Surface polishing-finishing processing system based on fluid-field restriction type hydraulic ginding-particle flow

A technology of finishing processing and abrasive flow, which is applied in the field of structured surface finishing processing system of mechanical parts, can solve the problems that the surface with special size and structure cannot be processed, and achieve good environmental protection of the processing environment, good texture randomness and surface roughness The effect of high degree and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

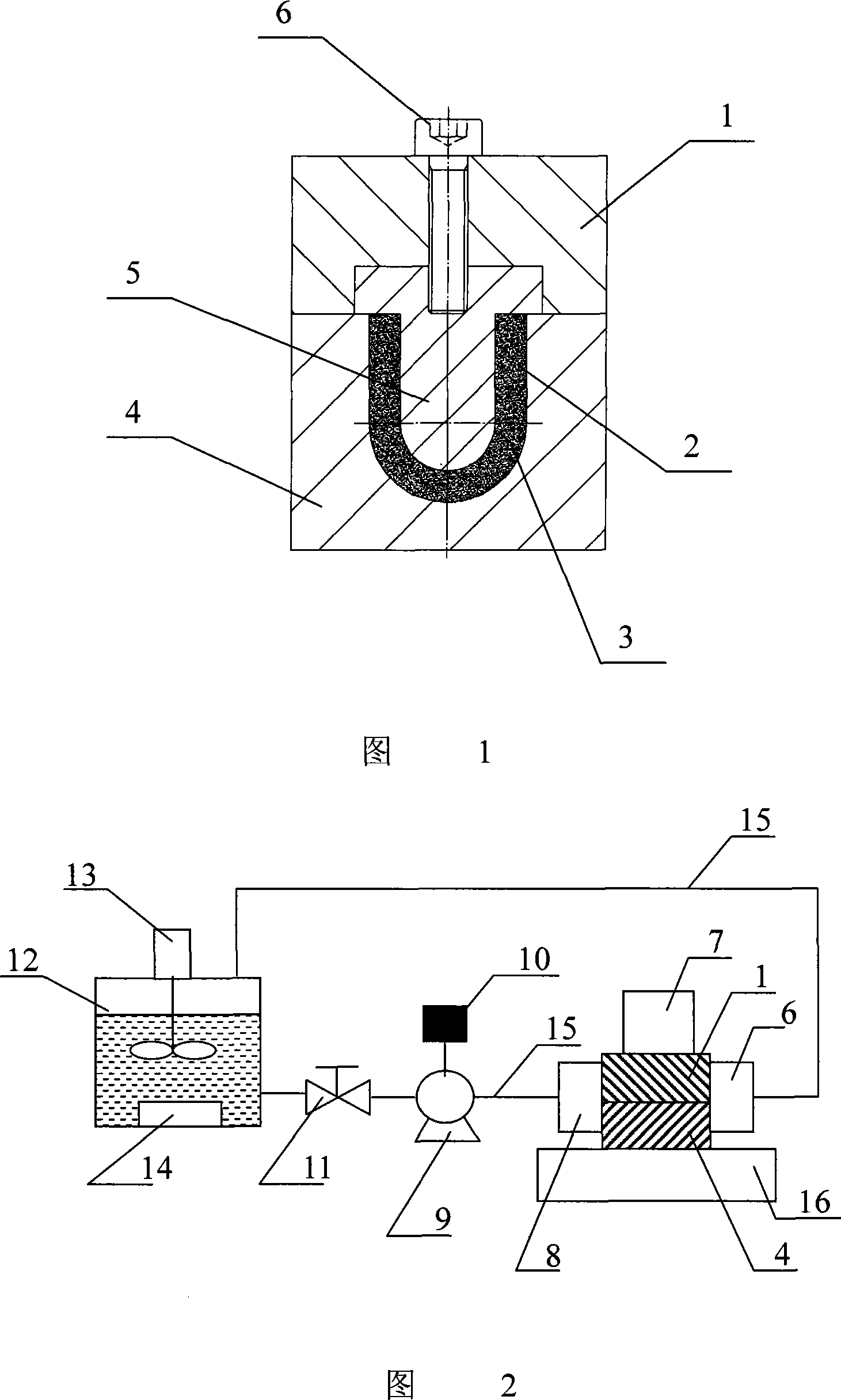

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

[0018] Referring to Fig. 1 and Fig. 2, a surface finishing system based on flow field constrained hydrodynamic abrasive flow includes a workbench 16 for placing a workpiece 4 to be processed, and a liquid-solid surface formed with the structured surface 2 of the workpiece 4 to be processed. Constraint module 5 of flow channel of two-phase abrasive grain flow, clamp 1 and abrasive grain flow circulation system for connecting restraint module 5 and processed workpiece 4, said abrasive grain flow circulation system includes liquid storage tank 12, pipeline 15 , diaphragm pump 9, the pipeline 15 is connected to the liquid storage tank 12, the membrane pump 9 is installed on the pipeline 15, the pipeline 15 is provided with the outlet guide module 6 communicated with the outlet of the flow channel 3, and the flow channel 3 The inlet diversion module 8 connected to the inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com