Ceramic brick transfer printing apparatus and transfer printing method thereof

A technology for transfer printing and ceramic tiles, applied in the field of transfer printing and dry powder transfer printing devices, can solve the problems of reduced wear resistance, and achieve the effects of good decorative effect, strong matching and significant economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

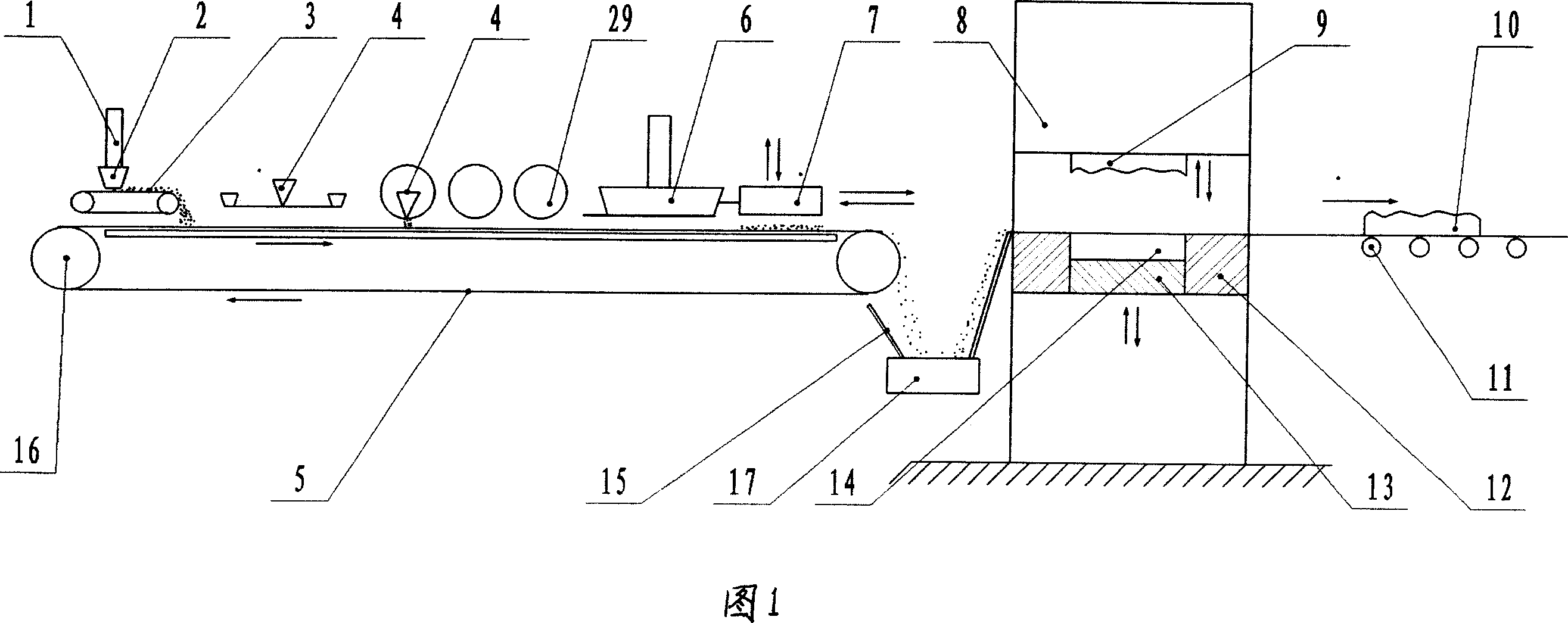

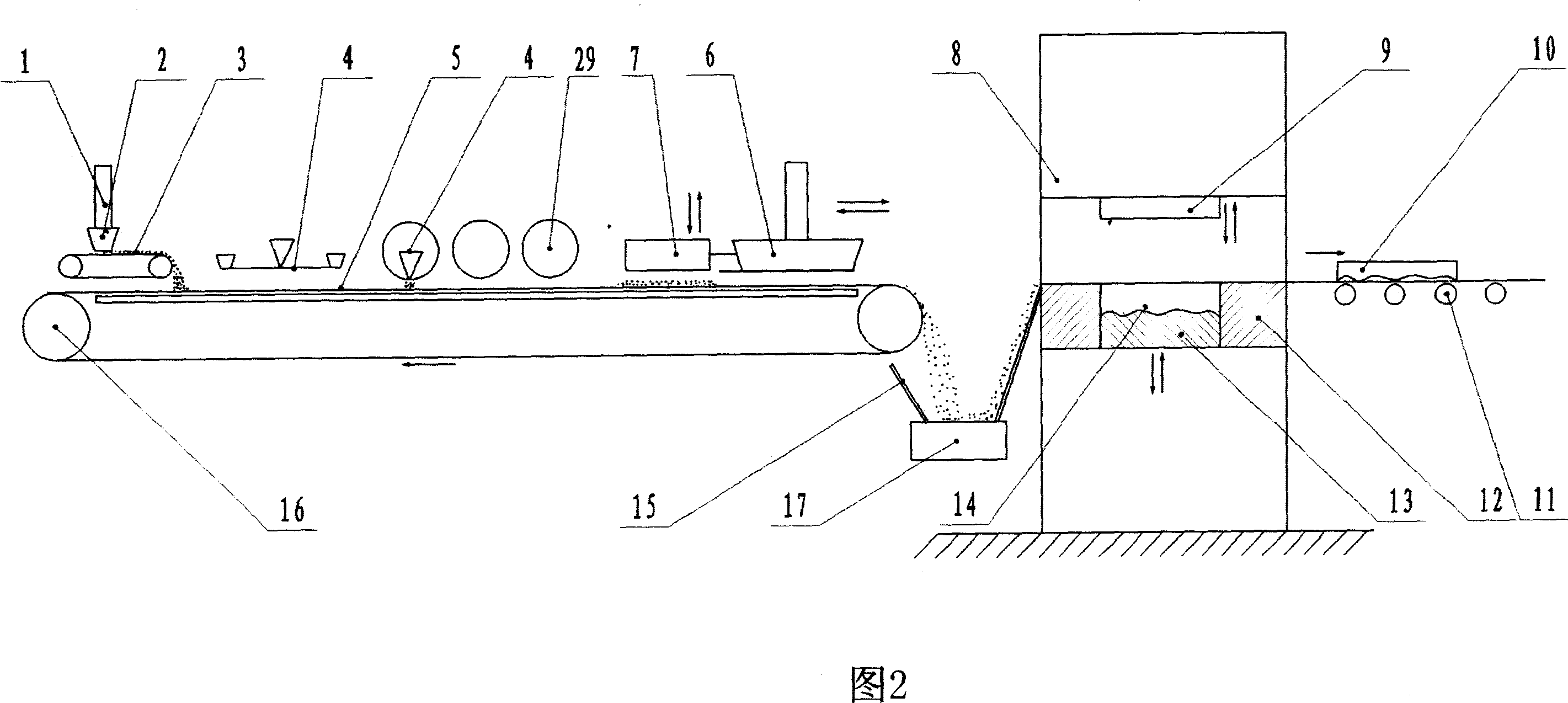

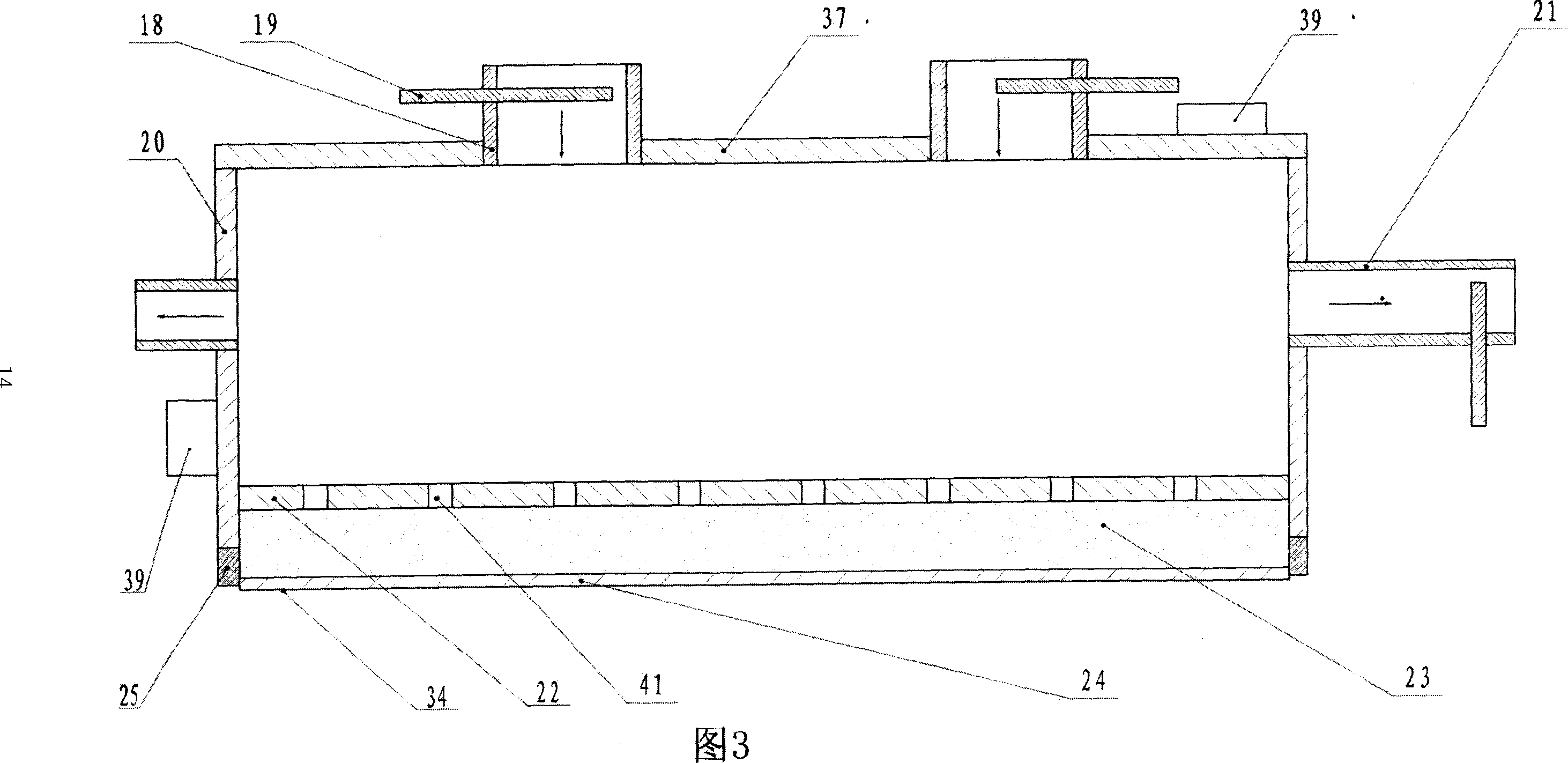

[0033] The ceramic dry powder transfer printing device of the present invention mainly includes a pattern material holder 5 and a forming machine, and a suction cup 7 for receiving the pattern material from the pattern material holder 5 is arranged between the pattern material holder 5 and the forming machine. The suction cup 7 is located above the pattern material holder 5, and above the pattern material holder 5, there is also a pattern machine 4 or a pattern machine 4 and a dryer. When performing wet decoration, the dryer can dry the pattern material so that the suction cup can absorb it. . The pattern machine 4 includes one or more of dry or wet screen printing, rubber roller printing, glaze throwing, and powder spraying decoration equipment. The patterned material holder 5 is provided with fine ventilation holes, and the top of the patterned material holder 5 is provided with a base hopper 6 . The pattern material support 5 can be a support belt, a support plate or a sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com