Clutch mechanism having cushioning function

A clutch mechanism and function technology, applied in the direction of intermeshing clutches, clutches, mechanical drive clutches, etc., can solve problems such as efficiency, high cost, and complex components that do not meet industrial demands and economic demands, and achieve guarantees Safe and long service life, injury prevention, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

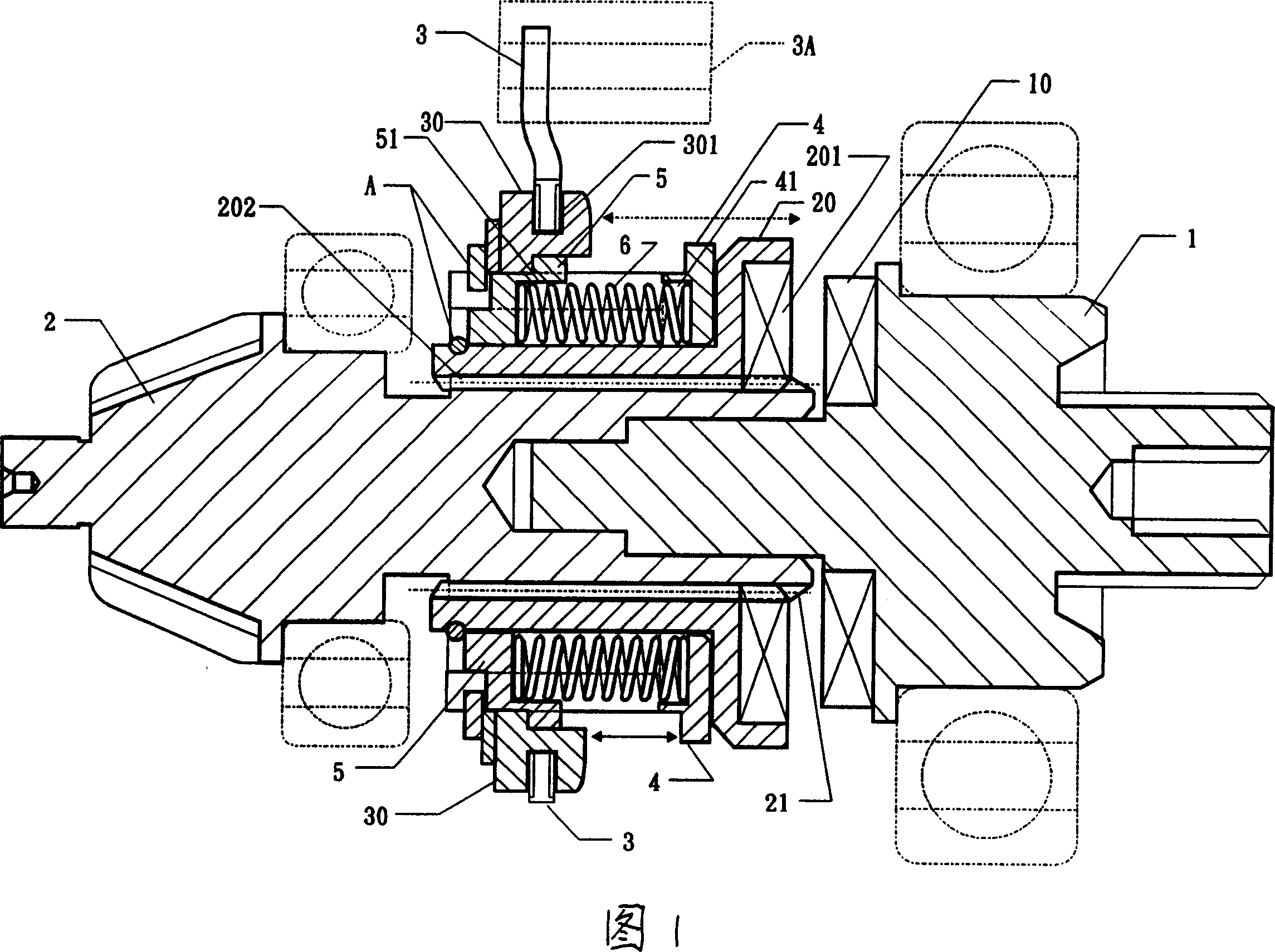

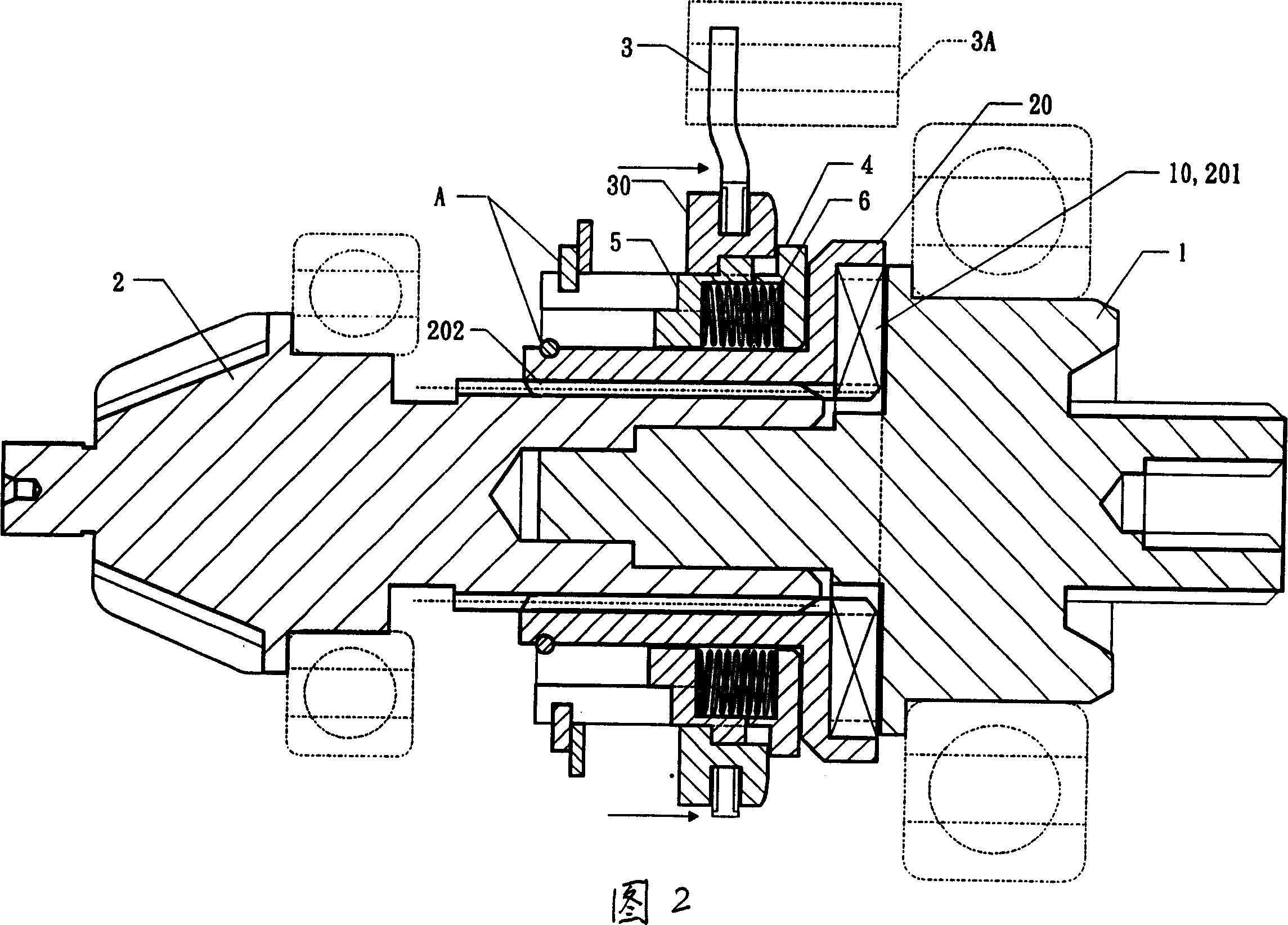

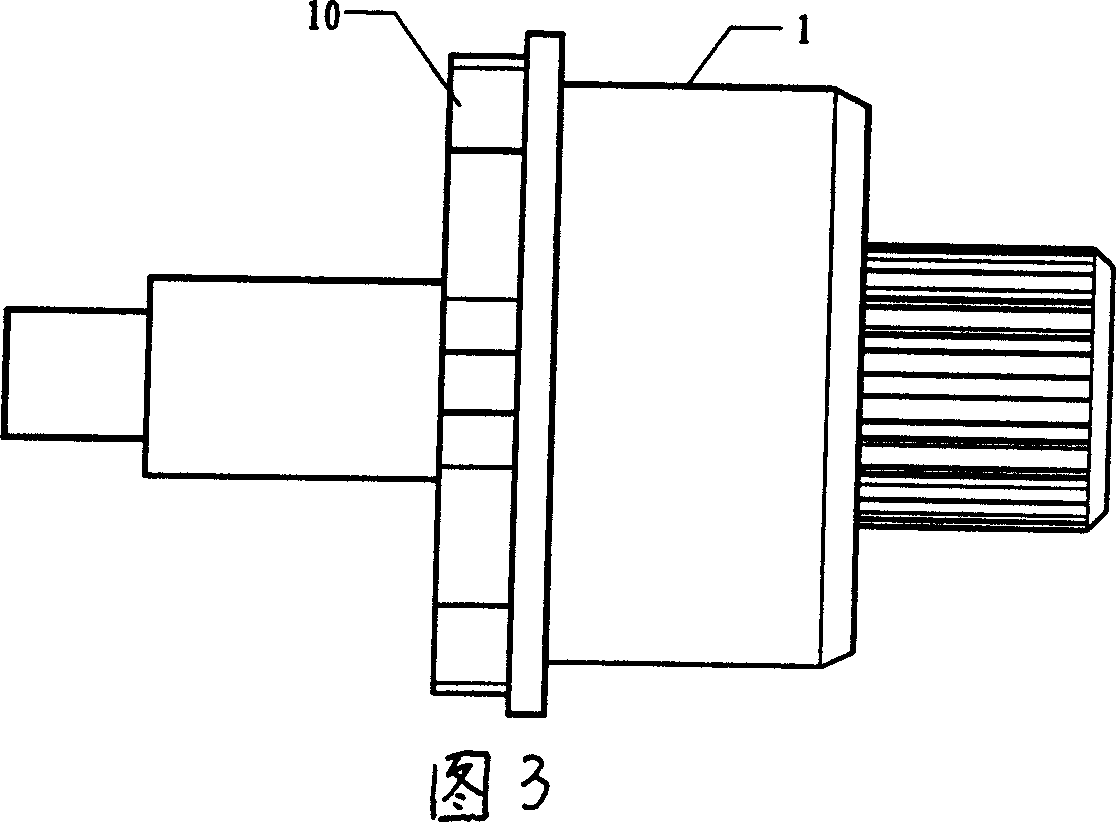

[0044] First referring to the accompanying drawings, Fig. 1 and Fig. 2 are all schematic diagrams of an embodiment of a clutch mechanism with a buffer function in the present invention, the first mandrel 1 of the clutch mechanism is fixedly provided with an engaging tooth surface 10, and the front section shaft of the second mandrel 2 The body is provided with a rack 21 for positioning and meshing and can be axially displaced on the setting of the clutch sleeve 20 on the shaft rod of the second mandrel 2. The front end of the clutch sleeve 20 is provided with an engaging tooth surface 201, and the shaft hole of the sleeve is There is a tooth groove 202 that can be engaged and positioned and axially displaced, and the clutch sleeve 20 on the shaft of the second spindle 2 is linked by a clutch collar 30 that can be axially displaced by the control of the shift fork 3. A buffer mechanism is provided between the clutch collar 30 and the clutch sleeve 20. The buffer mechanism includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com