Modular packing system

A packaging system and packaging box technology, applied in the direction of packaging, packaging machines, packaging cigarettes, etc., to achieve the effect of huge cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

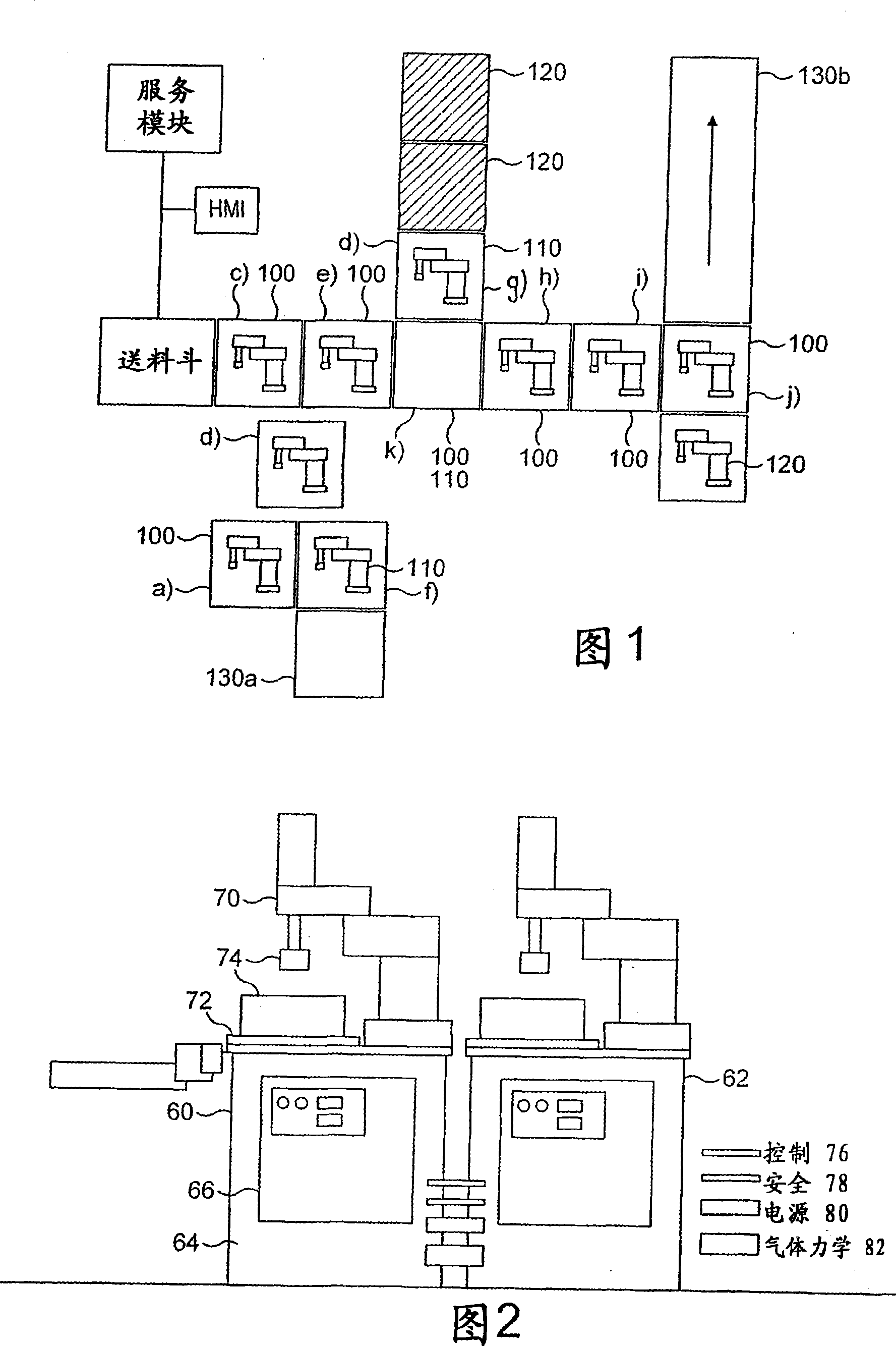

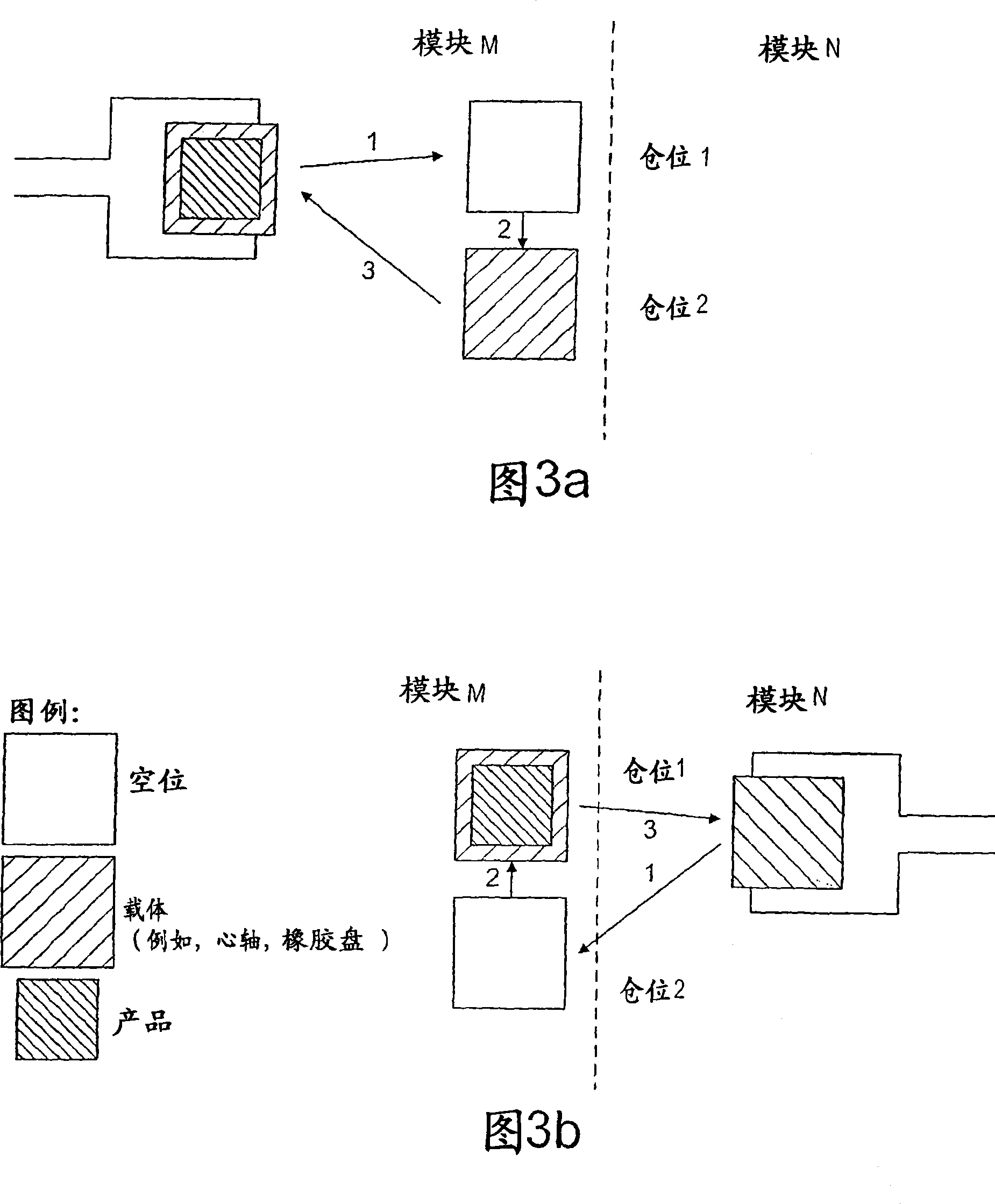

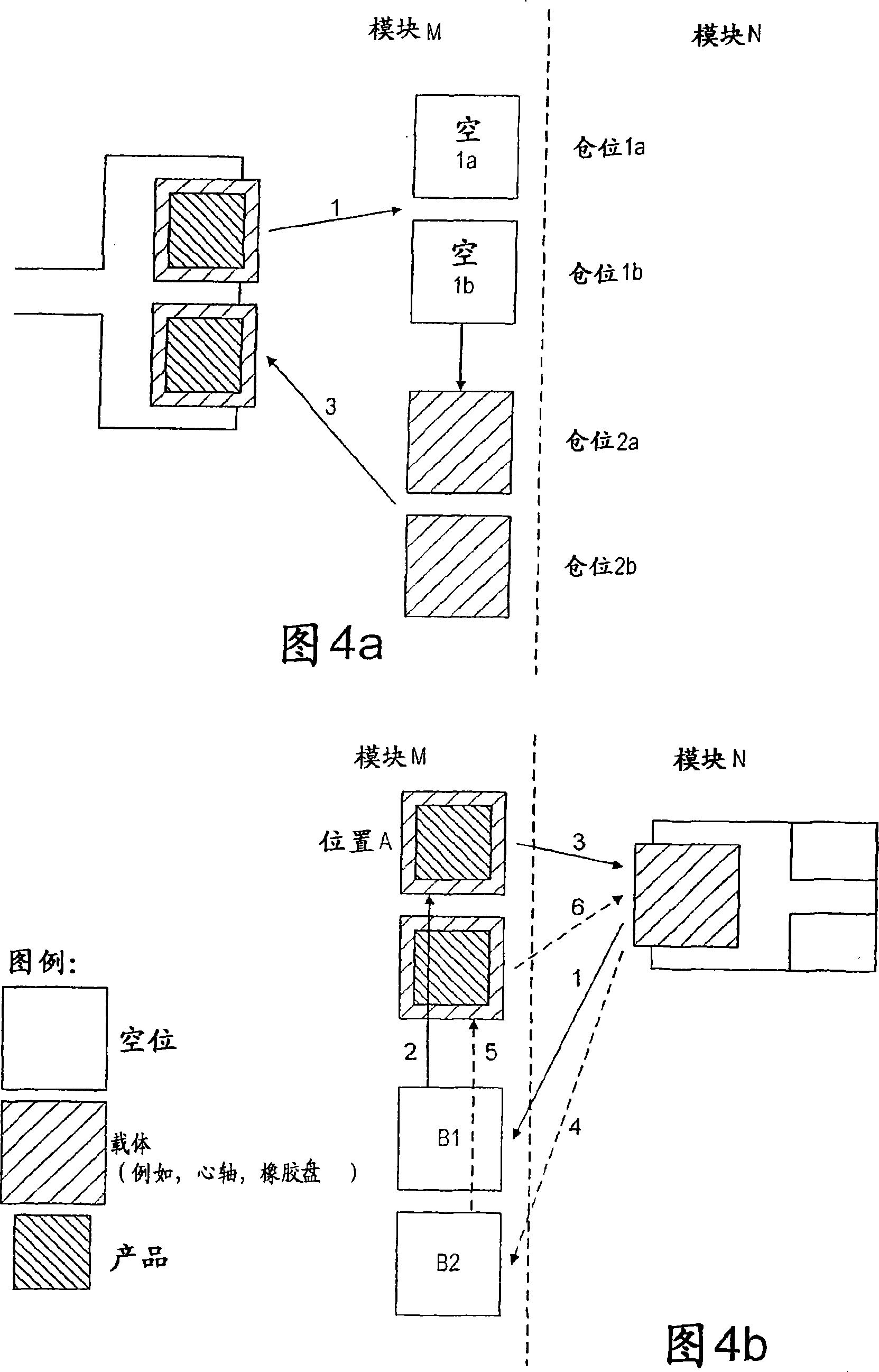

[0034] The packaging system configuration represented in Figure 1 is an exemplary configuration used to illustrate the reconfigurable modular nature of some embodiments of the invention. The packaging system is intended to be used for packaging cigarettes or other stick-shaped articles, but the invention is not limited to packaging this type of article and may be extended to packaging other types of articles, such as various food products, including confectionary products; writing Stationery, such as colored pencils or crayons or other stick-shaped items.

[0035] Similarly, the present invention is not limited to any particular packaging system configuration. Indeed, the invention allows reconfiguration of the modules in order to carry out different types of packaging for different types of items.

[0036] The arrangement represented in Figure 1 is intended to be used for packaging collating stacks of cigarettes in packs having rigid plastic end caps and metallized foils wra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com