Torque testboard

A technology of torque converter and test bench, applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problem of not comprehensively reflecting the overall performance of the torque converter, and achieve the effect of ensuring the safety of personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

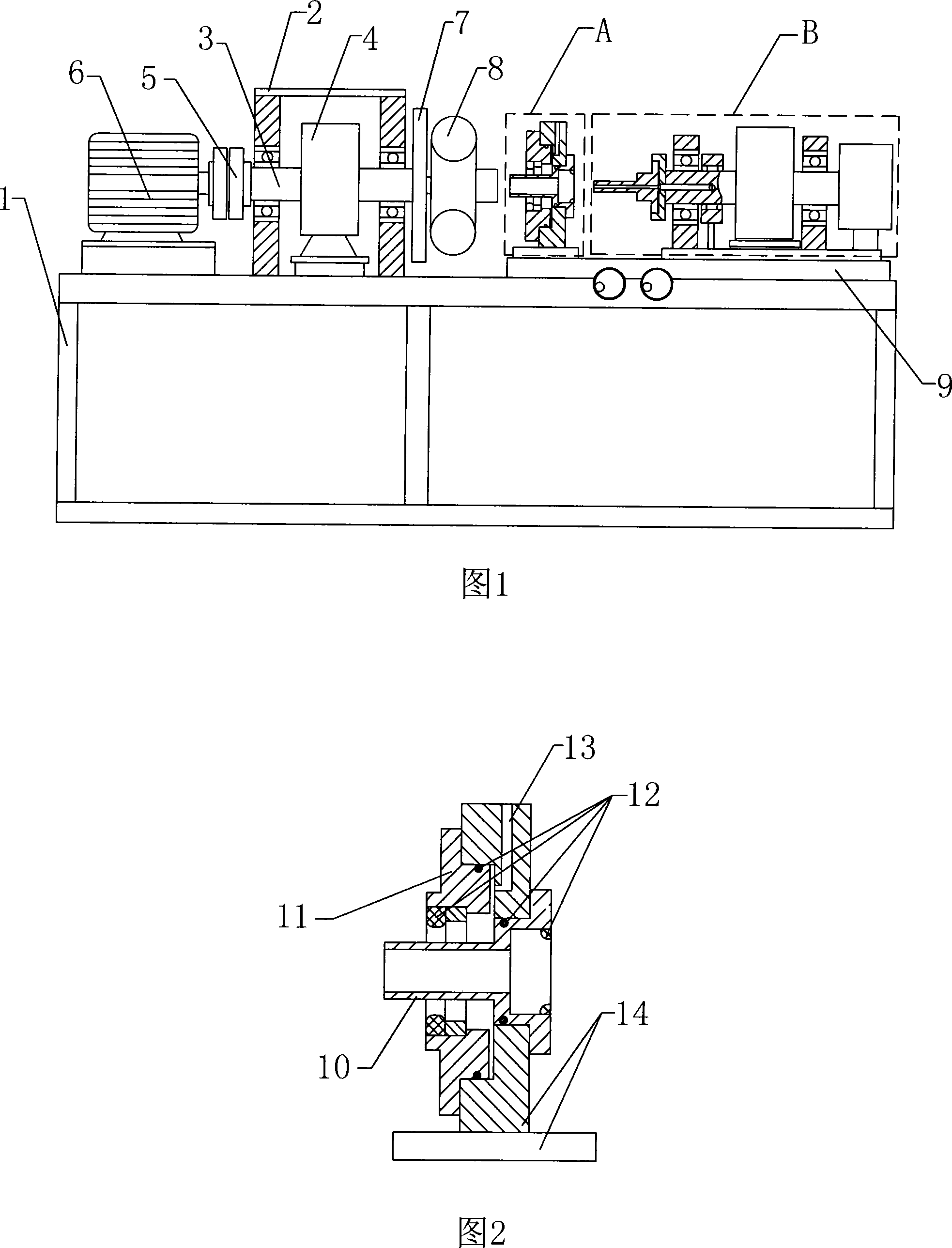

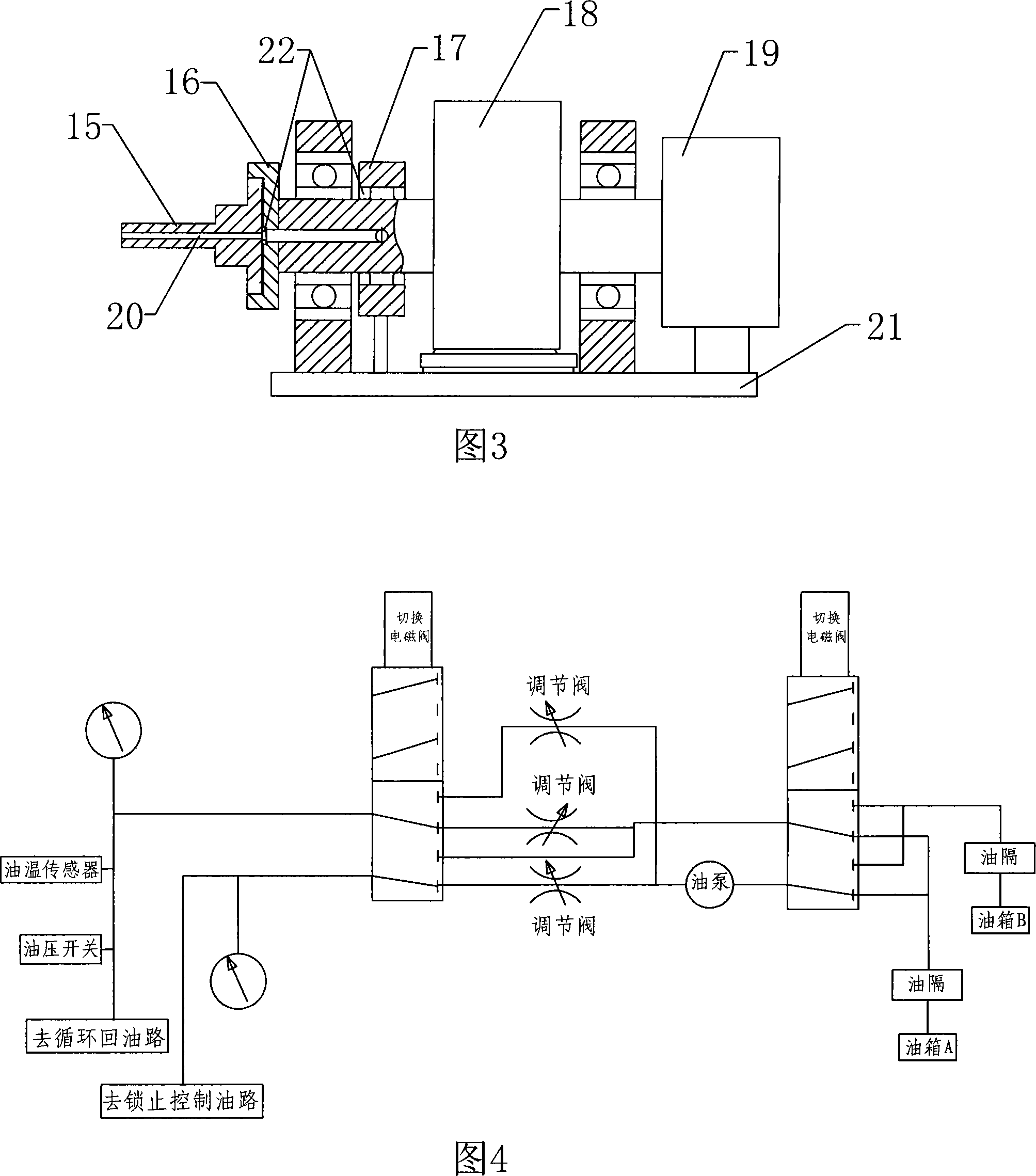

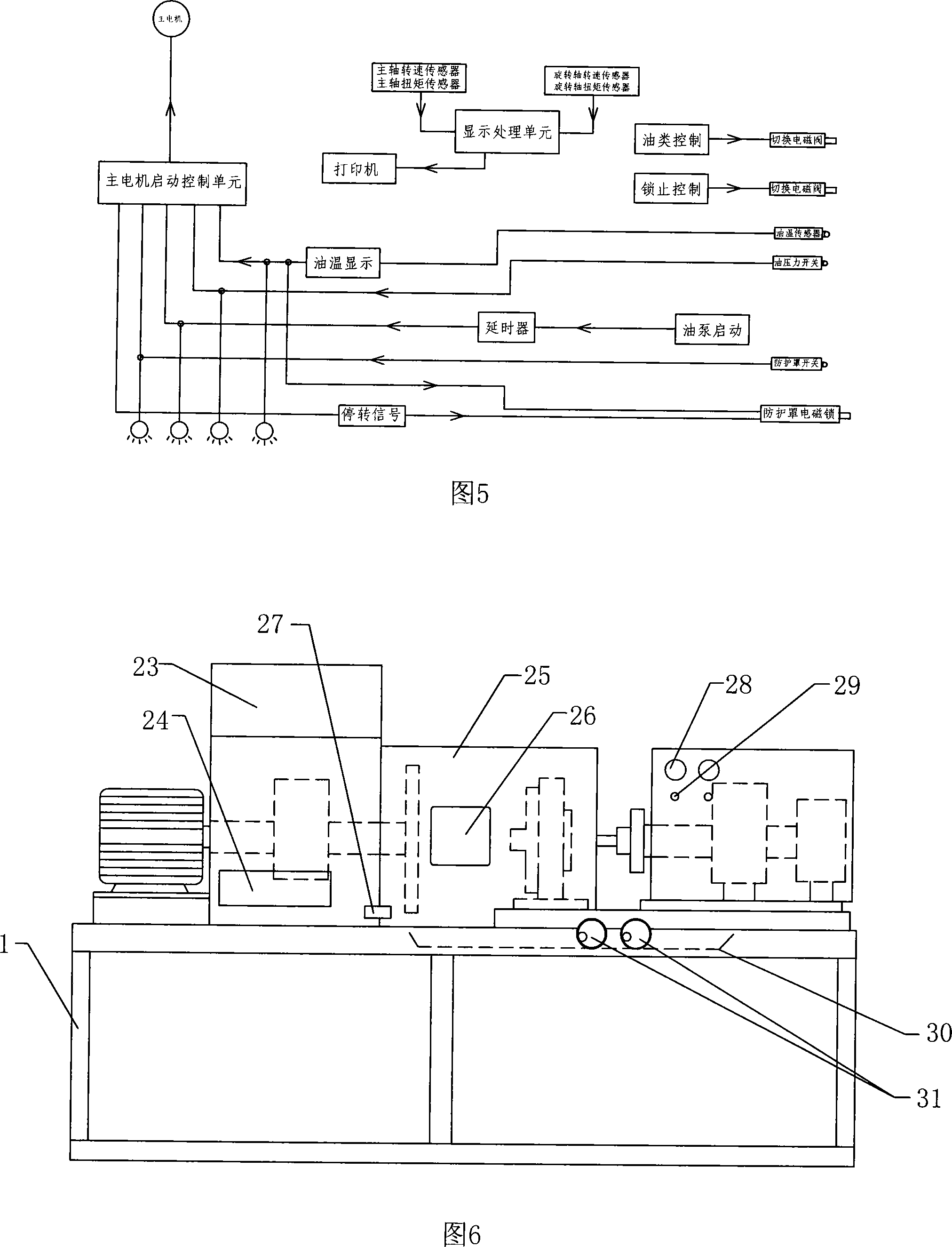

[0023] As shown in FIG. 1 , the present invention includes upper and lower parts, the upper part is a test work platform, and the lower part is a chassis 1 . The test working platform includes the main transmission mechanism 2, the torque converter guide wheel fixing mechanism and the turbine transmission mechanism. The torque converter guide wheel fixing mechanism and the turbine transmission mechanism are slidingly connected to the guide rail 9 on the top of the chassis 1; the main transmission structure 1 is equipped with a speed sensor and a torque sensor 4 on the main shaft 3, and one end is connected to the main shaft through a coupling 5 with a buffer device. The motor 6 is connected, and the other end is provided with a connecting flange 7 to meet the needs of connecting various torque converters 8 . The distance between the main shaft 3 and the top of the cabinet 1 can be 220mm. The main motor 6 is a controllable frequency conversion motor with a power of 7.5-10KW, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com