Left and right prefastening parallel connection structure six-dimensional force sensor

A six-dimensional force sensor and pre-tightening technology, which is applied in the direction of instruments, measuring force, and measuring devices, can solve problems such as force coupling or complex calibration methods, and achieve the effects of easy solution, low cost, and reduced adjustment workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

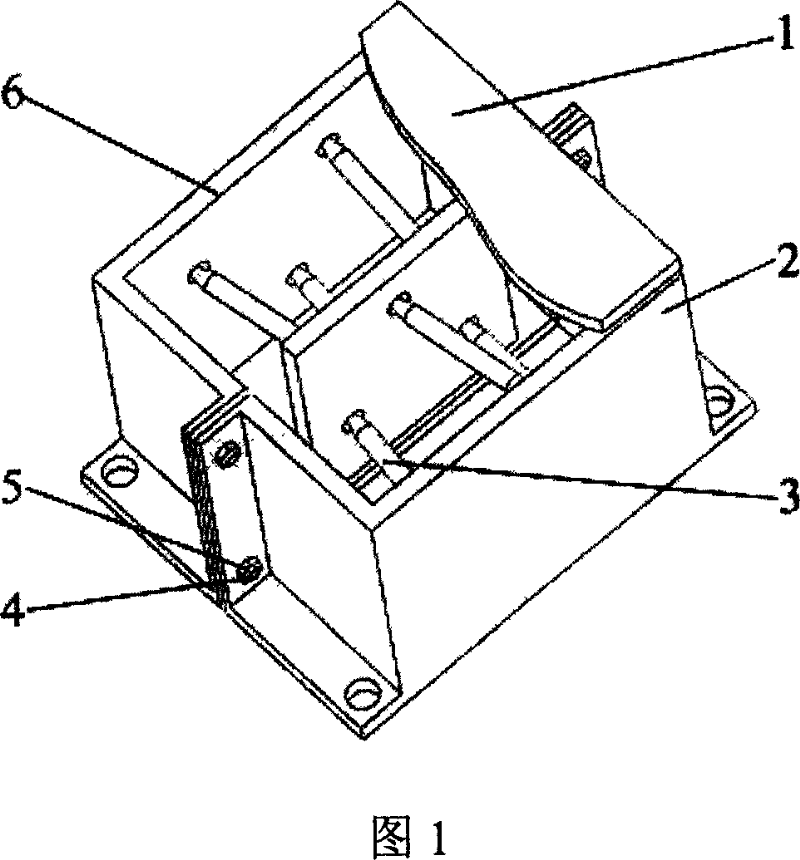

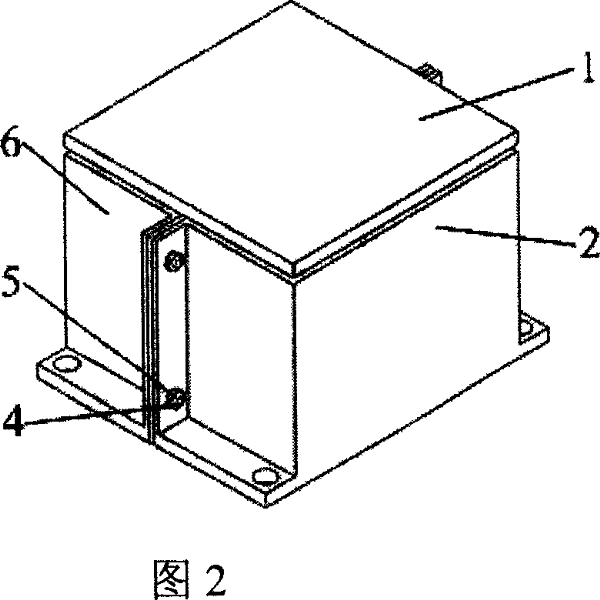

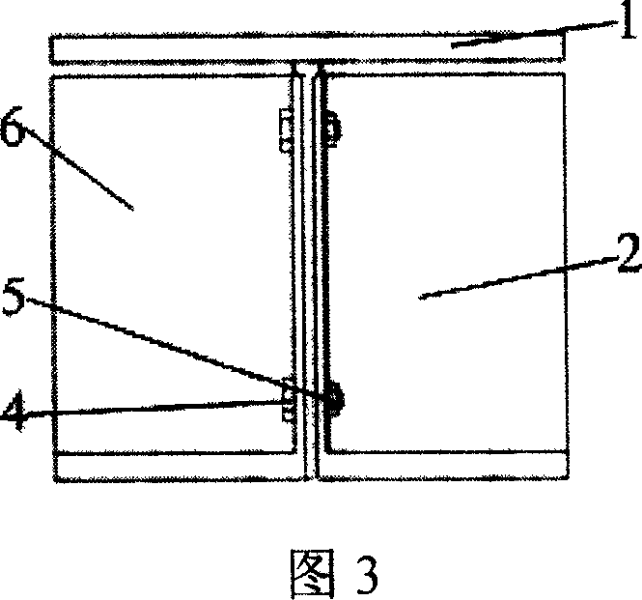

[0015] The left and right preloaded parallel structure six-dimensional force sensor (see Figure 1) is composed of a left preloaded platform 6, a force measuring platform 1, a right preloaded platform 2, six detection components 3, bolts 4 and nuts 5. The left preload platform 6 is a semi-open shell member. Three ball sockets are distributed on the inner surface of the left plate of the left preload platform 6. The three ball sockets are evenly distributed on the same circumference. The geometric center is the center of the circle. Bolt holes are provided on the flanges of the two side plates of the left pre-tightening platform 6, and bolt holes are also provided on the both sides edges of the bottom plate of the left pre-tightening platform. The right preload platform 2 and the left preload platform 6 have the same structure and are semi-open shell members that are symmetrical to each other. There are three ball sockets distributed on the inner side of the right side plate of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com