Lubricant multilevel automatic oil and water separating system and the control method thereof

A technology for oil-water separation and lubricating oil, applied in separation methods, liquid separation, lubricating compositions, etc., can solve problems such as resource waste, increased production costs, low viscosity, etc., to improve production efficiency, improve automation, and reduce pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

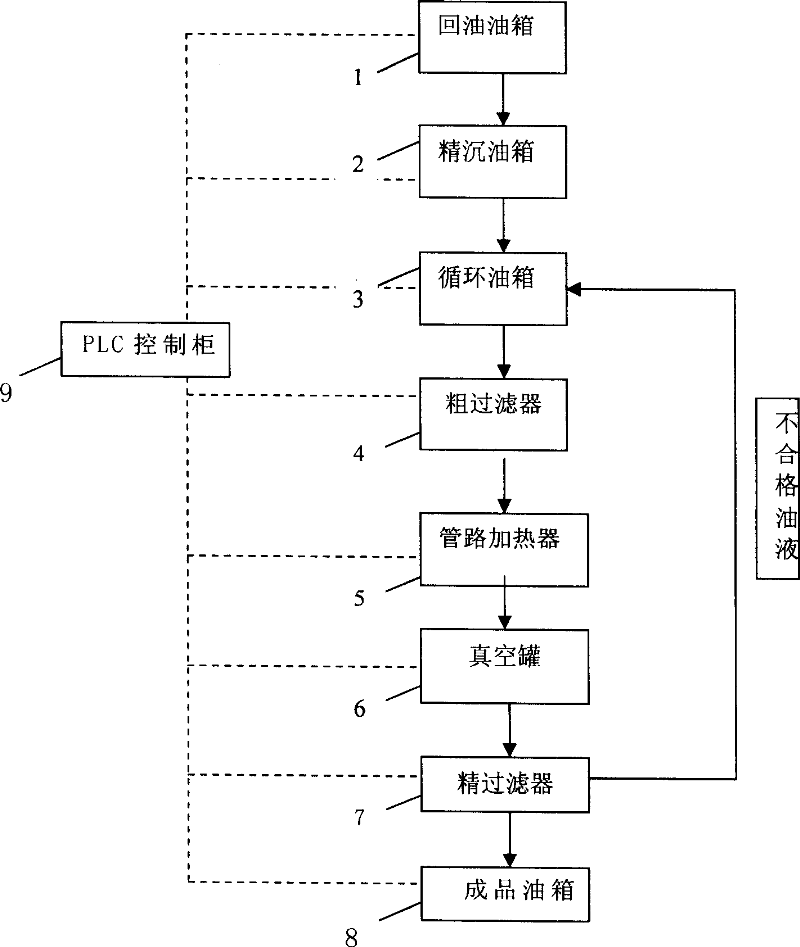

[0025] The lubricating oil multi-stage automatic oil-water separation system and its control method of the present invention will be described in conjunction with the drawings and embodiments.

[0026] The oil circuit of the lubricating equipment is modified, and the oil return line is divided into two parts: one part is full of impurities and pollution, and cannot be directly returned to the oil tank for use; the other part is clean and pollution-free, and can be directly returned to the oil tank for reuse.

[0027] As shown in Figure 1, the lubricating oil multi-stage automatic oil-water separation system structure of the present invention is to comprise return oil oil tank 1, fine sink oil tank 2, circulation oil tank 3, coarse filter 4, pipeline heater 5, vacuum tank 6, Fine filter 7, finished product oil tank 8 and PLC control cabinet 9, the oil return oil tank 1 is connected to fine sink oil tank 2, circulating oil tank 3, coarse filter 4, pipeline heater 5, vacuum tank 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com