Straight-through current transformer for taking voltage from wrapping conductor using puncturing method

A current transformer and core-through technology, applied in the field of transformers, can solve the problems of easy electricity theft and low efficiency, and achieve the effect of avoiding electricity theft, easy to use, and realizing the anti-theft function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

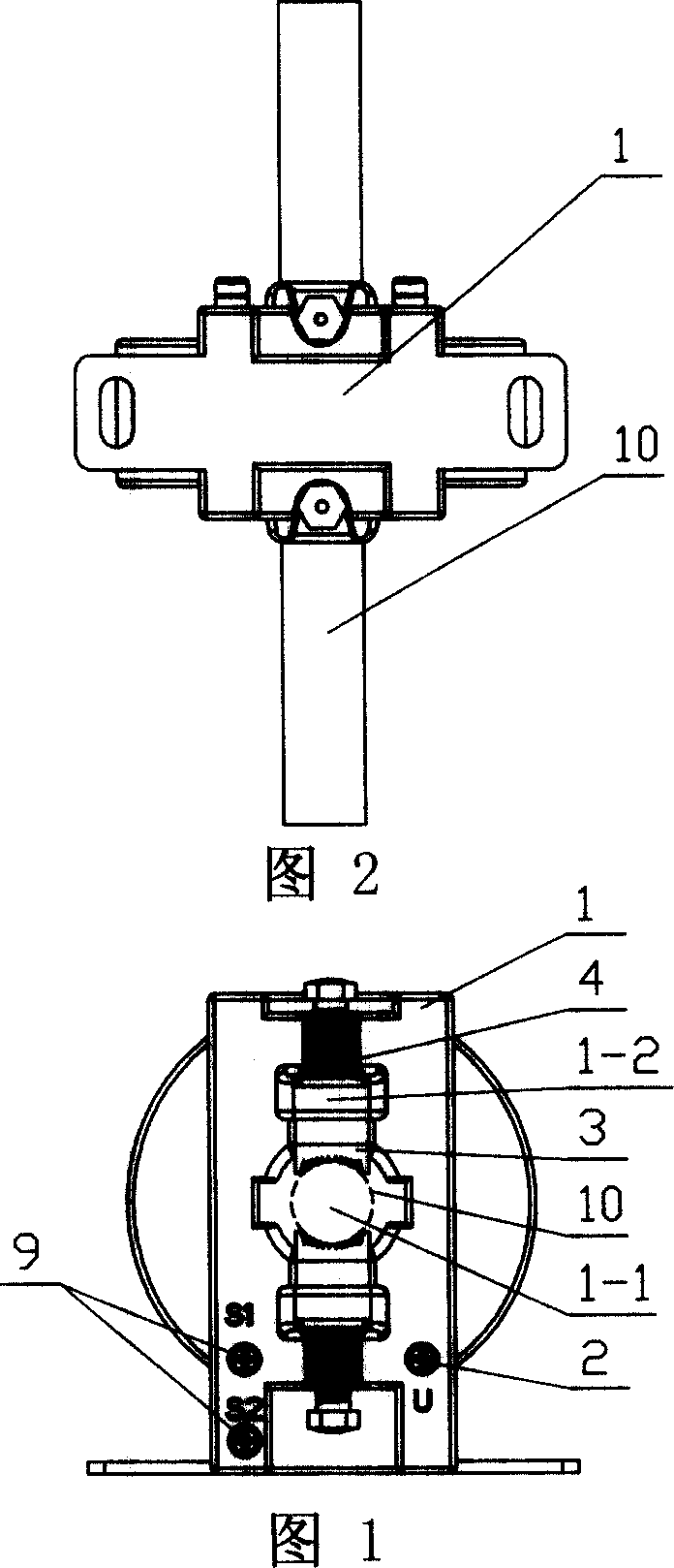

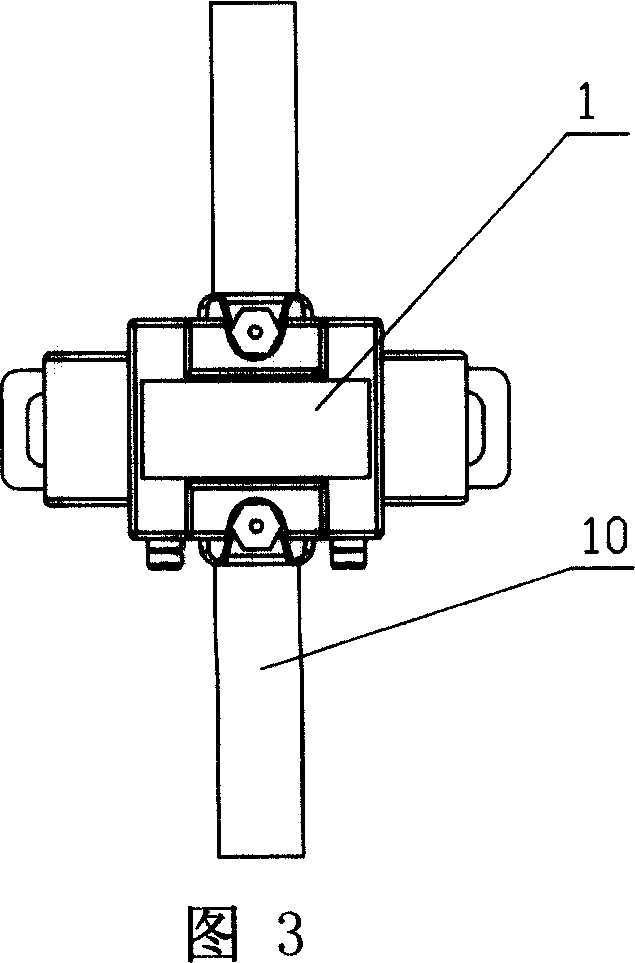

[0040] A core-through current transformer that uses a puncture method to take voltage from the sheathed wire, referring to Figures 1 to 5, it includes a transformer body 1, and the transformer body 1 is respectively provided with a voltage line outlet terminal 2 and a voltage-taking component 3. The voltage line outlet terminal 2 and the voltage-taking component 3 have a connection relationship, and this connection relationship includes any connection in the prior art. For example, Baoding Kaiyu Electric Co., Ltd. has produced a LDF1-0.66 guide rod penetrating type current transformer, which casts the connecting wire between the voltage line outlet terminal 2 and the voltage-taking component 3 together in the transformer housing; the same thing as this embodiment is that it sets three on the transformer The outlet terminals are two current wire outlet terminals 9 and one voltage wire outlet terminal 2; the difference from this embodiment is that the voltage taking part 3 in thi...

Embodiment 2

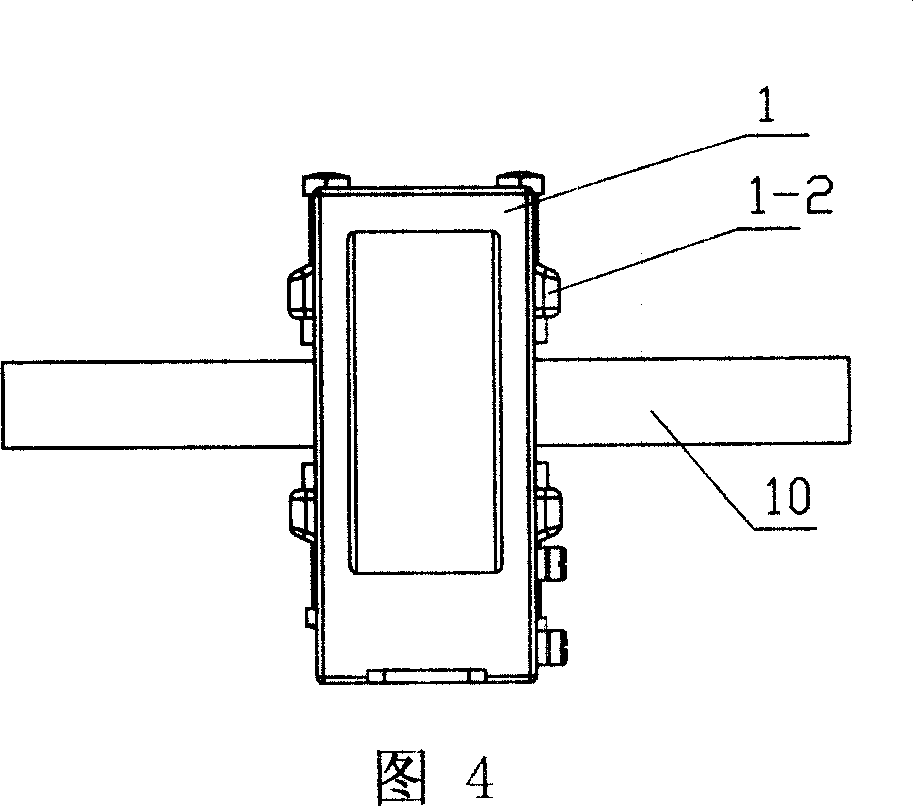

[0048] For the situation where the voltage is taken through the metal stud 4 as a conductor, a more preferred structure is that on the transformer body 1, two metal inserts 1-2 are set around the through-hole 1-1, referring to Figure 7, all The metal inserts 1-2 are electrically connected through a conductor 15. Referring to FIG. 8, the conductor 15 in this embodiment is a metal sheet, and of course a wire can also be used for electrical connection. All metal inserts 1-2 are threaded with studs 4, and like this, the voltage-taking parts in two directions pierce the tips into the bus bar at the same time, so that the electrical connection is more stable and accurate, so that the voltage on the bus bar can be better connected The signal is passed on.

[0049] It is conceivable that in practical applications, the studs are not limited to the two mentioned above, and may also be three, four, or more, and the fixing method between the studs and the transformer is not limited to fix...

Embodiment 3

[0053] The difference from the existing structure is that the No. 1 anti-stealing mask 5 described in this embodiment is connected to the surface of the transformer body 1 in a non-detachable manner. It can be seen that the anti-stealing mask defined in this embodiment is fixed. On the body of the transformer, in this way, the transformer can be used in any position and not limited to the box. The mask is connected to the transformer body in a non-detachable way, that is to say, after the metering department fixes the anti-stealing mask to the transformer, the mask cannot be removed from the transformer without destroying it. Those who can't hide the eyes and ears to steal electricity can greatly increase the degree of protection against electricity theft.

[0054] Referring to Figures 9 to 11, this non-detachable connection structure is that the No. 1 anti-stealing mask 5 located on one side of the transformer is a whole, and the No. 1 anti-stealing mask 5 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com