One-shot forming production line apparatus for seat cushion and back-cushion

A technology for production line equipment and seat cushions, which is applied in the field of one-shot molding production line equipment, can solve problems such as easy control of procedures and process conditions, low degree of mechanization, and unstable product quality, so as to achieve standardization and stable product quality , process coherent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

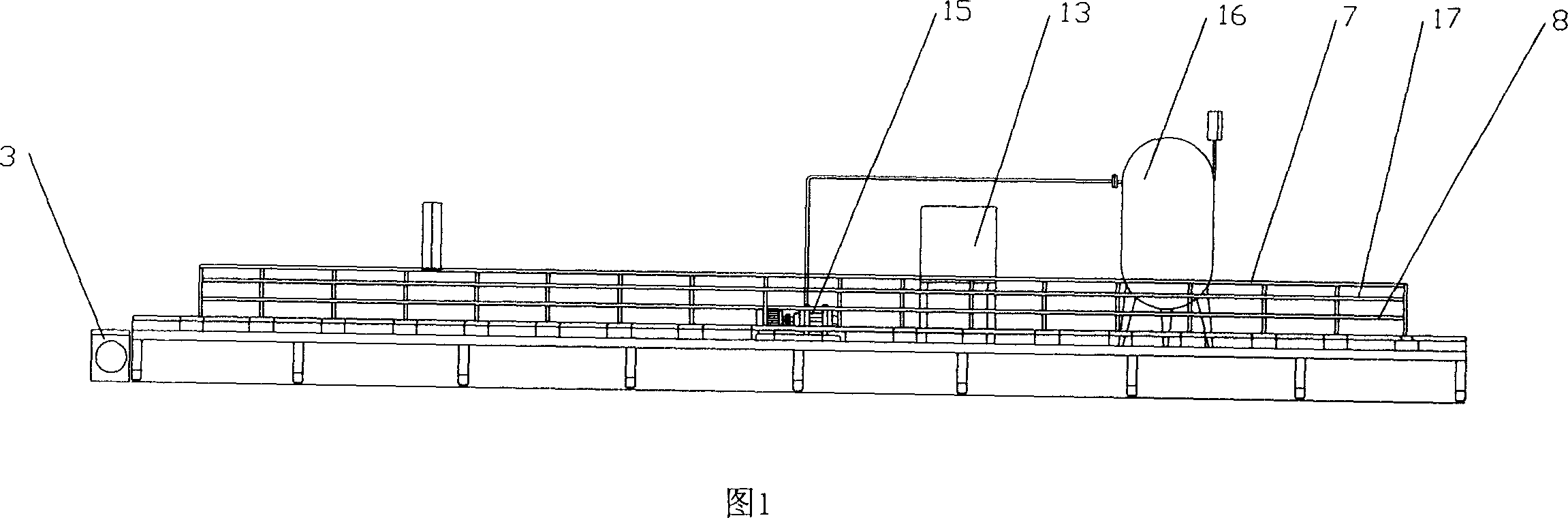

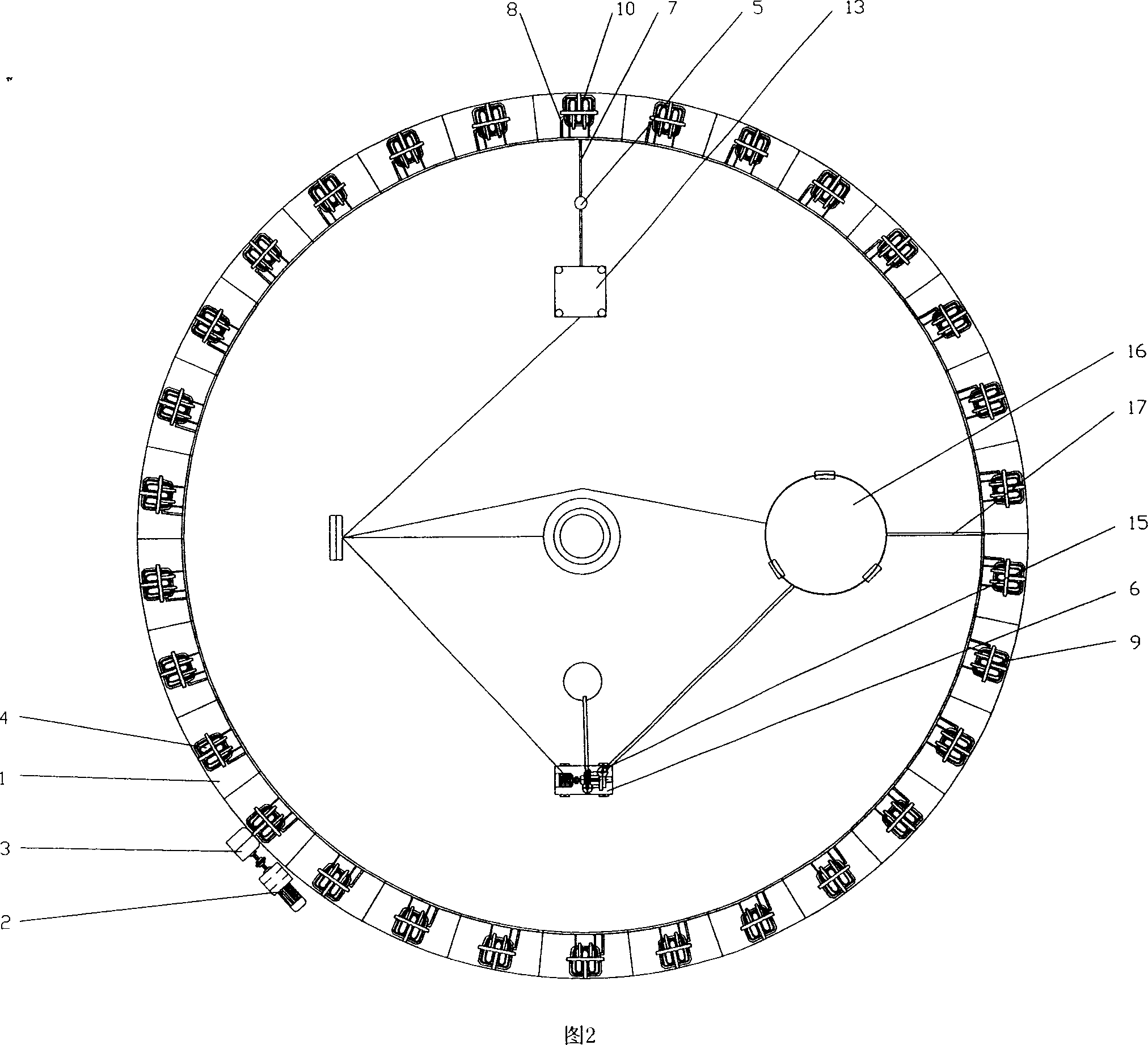

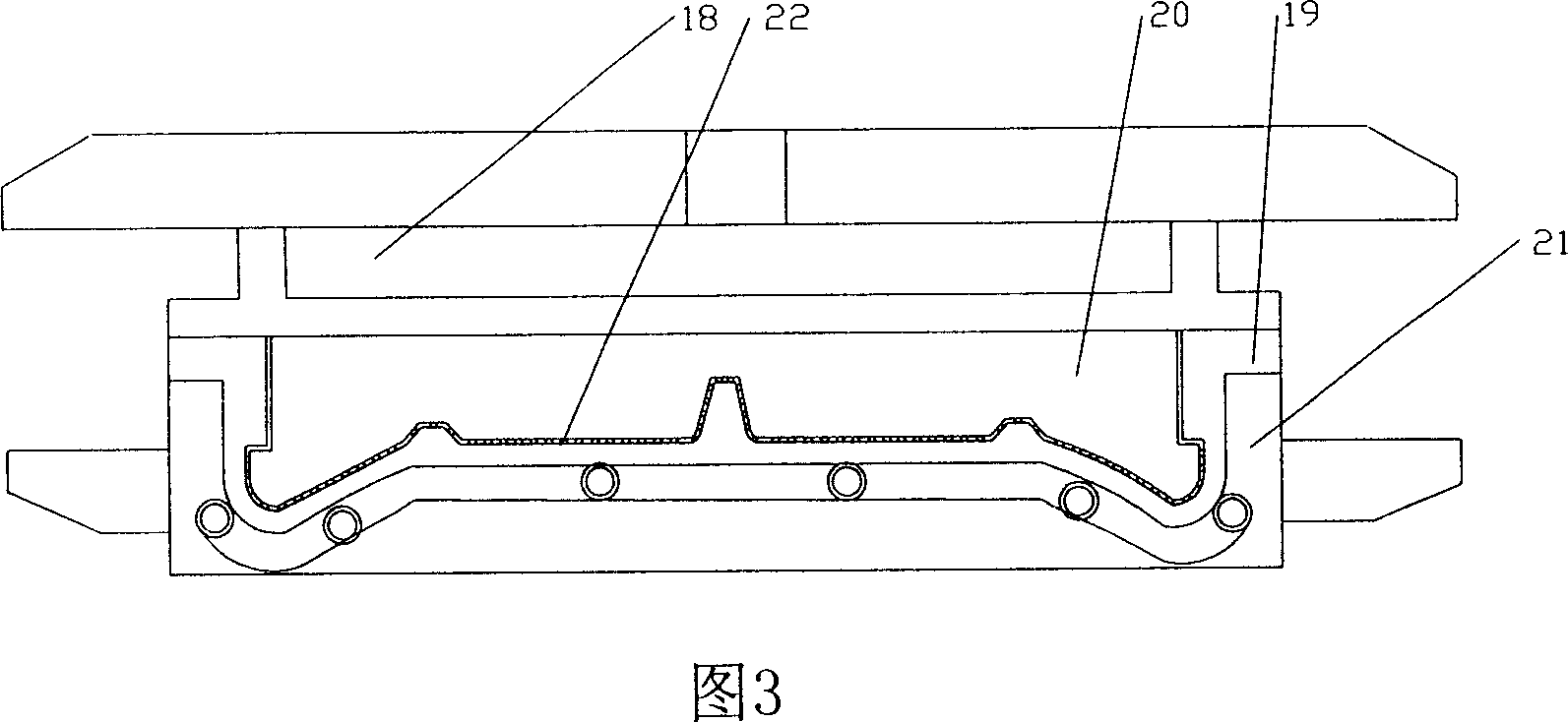

[0023] As shown in Figures 1 to 4, the main body of the equipment of the one-time forming production line for seat cushions and back cushions of the present invention is a turntable mechanism. The turntable mechanism is composed of a turntable 1 and a turntable drive device. The speed reducer 3 connected by transmission on the output shaft constitutes, and the sprocket assembled on the output shaft of the speed reducer 3 cooperates with the ring gear formed by the fixed circle chain at the bottom of the turntable 1 . There is a one-time forming mold 4 with a circle of seat cushion and back cushion installed around the turntable 1. The one-time forming mold 4 is a vacuum-absorbing one-time forming mold for cold plastic high-resilience foaming materials and fabrics. The mold 4 is equipped with a vacuum for fabrics. structure and the liquid circulation heat exchange mechanism 9 for the foaming material, a liquid temperature control circulation device and a vacuum pumping device 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com