Rotating type shaver with a plurality of knife tackles

A rotary, shaver technology, applied in the field of multi-cutter rotary shavers, can solve the problems of user discomfort, difficult processing, poor performance, etc., and achieves improved shaving performance and shaving comfort, The effect of low manufacturing cost and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

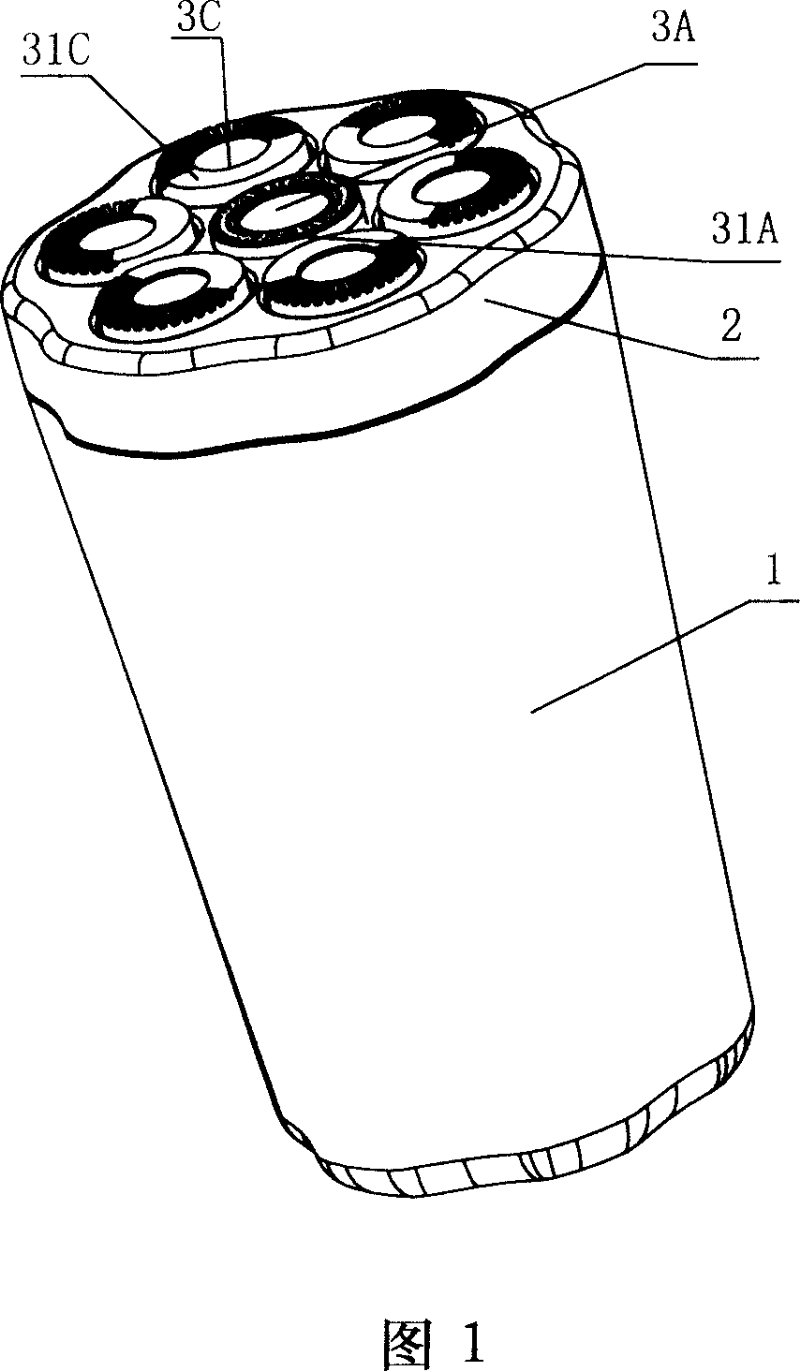

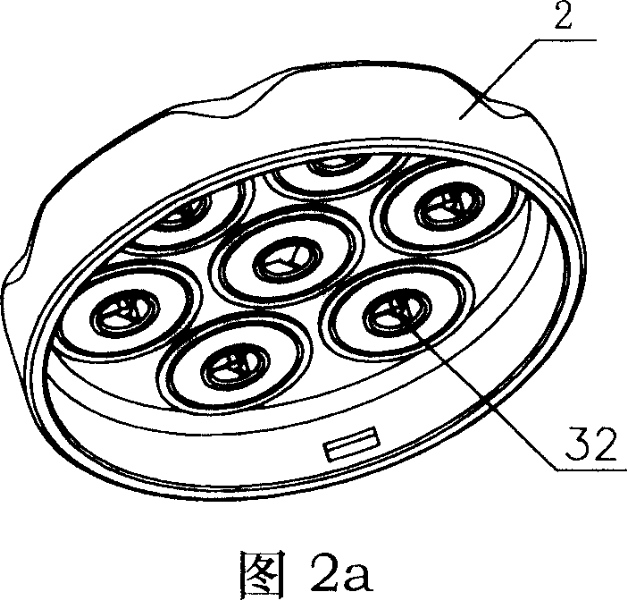

[0037] As shown in Figures 1, 2a, and 3b, the seven-blade rotary shaver has a housing 1 with a bracket 2 on which seven razor units are installed, wherein: the central razor unit 3A It consists of the outer cutter 31A and the inner cutter 32 , and the peripheral razor group 3C consists of the outer cutter 31C and the inner cutter 32 . Obviously, the inner cutters 32 used by the seven razor groups are the same (see Figure 2a), but there are two types of outer cutters: one is the outer cutter 31A of the central razor group, with a small circular hole The short must enter the beard hole, and the other is the outer cutter 31C with the long must enter the beard hole of the slit form on the protruding ring slightly more than half. In this seven-blade rotary shaver, one central razor unit 3A and six peripheral razor units 3C are mounted on the bracket 2 . Wherein, the razor group 3A is arranged on the central part of the bracket 2, and the remaining 6 peripheral razor groups 3C are ...

Embodiment 2

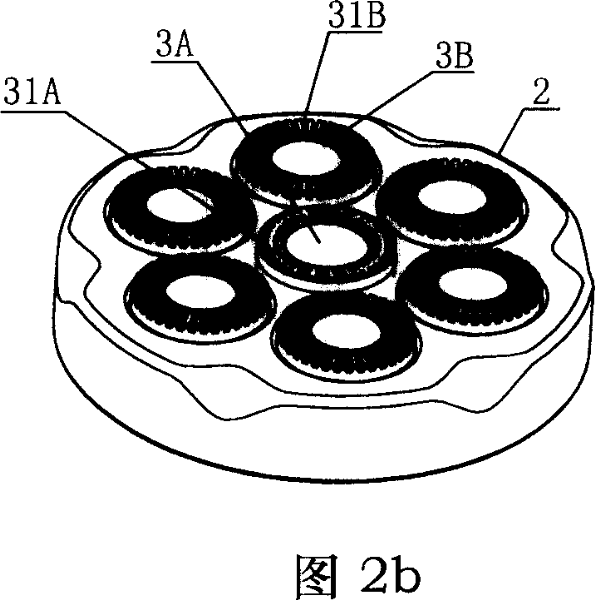

[0039] As shown in Figures 2b and 3a, the outer cutters 31B of the six peripheral razor groups 3B of the seven-blade rotary shaver have slit-type long beard inlet holes, thus forming the outer periphery of the shaver head. Part preliminary shaving area (long beard cutting and shaving area), which is the difference from Embodiment 1; all the other structures are the same as Embodiment 1, and will not be repeated here.

Embodiment 3

[0041] As shown in Figure 4a, in the four-blade rotary shaver, one razor unit 3A and three razor units 3B are installed on the bracket 2, wherein one central razor unit 3A is arranged in the center of the bracket 2 On the position, the remaining three peripheral razor sets 3B are evenly arranged around the razor set 3A. The outer cutting knife 31A of the central razor group 3A has a small circular hole-shaped short beard inlet hole, thereby forming a root-aligned shaving area (short beard cutting area) at the center of the shaver head, and the remaining three peripheral razors The outer cutter 31B of the group 3B has a slit-shaped long beard inlet hole, thereby forming a preliminary shaving area (long beard cutting area) on the periphery of the shaver head.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com