Hob type paper cutter

A paper cutter and hob-type technology, applied in the field of hob-type paper cutters, can solve the problems of inability to use other purposes, inability to use, low utilization rate, etc., and achieve the effect of expanding the application and utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

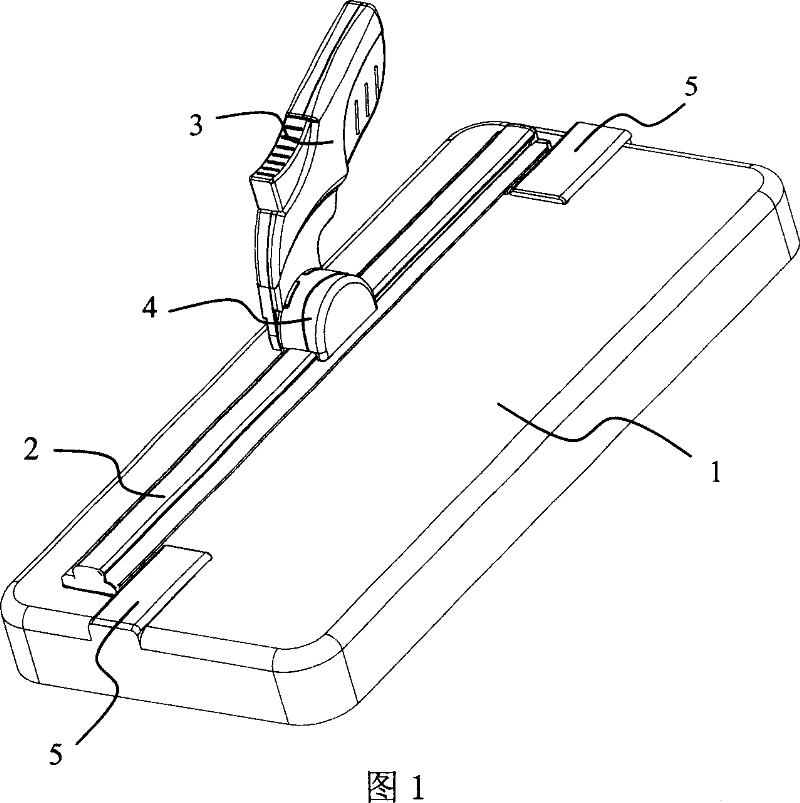

[0018] As shown in Figure 1 and Figure 2.

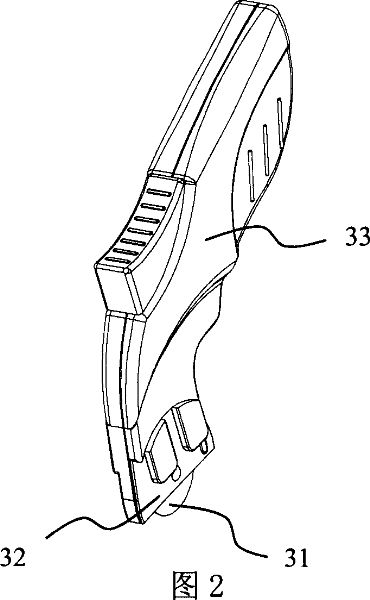

[0019] A hob-type paper cutter includes a bottom plate 1 , a hob assembly 3 and a slide rail 2 . The slide rail 2 is installed on the bottom plate 1, and a slide member 4 is arranged on the slide rail. The hob assembly 3 includes a blade 31 and a knife holder 32 for installing the blade, and the knife holder 32 is provided with a handle 33 which is convenient for the operator to hold. One side of the slider 4 and one side of the tool holder 32 are respectively provided with bayonets that match each other, so that the hob assembly 3 can be quickly and easily installed on the slider 4 or disassembled from the slider 4 .

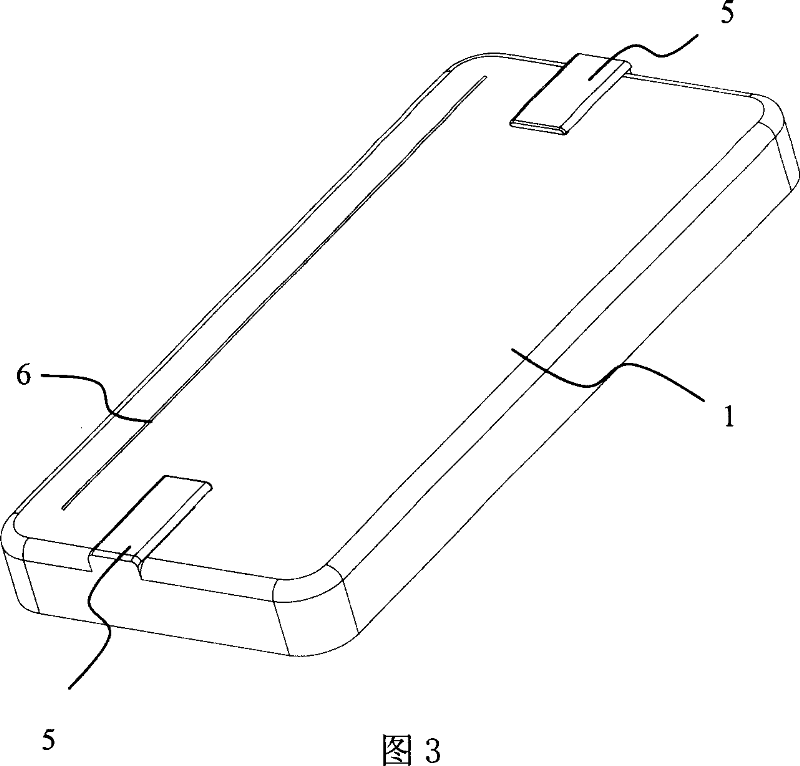

[0020] A linear knife groove 6 is arranged on the base plate 1 below the side of the slide rail 2, as shown in Figure 3 (the slide rail, slide block and hob assembly are not shown in Figure 3), when the hob assembly 3 is installed on the slide 4 and when sliding along the slide rail 2, the edge of the blade 31 just ...

Embodiment 2

[0025] A hob-type paper cutter, except that the hob assembly is fixedly mounted on the slide, and the slide is detachably mounted on the slide rail, the rest of the structure is the same as that of the paper cutter in Embodiment 1.

[0026] When the slide is removed from the rail, the hob assembly, together with the slide, can be used alone as a knife.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com