Process of repairing pit in asphalt road

A technology of asphalt pavement and new technology, which is applied in the field of traffic road maintenance, can solve the problems of poor repair quality, cumbersome pavement pothole repair process, and long operation time, so as to reduce the investment in fixed assets and facilitate the construction process The effect of short operation and operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

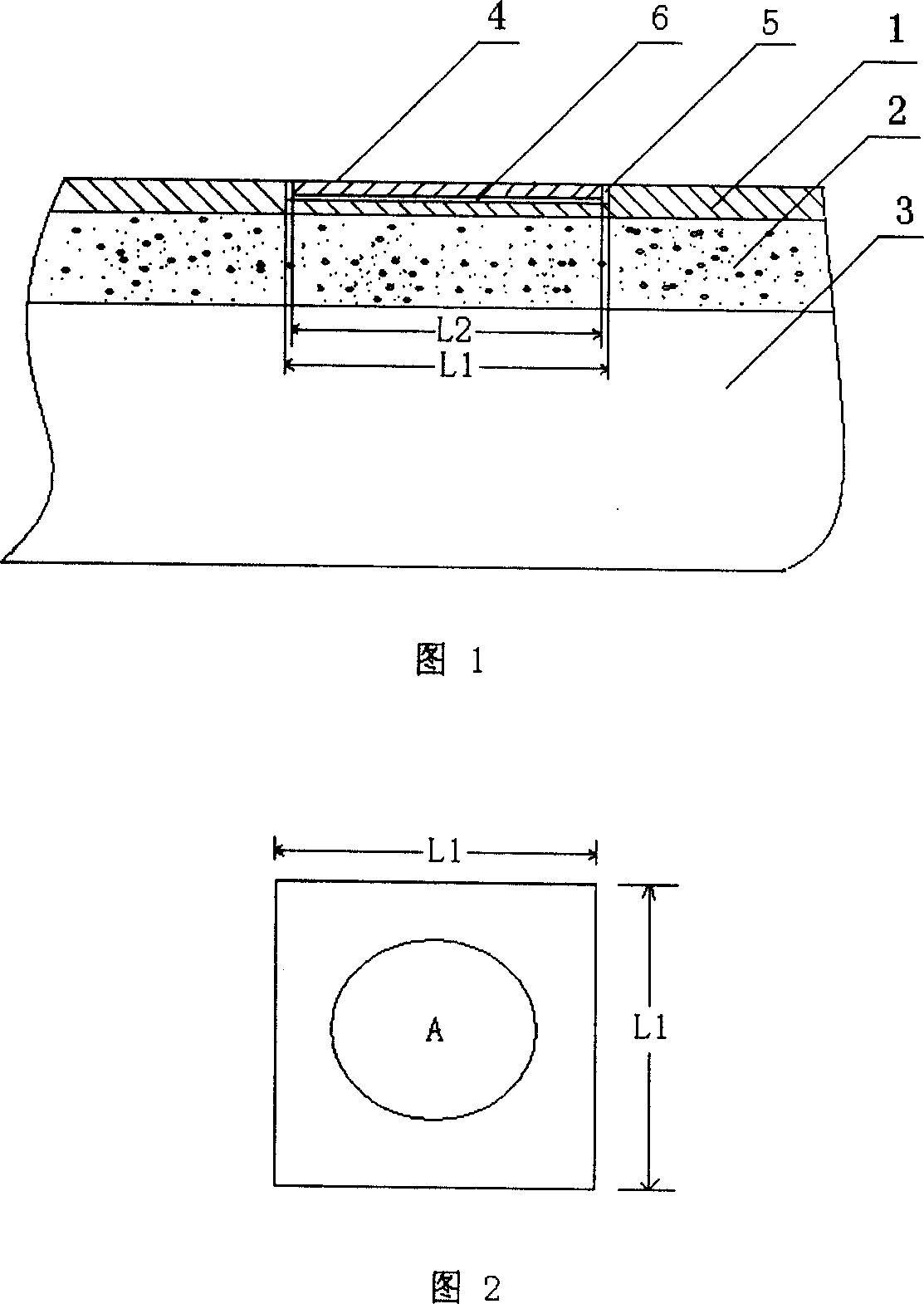

[0024] See Figure 1, a new process for repairing potholes on asphalt pavement. This process is to first clean the damaged potholes at room temperature, trim the periphery and bottom of the potholes according to the specified size, and then make the pre-prepared potholes corresponding to the size of the repaired pits. Apply pavement asphalt brick adhesive on the bottom, side, and pit bottom of the pavement asphalt bricks, bond the pavement asphalt bricks to the bottom of the pit and the cutting surface, and keep the road surface smooth, and then use the pavement asphalt brick adhesive to seal the pavement asphalt The gap between the brick and the original pavement is filled, and the technical standard of the original pavement can be reached after a short period of health maintenance, and the pothole repair of the pavement can be completed.

[0025] 1. Pavement asphalt bricks

[0026] Pavement asphalt bricks are produced by professional manufacturers. They are made of the same p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com