 , and the sliding block 531 can slide relative to the sliding slot 522 so that the clip 530 slides relative to the case cover 520 . Specifically, the extending direction of the chute 522 is perpendicular to the depth direction of the box body 510, and the clip 530 can slide along the extending direction of the chute 522 to achieve engagement with the card slot 511 or disengage from the card slot 511, thereby locking the box. The relative position of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com