Gas hermetic apparatus and hermetic method of glass base plate annealing furnace

A glass substrate and annealing furnace technology, applied in the field of ultra-thin glass substrate manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

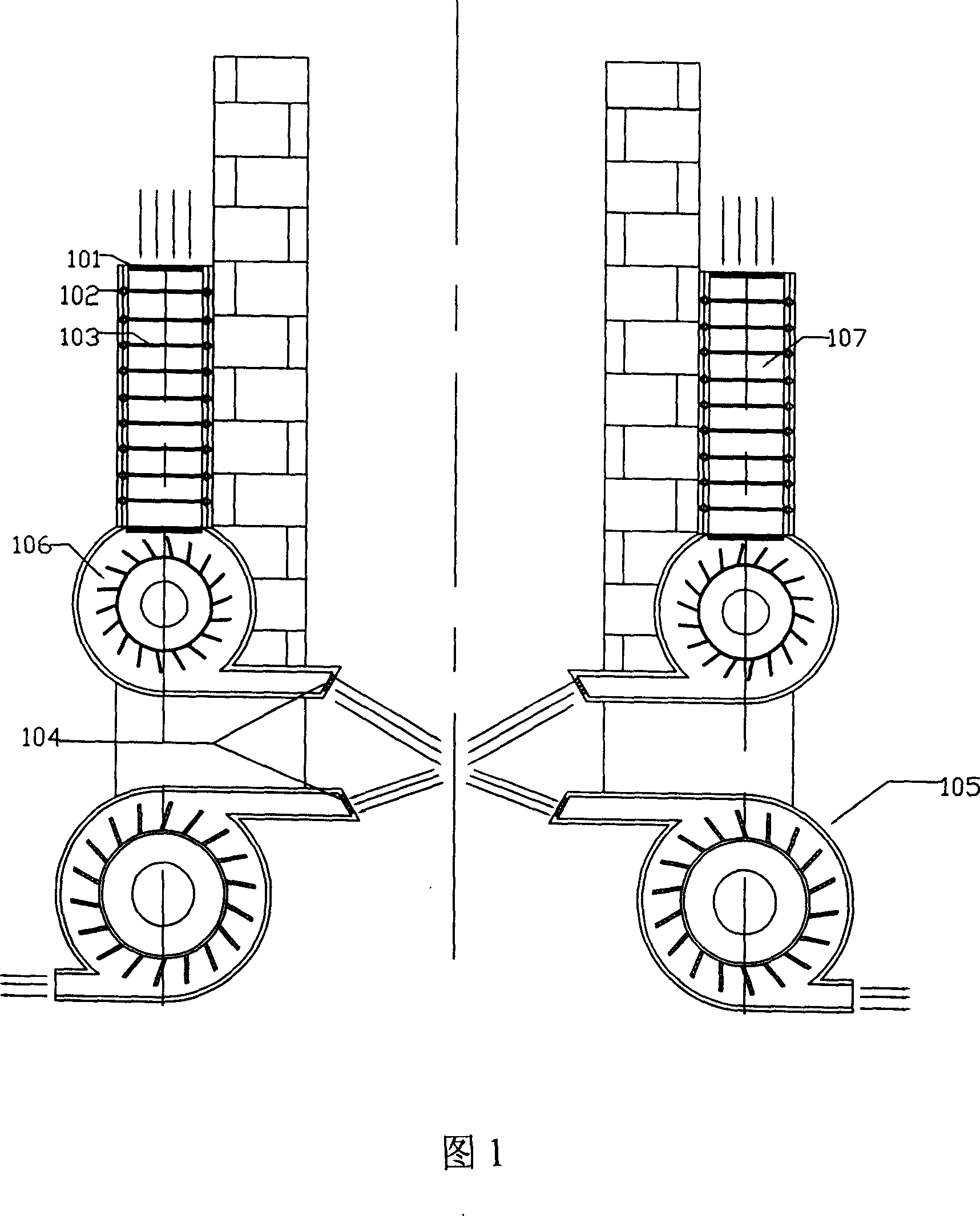

[0026] As shown in the air lock system at the lower end of the annealing furnace in Figure 1, the clean air is heated to the necessary temperature by heating the metal heat sink 103, and the preheated clean air passes through the blower 106 to form a gas blocking layer at the lower end of the glass ribbon, and the grid-shaped regulating plate 104 It is used to adjust the direction angle of the air curtain, to minimize the possibility of the air curtain returning to the upper side after it touches the glass ribbon, and to add an air tractor 105 at a suitable position at the lower end, which is used to form a negative pressure at the lower end of the air curtain , thus pulling the return air of the air curtain to flow downward.

[0027] Similarly, the inlet of the air traction machine 105 (traction fan) adopts the structure of grid-shaped regulating plate 104, which is used to adjust the wind direction for its formation of traction. The air volume produced by the air tractor 105...

Embodiment 2

[0029] As shown in the air lock system at the lower end of the annealing furnace in Figure 1, the clean air is heated to the necessary temperature by heating the metal heat sink 103, and the preheated clean air passes through the blower 106 to form a gas blocking layer at the lower end of the glass ribbon, and the grid-shaped regulating plate 104 It is used to adjust the direction angle of the air curtain, to minimize the possibility of the air curtain returning to the upper side after it touches the glass ribbon, and to add an air tractor 105 at a suitable position at the lower end, which is used to form a negative pressure at the lower end of the air curtain , thus pulling the return air of the air curtain to flow downward.

[0030] Adjust the grid-shaped wind direction plate 104 at the outlet of the blower 106 so that the return air flows as far as possible below the annealing furnace. Gradually increase the deflection direction of the grid-shaped wind direction plate 104, ...

Embodiment 3

[0032] As shown in the air lock system at the lower end of the annealing furnace in Figure 1, the clean air is heated to the necessary temperature by heating the metal heat sink 103, and the preheated clean air passes through the blower 106 to form a gas blocking layer at the lower end of the glass ribbon, and the grid-shaped regulating plate 104 It is used to adjust the direction angle of the air curtain, to minimize the possibility of the air curtain returning to the upper side after it touches the glass ribbon, and to add an air tractor 105 at a suitable position at the lower end, which is used to form a negative pressure at the lower end of the air curtain , thus pulling the return air of the air curtain to flow downward.

[0033] FIG. 5 is an effect diagram of air curtain formation without using the air tractor 105 and at the same time, the blower 106 has no deflection angle. It can be found that the return air after the air curtain reaches the glass substrate will dissipat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com