Method for producing tubes of quartz glass

A technology of quartz glass tube and quartz glass, which is applied in glass forming, glass reshaping, glass production, etc. It can solve the problems of damage to the inner wall of the tube, complexity, and complexity of sealing plugs, and achieve a simple method and reduce material Loss, to achieve the effect of following the movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

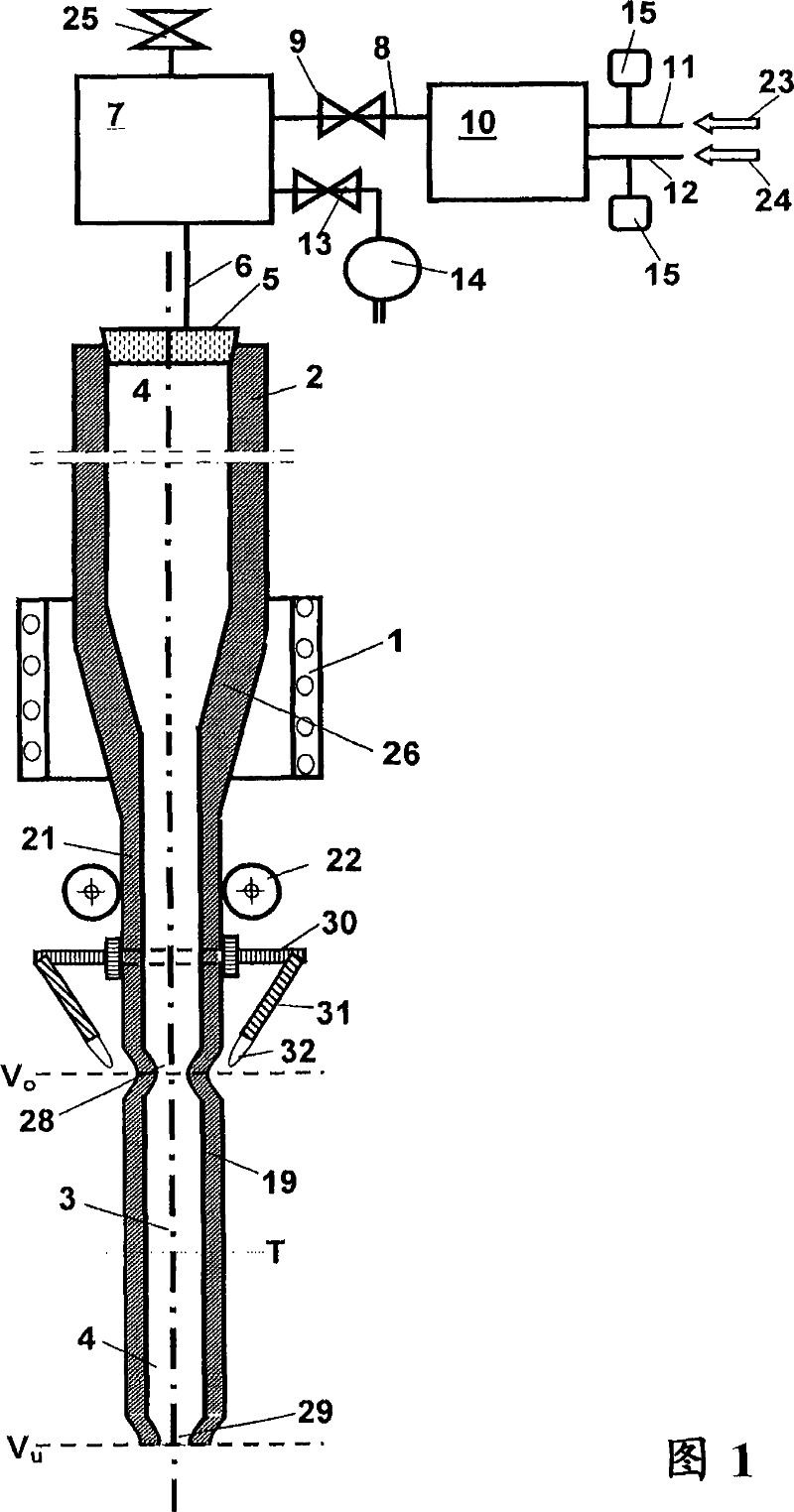

[0036] The drawing plant according to FIG. 1 comprises a vertically arranged furnace which can be heated to temperatures above 2300° C. and which comprises an annular resistance heating element 1 , a gas supply system and a pulling device 22 .

[0037] During the drawing process, a hollow cylinder 2 of synthetic quartz glass (shown shaded) with a vertically oriented longitudinal axis 3 is continuously supplied to the heating element 1 from above and heated in a zone-wise manner between them, and is drawn from the The softened area of the brewing 26 draws the tubing.

[0038]The hollow cylinder 2 and the tube wire 21 have a joint bore 4 . The hole is open downwards and closed upwards by a plug 5 . A purge gas line 6 protrudes through the plug 5 into the bore 4 , the purge gas being supplied from a process vessel 7 with a gas mixture consisting of oxygen and nitrogen. The process container 7 is connected to a mixing container 10 via a mixed gas line 8 which can be closed by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com