Machine tool

A technology of machine tools and linear motors, applied in the direction of metal processing machinery parts, large fixed members, driving devices, etc., to achieve the effect of preventing bad conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

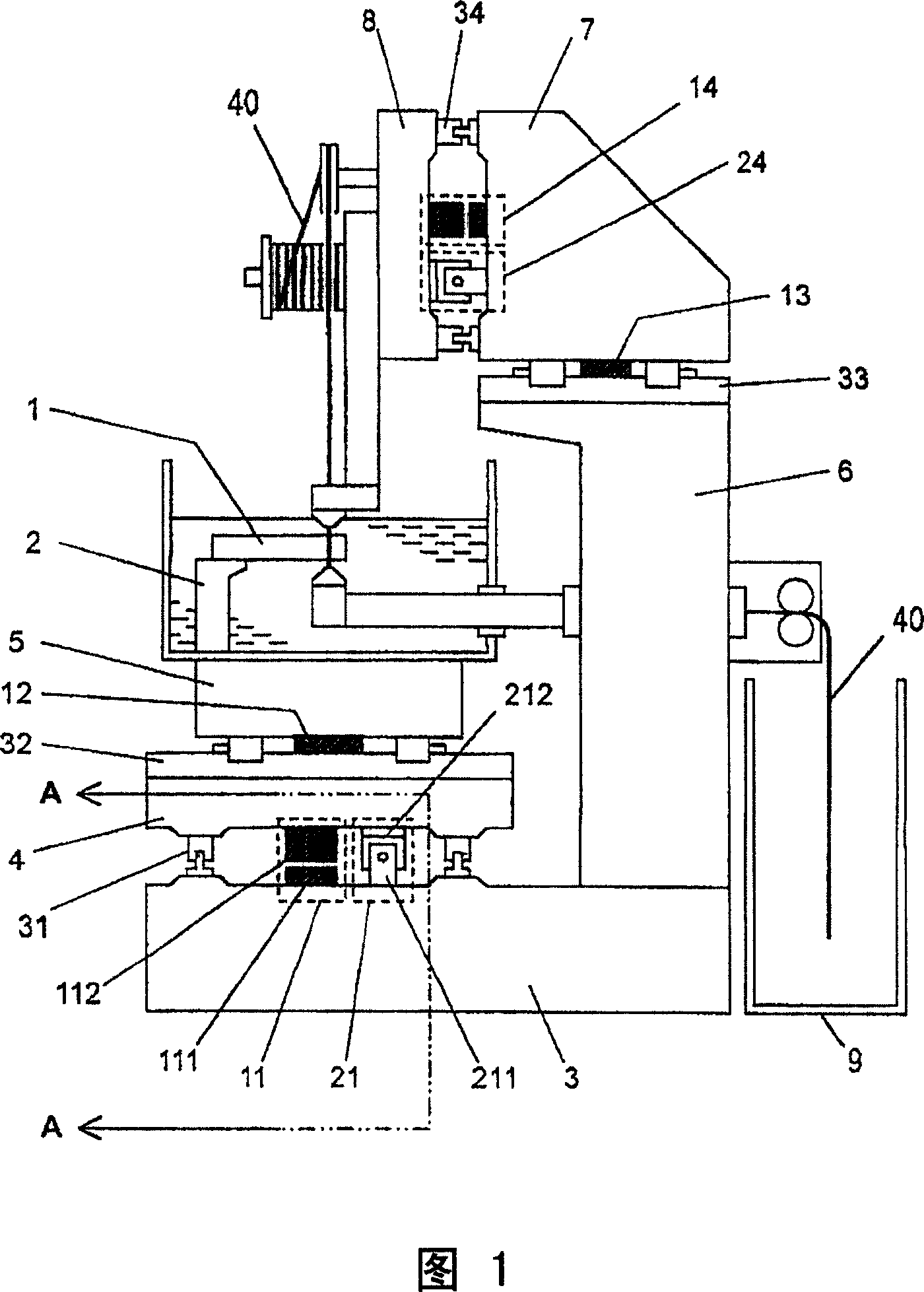

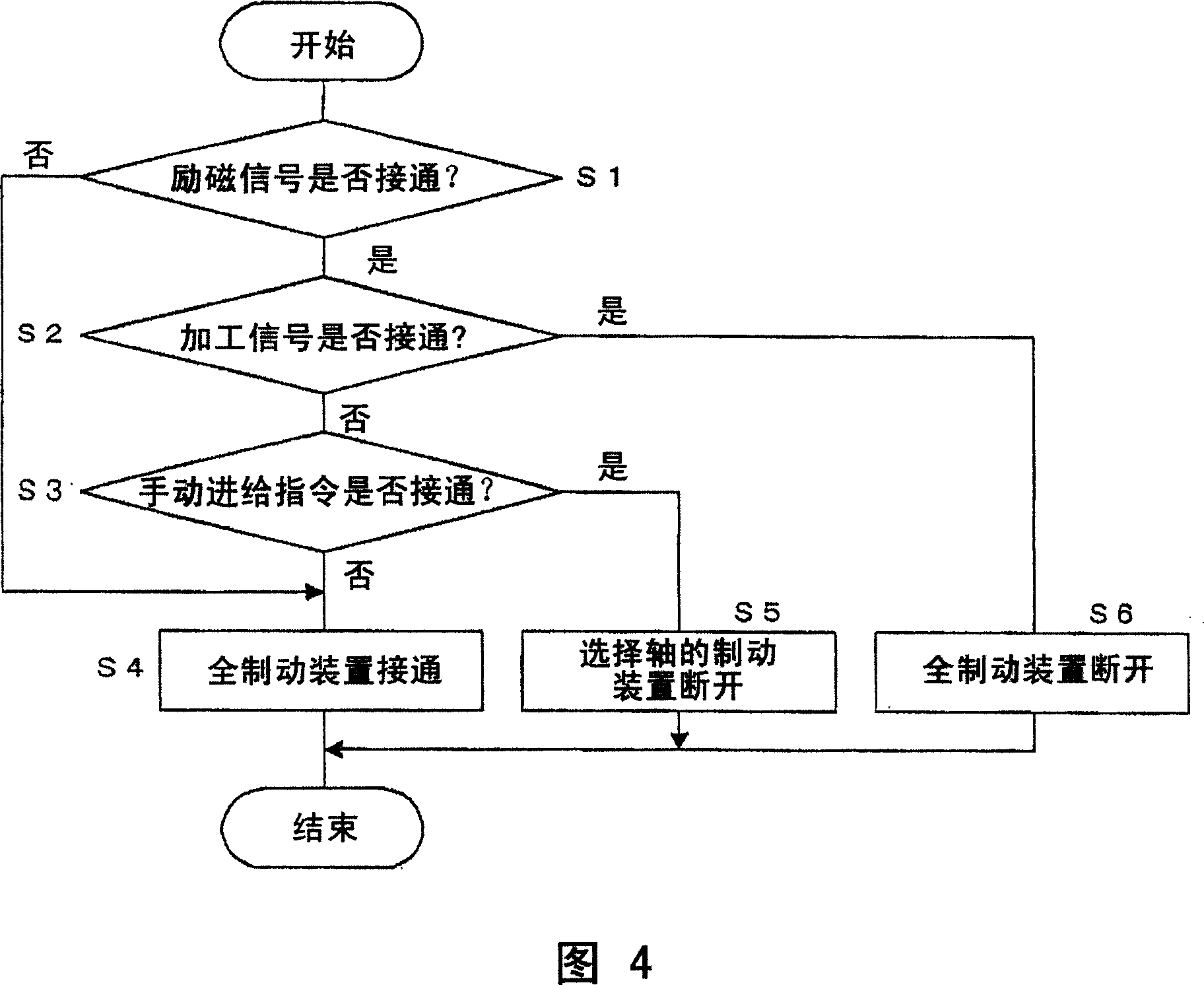

[0022] Hereinafter, an example in which the machine tool is a wire electric discharge machine will be described as one embodiment to which the present invention is applied. Especially in wire electric discharge machines, the possibility of applying a large external force to the shaft feeder during processing is low, and the possibility of applying a large external force in preparation for processing such as setting the workpiece on the workpiece placement table high. Therefore, in the present embodiment, it is necessary to prevent the linear motor from being overloaded due to a large external force acting during the processing preparation.

[0023] FIG. 1 is a schematic diagram of a wire electric discharge machine according to this embodiment.

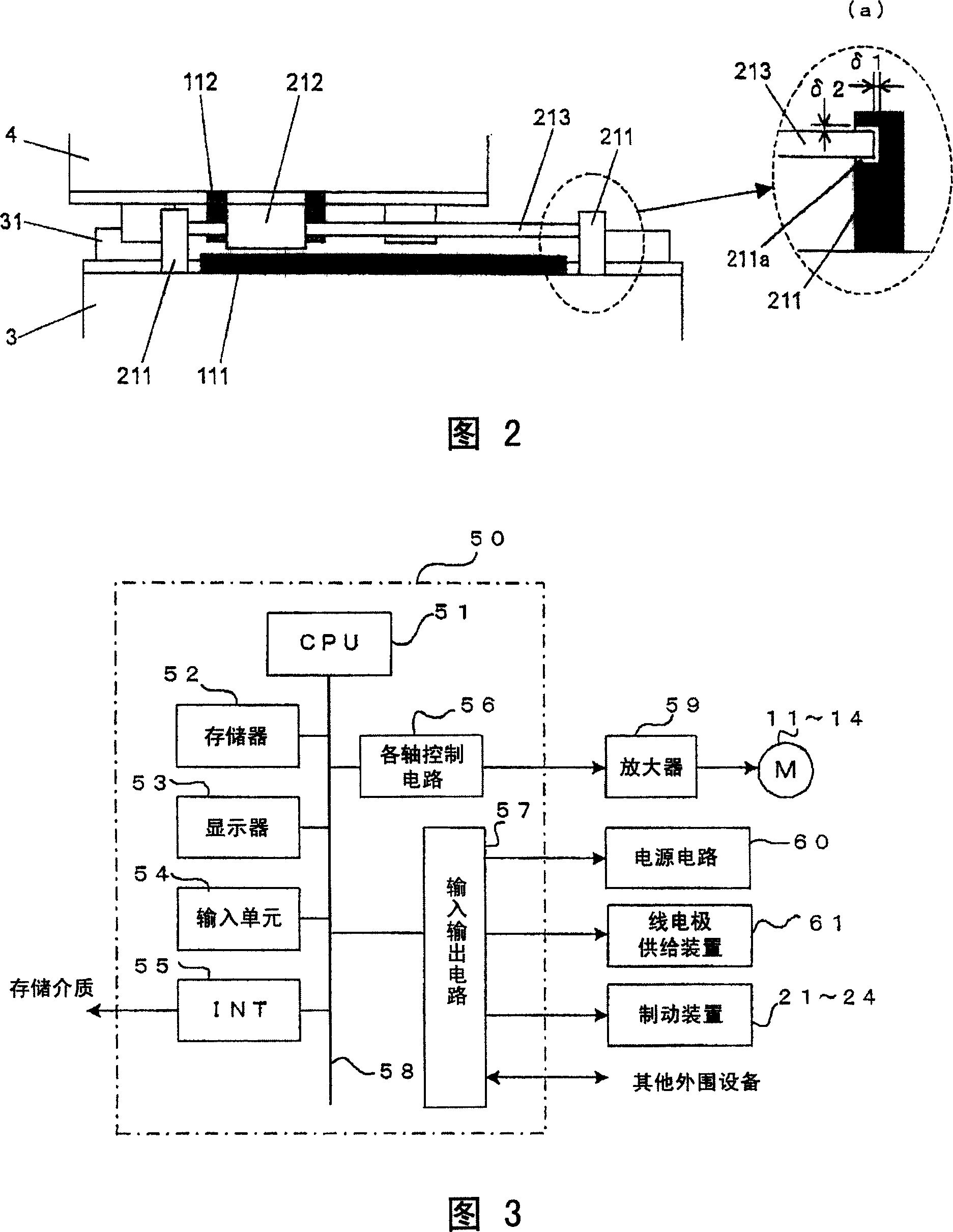

[0024] A saddle 4 is installed on the bed 3 of the wire electric discharge machine, so that the saddle 4 can move along a direction perpendicular to the paper surface of FIG. 1 through a linear moving guide rail 31 . In addition, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com