PERC-CZTS laminated solar cell and preparation method thereof

A solar cell, copper-zinc-tin-sulfur technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve problems such as loss of spectral energy and inability to use high-energy photons, and achieve simple process, low cost, and improved battery efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

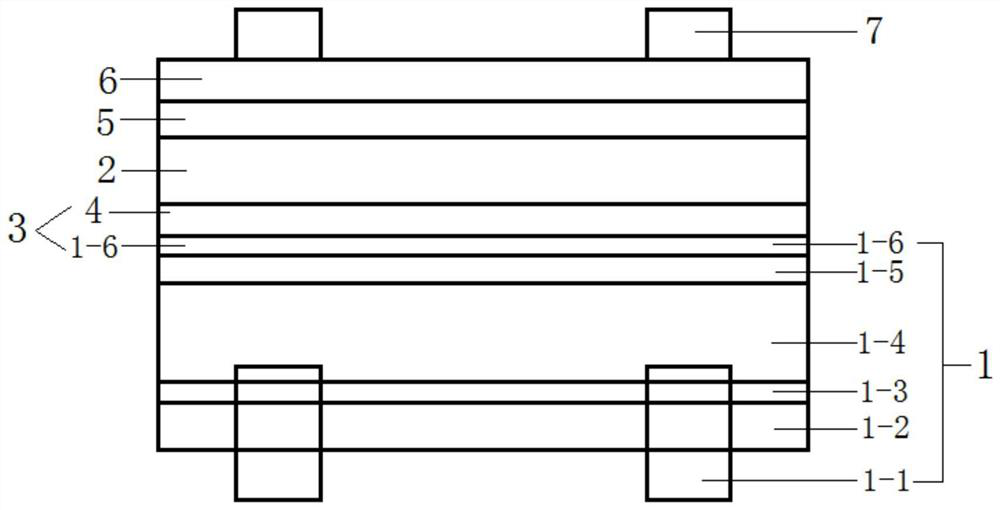

[0050] like figure 1 As shown in the figure, a PERC-copper-zinc-tin-sulfur tandem solar cell is characterized in that, the tandem solar cell comprises a bottom cell 1, a top cell 2 with a thickness of 2 μm, a top cell 2 with a thickness of 2 μm, and a top cell 2 arranged on the bottom cell 1 and the top layer. The connection layer 3 between the cells 2 and the cadmium sulfide transition layer 5, the zinc oxide window layer 6 and the top electrode 7 arranged on the top cell 2 in sequence; wherein: the top cell 2 is a copper-zinc-tin-sulfur cell; The connecting layer 3 is a tunneling layer formed by the ultra-thin silicon oxide layers 1-6 and the MoSxOy layer 4; the thickness of the transition layer 5 is 60 nm; the thickness of the window layer 6 is 100 nm. Wherein: the underlying battery 1 includes a bottom electrode 1-1, a first passivation layer (SiNx) 1-2 with a thickness of 80 nm, a second passivation layer (AlOx) 1-2 with a thickness of 5 nm, which are sequentially arrange...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com