Water-proof slide fastener

A waterproof zipper and zipper tape technology, which is applied to clothing, fasteners, fastener components, etc., can solve the problem that it is difficult to form the rear size 204, the formation of the rear size 204 is troublesome, and it is difficult to install the mold on the surface of the fastener element 203, etc. problem, to achieve the effect of simple structure, ensuring air tightness and water tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

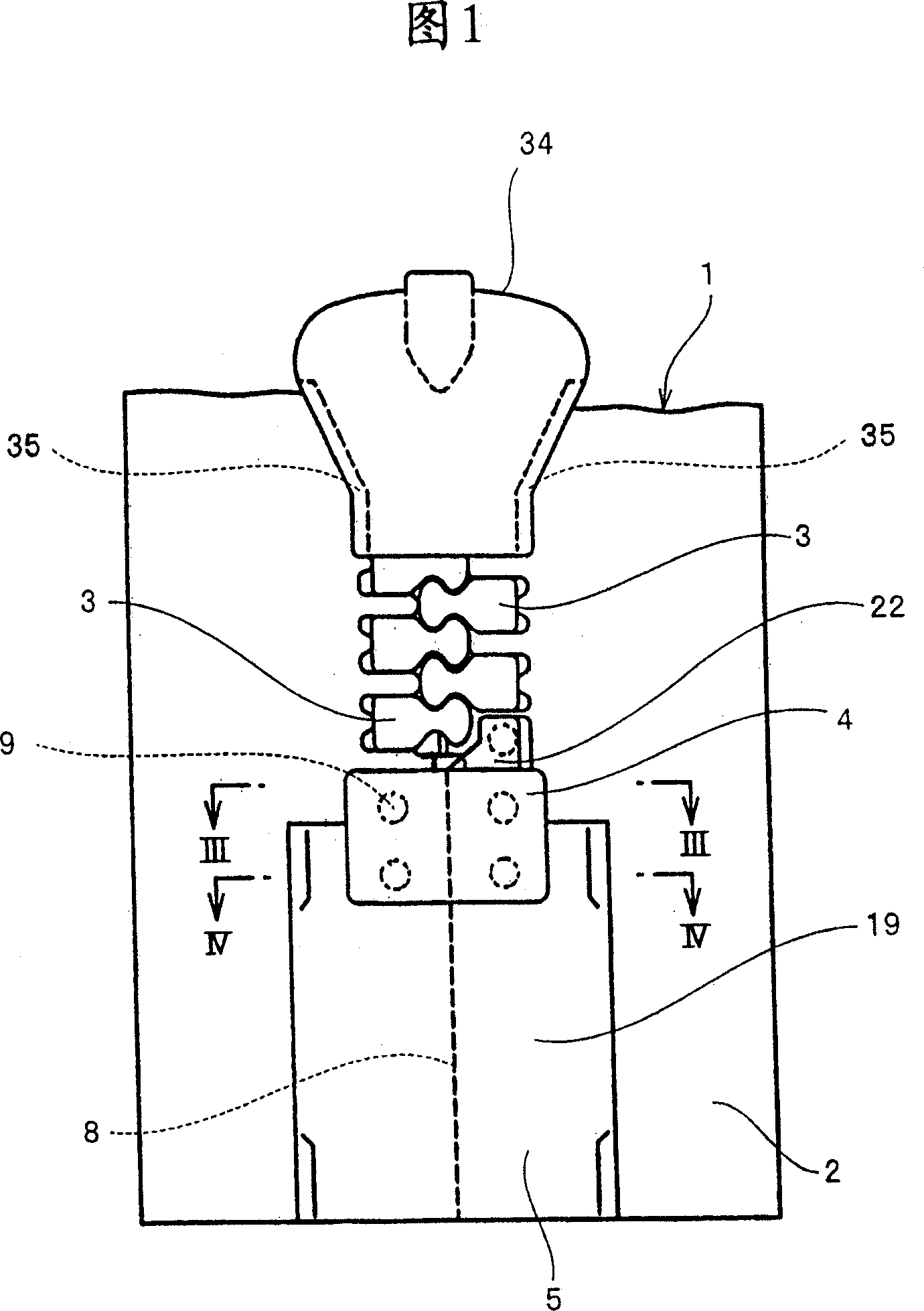

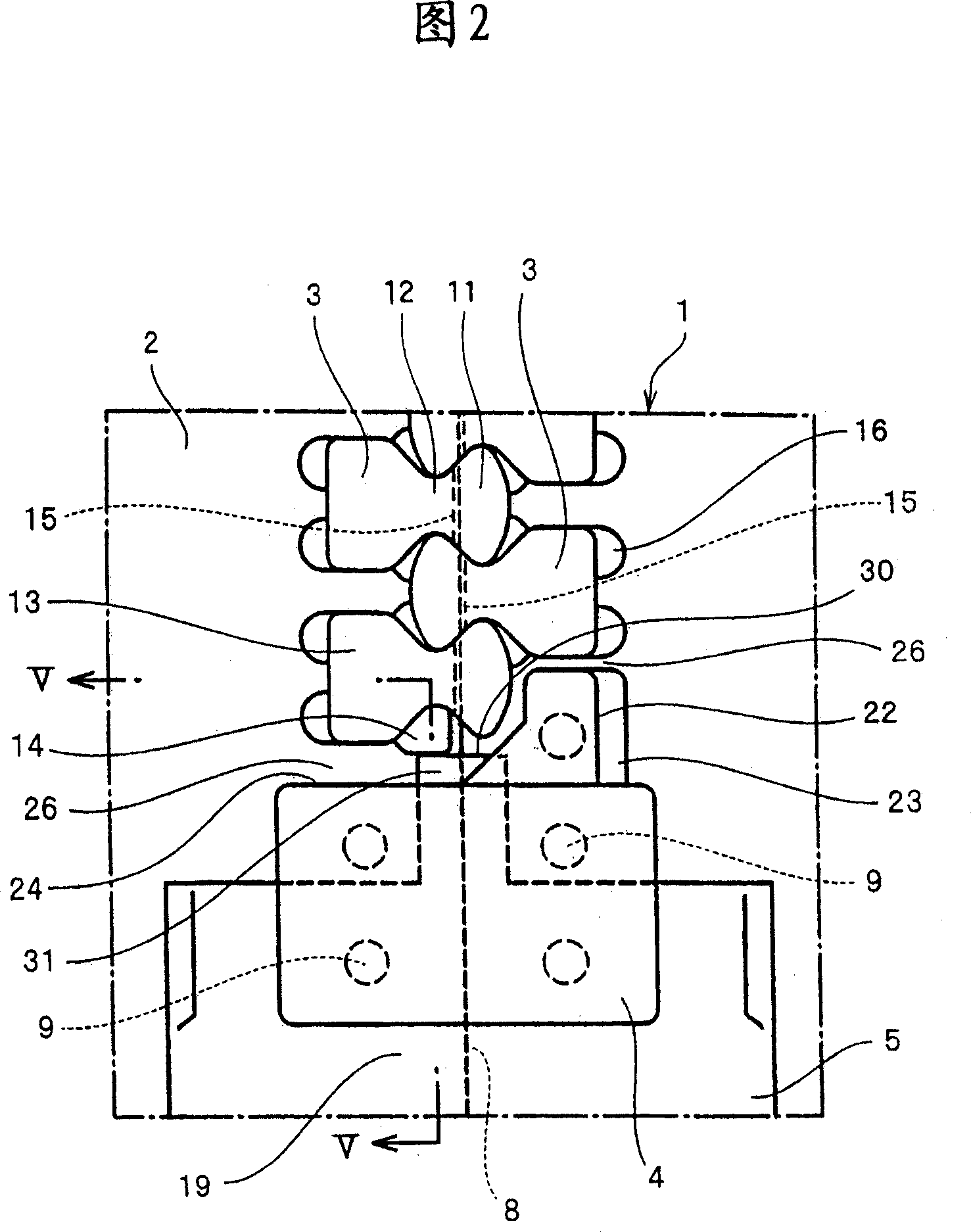

[0037] As described above, in the waterproof zipper according to the first embodiment shown in FIGS. 1 to 6, each zipper tape 2 is made of elastic material (for example, thermoplastic elastic material or synthetic rubber) in a woven or knitted fabric The front and rear surfaces of the zipper are coated to provide waterproof performance, and through holes 9 are formed in the opposite edges 8 of the zipper tape 2 so that they pass through the front and rear surfaces. The fastener elements 3 are formed on the front and rear surfaces of the zipper tape 2 by injection molding with the aid of through holes 9 of thermoplastic resin, such as polyamide, polyacetal, polypropylene, and polybutylene terephthalate. Esters, or the like.

[0038] In the structure of each element 3 formed on the fastener tape 2, an enlarged joint head 11 is formed at its front end, an joint concave portion 15 is provided inside the front end of the joint head 11, and the fastener tape on the mating side The oppos...

no. 2 example

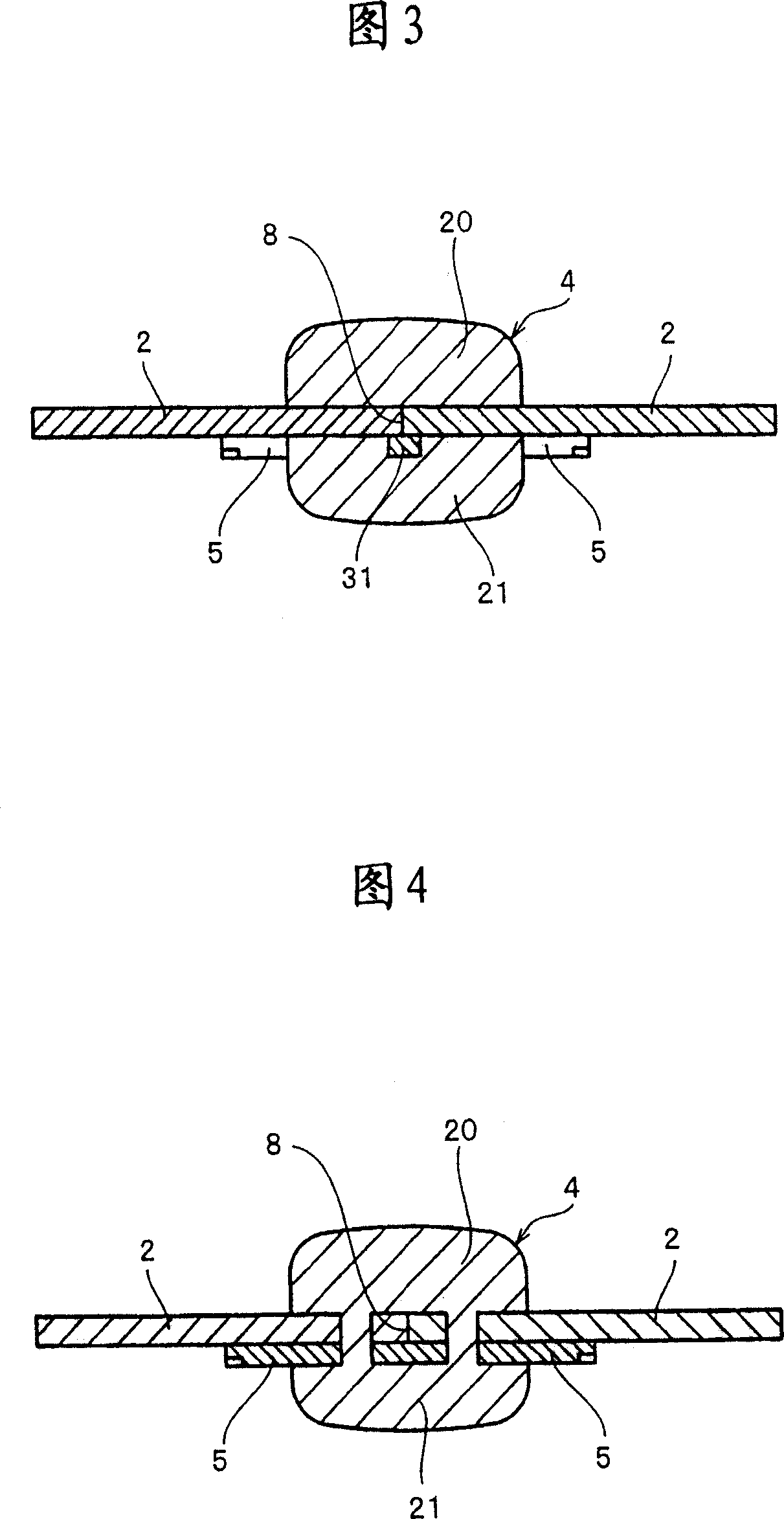

[0042] The waterproof slide fastener according to the second embodiment shown in FIG. 7 differs from the waterproof slide fastener of the first embodiment in the shape of the sheet member 5, wherein the sheet member 5 is connected to the space portion 19 of the fastener chain 1. Lined on top. The material of the sheet member 5 is the same as in the first embodiment, and the sheet member 5 is formed by coating the front and rear surfaces of a woven or knitted fabric or non-woven fabric with a thermoplastic elastic material or synthetic rubber, or using resin Film formation. The sheet member 5 is provided with a protruding piece 31 that protrudes upward along the opposite edge 8 of each of the left and right zipper tapes 2 arranged in parallel. The protruding piece 31 protrudes in a stepped form, that is, its front end portion 30 is on the side of the engagement protrusion 14 formed in the neck 12 of the fastener element 3 (that is, adjacent to the fastener element 3) on one side. E...

no. 4 example

[0048] The difference between the waterproof slide fastener according to the fourth embodiment shown in FIG. 9 and the waterproof slide fasteners in the respective embodiments is that the shape of the sheet member 5 connected to the rear surface of the space portion 19 of the fastener chain 1 is modified. The material of the sheet member 5 is the same as that of each embodiment.

[0049] The sheet member 5 is formed by linearly cutting the front end portion 30 of the sheet member 5, and is bonded to the rear surface of the fastener tape 2, so that the front end portion 30 is in contact with the neck portion 12 adjacent to the fastener element 3. The side ends of the engaging protrusion 14 formed inside are in contact. The back stop 4 having the same shape as each of the embodiments is formed on the sheet member 5 by injection molding by means of through holes formed in the space portion 19 to ensure waterproof performance.

[0050] In the first to fourth embodiments, the sheet mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com