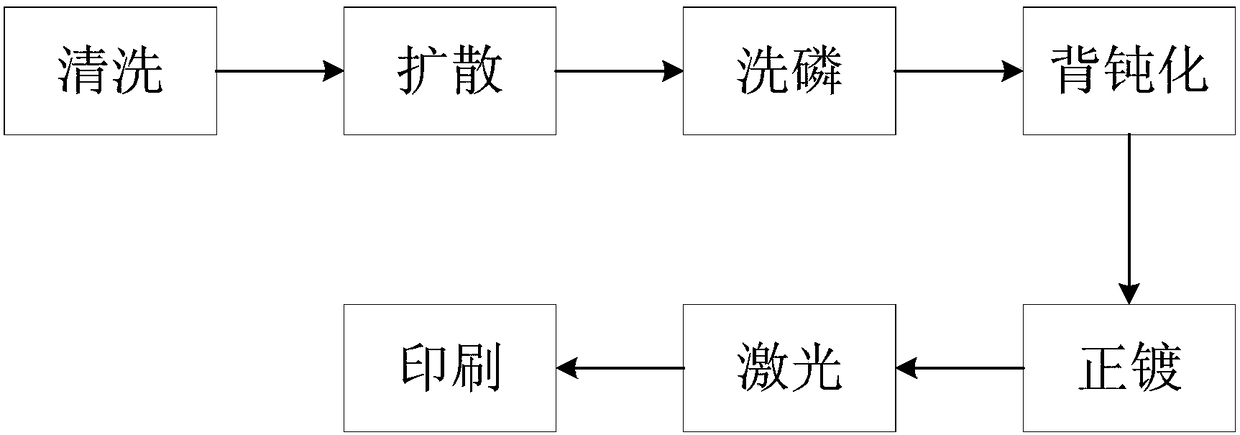

Battery preparation method for improving perc back passivation effect

A back passivation and battery technology, which is applied in the manufacture of circuits, electrical components, final products, etc., can solve the problems of poor MAIA back passivation effect, abnormal luminescent EL, and influence on AlOx, so as to improve the back passivation effect and increase Compactness, efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

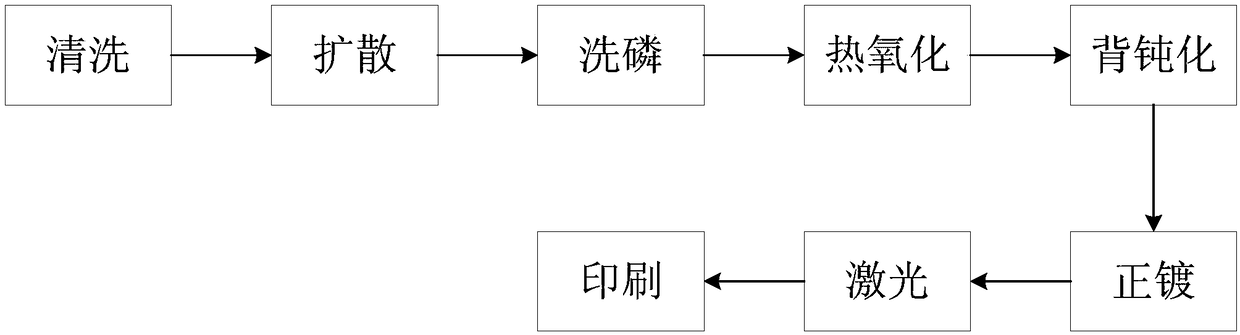

[0026] Such as figure 2 As shown, a battery preparation method for improving the PERC back passivation effect of the present invention includes cleaning, diffusion, phosphorus washing, MAIA, front coating, laser groove and screen printing on the silicon wafer. It is characterized in that, in A thermal oxidation process is added between phosphorus washing and MAIA processes.

[0027] The specific steps of this embodiment include:

[0028] Step 1: Cleaning, place the wafer in HF / HNO 3 Wash in the mixed solution to remove the surface damage layer, cutting line marks and metal ions, etc.;

[0029] Step 2: Diffusion, the silicon wafer is diffused under normal pressure, and its s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com