Hub unit, rolling bearing assembly and manufacture method thereof, as well as assembling apparatus for rolling bearing assebly and assebly method thereof

A technology of rolling bearing and hub unit, applied in the direction of rolling contact bearing, shaft and bearing, bearing of rotary motion, etc., can solve the problem of cracks in annular components, and achieve the effect of high suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

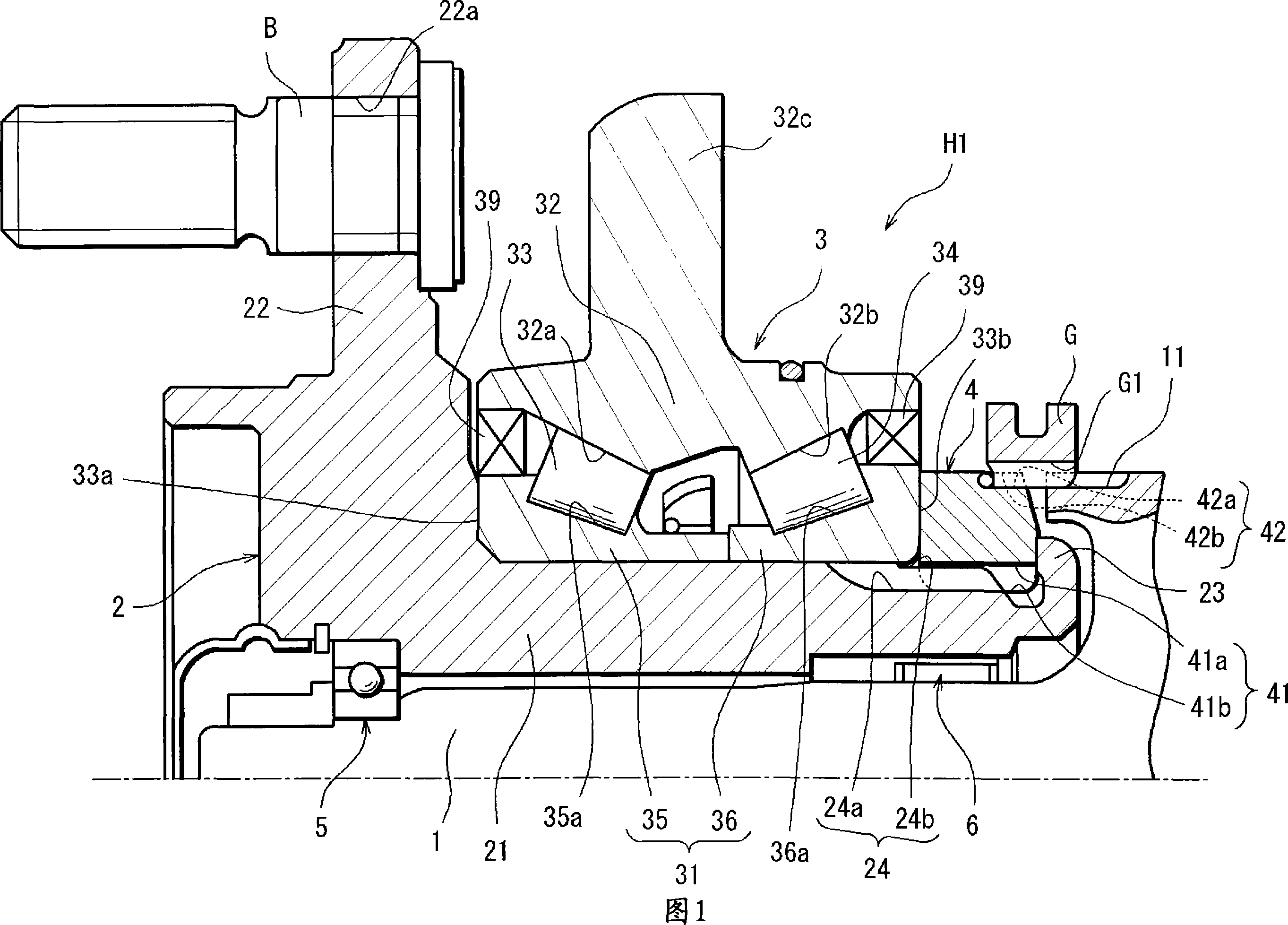

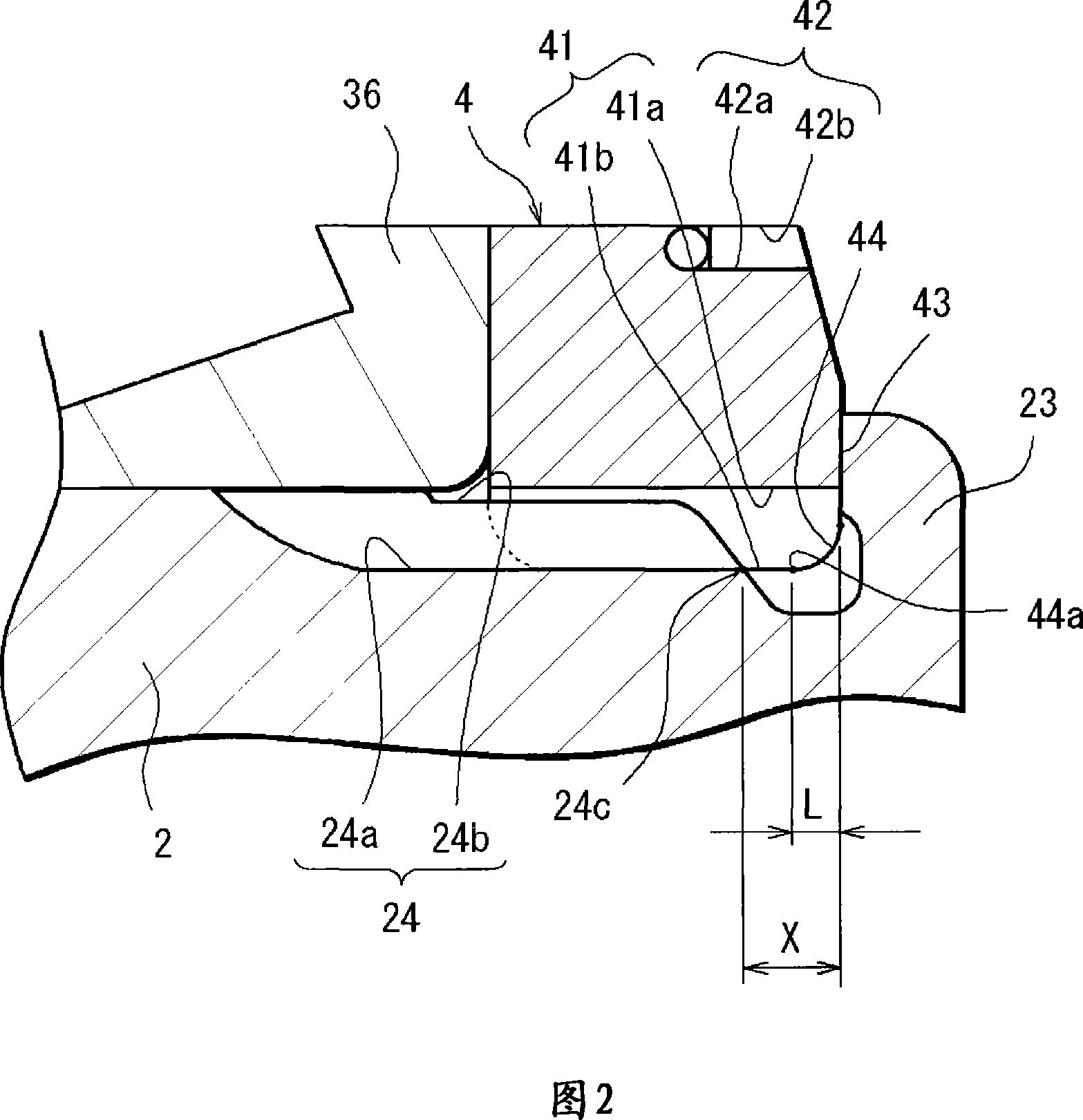

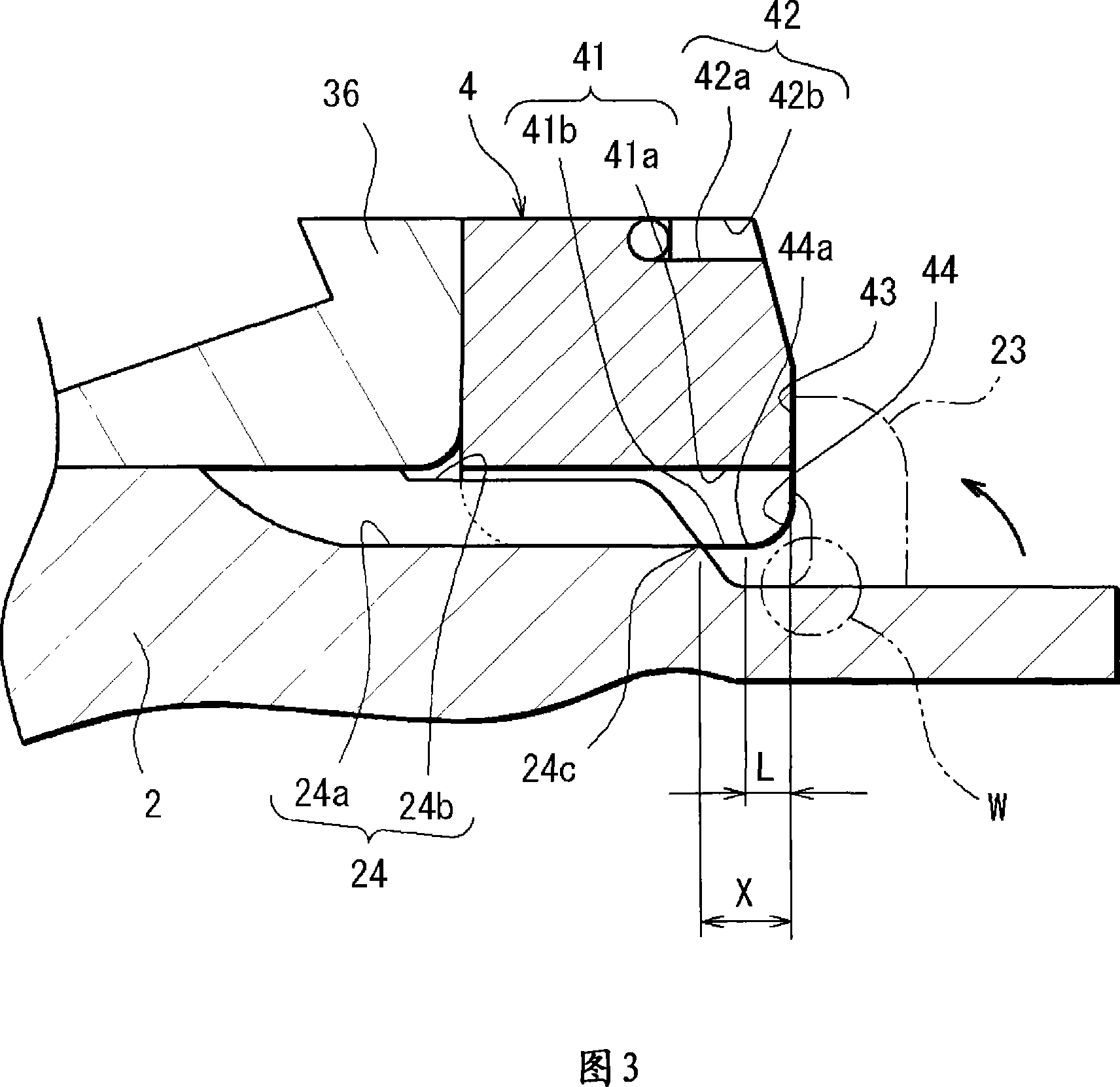

[0048] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings. Fig. 1 is a cross-sectional view showing a first embodiment of the hub unit of the present invention. The hub unit H1 according to this embodiment is, for example, a hub unit used in a free hub mechanism of a time-sharing four-wheel drive automobile. The structure of the free hub mechanism includes: a hub shaft 2 coaxially mounted on the axle 1 of the drive system; a double-row tapered roller bearing 3 as a rolling bearing embedded in the axial center of the hub shaft 2; and a double-row tapered roller bearing 3 A connecting ring (ring member) 4 in which the row of tapered roller bearings 3 are arranged side by side in the axial direction. In addition, the hub unit H1 is coaxially supported on the axle 1 (to be rotatable in the circumferential direction with respect to the axle 1 through the deep groove ball bearing 5 and the needle roller bearing 6 arranged between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com