Sea wave electricity generating device

An ocean wave power generation and generator technology, which is applied to ocean energy power generation, engine components, machines/engines, etc., can solve the problems of complex structure, high cost, poor stability in use, etc., and achieve the effect of not easy to damage and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

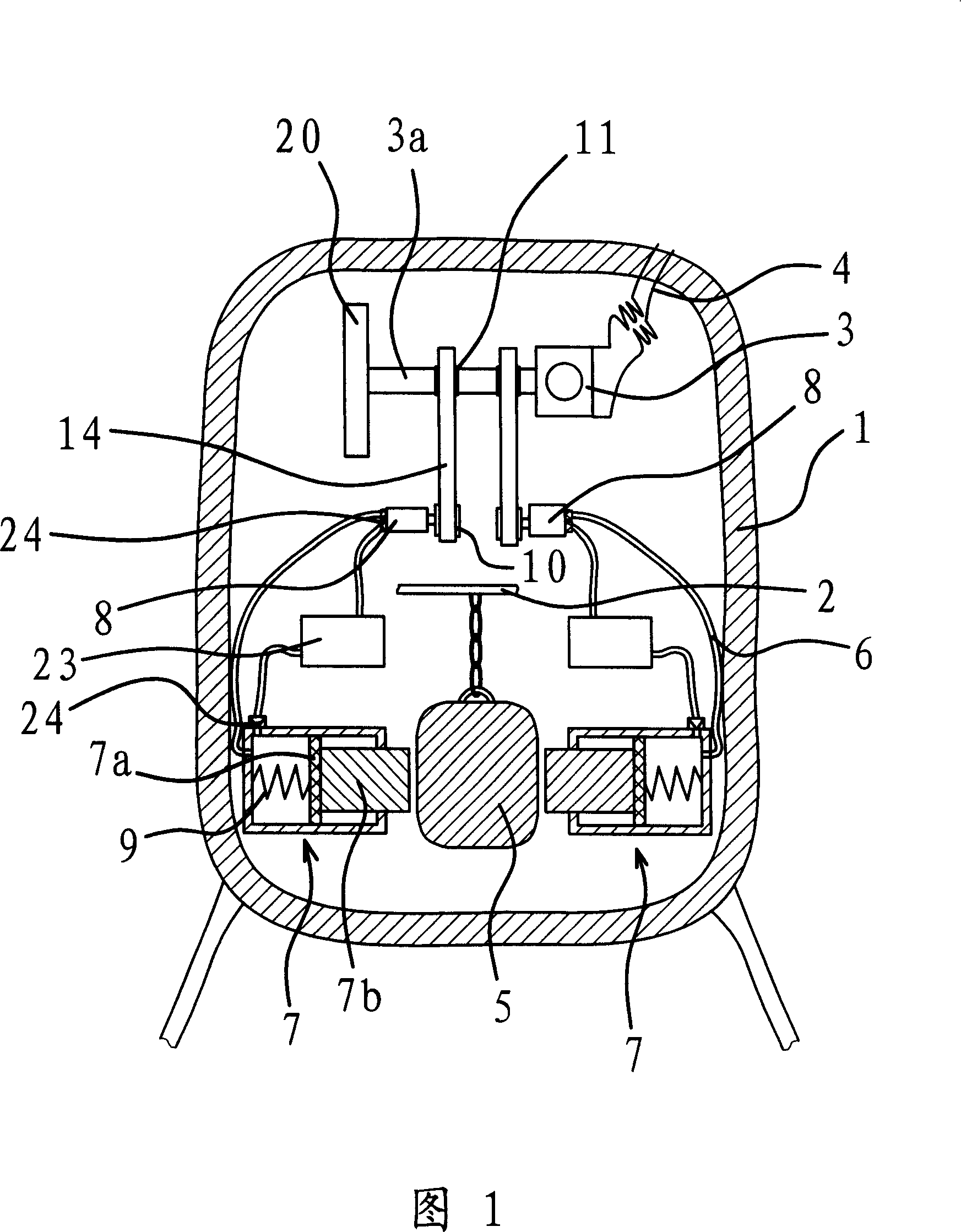

[0038] As shown in Figure 1, the wave power generation device is placed on the sea surface, and it includes a closed buoy 1 with a cavity inside, and the buoy 1 is connected to an anchor placed on the seabed through a rope.

[0039] The buoy 1 is provided with a bracket 2, a generator 3, a swing block 5, a hydraulic cylinder 7 and a hydraulic motor 8. The swing block 5 is hung on the support 2 by ropes, and the generator 3 has a rotating shaft 3a. The hydraulic cylinder 7 and the hydraulic motor 8 communicate through the pipeline 6, and a linkage mechanism is provided between the hydraulic cylinder 7 and the swing block 5, and a transmission mechanism is provided between the hydraulic motor 8 and the rotating shaft 3a of the generator 3, and the transmission mechanism The rotating shaft 3a can be continuously rotated in one direction.

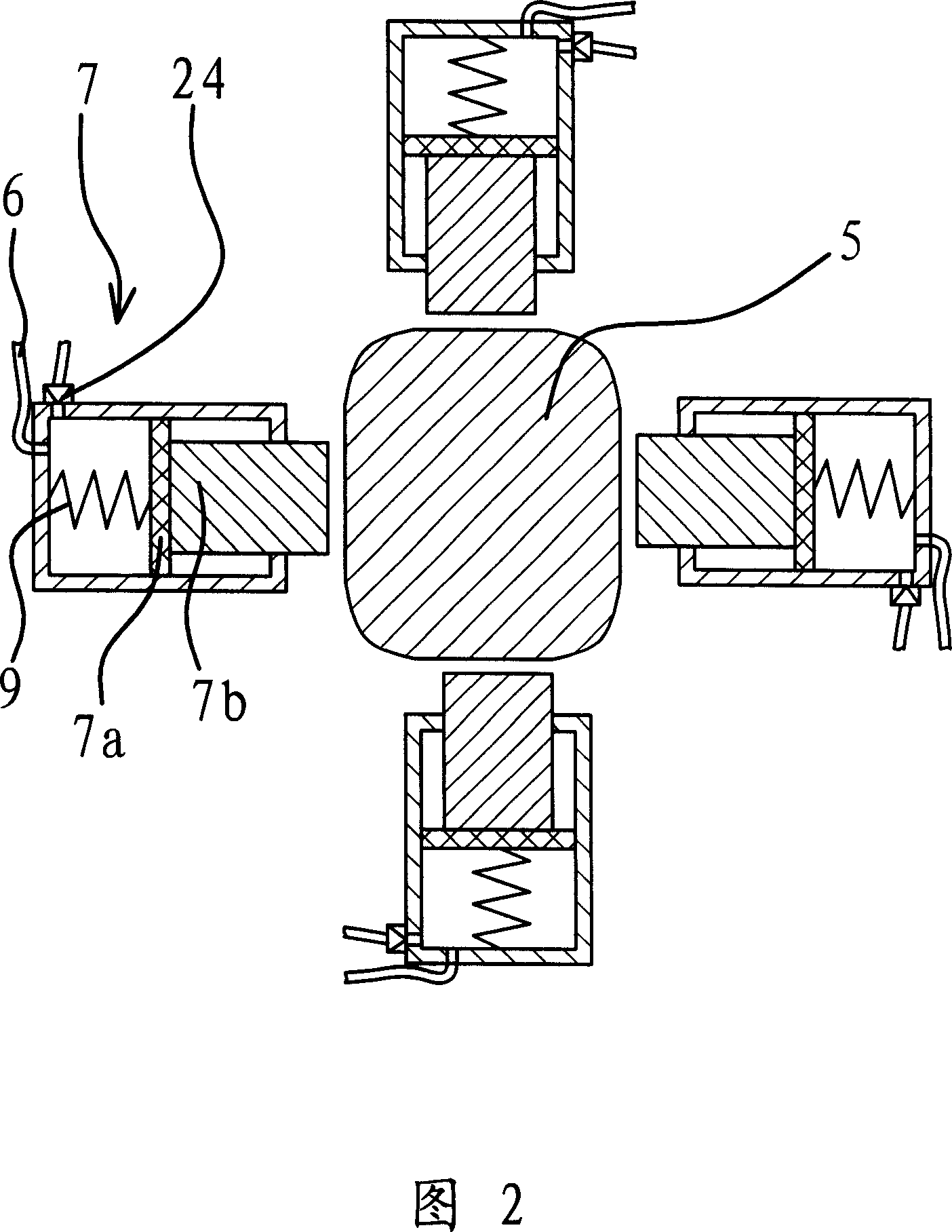

[0040] As shown in Figure 2, the linkage mechanism is a piston 7a and a piston rod 7b. The piston 7a is installed in the hydraulic cylinder 7...

Embodiment 2

[0052] As shown in Figure 4, the structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that the return spring 9 is sleeved on the piston rod 7b, and the two ends of the return spring 9 are respectively fixedly connected to the piston 7a And on hydraulic cylinder 7, see as shown in Figure 3. It can be seen that the piston rod 7b has a tendency to move outwards due to the tension of the return spring 9, and when the swing block 5 is separated from the piston rod 7b, the piston rod 7b can automatically reset.

Embodiment 3

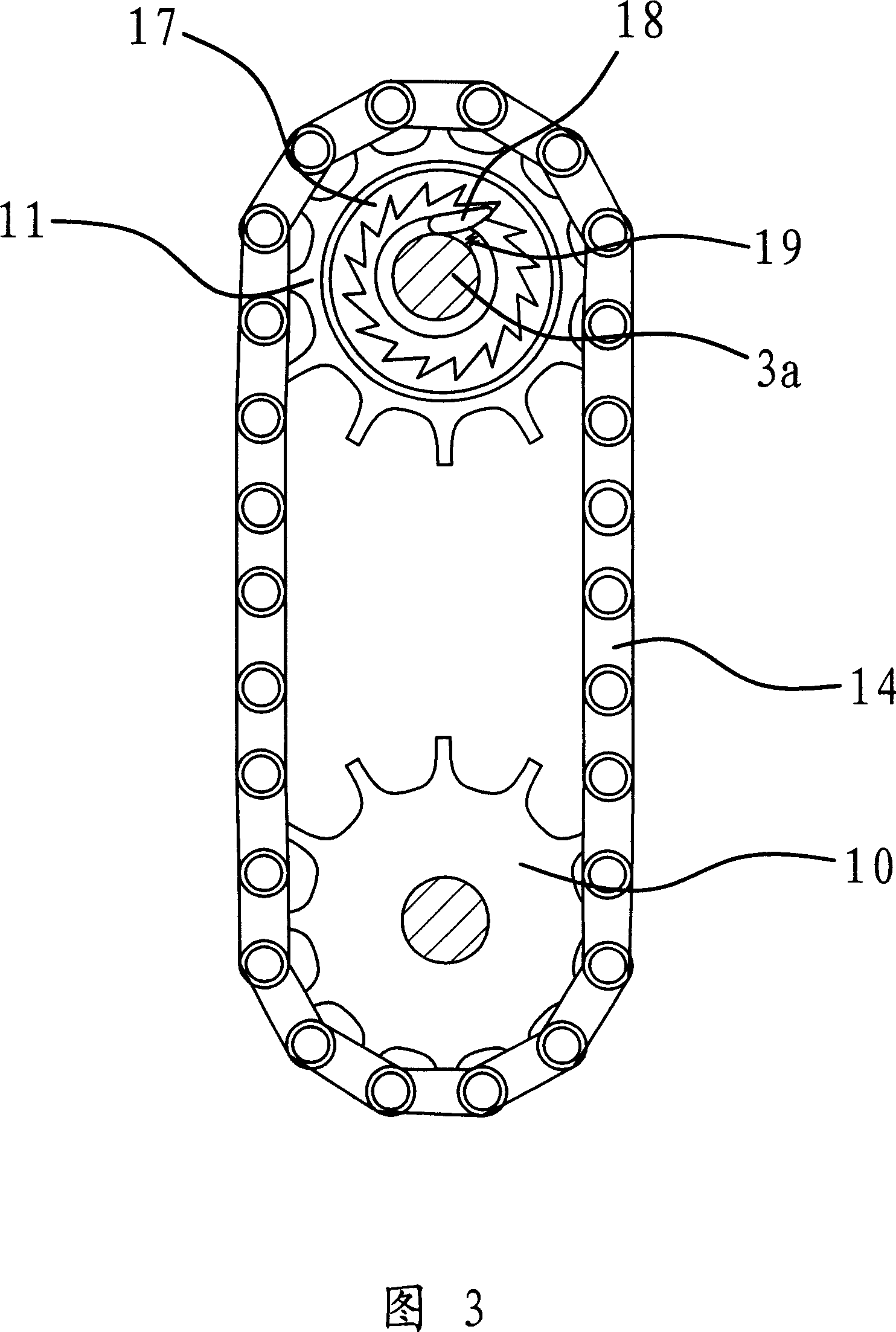

[0054] The structure and principle of this embodiment are basically the same as that of Embodiment 1. The difference is that the above-mentioned transmission mechanism also includes a sub-support 21 arranged in the buoy 1. The sub-support 21 is provided with a rotatable transmission shaft 22, the transmission shaft 22 is provided with sprocket three 12, and sprocket three 12 and sprocket one 10 are socketed with transmission chain two 11, and between described sprocket three 12 and transmission shaft 22, be provided with the unit that makes transmission shaft 22 one-way rotations. To the device, the transmission shaft 22 is also fixedly connected with a sprocket four 13, and the sprocket four 13 and the sprocket two 11 are sleeved with a drive chain three 16, as shown in Figures 5 and 6.

[0055] When the hydraulic motor 8 is in operation, the first sprocket 10 rotates, and the second sprocket 15 can drive the third sprocket 12 to rotate. Under the action of the one-way device,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com