Wast gas purifier

An exhaust gas purifier and exhaust gas purification technology, applied in chemical instruments and methods, exhaust devices, machines/engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

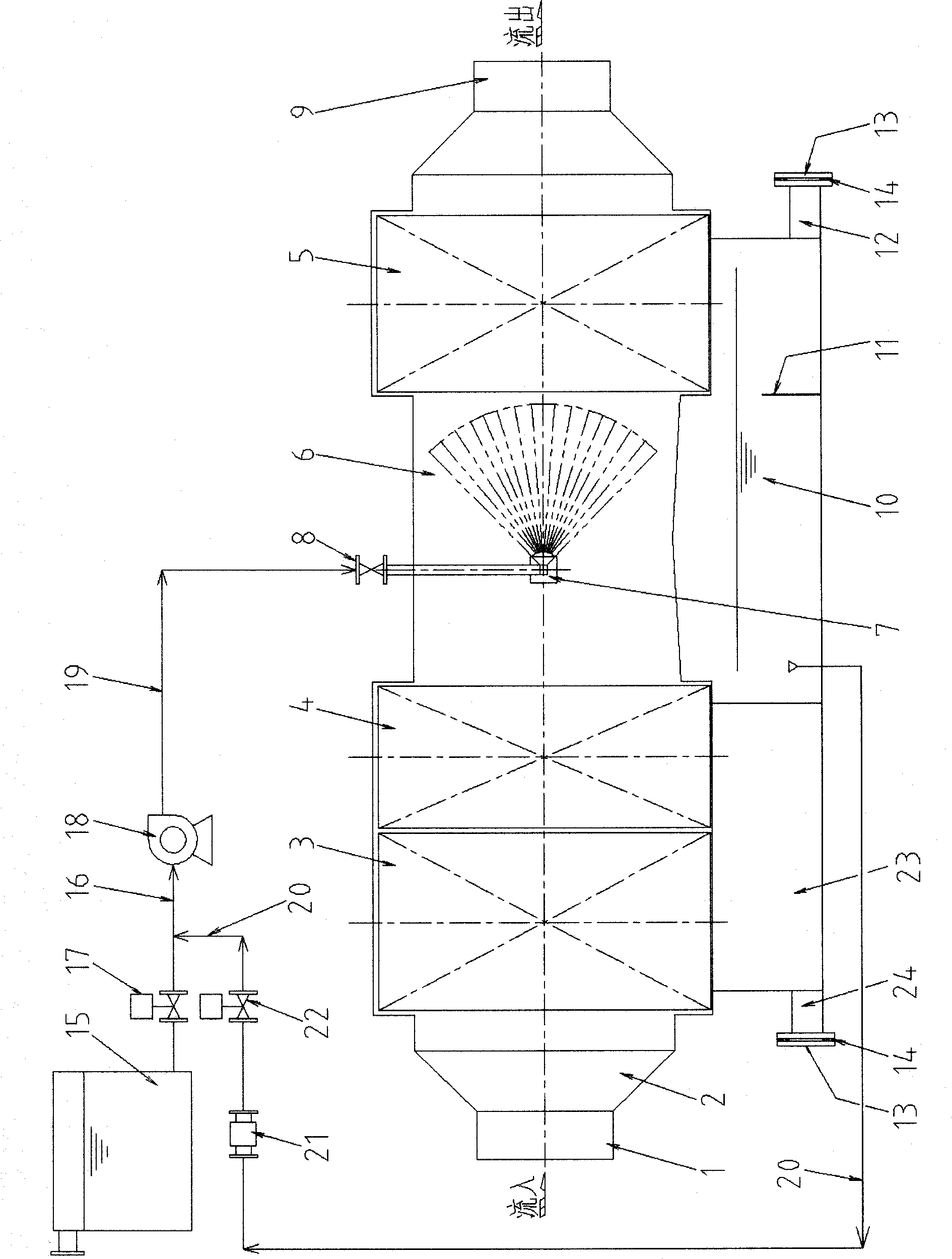

[0029] The device of the present invention will be further described below in conjunction with the embodiments and the drawings.

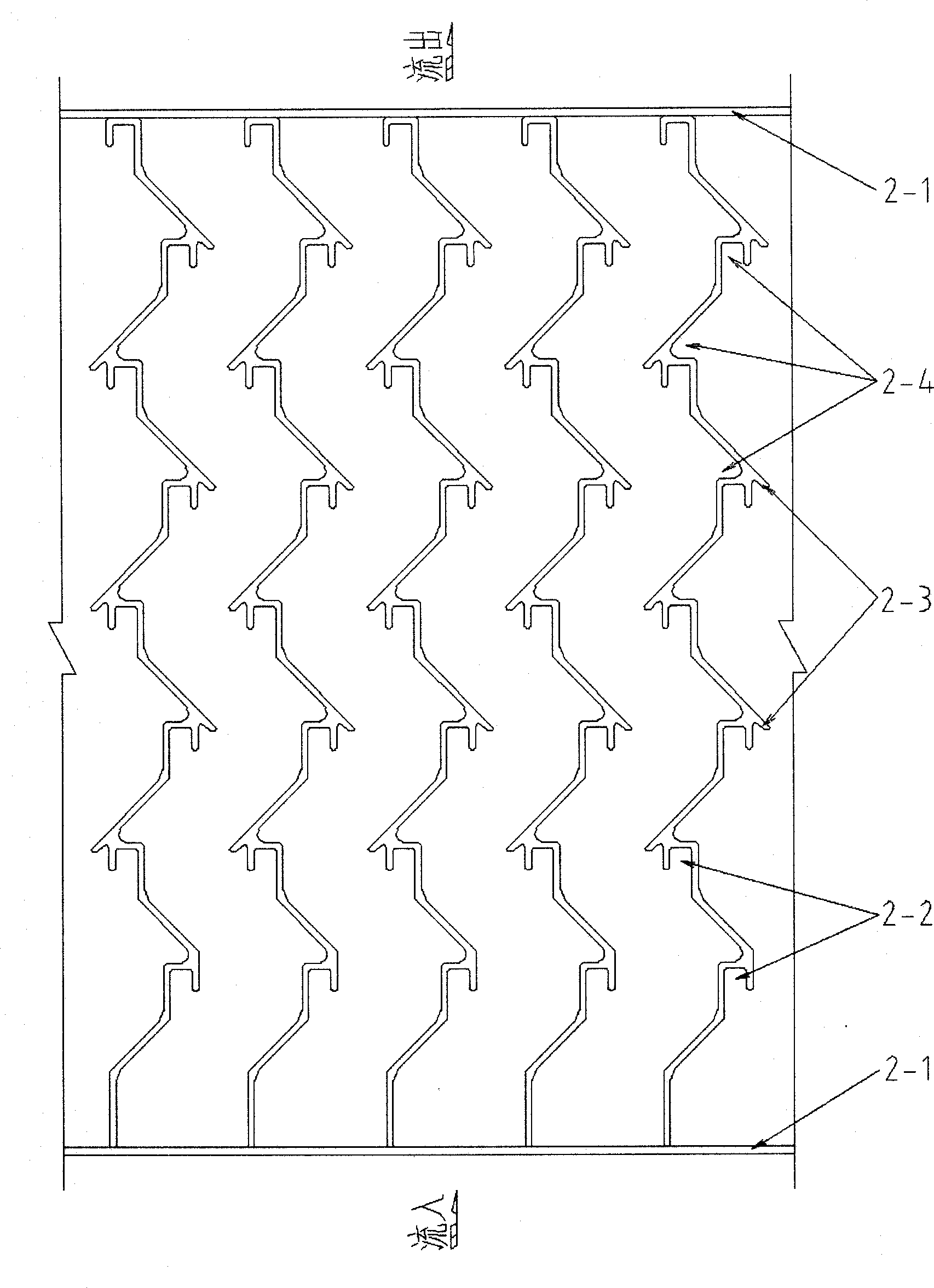

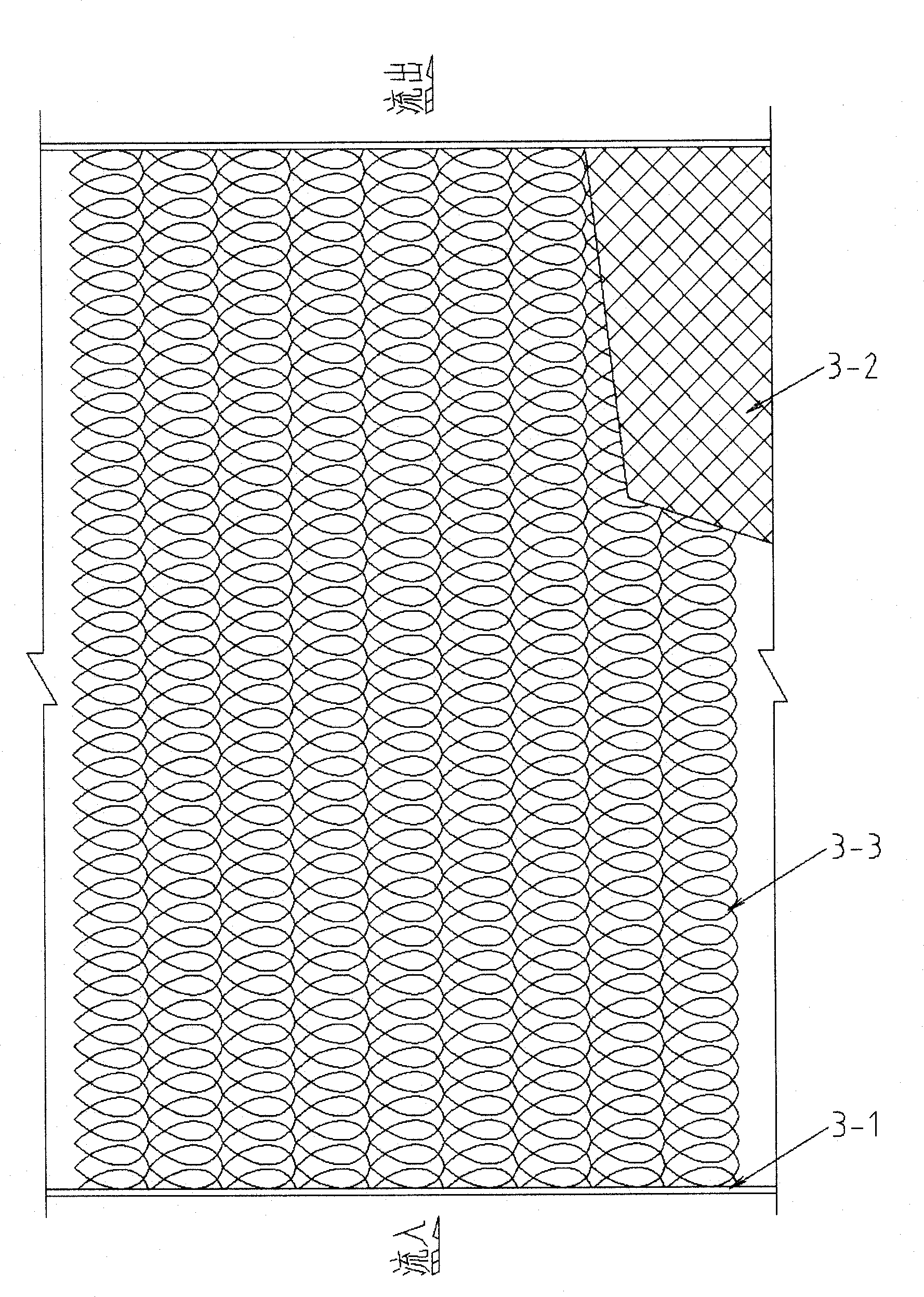

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the exhaust gas purifier includes a housing 1, an exhaust gas inlet pipe 2, a first-stage exhaust gas catalytic oxidation device 3, a second-stage exhaust gas filter contact device 4, an exhaust gas rectifying channel 6, a spraying water device 7, a second Three-stage exhaust gas purification and separation device 5, exhaust gas outlet pipe 9, manual control valve for urea dilution water 8, waste liquid collection box 10, waste liquid drainage pipe 12, fine dust particle storage box 23, fine dust particle discharge pipe 24, sealed end Cover 13, sealing gasket 14, urea dilution water storage tank 15, urea dilution water outlet pipe 16, urea dilution water outlet electric control valve 17, urea dilution water injection pump 18, urea dilution water drain pipe 19, waste liquid circulatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com