Can container

A tank container and grounding part technology, which is applied in the field of tank containers, can solve the problems of leaking content propellant, leakage of content propellant, unstable seam sealing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

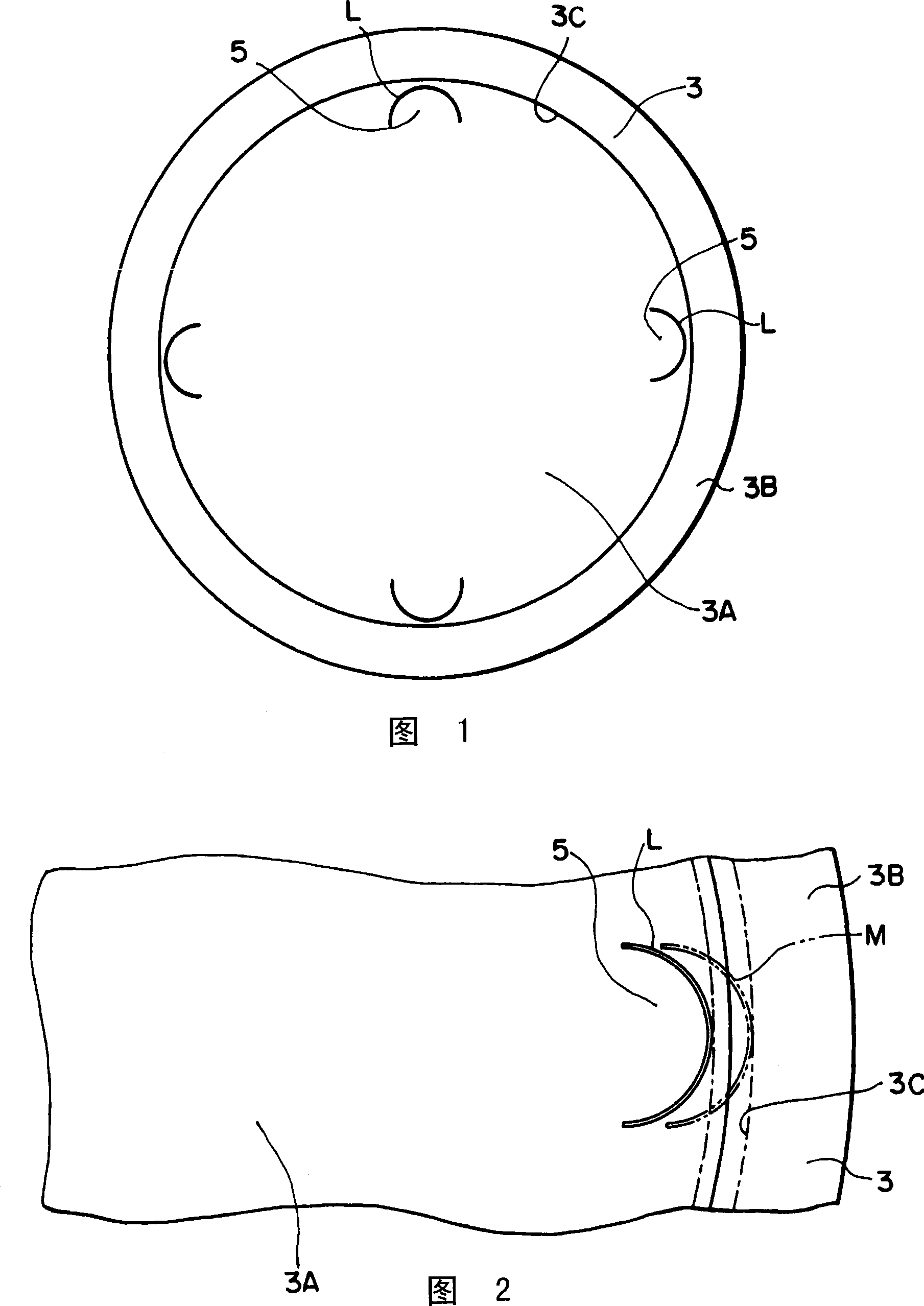

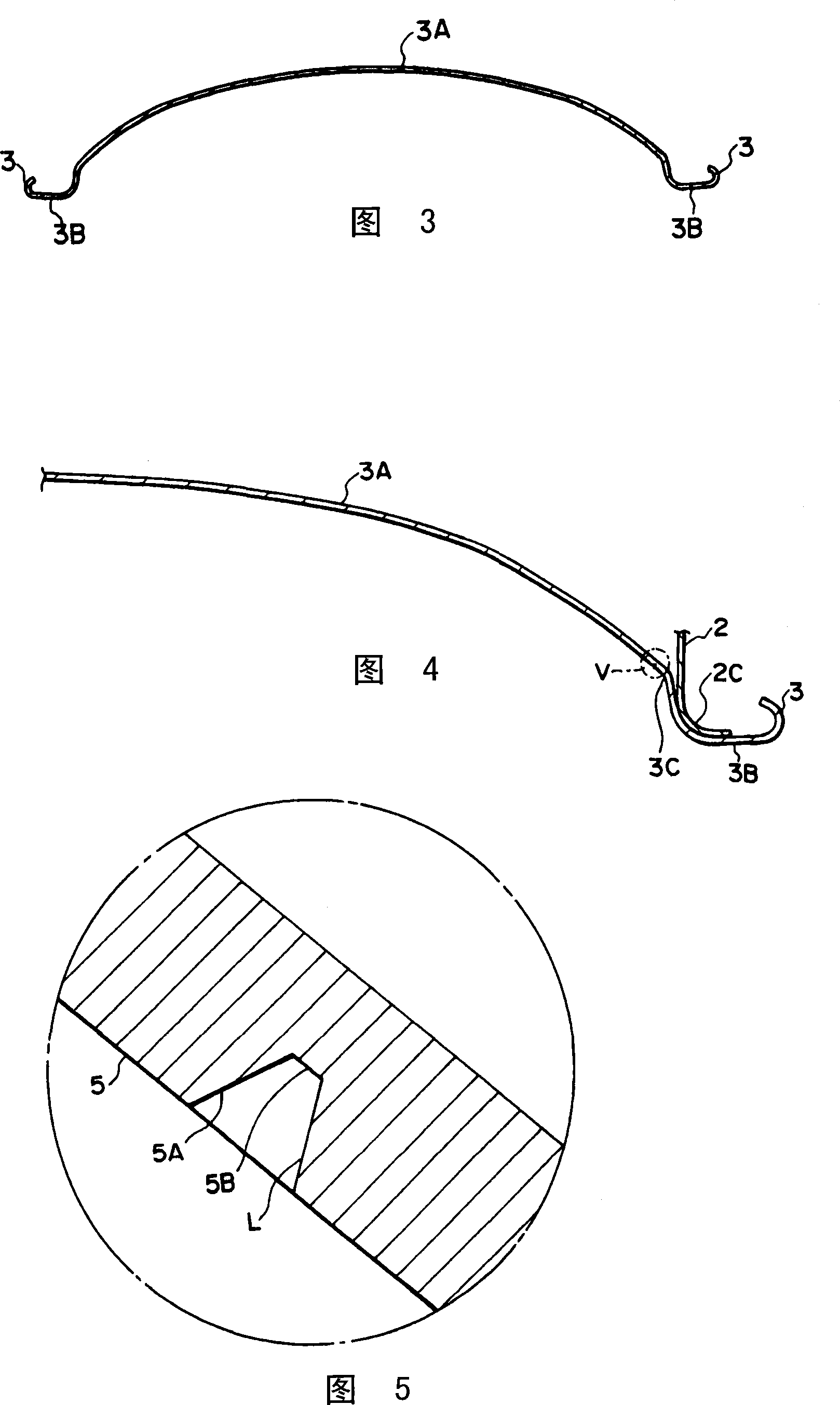

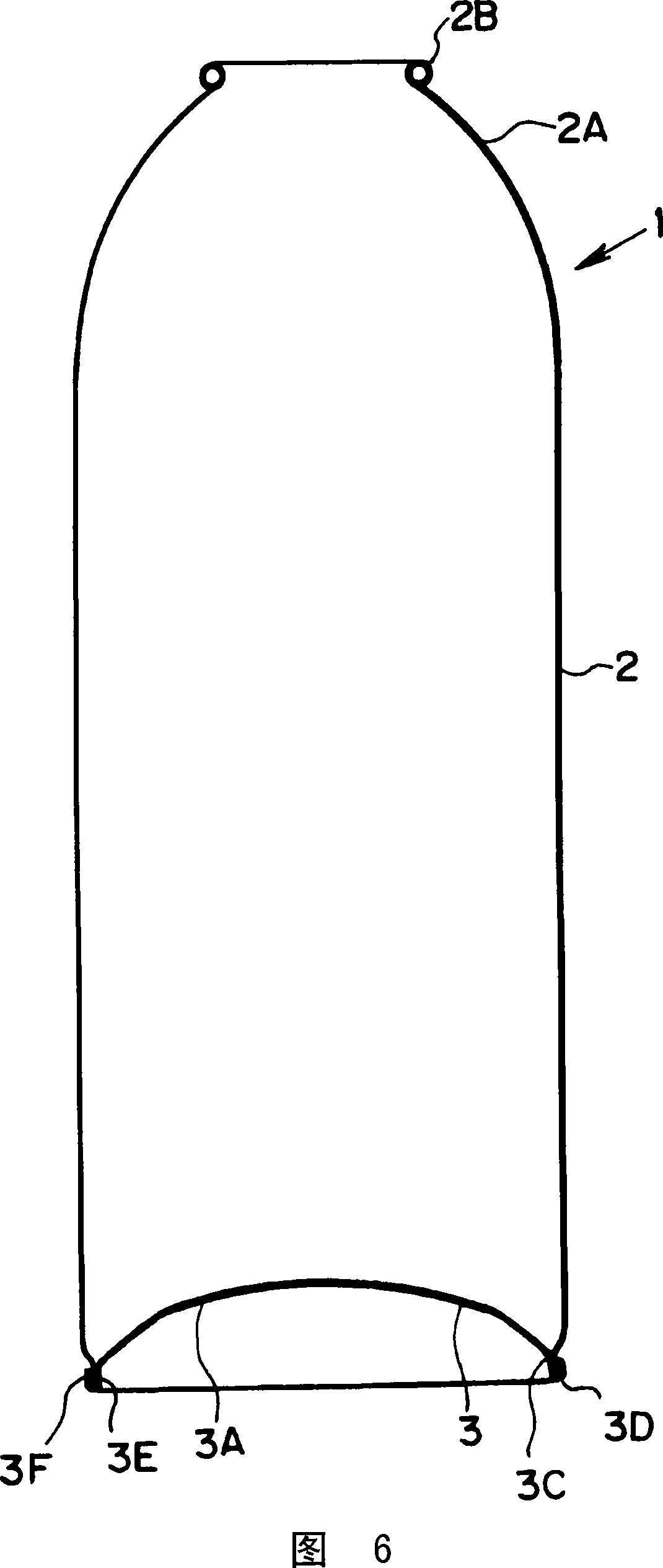

[0025] Embodiments of the present invention will be described below using the drawings. FIG. 6 and FIG. 7 show tank containers such as aerosol cans in which a propellant, which is a high-pressure gas, is filled inside a metal container. This can container (main body) 1 has a cylindrical metal can body portion (body portion) 2 . An aerosol valve member (not shown) for spraying the contents is attached to one end of the can body 2, and a disc-shaped metal bottom cover (can lid) 3 is fixed to the other end by seaming. In addition, the filled contents are cosmetics, insecticides, pharmaceuticals, detergents, paints, lubricants, food, etc., and high-pressure gas as a propellant.

[0026] As the metal material for the can body and the can lid of the can container of the present invention, a metal material that has been subjected to appropriate surface treatment or plating as necessary after rolling is used as the main material, and at least the surface that is in contact with the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com