Precise multifunctional lifting platform

A lifting platform, multi-functional technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems of high cost, difficult precision machining, unable to monitor the pressure of the platform, etc., and achieve the effects of high cost performance, simple structure and novel design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

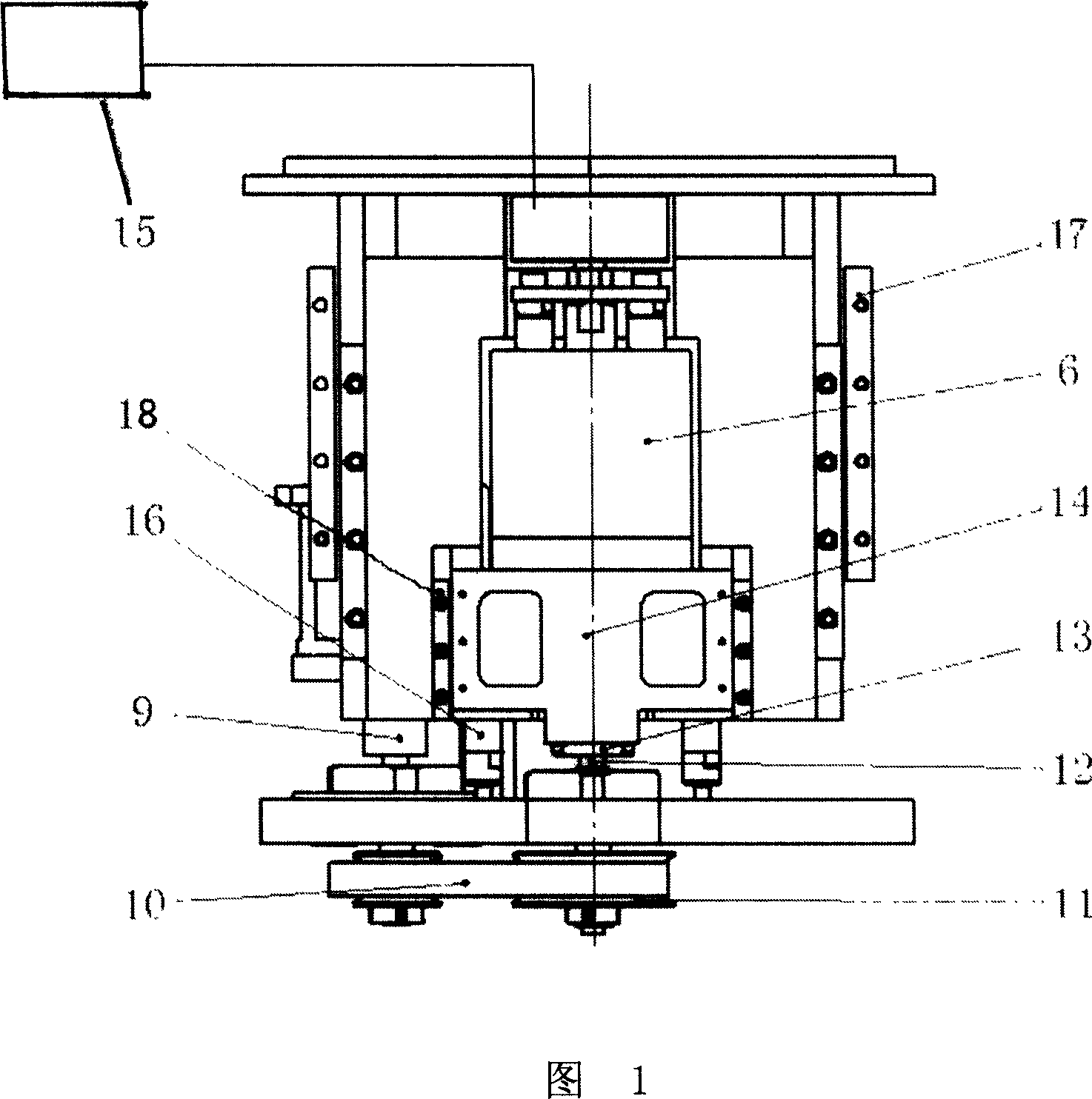

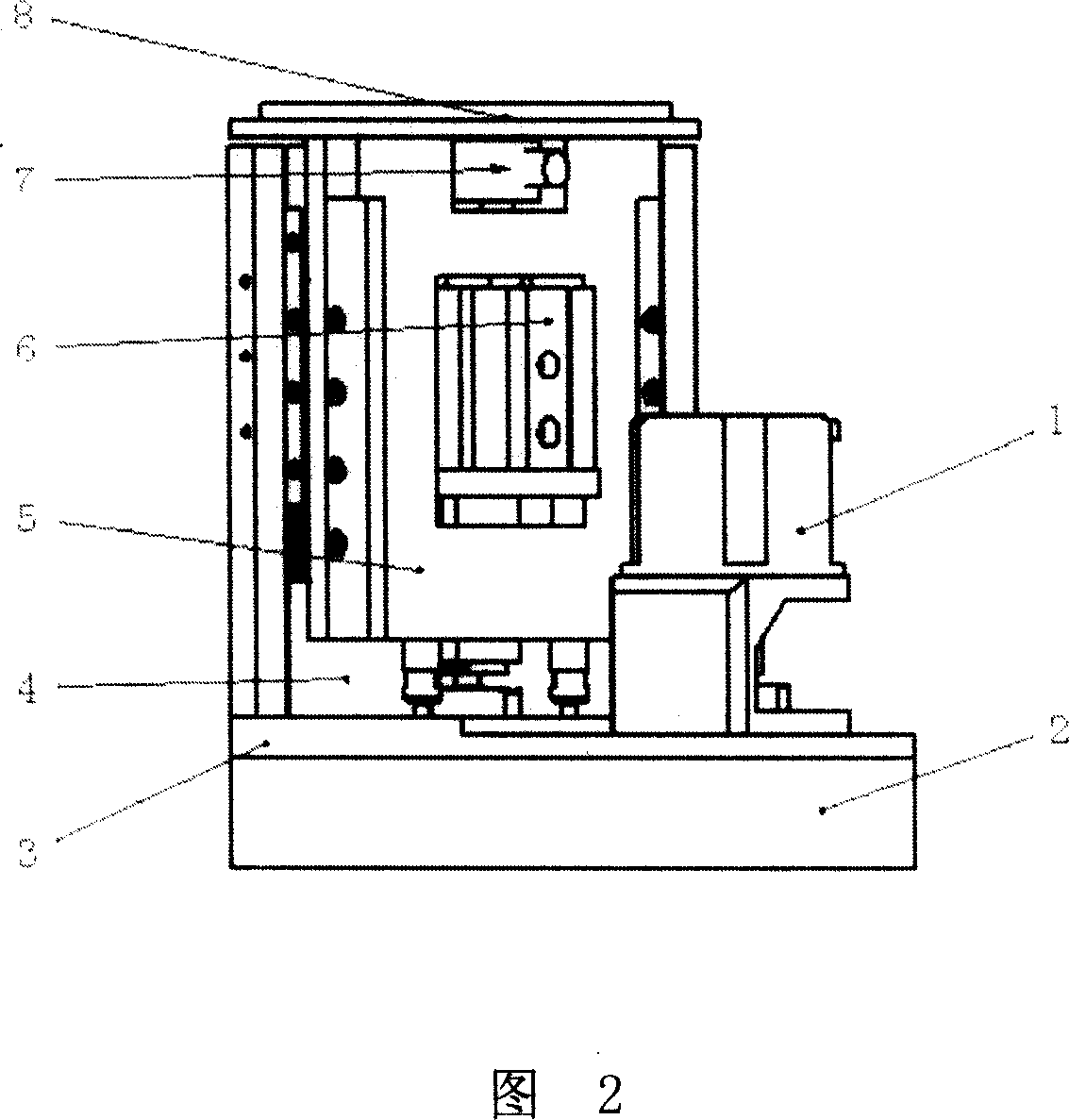

[0011] The present invention adopts two-level linear guide rails, and the first-level guide rails fixed on the sliding outer frame 4 realize the precise guidance of the platform; the second-level guide rails fixed on the sliding frame 5 ensure that when the platform moves to the lowest point (that is, when it is not working), The pressure detection point of the pressure sensor 7 does not touch the head of the piston rod of the cylinder 6, which prolongs the service life of the pressure sensor 7; the low-friction cylinder, pressure sensor, and precision pressure regulating valve cooperate with the computer system to realize the closed-loop control of pressure. The low-friction cylinder 6 and the small sliding part 14 are fixed with screws, the small sliding part 14 is connected with the sliding frame 5 through the cross roller guide rail, the sliding frame 5 is connected with the sliding outer frame 4 with the cross roller guide rail, and the two pairs of guide rails can be adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com