Human milk fortifiers and methods for their production

A technology of human milk fortifier and fortifier, which is applied in the field of human milk fortifier and can solve the problem of not being able to provide enough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

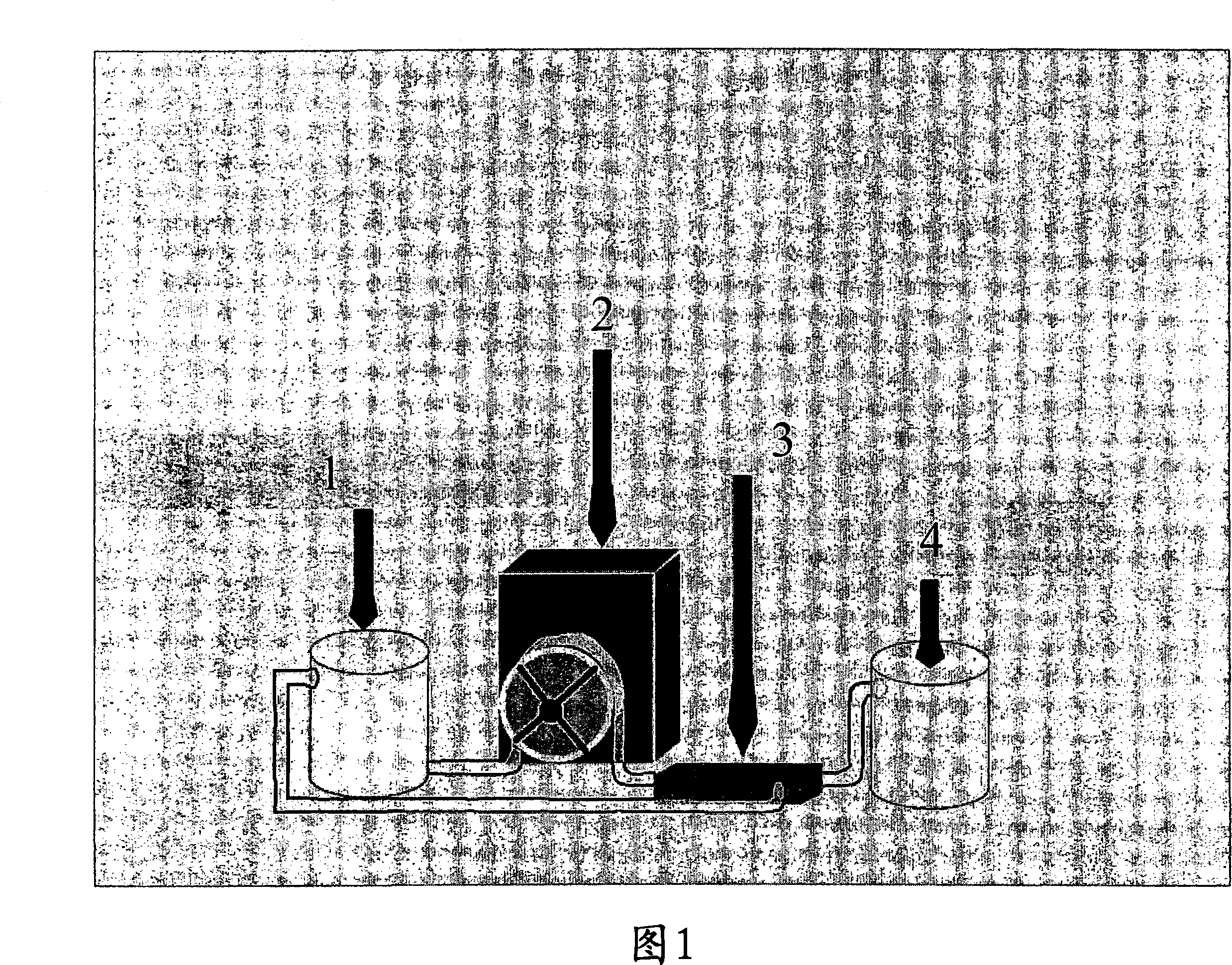

Method used

Image

Examples

Embodiment 1

[0052] A liquid sample (100ml) of the human milk sample was collected. Human milk was collected from mothers of preterm infants or from human milk donors at >10 and <90 days postpartum, respectively. Milk samples were collected from milk expressed from the udder over the course of a day. The basic composition of this milk can be summarized as follows: 3.8% fat, 0.8% protein and 5.2% carbohydrates. Determine the actual energy content of the milk samples. The non-aqueous part of the milk (cream fat) was separated from the water part by centrifugation (10000rpm, 4°C) and the top layer (cream fat) was carefully removed and a known volume was added to 140ml of the mother's own milk to increase the energy in her milk levels up to the recommended levels for premature infants of a specific weight and age.

[0053] In addition, pasteurization and standard hospital-grade bacterial testing can be performed as standard operations.

[0054] Premature babies can be observed to grow and ...

Embodiment 2

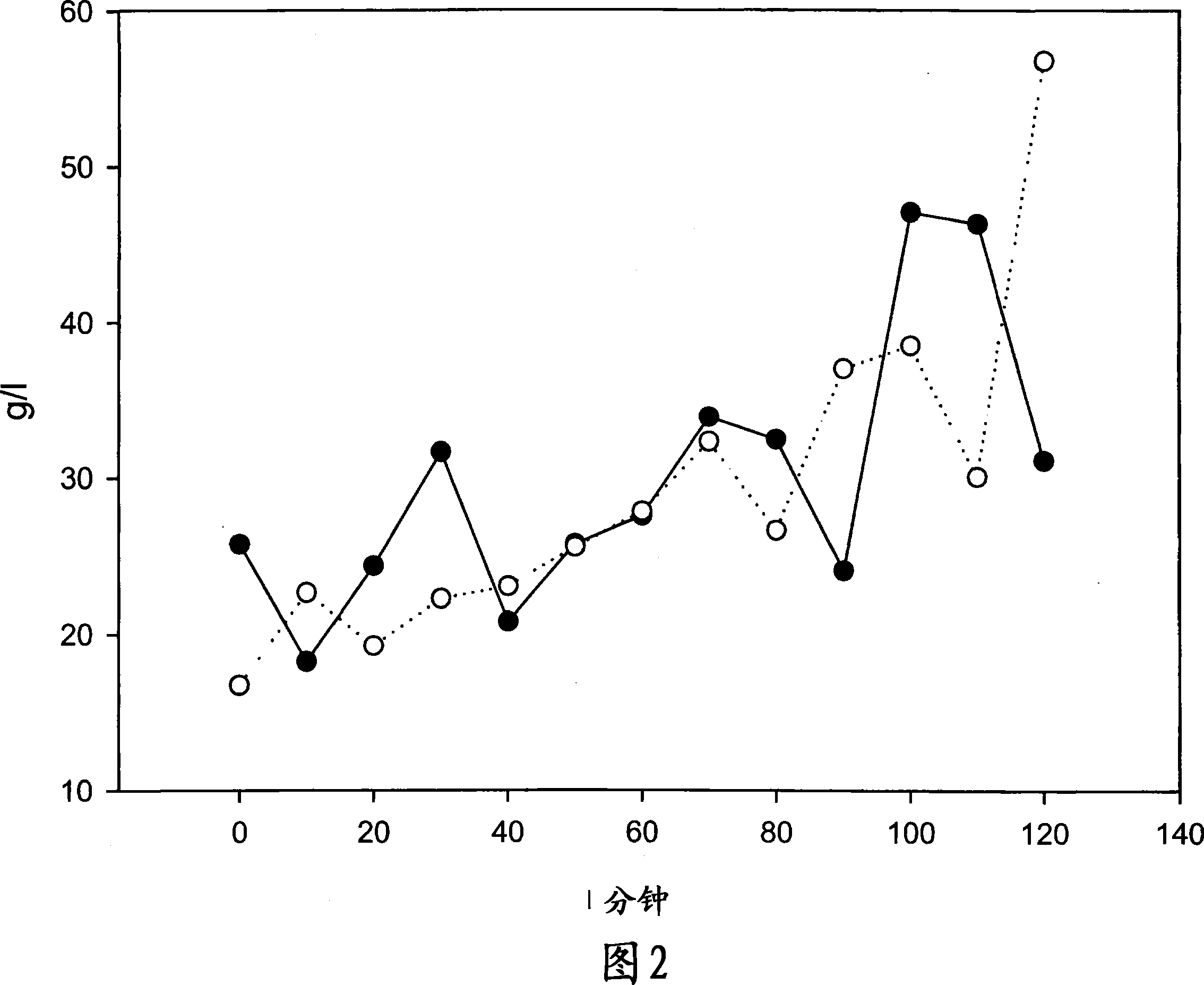

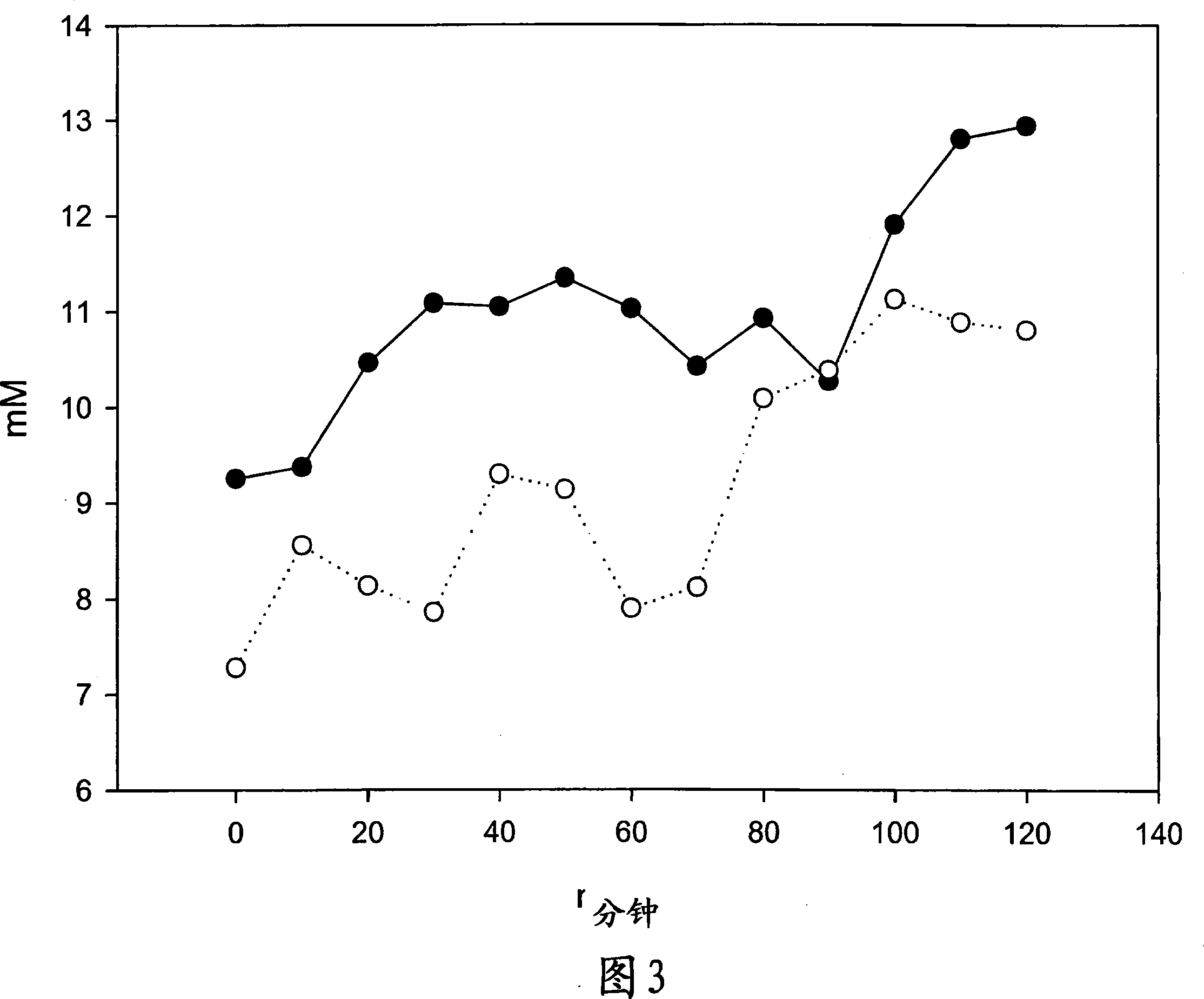

[0056] A liquid sample (150ml) of the human milk sample was collected. Human milk was collected from mothers of infants with special needs (premature infants or sick full-term infants) or from human milk donors at >10 days and <90 days postpartum, respectively. Milk samples were collected from milk expressed from the udder over the course of a day. The basic composition of this milk can be summarized as follows: 3.8% fat, 0.8% protein and 5.2% carbohydrates. Determining the concentration of protein in milk samples. The non-aqueous part (cream) of the milk was separated from the water part by centrifugation (10000 rpm, 4°C) and the top layer (cream) was carefully removed. The aqueous layer was then concentrated by passing it through a filter impermeable to milk protein (30Kd Omega ultrafiltration tangential flow membrane, Pall; temperature as cold as possible, 19°C in specific cases). After the water fraction has been concentrated 5 times (pass the liquid through the filter ...

Embodiment 3

[0060] A liquid sample (500ml) of the human milk sample was collected. Human milk was collected from human milk donors who were more than 90 days postpartum. Milk samples were taken from milk expressed from the udder over the course of several days and stored frozen. The basic composition of this milk can be summarized as follows: 3.8% fat, 0.8% protein and 5.2% carbohydrates. Determination of protein concentration in milk samples. The non-aqueous part (cream) of the milk was separated from the water part by centrifugation (10000 rpm, 4°C) and the top layer (cream) was carefully removed. The aqueous layer was then concentrated by passing it through a filter impermeable to milk proteins (30Kd Omega ultrafiltration tangential flow membrane, Pall; temperature as cold as possible, in particular cases 19°C). After the aqueous fraction was concentrated 5-fold (as described in Example 2), the concentrated solution was centrifuged at high speed (210000 rpm, 4°C) to pellet the casei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com