Solar aluminum-back full-coverage main-grid-free crystallization silicon cell piece and production technology thereof

A technology of crystalline silicon cells and solar energy, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of non-symmetrical distribution of front and back electrodes, inability to achieve good printing effect, damage to PN junction of cells, etc., and achieve reduction The amount of silver paste used, the effect of strengthening the back passivation and reducing the effect of compounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with the accompanying drawings.

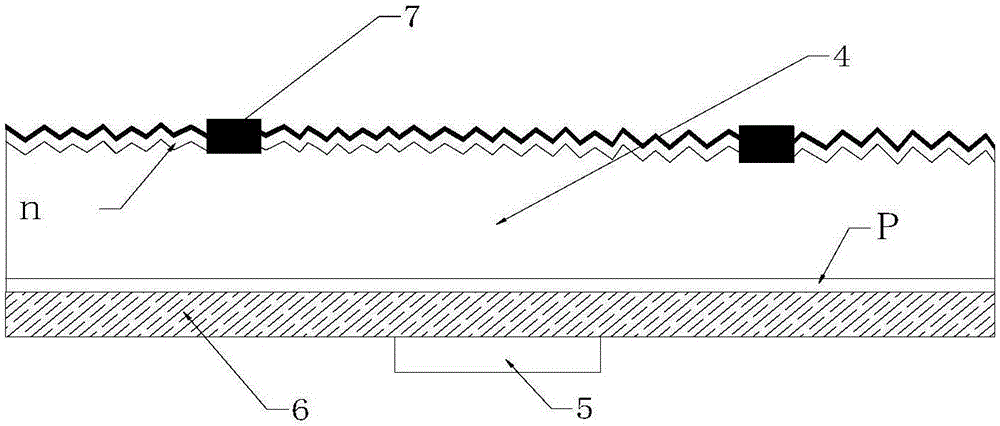

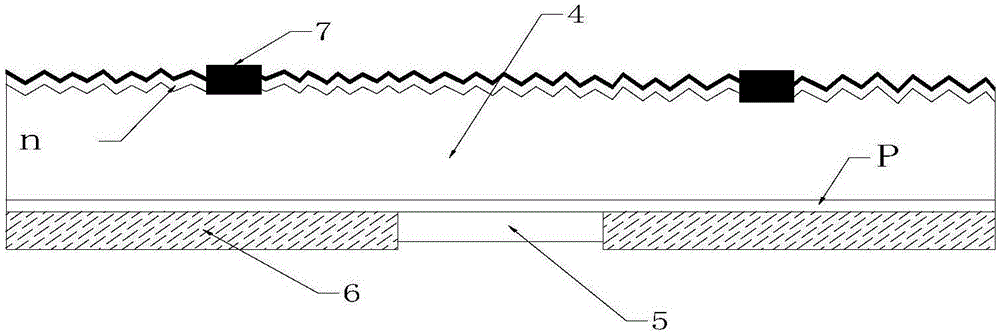

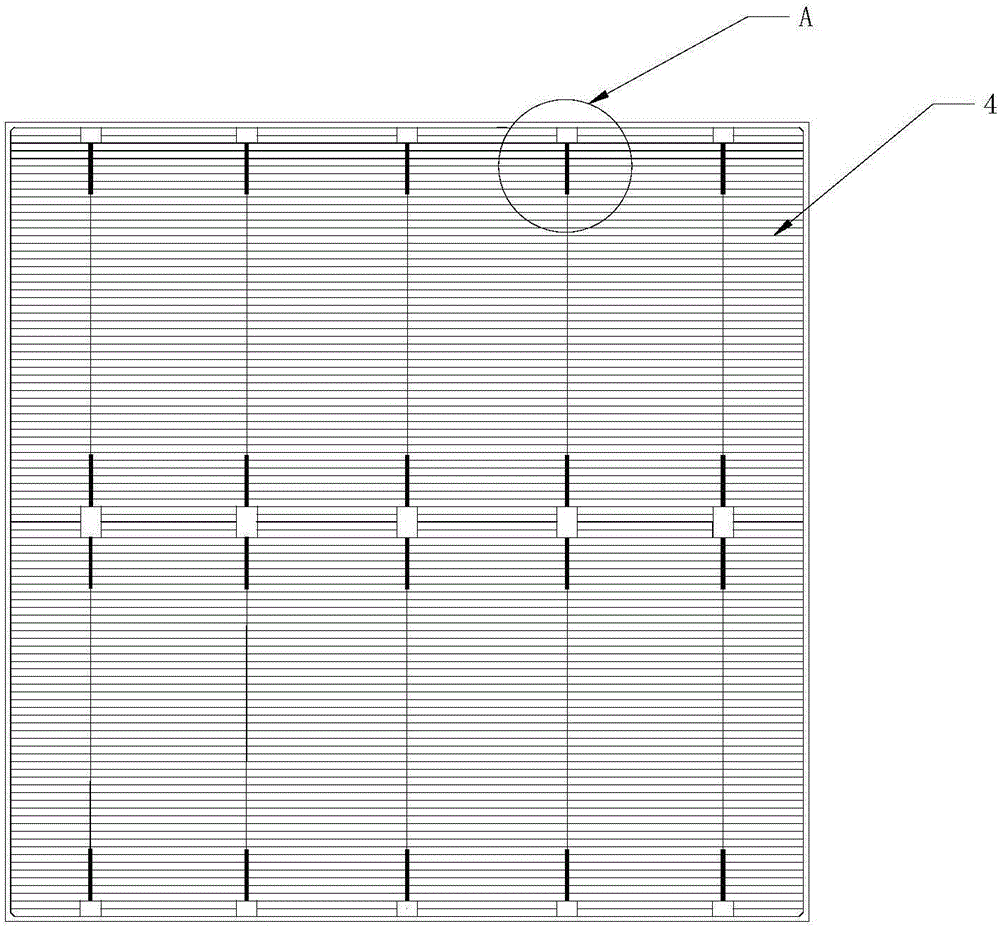

[0056] A solar aluminum back full-covered crystalline silicon cell without busbars, comprising cells 4, thin grids and back electrodes 5, the front of the cells 4 is densely covered with fine grids in a horizontal direction, the back is provided with an aluminum back 6 and arrayed The back electrode 5 also includes a thickened fine grid line 2 and a main grid line reserved part 3. The two ends of the vertical direction of the thin grid line of the battery sheet 4 are provided with a rectangular thin grid line terminal 1, and the rectangular thin grid line terminal 1 is Thickened fine grid lines 2 perpendicular to the thin grid lines are arranged between them, and a main grid line retention part 3 is provided between the end 1 of the rectangular thin grid line and the thickened thin grid line 2, and the aluminum back 6 completely covers the battery sheet 4 , the back el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com