Leadless conductive target plate

A conductive target and leadless technology, which is applied in the direction of targets, other rubber adhesives, adhesive types, etc., can solve the problems of shooting accuracy uncertainty, lead wire disconnection, affecting target reporting work and shooting training, etc. To achieve the effect of prolonging the continuous working time and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

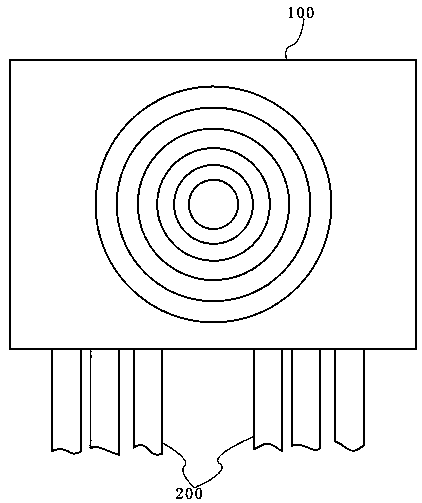

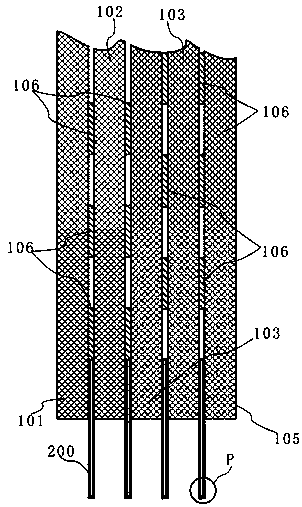

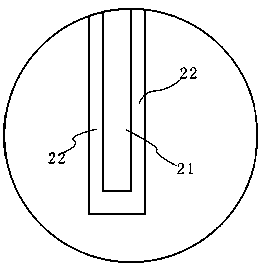

[0028] Such as Figure 1-3 As shown, this embodiment provides a leadless conductive target board, including a target 100 with several groups of conductive units 106 built in and a conductor 200 electrically connected to each conductive unit 106 and exposed to the target 100. The conductor 200 It includes a conductive cloth 21 with a width of not less than 1 cm and a waterproof insulating layer 22 sealingly covering the conductive cloth 21. The waterproof insulating layer 22 is preferably a silicone rubber layer, and the width of the conductive cloth 21 is preferably 1 cm to 2 cm.

[0029] The target 100 includes five insulating plates that are bonded together in sequence, from front to back, they are insulating plate A101, insulating plate B102, insulating plate C103, insulating plate D104 and insulating plate E105, wherein the front surface of the insulating plate A101 The target surface pattern is printed, the conductive unit on the front surface of the insulating board B102...

Embodiment 2

[0032] This embodiment also provides a leadless conductive target plate, which further makes the following improvements on the basis of the technical solution described in the above-mentioned embodiment 1: Figure 4 As shown, the conductor 200 also includes a heat dissipation layer 23 and a damping adhesive layer 24, the damping adhesive layer 24 is bonded to the front end of the waterproof insulating layer 22 on the front side of the conductive cloth 21, and the heat dissipation layer 23 is embedded in the Between the damping rubber layer 24 and the waterproof insulating layer 22 .

[0033] The main function of the damping rubber layer 24 is to reduce the impact of the bullet on the conductive cloth 21, reduce the lethality of the bullet to the conductive cloth 21 or make the bullet blocked in the damping rubber layer 24, and after the bullet penetrates the damping rubber layer 24 The bullet holes on the damping adhesive layer 24 will shrink automatically, reducing the damage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com