Coal-burning installation based on calcium sulphate oxygen carrier and coal burning method

A technology of calcium sulfate and oxygen carrier, which is applied in the combustion method, the fuel burned in the molten state, the type of combustion, etc., can solve the problems of increased power generation cost, high cost, low separation efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

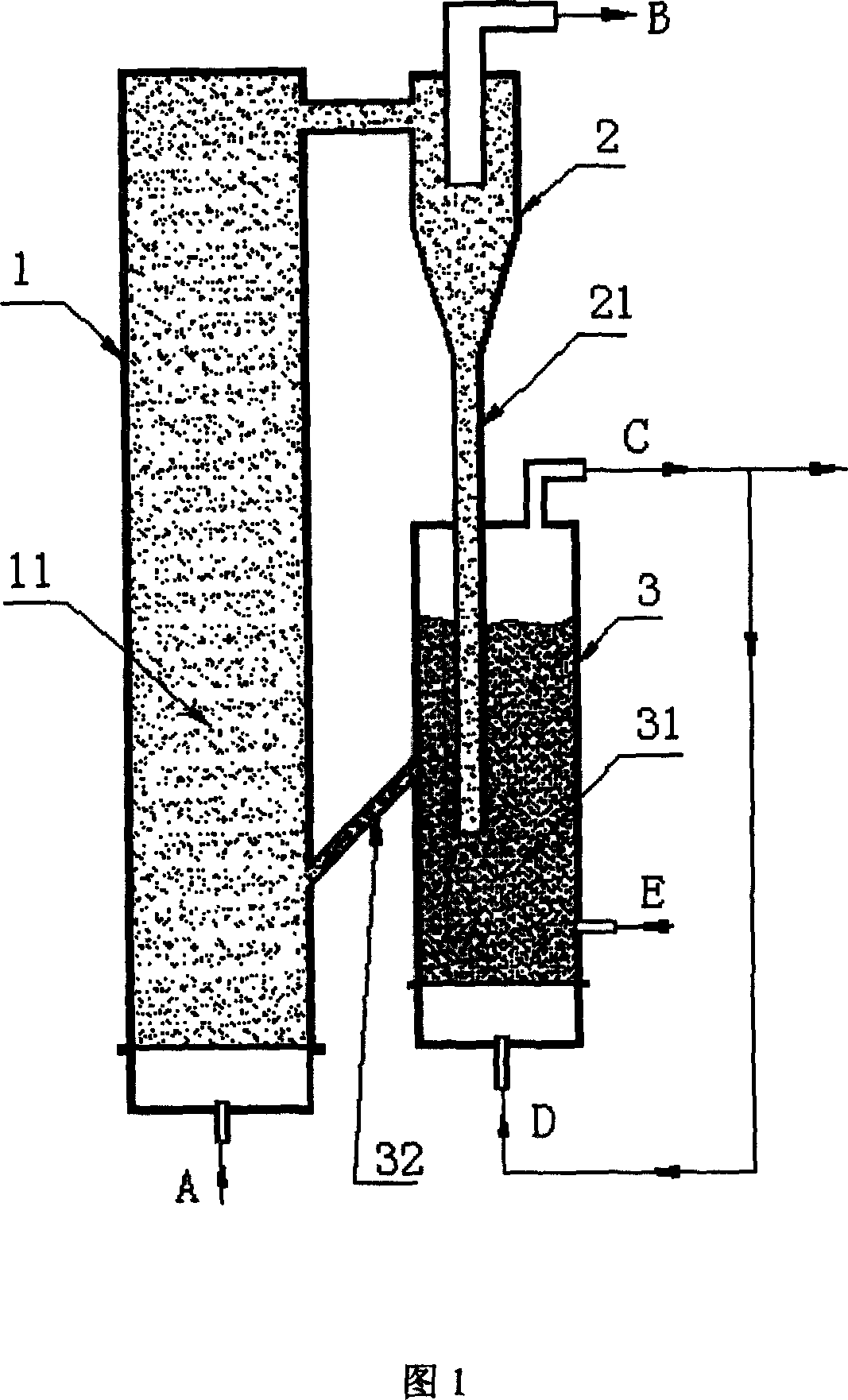

[0015] The coal burning device based on the calcium sulfate oxygen carrier of the present invention is composed of a circulating fluidized bed 1, a cyclone separator 2, and a fluidized bed 3 connected to form a circulation loop. The upper part of the circulating fluidized bed 1 communicates with the upper part of the cyclone separator 2, the lower part of the cyclone separator 2 communicates with the fluidized bed 3 through the material leg 21, and the fluidized bed 3 communicates with the lower part of the circulating fluidized bed 1 through the return pipe 32. The bottom of the circulating fluidized bed 1 is provided with an air inlet A, the top of the cyclone separator 2 is an oxygen-poor air outlet B, the upper part of the fluidized bed 3 is provided with an exhaust port C, and the bottom of the fluidized bed 3 is provided with There is an air inlet D, the exhaust port C on the upper part of the fluidized bed 3 communicates with the air inlet D on the bottom of the fluidize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com