Rotor plate of highly effective permanent magnetism synchronous motor

A permanent magnet synchronous motor, rotor punching technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of increasing motor vibration and noise, increasing motor loss, affecting motor magnetic density, etc. , to achieve the effect of reducing temperature rise and noise, reducing harmonic content, and reducing additional losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

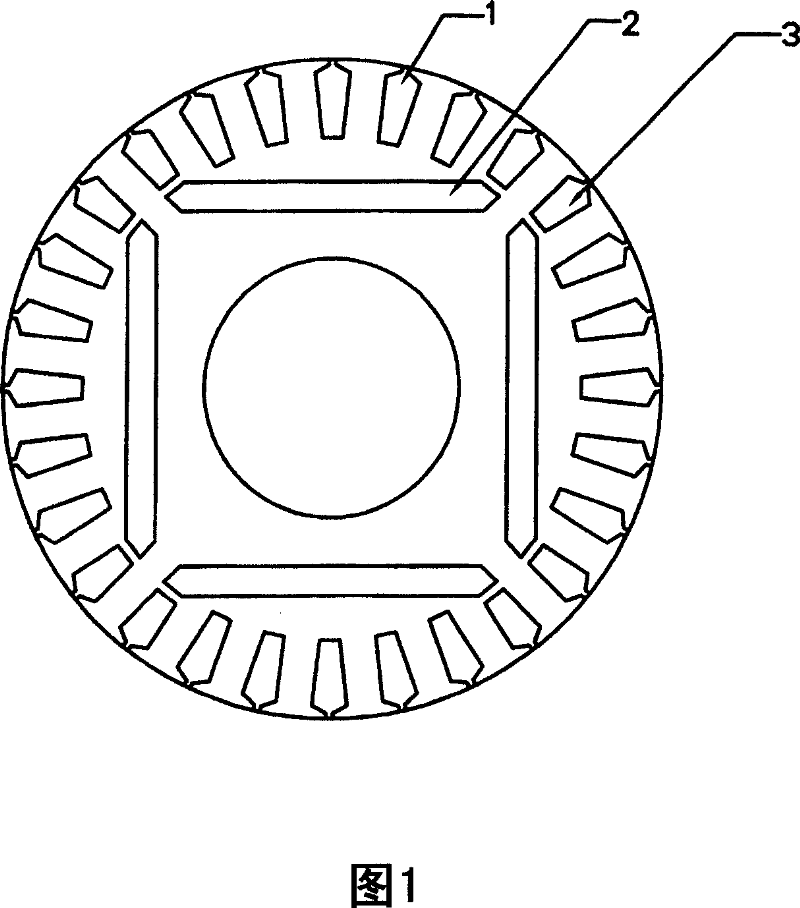

[0013] Disclosed is a rotor punch of a high-efficiency permanent magnet synchronous motor. The rotor slots have two sizes: one is a common slot (1), and the other is a shallow slot (3). These two grooves have different depths, and the ratio of the shallow groove (3) to the common groove (1) is between 0.6 and 0.95. The number of shallow grooves is related to the number of magnetic steel grooves, which is twice the number of magnetic steel grooves.

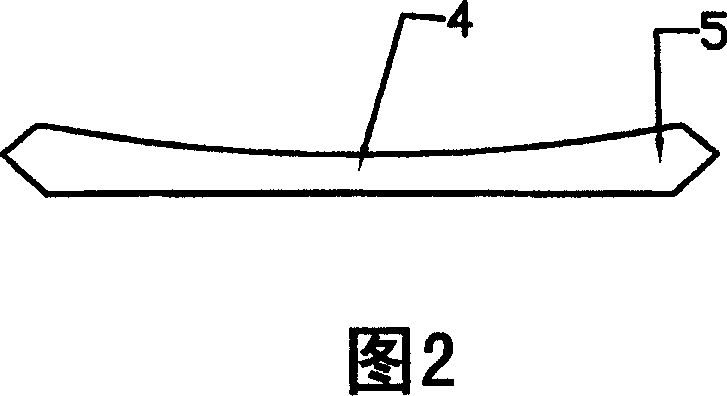

[0014] A non-uniform magnetic steel groove (2) is opened on the rotor punch. The side of the non-uniform magnetic steel groove close to the center of the circle is a straight line, and the other side is an arc or two broken lines; or both sides are arcs. The width of the non-uniform magnetic steel slot varies everywhere, and the width (4) is the narrowest in the middle, and the width (5) is the largest at both ends. The ratio of the width (4) at the narrowest point in the middle to the width (5) at the widest point at both ends i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com