Color sequential display device with back-light time delay control and its controlling method

A control method and delay control unit technology, applied to static indicators, instruments, etc., can solve problems such as uneven brightness between the upper and lower panels and scan time difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

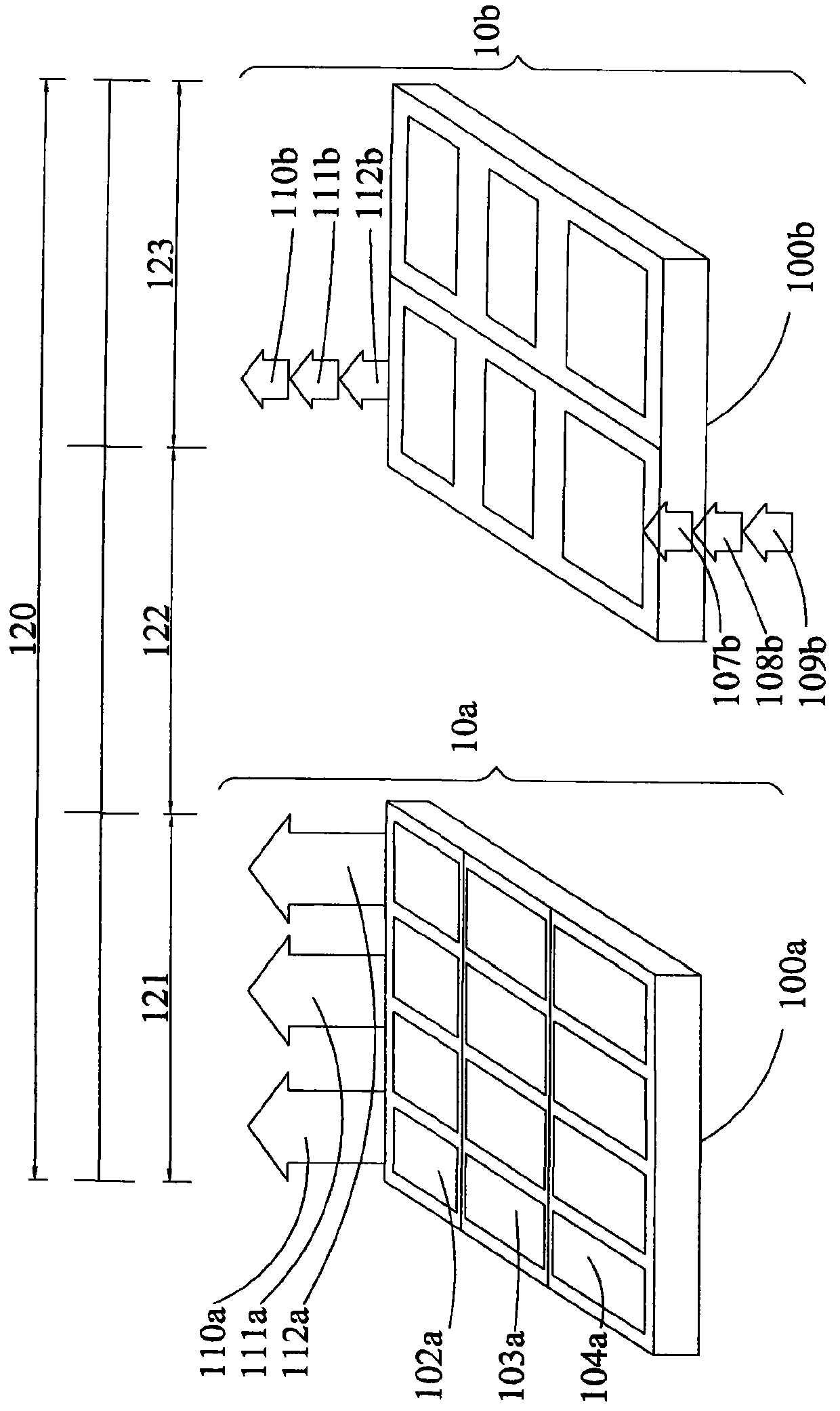

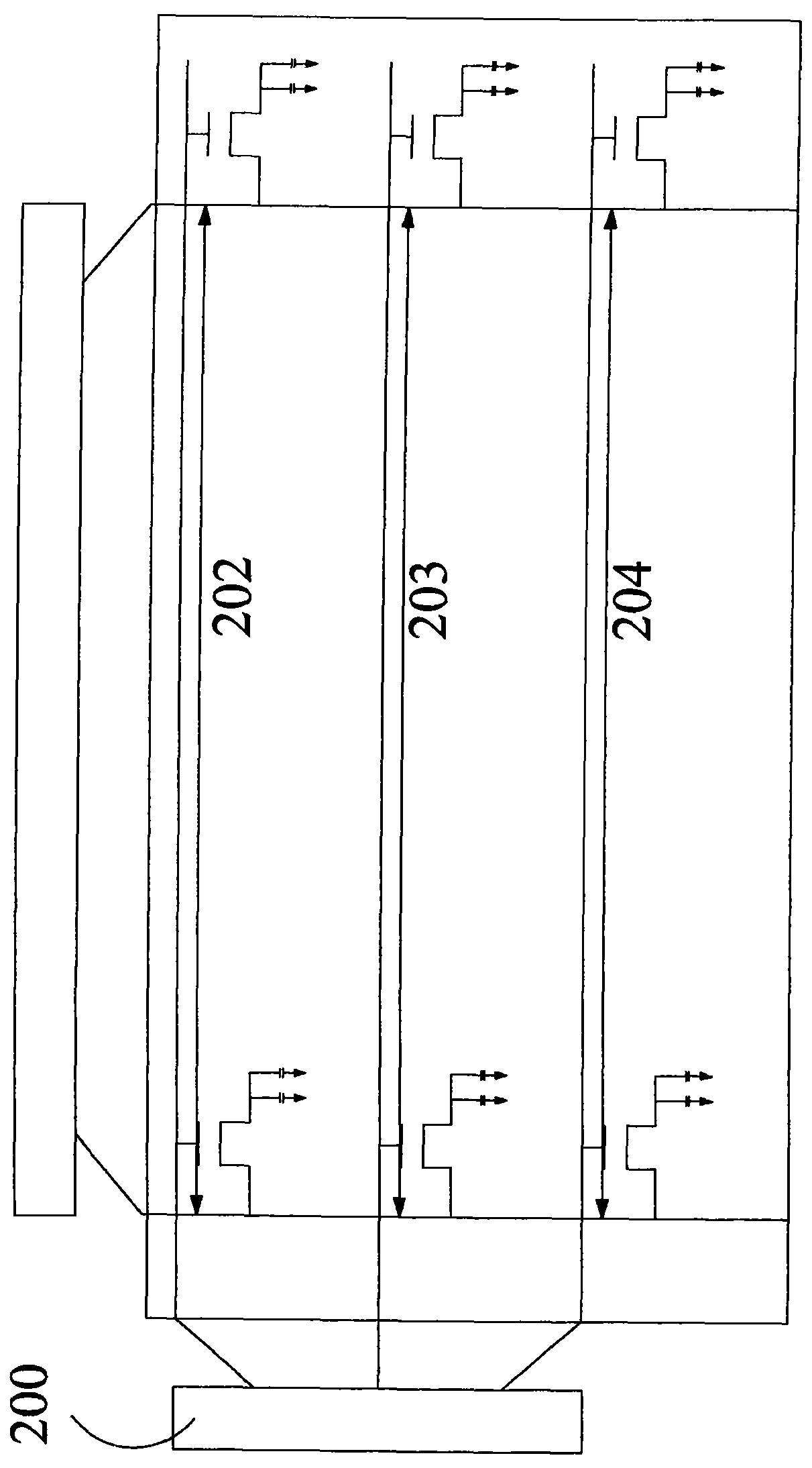

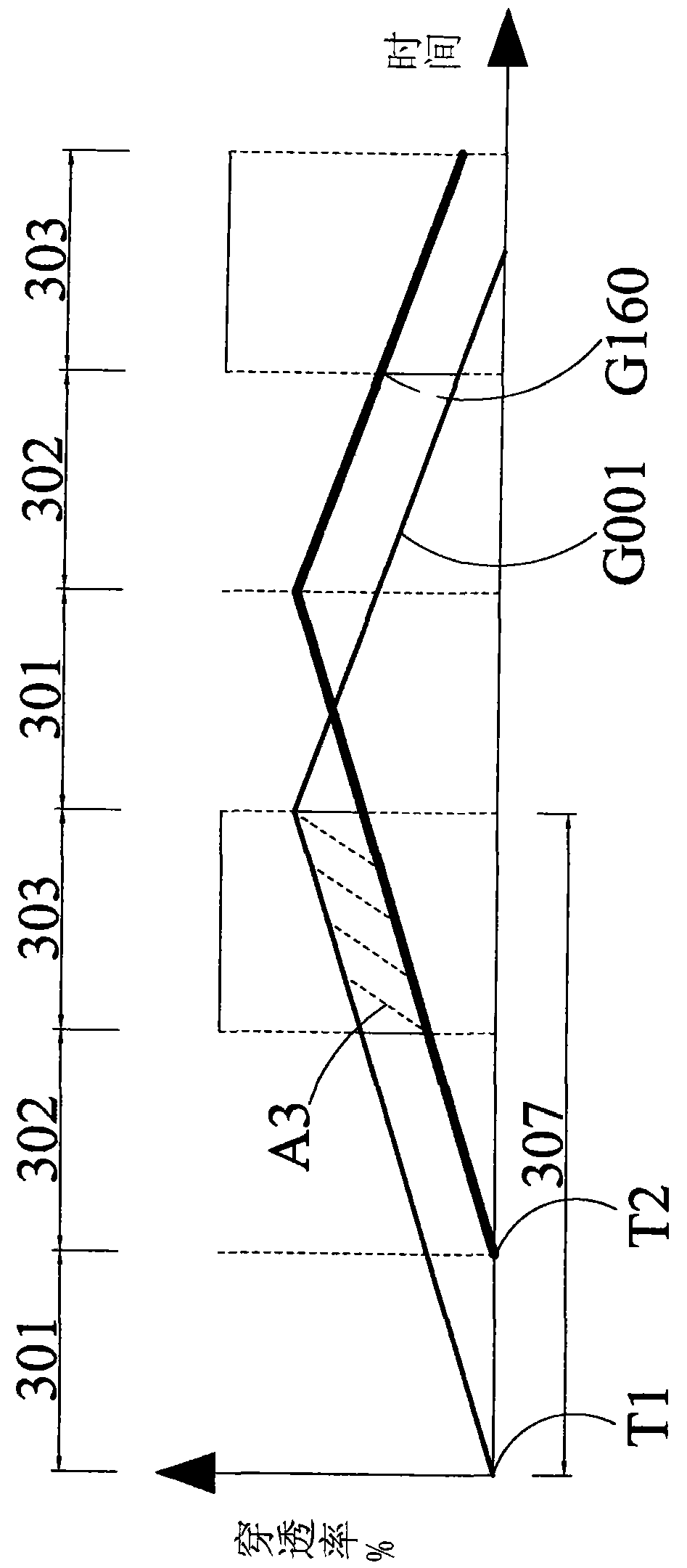

Please refer to FIG. 7, which is a functional block diagram of a color sequential display with backlight time delay control according to a first preferred embodiment of the present invention. The color sequential display includes a liquid crystal panel 704, a backlight 703, a source data driving circuit 705, a gate scanning driving circuit 706, a backlight control circuit 702, and a backlight delay control unit 701. The three-primary color (RGB) backlight 703 is, for example, a light-emitting diode array (LED Array). In the three sub-frames constituting each frame, the three-primary color light sources are switched on in time sequence to enter the liquid crystal panel 704. The source data driving circuit 705 provides a data line voltage that determines the turning angle of the liquid crystal molecules. The gate scan driving circuit 706 sequentially supplies scan line voltages to the scan lines on the panel 704. The backlight control circuit 702 provides a backlight driving voltage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com