Device for forming the vessel of brick filling machine

A molding device and a technology of brick packaging, which is applied in the field of packaging container molding devices, can solve the problems of package damage, leakage of packaging, pollution, etc., and achieve the effect of beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

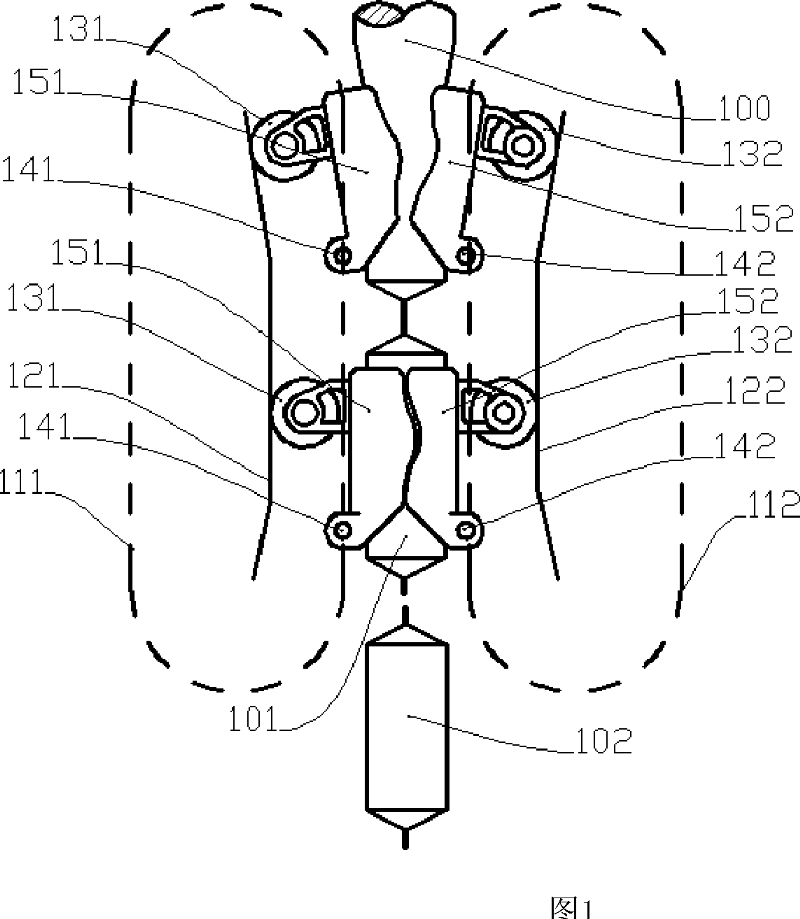

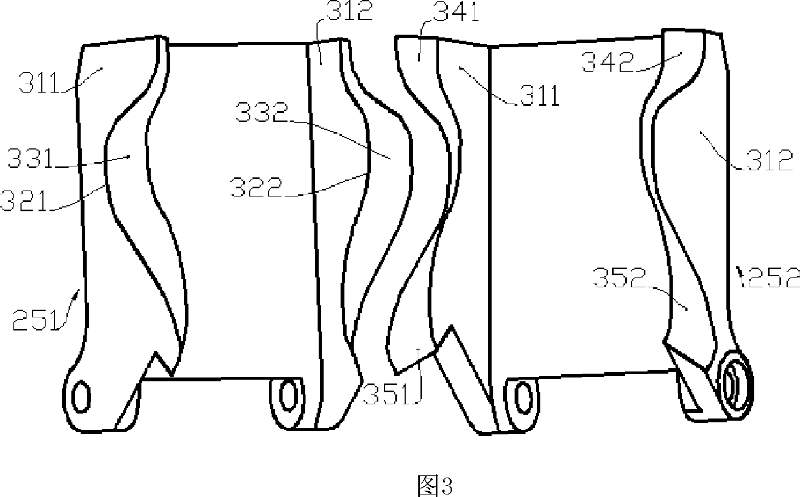

[0022] Fig. 3 is the preferred embodiment of the present invention. The molding device includes a pair of capacity holders 251,252.

[0023] The rib plate 311 on one side of the capacity holder 251 / 252 has a recess 321; the recess 321 has a cut-in surface 331 inclined toward the outside of the capacity holder 251 / 252; the two ends of the recess 321 have curved surfaces 341 and The curved surface 351 ; the curved surface 341 , the cut-in surface 331 , and the curved surface 351 are smoothly connected in sequence to form the cut-in surface of the rib 311 together.

[0024] The rib plate 312 on the other side of the capacity holder 251 / 252 has a convex portion; the convex portion 322 has a cut-in surface 332 inclined toward the inside of the capacity holder 251 / 252; The curved surface 342 and the curved surface 352 ; the curved surface 342 , the cut-in surface 332 , and the curved surface 352 are sequentially and smoothly connected to form the cut-in surface of the rib 312 toget...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com