Sealing equipment of sealed hole

A technology of sealing device and sealing hole, which is applied in the direction of cable entry sealing device, engine sealing, engine components, etc., to achieve the effect of simple structure, reliable sealing performance and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

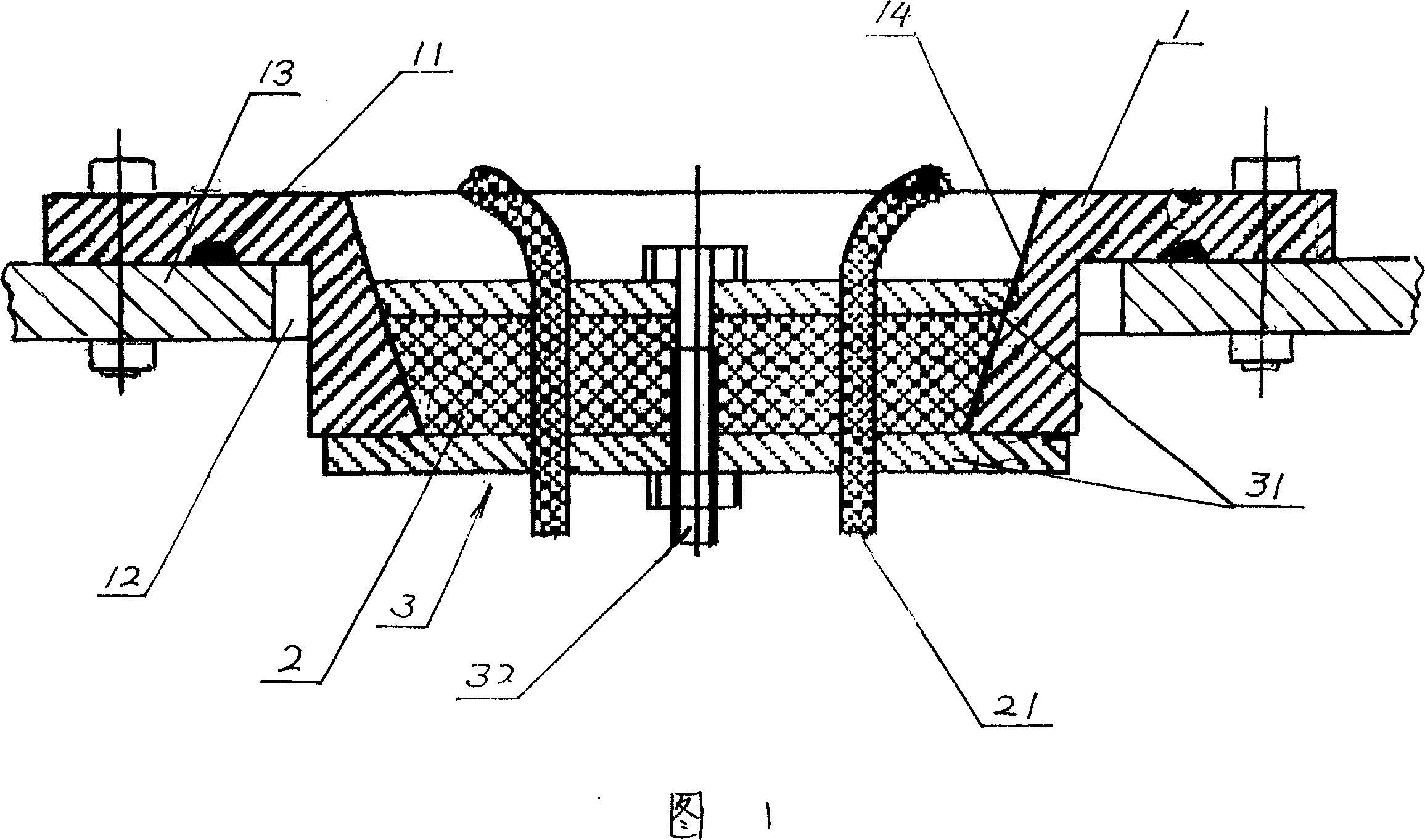

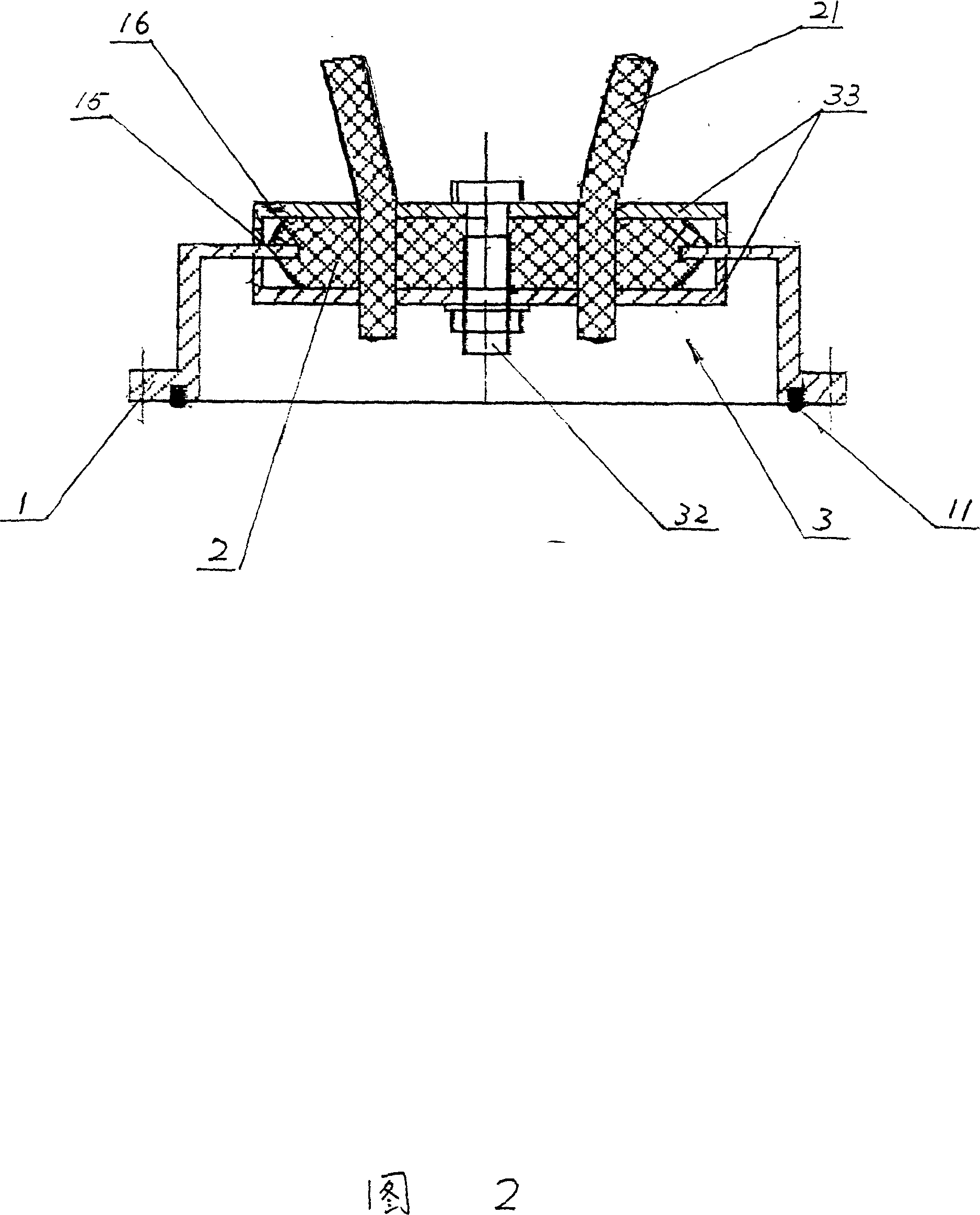

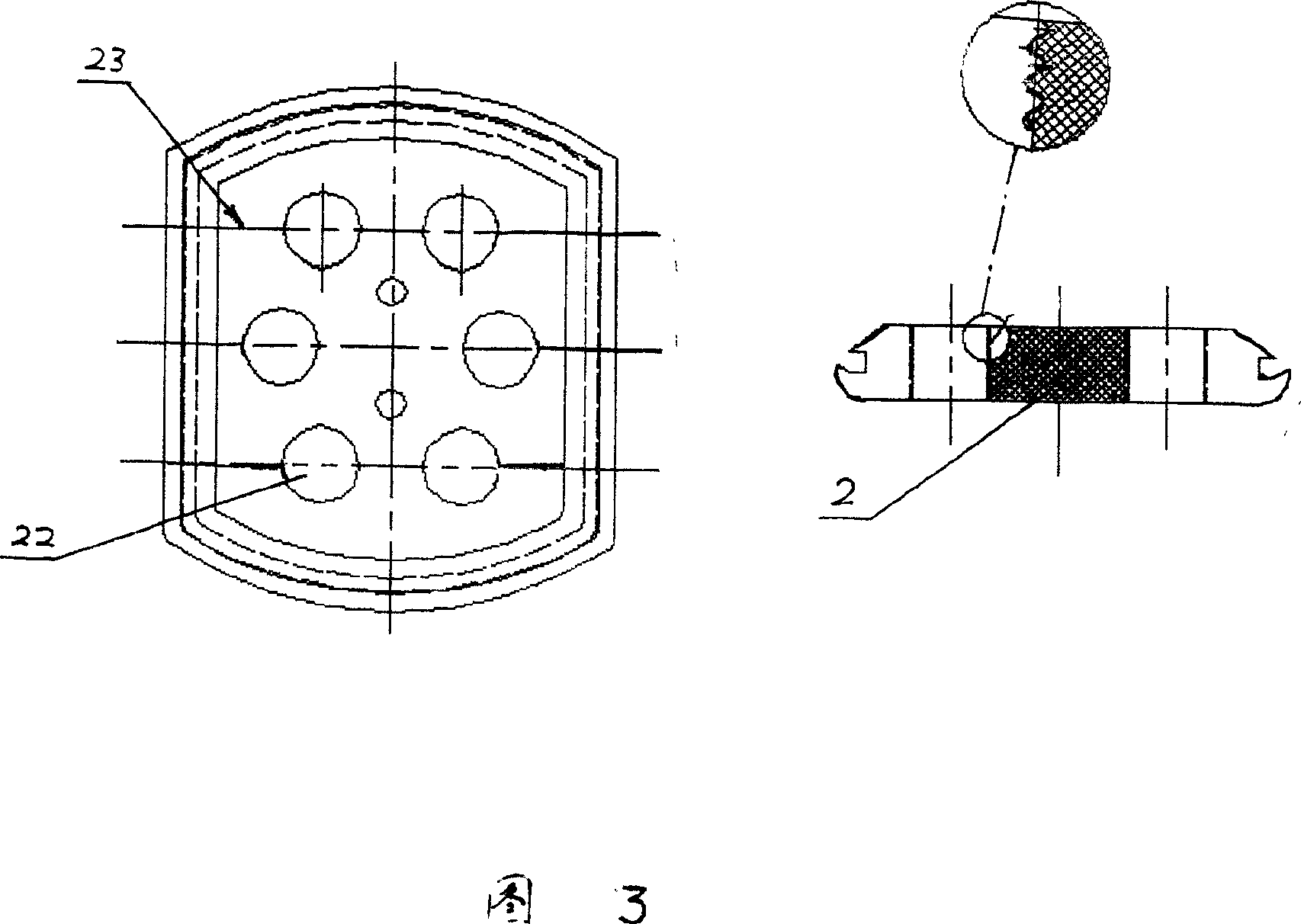

[0017] As shown in Figure 1, Figure 2, Figure 3 and Figure 4, a sealing device for sealing holes is mainly composed of an auxiliary sealing connection device 1, an elastic sealing member 2 and a compression device 3, wherein: there will be a sealing member 11 The auxiliary sealing connection device 1 covers the hole 12 that needs to be sealed and is connected with the main structure 13. Its structure is similar to a flange and is provided with a mounting hole 14; an elastic seal 2 is placed in the mounting hole 14, Its shape is adapted to the shape of the installation hole 14 of the auxiliary sealing connection device 1, and its installation cross-sectional area is larger than the hole cross-sectional area of the installation hole 14 of the auxiliary sealing connection device 1. The elastic sealing member 2 is provided with an extension through the hole 12. The extension holes 22 corresponding to the number of pieces 21, the diameter of the holes should be slightly smaller th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com