Wast gas purifier

An exhaust gas purifier, exhaust gas purification technology, used in chemical instruments and methods, exhaust devices, machines/engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

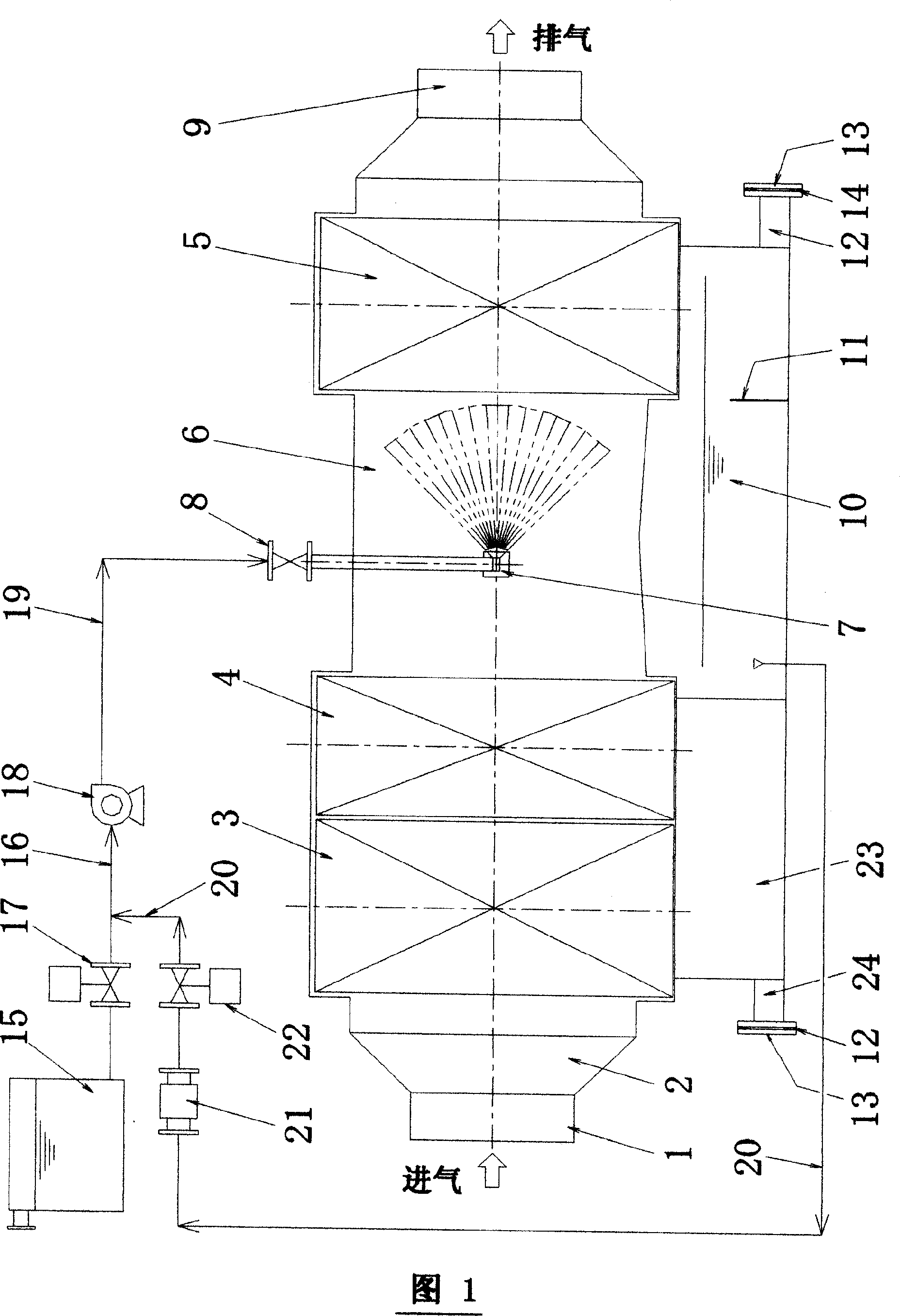

[0024] The device of the present invention will be further described below in conjunction with the embodiments and accompanying drawings.

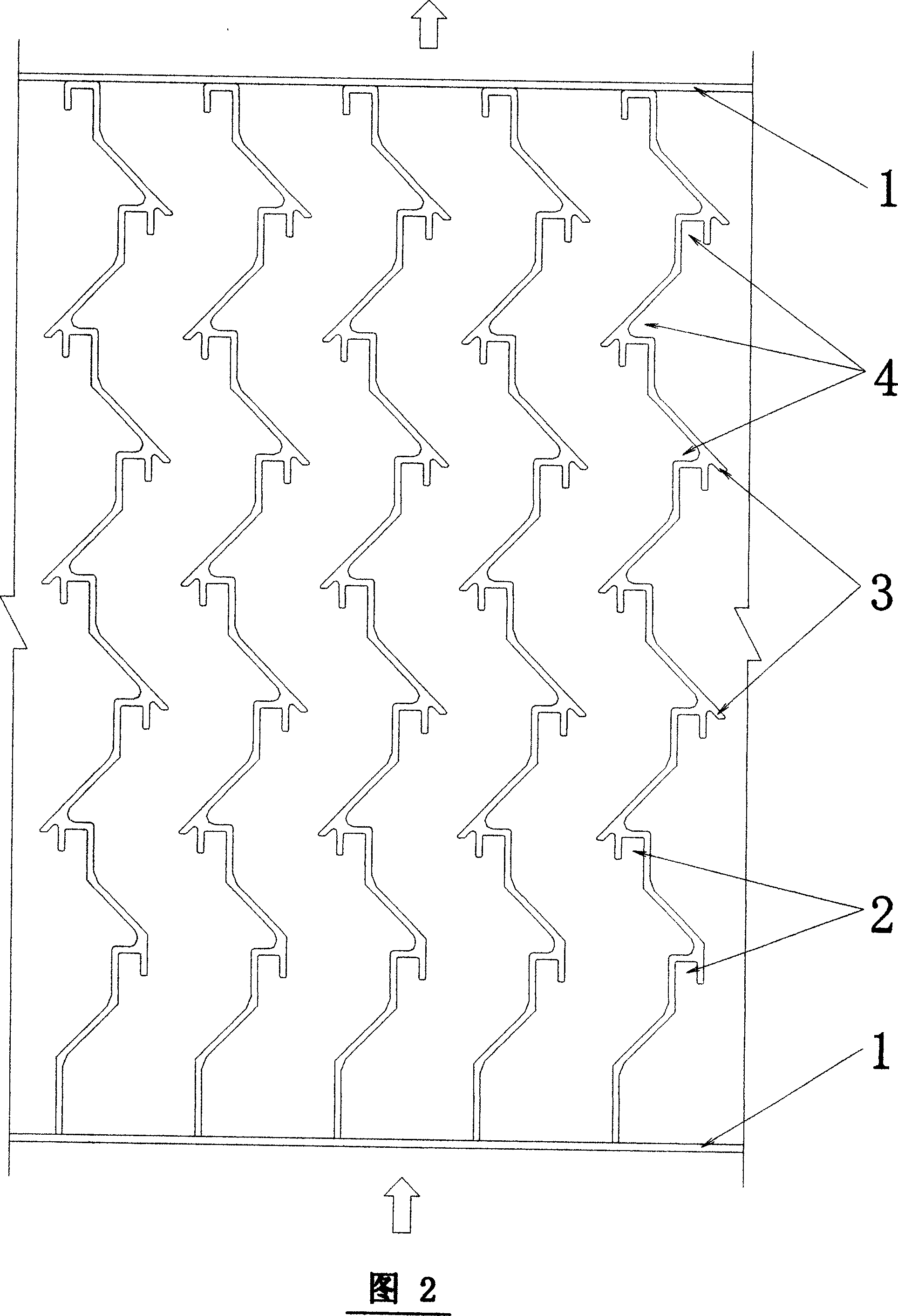

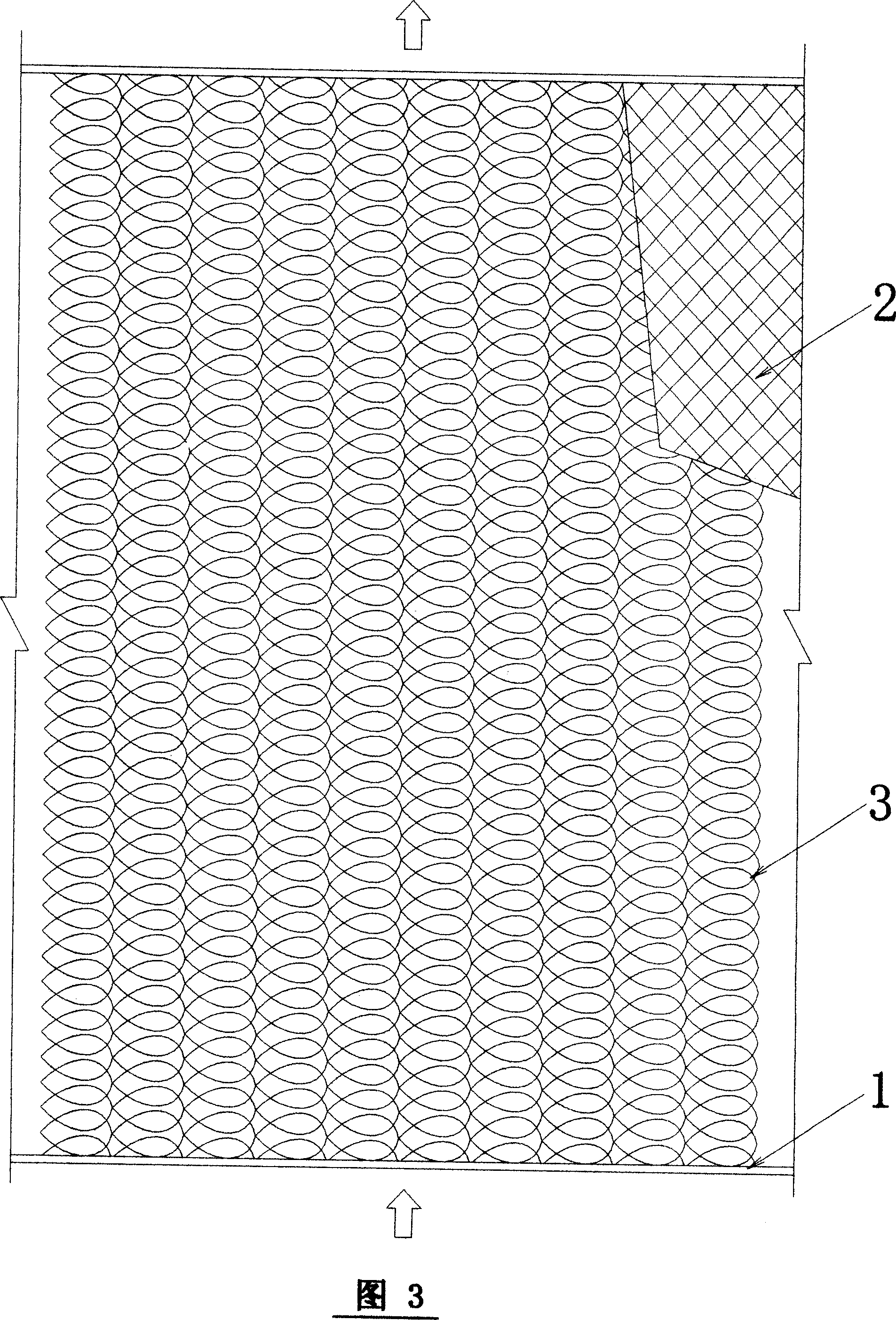

[0025] As shown in Figure 1, when the exhaust gas discharged by the internal combustion engine due to incomplete combustion enters the exhaust gas inlet pipe 2 in the exhaust gas purifier housing 1, it passes through the first-stage exhaust gas catalytic oxidation device 3 to obtain preliminary catalytic oxidation. After the purification treatment, the waste gas flows through the second-stage exhaust gas filtration and contact device 4 for large-area contact and filtration to obtain further catalytic oxidation purification treatment. The exhaust gas after the secondary catalytic oxidation purification treatment will produce some turbulent flow, which is installed in the exhaust gas rectification channel 6 between the second-stage exhaust gas filtering contact device 4 and the third-stage exhaust gas purification and separation device 5, aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com