Speed inhibitor for automobile

A technology for retarders and vehicles, applied in the direction of electric brakes/clutches, electrical components, electromechanical devices, etc., which can solve the problems of heavy weight, heavy load of car battery packs, and large energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

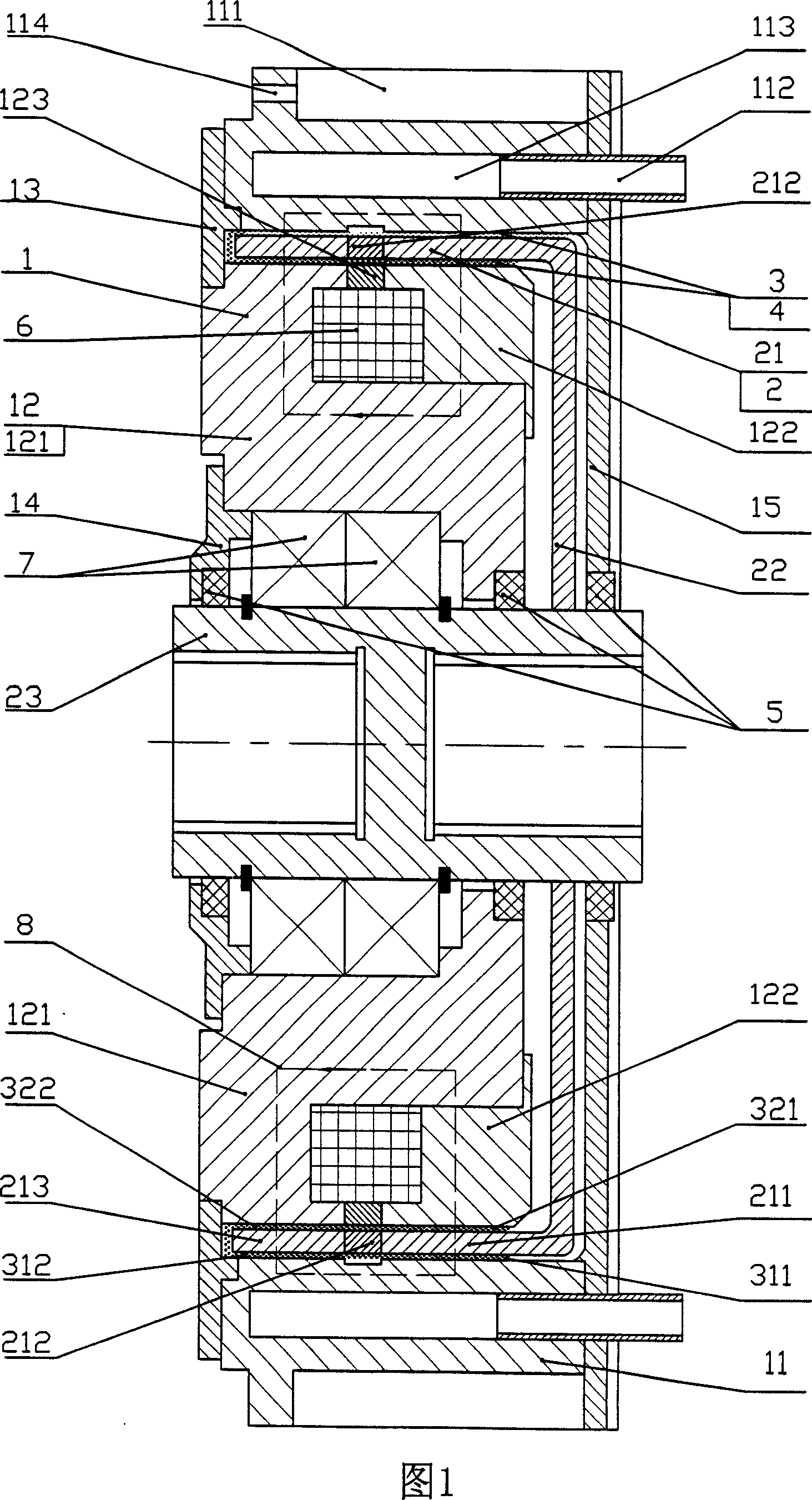

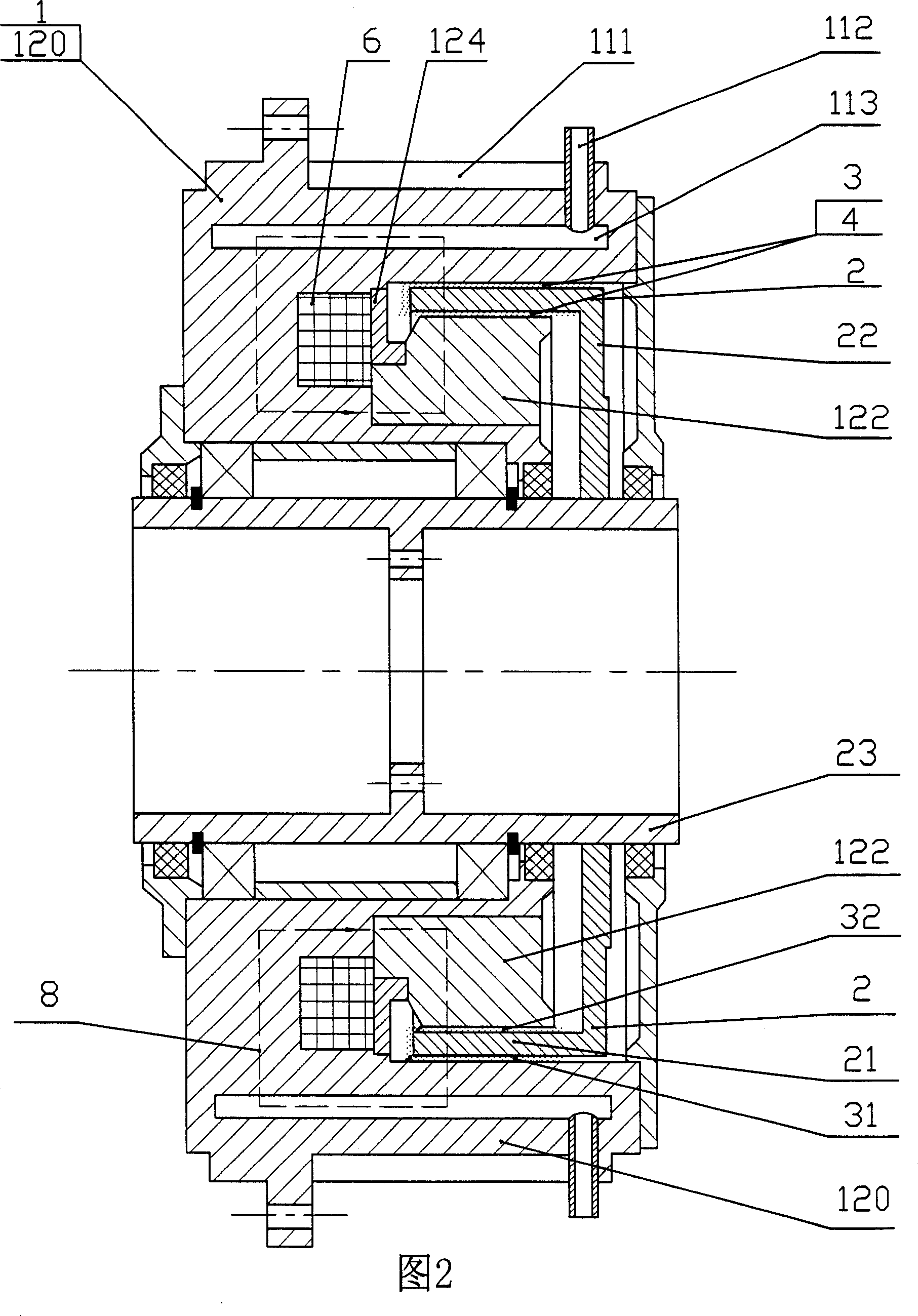

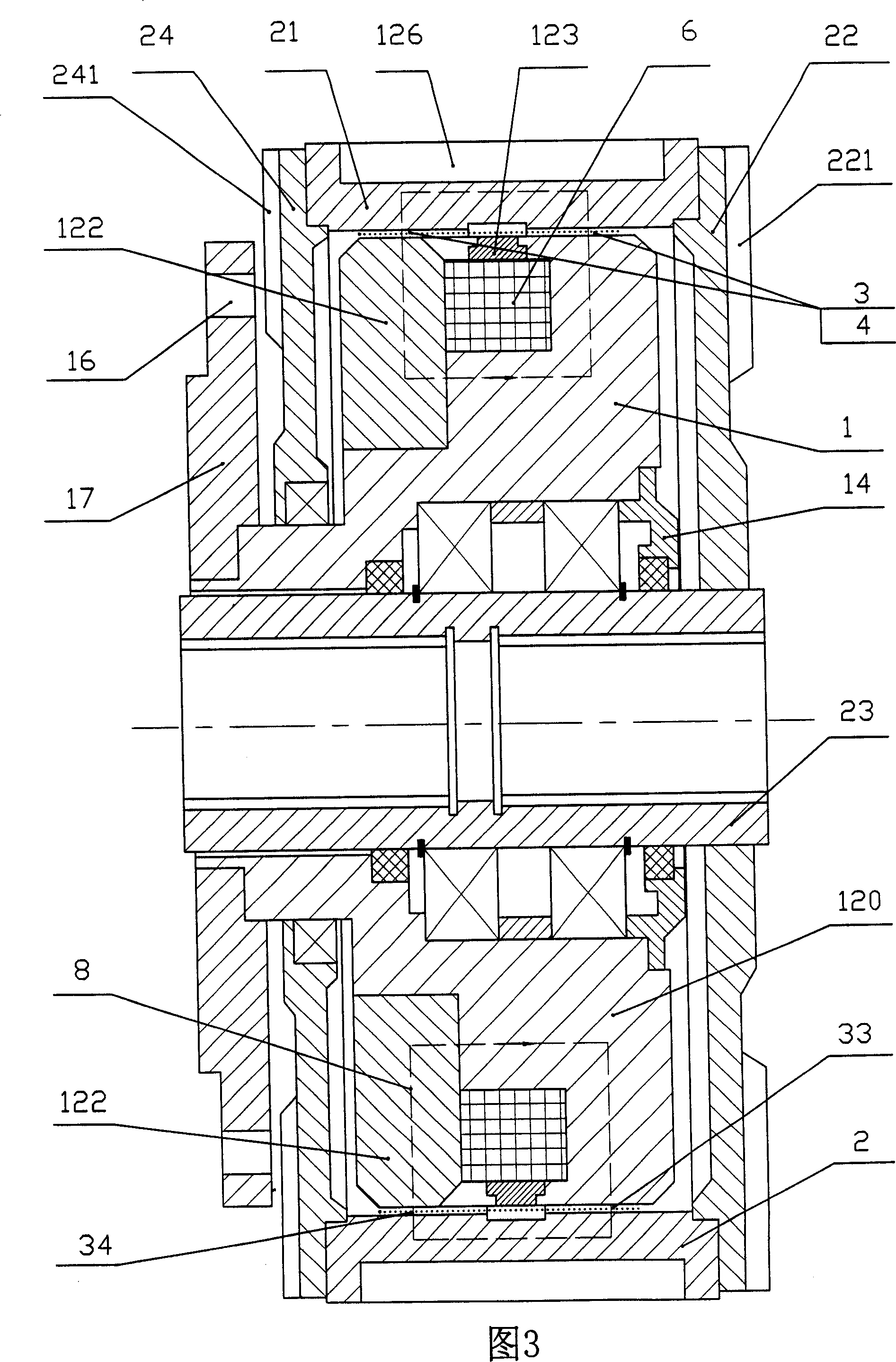

[0015]In the structural diagram of the first embodiment of the vehicle retarder of the present invention shown in FIG. 1 , the stator consists of an outer stator 11 , an inner stator 12 , a magnetic isolation ring 13 , a bearing cover 14 and a rear cover 15 . There are fixed installation holes 114 on the outer stator; in order to improve the heat dissipation performance of the vehicle retarder, a heat sink 111 can be provided on the outer stator 11 made of soft magnetic material; as a supplement for natural cooling, it can also A liquid cooling pipeline 113 and a liquid inlet and outlet joint 112 are provided in the outer stator 11 . The inner stator 12 made of soft magnetic material includes an inner stator body 121 and a pole shoe 122 matched with the inner stator body 121, and the inner stator body 121 and the pole shoe 122 are installed with an excitation coil between them along the axial direction 6. The inner stator body 121 is fixedly coupled with the outer stator 11 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com