Foam concrete wall for buildings construction

A technology of foam concrete and concrete, which is applied in the direction of architecture, building components, building structures, etc., and can solve the problem of high total cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

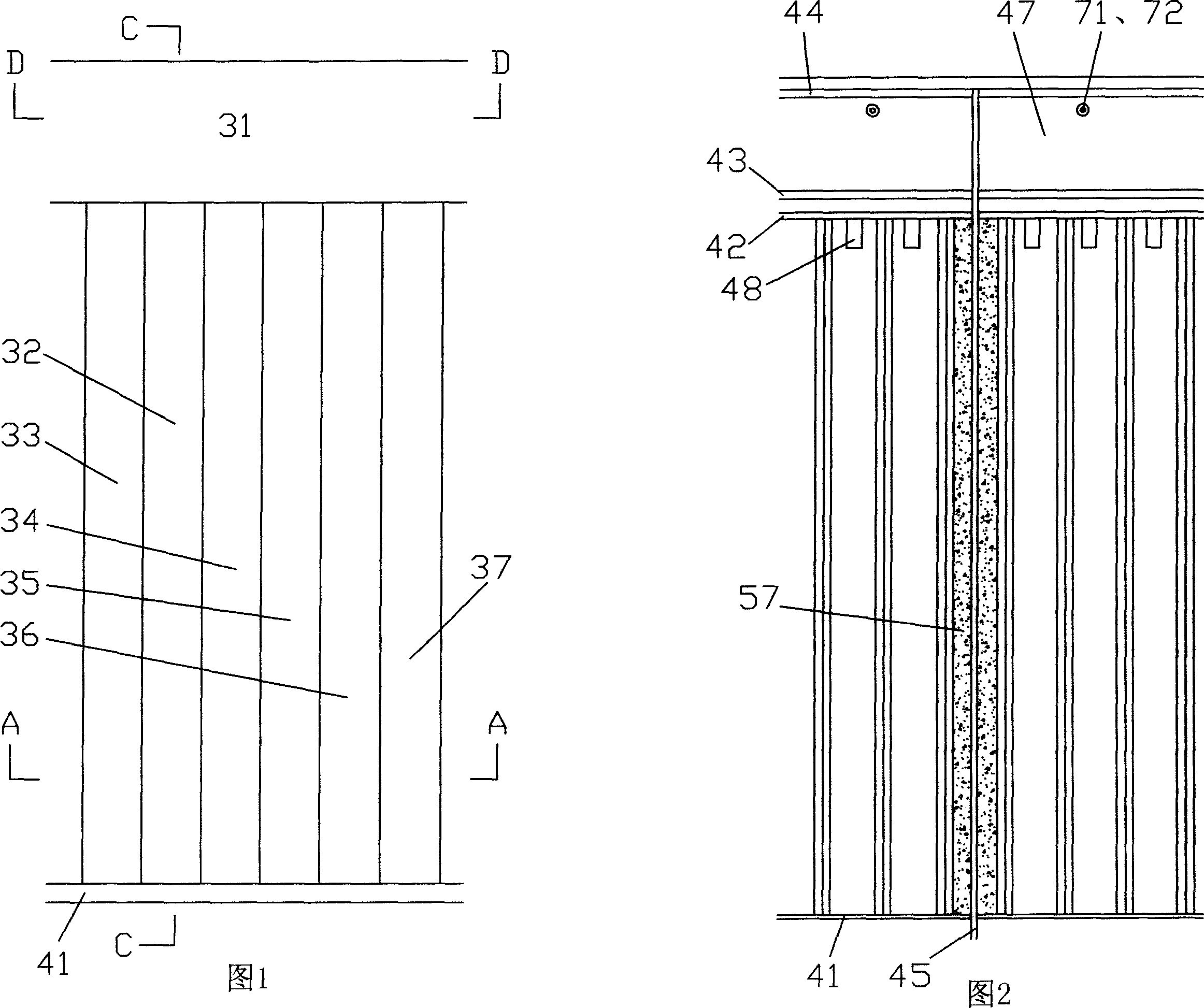

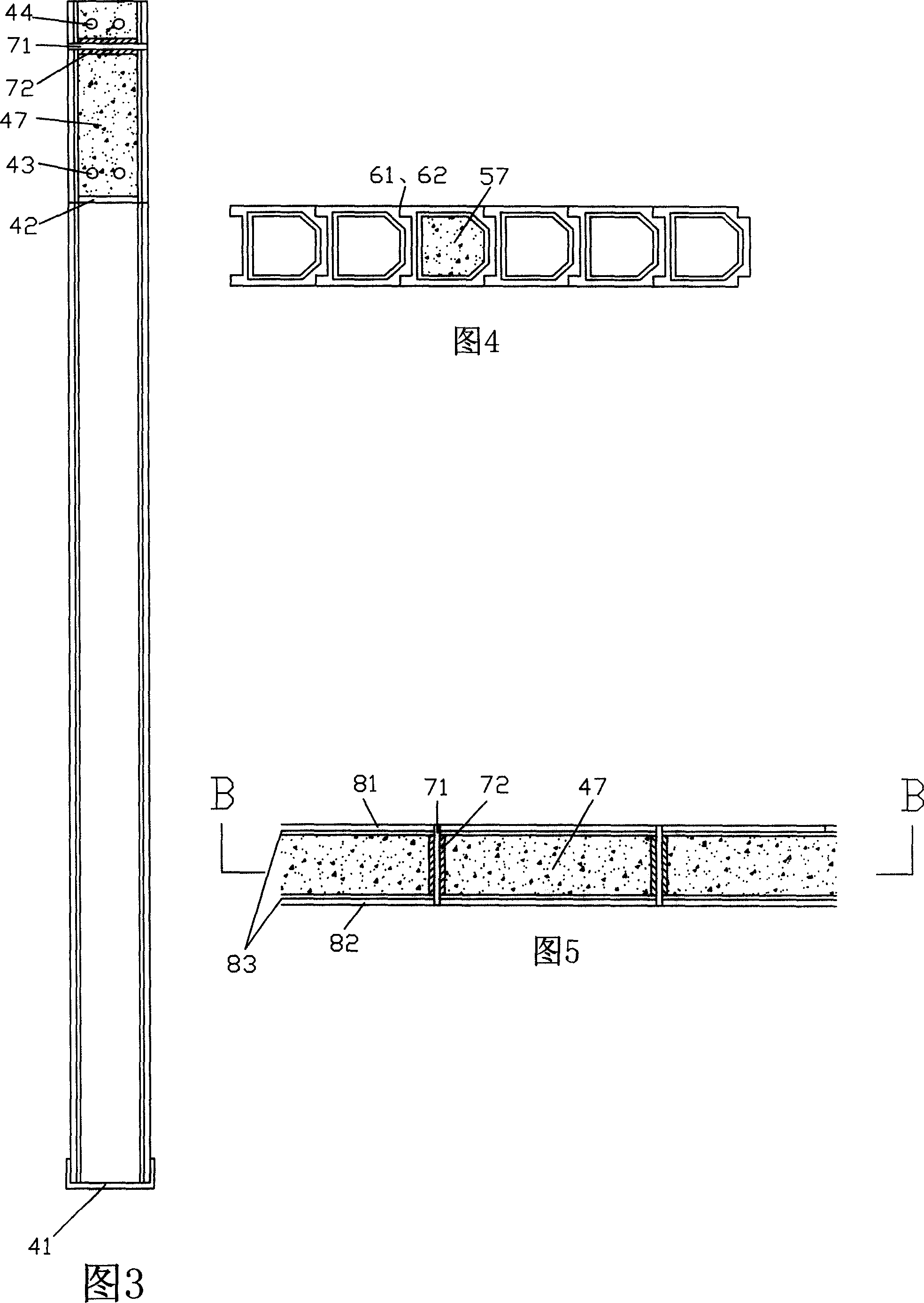

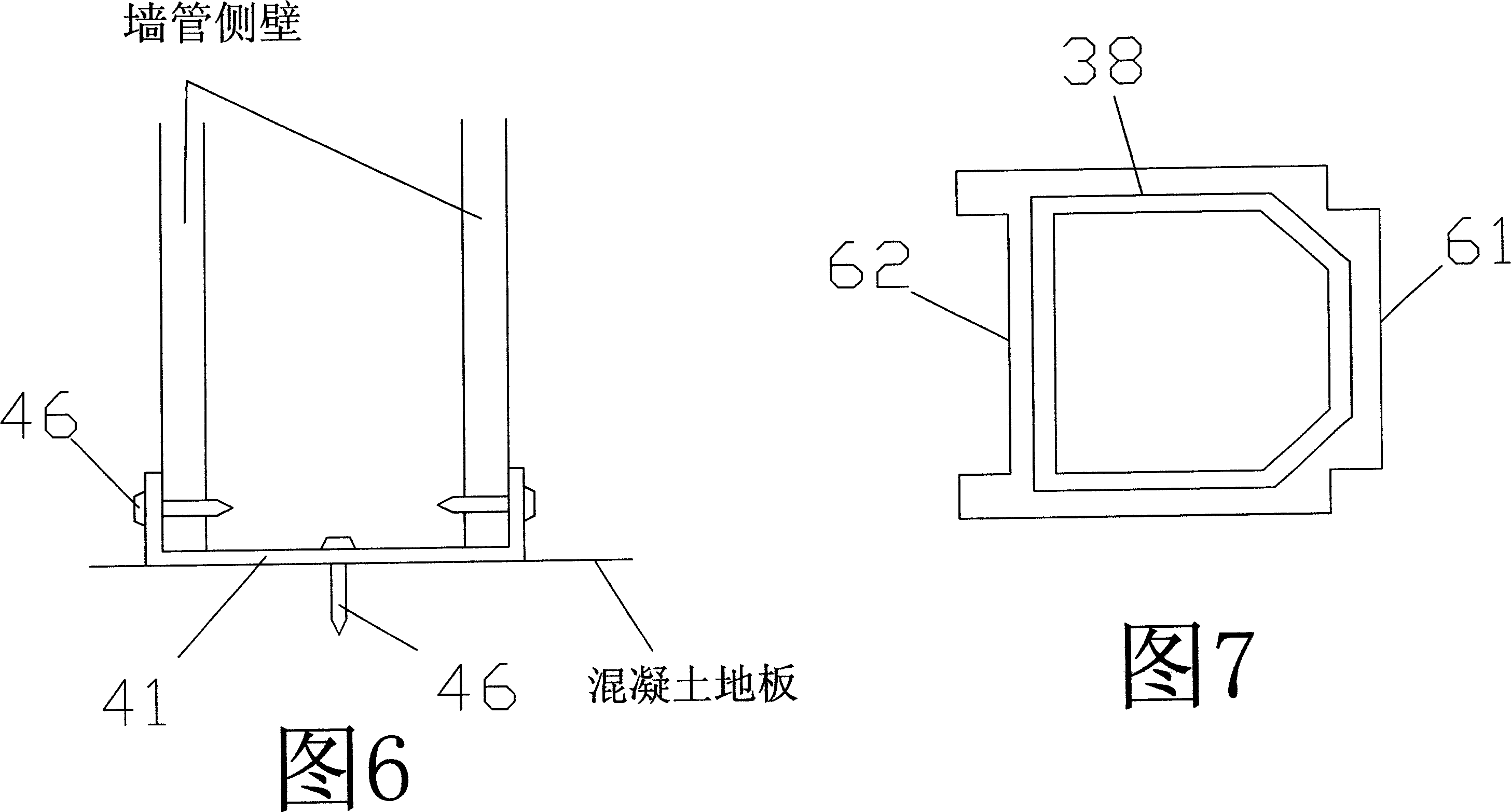

[0025] The present invention will be explained in detail here and illustrated with accompanying drawings. Reference numbers therein are shown in several different views of the same part.

[0026] The technology for producing AAC walls is well established and adopted by the construction industry. High-strength concrete has also been widely used in bridges and high-rise building structures. Low-density AAC is usually not strong enough to be used in load-bearing walls.

[0027] The present invention uses a fiber mesh within the CWS to enhance structural strength. As in January 1969, the paper "Stability of Fibers in Composite Materials" by Zhong Wenyi and others did the resistance analysis. High-strength concrete is also used to strengthen the AAC components. Due to their increased strength, walls can be constructed from hollow wall tubes rather than the currently common solid bricks. The weight of the components is also reduced for easy installation.

[0028] The material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com