Process and apparatus for making multicomponent phase reinforced composite metal material

A metal composite material and manufacturing process technology, which is applied in the field of large-volume metal matrix composite material manufacturing technology and equipment, can solve the problem of being unable to manufacture reinforced metal composite materials with low specific gravity alloy particles, unable to manufacture multi-component reinforced particle metal composite materials, and unable to manufacture Problems such as bimetallic composite materials, to avoid pollution and uneven distribution, improve various performances, and improve various performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

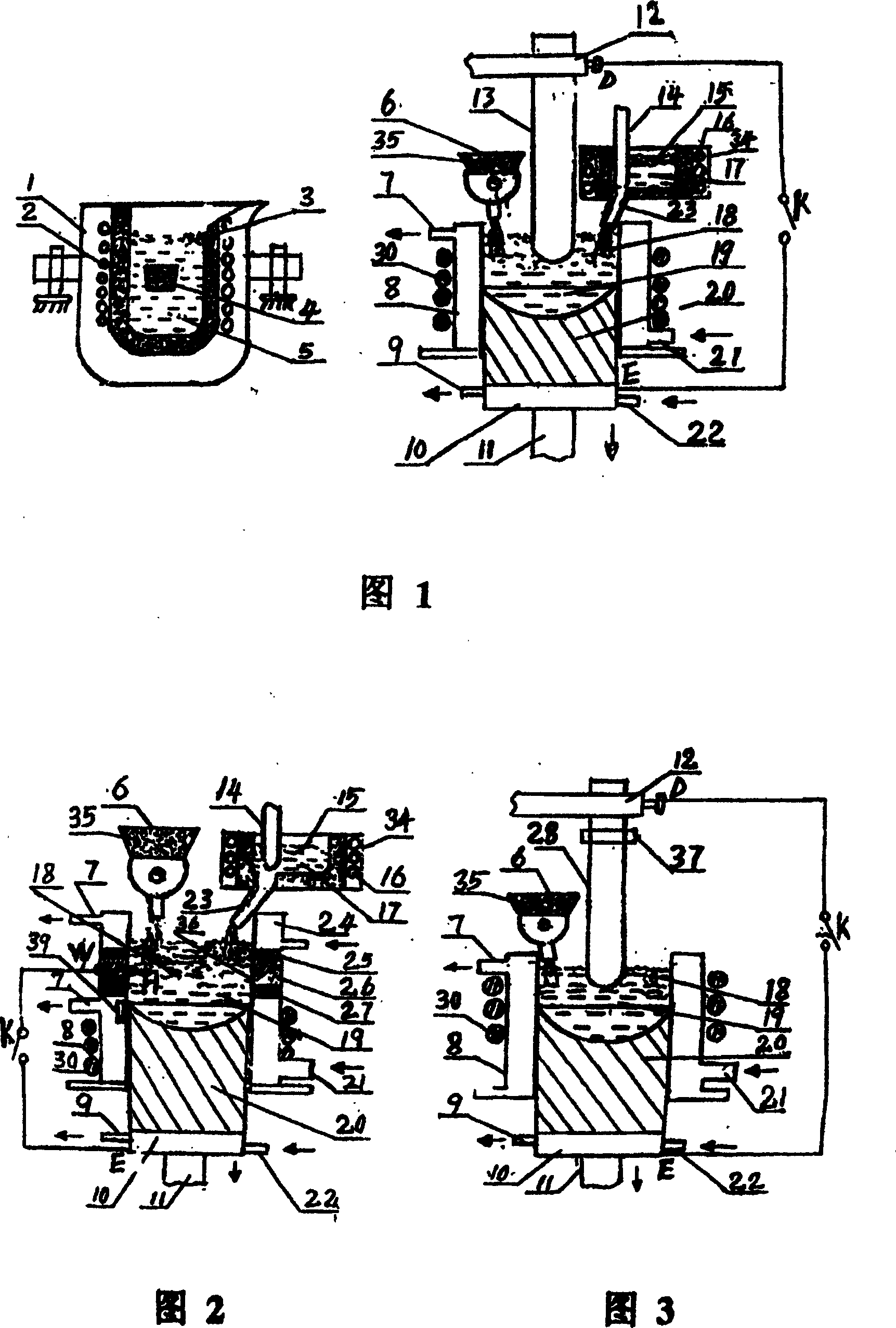

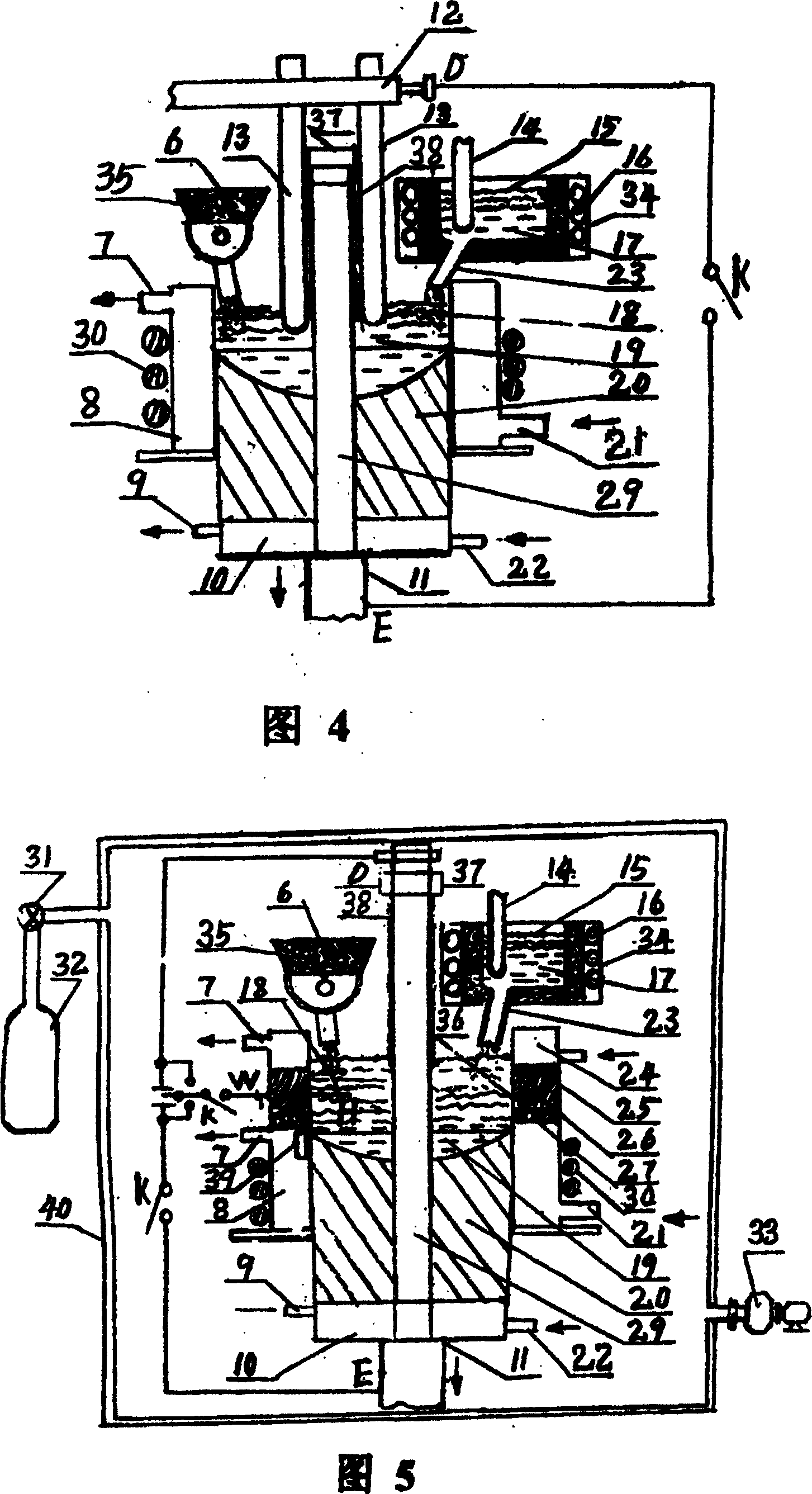

[0019] Embodiment 1: In Figure 1, the equipment is composed of smelting reaction synthesis equipment and melting casting molding equipment. The smelting reaction synthesis equipment includes induction melting furnace 1, induction heating power supply 2, mold slag 3, metal liquid 5, and reaction synthesis enhancement Granular prefabricated blocks consist of 4. The melting and casting molding equipment has an electrode holder 12, a non-consumable electrode 13 is connected to the electrode holder 12, a water-cooled crystallizer 8 is installed under the non-consumable electrode 13, and an electromagnetic crystallizer is installed outside the water-cooled crystallizer 8 The agitator 30 is connected with the water inlet pipe 21 and the water outlet pipe 7 respectively at the lower part and the upper part of the water-cooled crystallizer 8, and the bottom water tank 10 is installed at the bottom of the water-cooled crystallizer 8, and the water inlet pipe 2 and the water outlet pipe 2...

Embodiment 2

[0022] Embodiment 2: In Fig. 2, the water-cooled crystallizer is a combined conductive crystallizer, and the combined conductive crystallizer is composed of a water-cooled crystallizer 8, a conductive crystallizer 26, a water-cooled ring 24, a high-temperature-resistant insulating pad 25 and 27, and a high-temperature-resistant conductive crystallizer. Composed of ceramics 36, the conductive crystallizer 26 is located in the middle of the water-cooled crystallizer 8 and the water-cooled ring 24, and a high-temperature-resistant insulating pad 27 is installed at the connection between the conductive crystallizer 26 and the water-cooled crystallizer 8 and the water-cooled ring 24. A layer of high temperature resistant conductive ceramics 36 is coated on the inner wall of the device, and a power supply W is connected to it, an electromagnetic stirrer is installed outside the water-cooled crystallizer 8, and an inner top of the cooling water jacket of the water-cooled crystallizer 8...

Embodiment 3

[0023] Embodiment 3: In FIG. 3 , the consumable electrode 28 cast from the mixed metal liquid 17 synthesized by reaction is connected to the electrode holder 12 . An ultrasonic vibration device 37 is mounted on the consumable electrode 28 . Turn on the power supply K, insert the consumable electrode 28 into the solid slag in the water-cooled crystallizer 8, so that under the action of resistance heat, the solid slag is ignited and melted into liquid electroslag 18, and the consumable electrode 28 Under the action of resistance heat, the liquid slag 18 is melted into metal droplets containing reinforcing particles, the voltage and current are adjusted to melt at a predetermined speed, and the particle feeder 6 is turned on at the same time. Make the reinforcement particles 35 flow into the water-cooled crystallizer 8 according to the predetermined flow rate, make the two-phase materials in the liquid electroslag 18, after being stirred by the electromagnetic stirrer 30, mix the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap