Construction technique for joint of wood structure house main body and concrete bed

A technology of concrete foundation and construction technology, applied in the direction of building structure, construction, etc., can solve the problems of irresistibility, large lateral load, and low lateral compressive load, so as to reduce the possibility of damp and improve lateral resistance. Compressive load, the effect of improving the connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

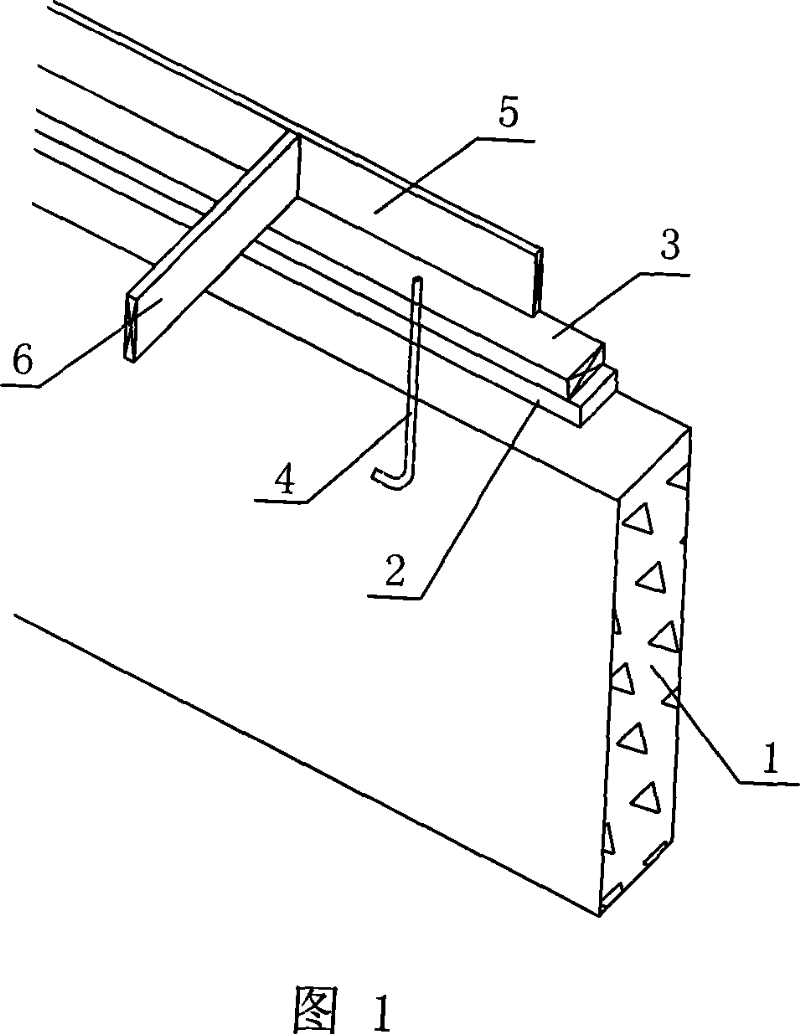

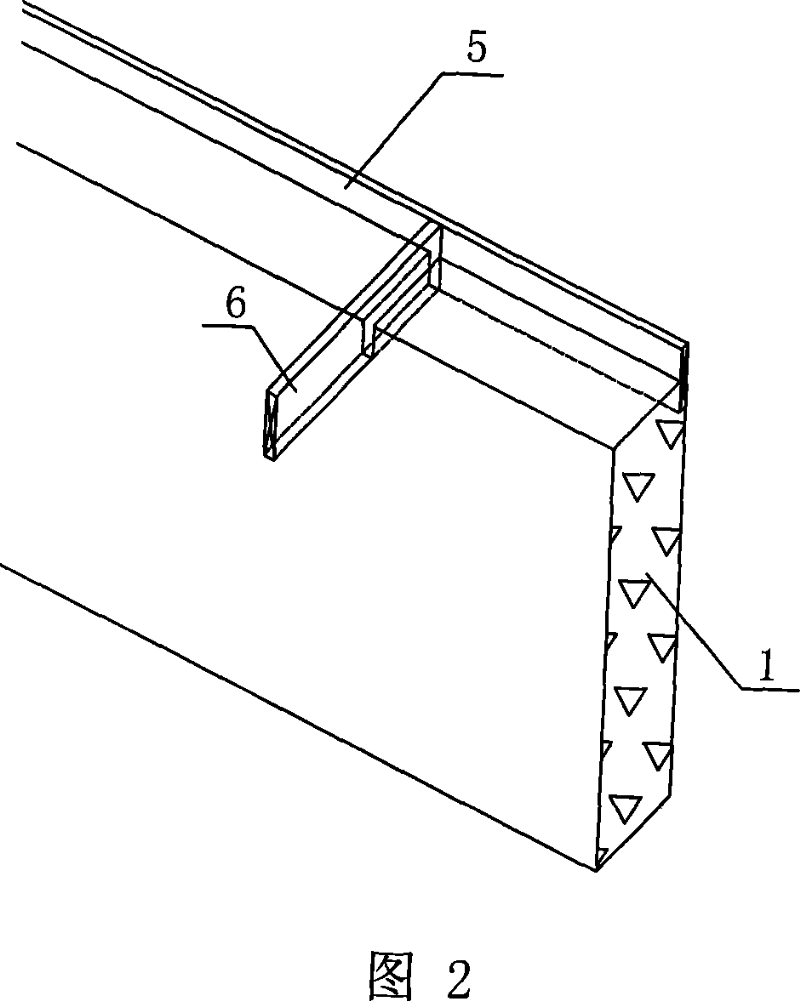

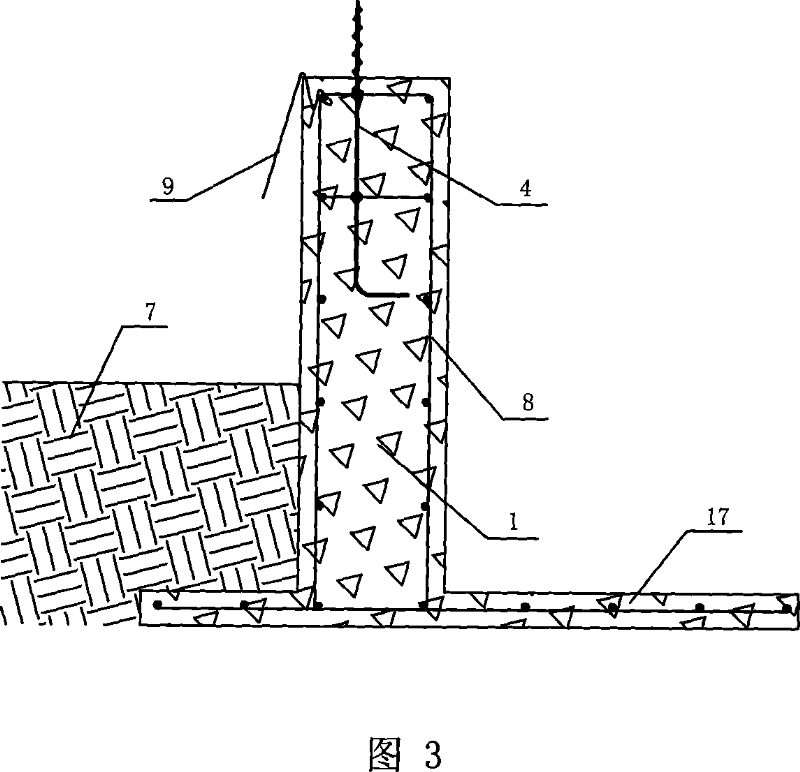

[0036] This embodiment is a construction technique for connecting the main body of a wooden structure house with a concrete foundation. During specific implementation, a 100mm concrete foundation cushion 17 is poured, and a φ12 threaded steel bar is used to bind the foundation wall reinforcement frame 8 according to the design drawings. The concrete foundation wall 1 has a width of 150mm and a height of 800mm.

[0037] A galvanized strip with a length of 500 mm and a width of 50 mm is made into a flexible connector 9 with three hooks at one end, arranged along the concrete base wall 1 at a distance of 800 mm, and there is a lot of length reserved outside the concrete base wall 1 at 300mm.

[0038] According to the design elevation of the concrete base wall 1 and considering the thickness of the base plank 3, the actual elevation of the anchor bolt 4 is determined, and the length of the anchor bolt 4 is 300 mm. Use a level to correct the height of the anchor bolts 4 at the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com