Automatic power on-off device for electric locomotive contact line

An automatic stop and contact line technology, applied in power lines, vehicle parts, transportation and packaging, etc., can solve the problems of manual operation, inability to use, misoperation, etc., and achieve the effect of simple structure, easy standardization and mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

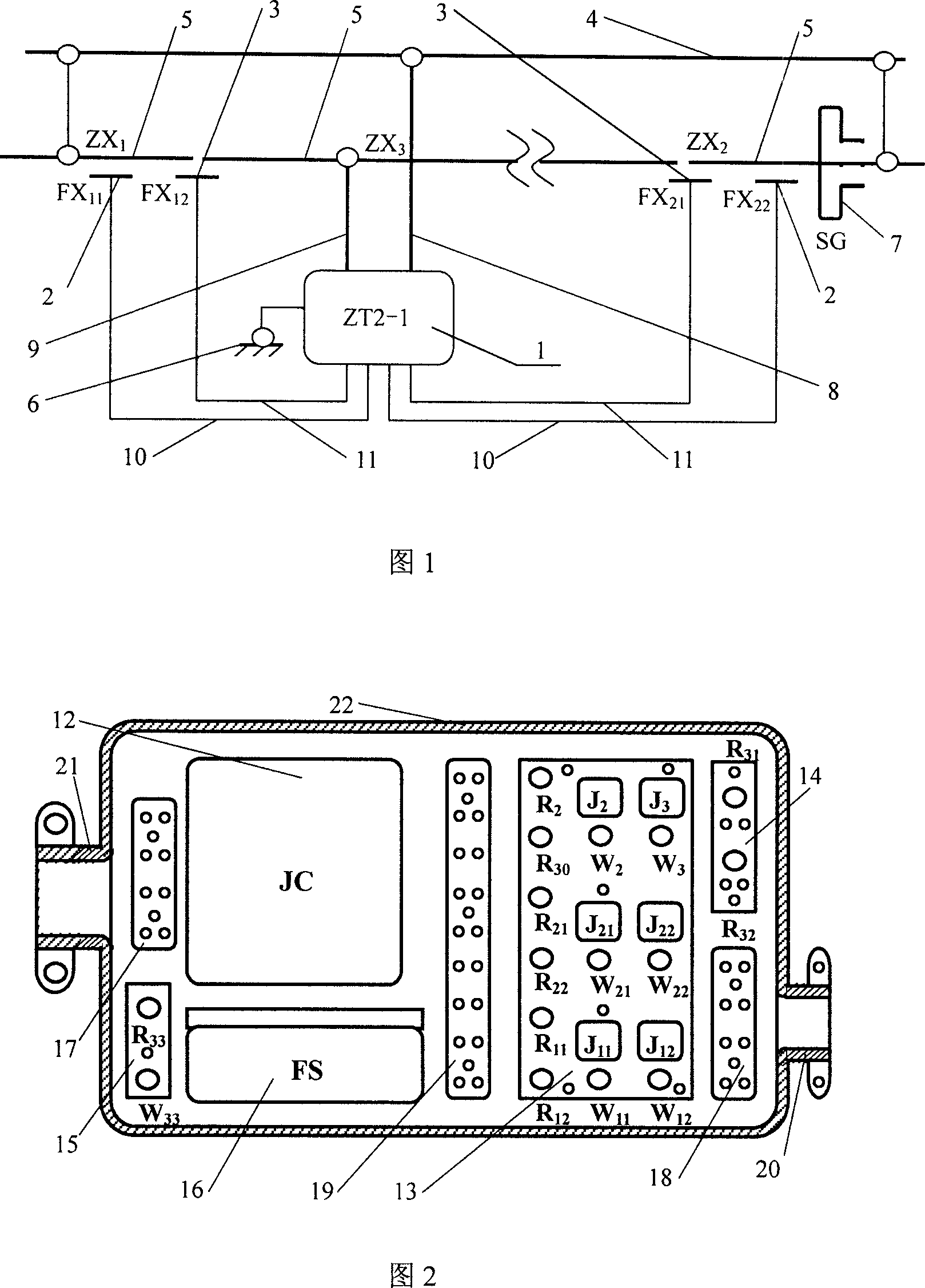

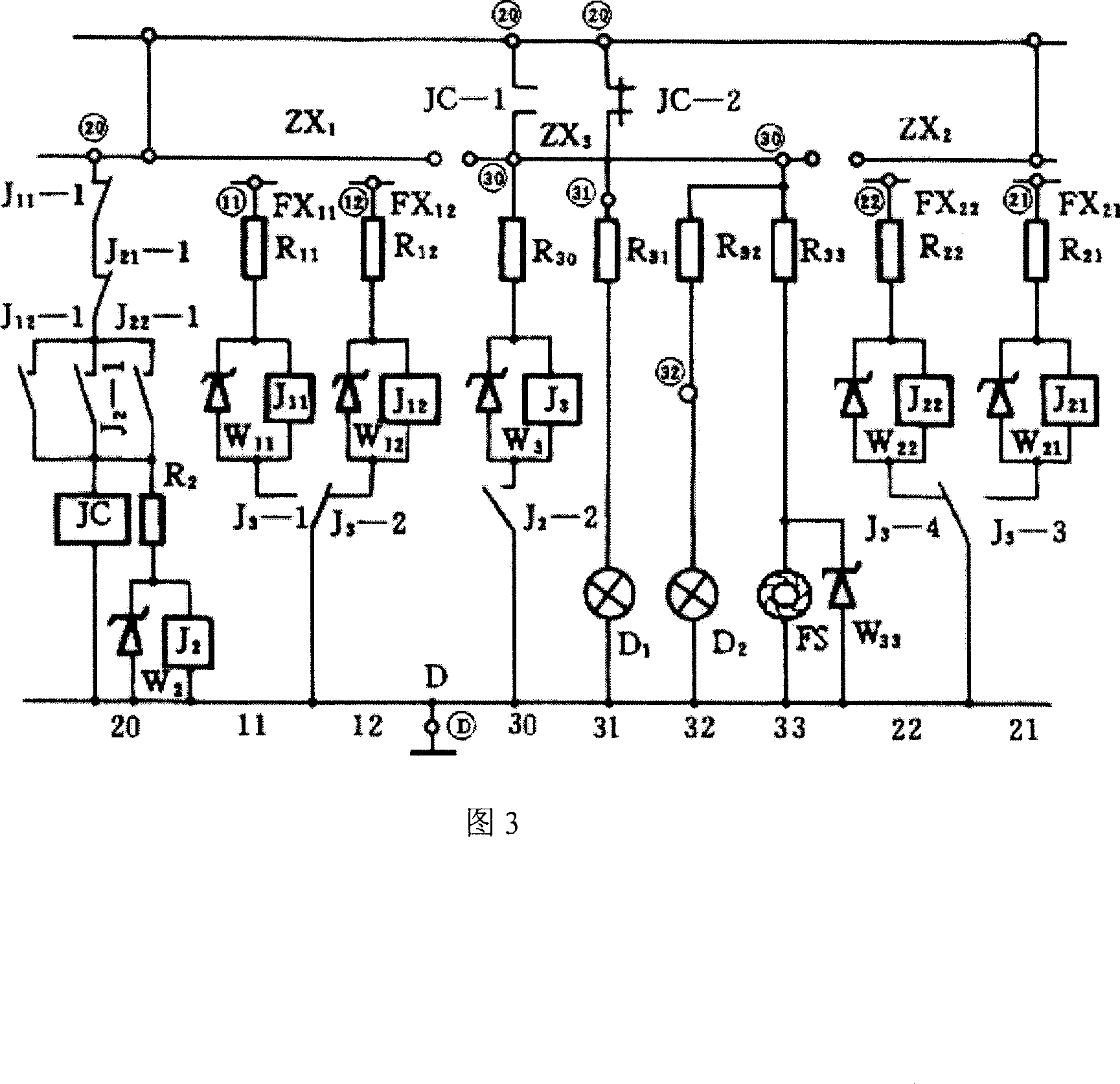

[0039] In the embodiment shown in the drawings, the two outer auxiliary contact lines (2) pass through the corresponding power failure signal line (10) cables, and pass through the control signal line on the side of the flameproof and heat dissipation shell (22) of the host (1) The wire nozzle (20) is introduced into the main engine (1), and is respectively connected to the corresponding terminals , The two inner auxiliary contact wires (3) pass through the corresponding power transmission signal line (11) cables, and pass through the control signal line nozzle (20) on the same side of the flameproof casing (22) of the host (1) to introduce the host (1), Connect to the corresponding terminals , The cable of the feed connection line (8) connected to the power line (4) passes through the load control line nozzle (21) on the other side of the flameproof enclosure (22) and leads to the host (1), and connects to the load terminal block (17) Corresponding terminals on the The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com