A kind of plexiglass transparent part edge reinforcement structure

A technology of plexiglass and reinforced structure, applied in the direction of slender components, building components, etc., can solve the problems of silver streaks and even cracks in the installation holes, and the holes are prone to chipping, etc., and achieve the effect of improving the stress resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

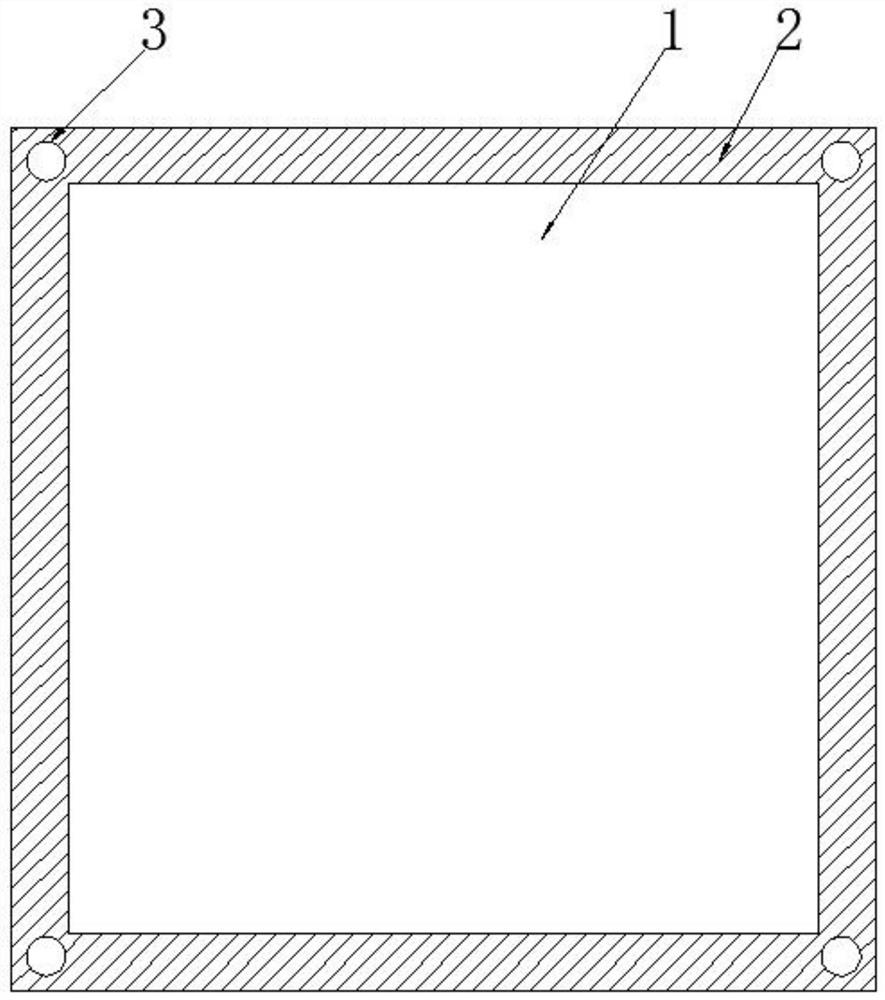

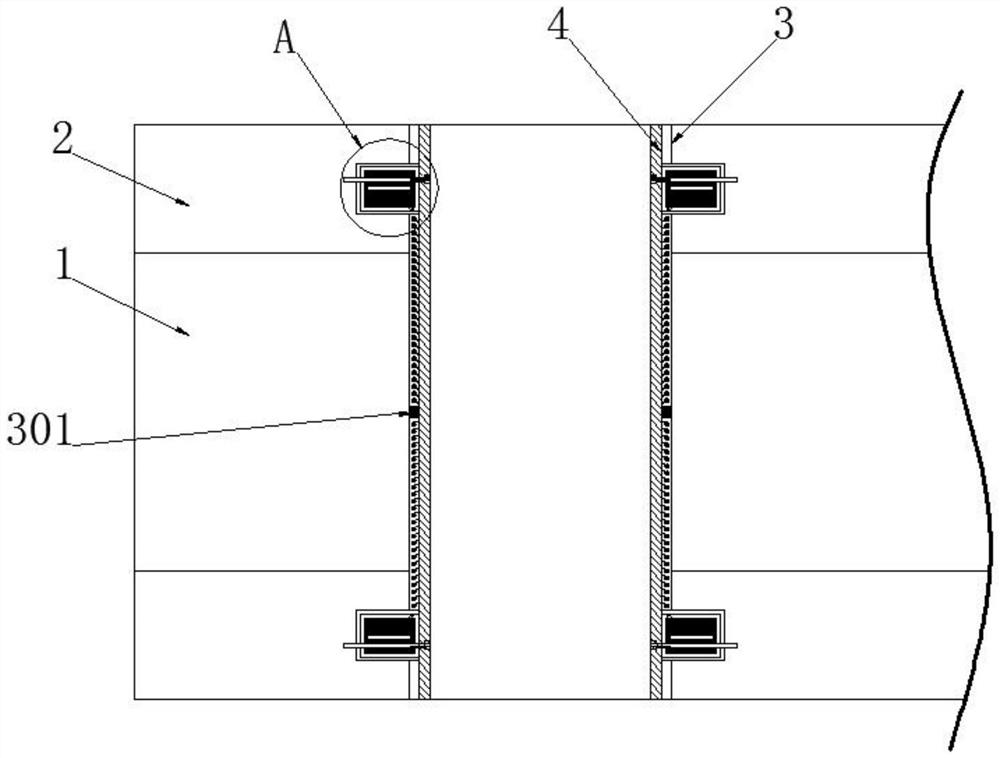

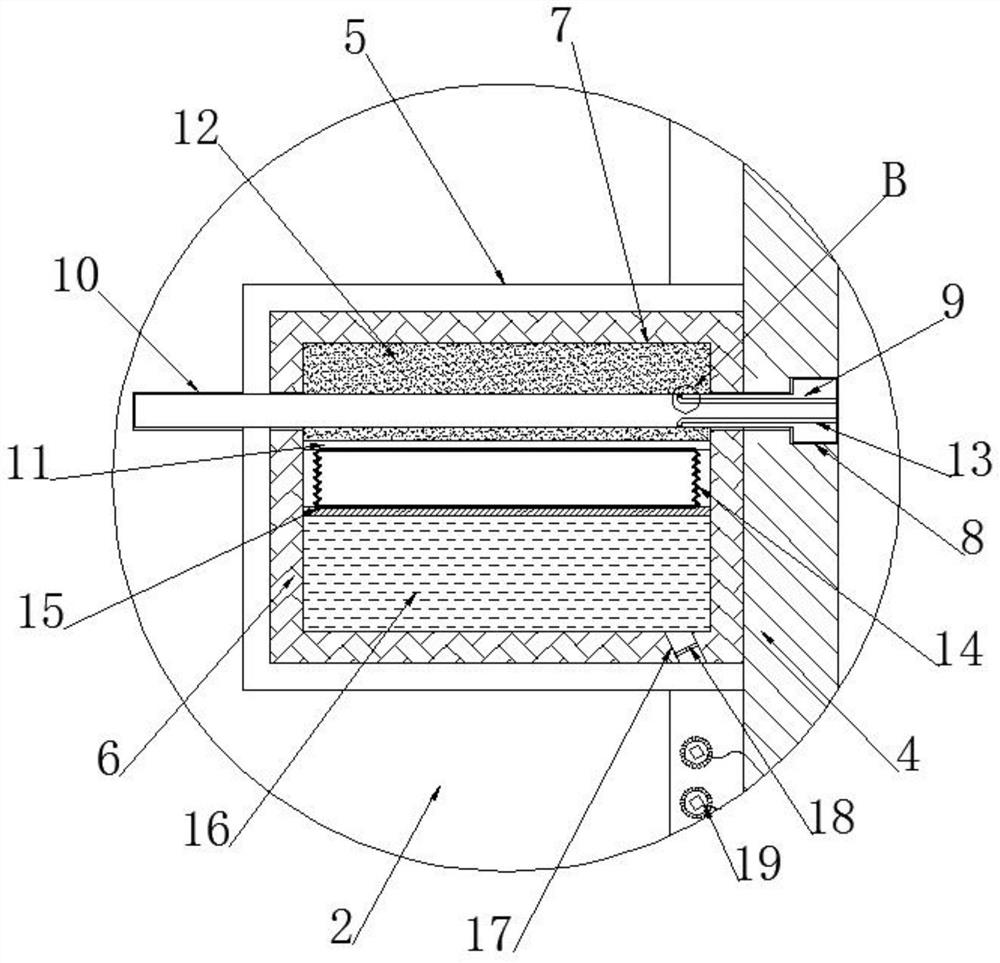

[0043] see Figure 1-3 , a plexiglass transparent part edge reinforcement structure, including plexiglass 1, the upper and lower ends of the plexiglass 1 are glued with polyester steel ring layers 2, and the four corners of the plexiglass 1 and the polyester steel ring layer 2 are drilled with each other. Connected installation holes 3, an inner protection ring 4 is arranged in the installation hole 3, an annular limit groove 5 is drilled in the inner wall of the installation hole 3 on the polyester steel ring layer 2, and a limit ring 6 is arranged in the annular limit groove 5 to limit the gap. A built-in annular cavity 7 is excavated in the position ring 6, and a plurality of evenly distributed threaded holes 8 are excavated in the inner wall of the inner protection ring 4. The threaded holes 8 are threadedly connected with a limit screw 9 that penetrates the limit ring 6, and an annular limit groove 5. The inner bottom end is drilled with a threaded groove 10 that matches ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com