Diamond wire-cut polysilicon wafer with one-side texturing and texturing method thereof

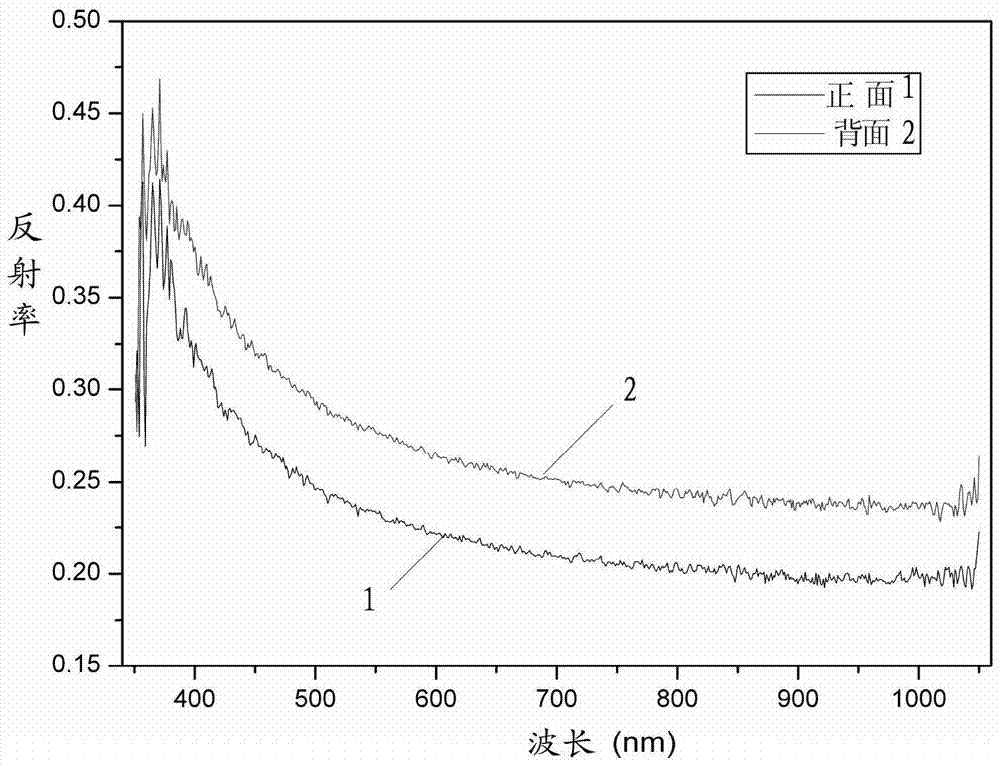

A technology of diamond wire cutting and polycrystalline silicon wafers, which is applied in chemical instruments and methods, crystal growth, and final product manufacturing, can solve the problems of increasing battery processing costs and high cost of coating processes, and achieves reduction of silicon wafer processing steps and optimization of surface microscopic structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

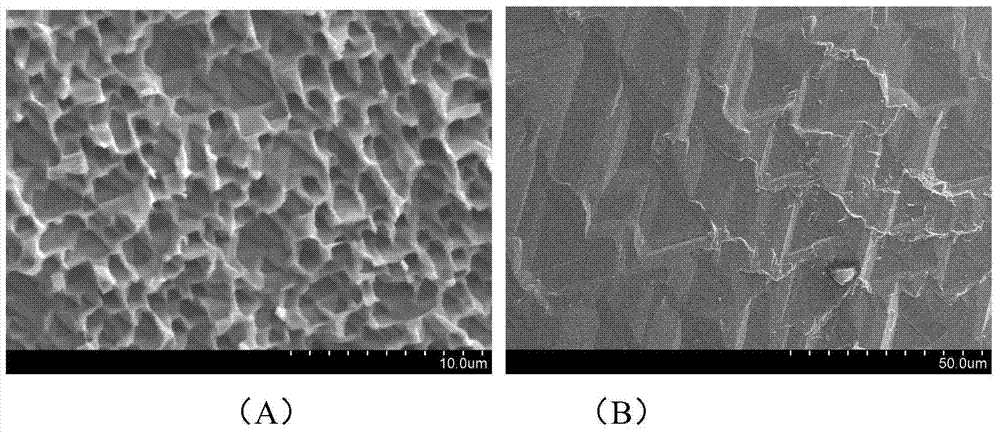

Embodiment 1

[0086] A method for single-sided texturing of a diamond wire-cut polysilicon wafer, comprising the steps of:

[0087] (1) Cleaning pretreatment:

[0088] Prepare a potassium hydroxide solution with a mass fraction of 5%, heat it to 60°C, put the diamond wire-cut polysilicon wafer into the solution for alkaline cleaning for 6 minutes, and perform chemical etching and polishing to remove residual impurities and surface traces on the silicon wafer surface; then Rinse the silicon wafer in a pure water bath at 30°C for 5 minutes to remove residual lye on the surface of the silicon wafer;

[0089] Afterwards, place the silicon wafer in a hydrofluoric acid solution with a mass fraction of 6% for acid cleaning for 4 minutes to remove residual silicate substances on the surface of the silicon wafer, wherein the acid cleaning temperature is 35°C;

[0090] (2) Prepare a surface structure layer with micro-defects:

[0091] Insert the silicon wafers that have undergone the above cleaning...

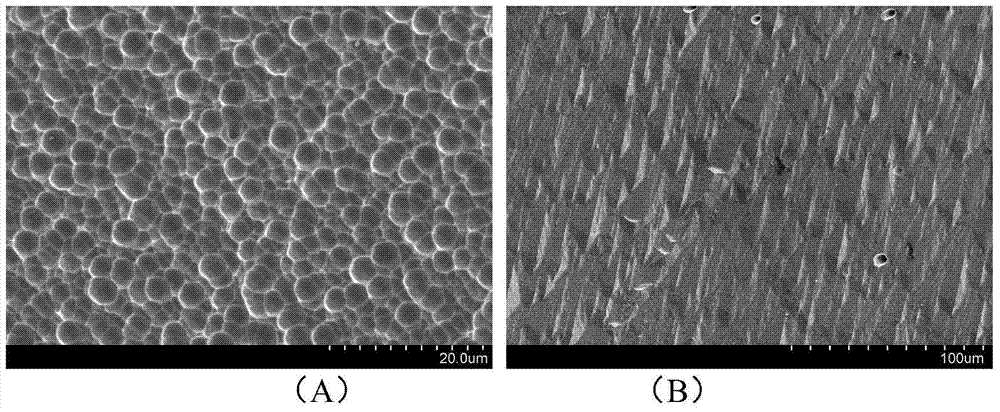

Embodiment 2

[0103] A method for single-sided texturing of a diamond wire-cut polysilicon wafer, comprising the steps of:

[0104] (1) Cleaning pretreatment:

[0105] Prepare a potassium hydroxide solution with a mass fraction of 6%, heat it to 80°C, put the diamond wire-cut polysilicon wafer into the solution for alkaline cleaning for 3 minutes, and perform chemical etching and polishing to remove residual impurities and surface traces on the silicon wafer surface; then Rinse the silicon wafer in a pure water bath at 50°C for 3 minutes to remove residual lye on the surface of the silicon wafer;

[0106] Afterwards, place the silicon wafer in a hydrofluoric acid solution with a mass fraction of 8% for acid cleaning for 3 minutes to remove silicate substances remaining on the surface of the silicon wafer, wherein the acid cleaning temperature is 25°C;

[0107] (2) Prepare a surface structure layer with micro-defects:

[0108] Insert the silicon wafers that have undergone the above cleanin...

Embodiment 3

[0116] A method for single-sided texturing of a diamond wire-cut polysilicon wafer, comprising the steps of:

[0117] (1) Cleaning pretreatment:

[0118] Prepare a potassium hydroxide solution with a mass fraction of 10%, heat it to 70°C, put the diamond wire-cut polysilicon wafer into the solution for alkaline cleaning for 4 minutes, and perform chemical etching and polishing to remove residual impurities and surface traces on the silicon wafer surface; then Rinse the silicon wafer in a pure water bath at 40°C for 4 minutes to remove residual lye on the surface of the silicon wafer;

[0119] Afterwards, place the silicon wafer in a hydrofluoric acid solution with a mass fraction of 3% for acid cleaning for 3 minutes to remove residual silicate substances on the surface of the silicon wafer, wherein the acid cleaning temperature is 30°C;

[0120] (2) Prepare a surface structure layer with micro-defects:

[0121] Insert the silicon wafers that have undergone the above cleanin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com