Linear sliding rail

A technology of linear slide rails and slide rails, applied in the direction of linear motion bearings, bearings, bearing components, etc., can solve the problems of difficult production, increased impact on the outer edge of the turntable, and the inability to increase the rigidity of the rigid body of the end cover and the slide seat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

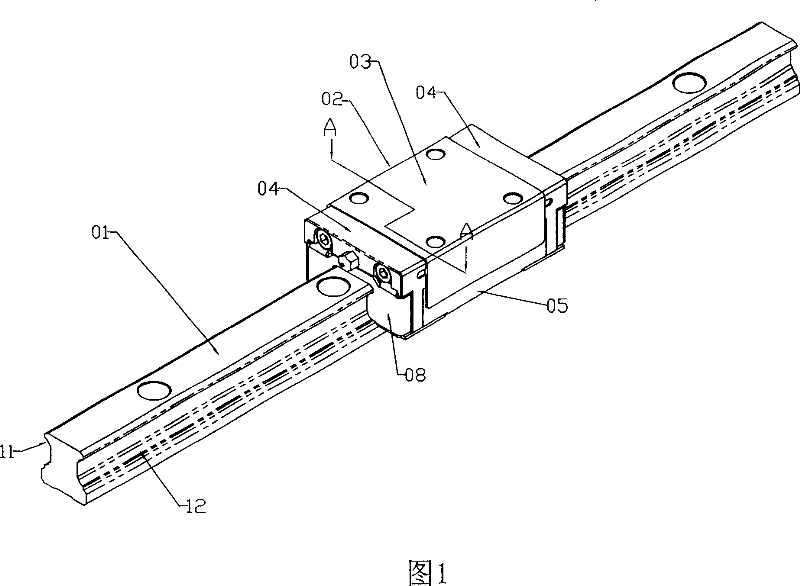

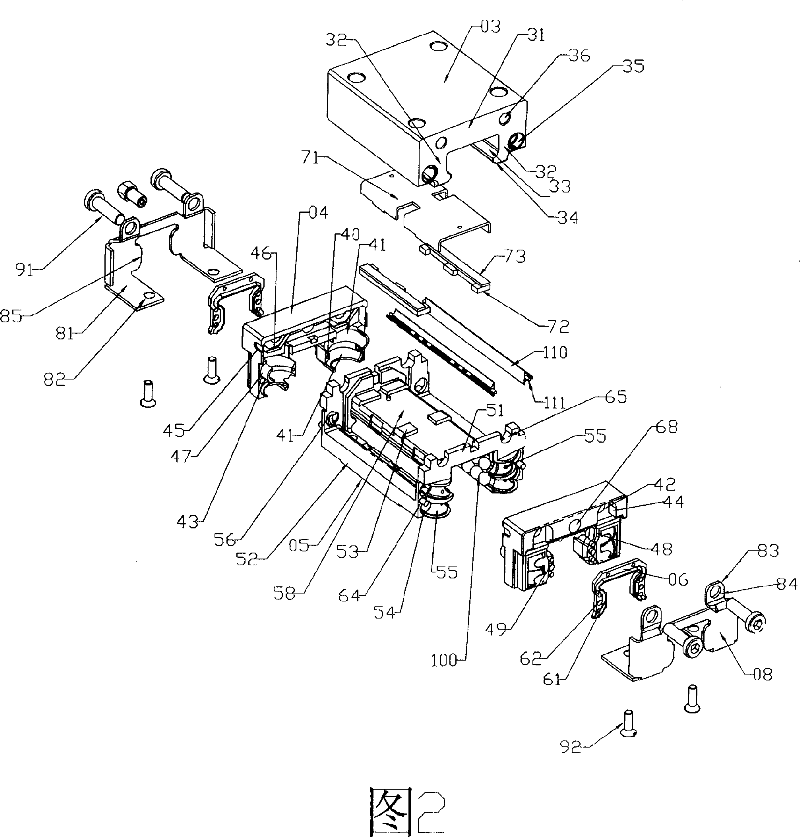

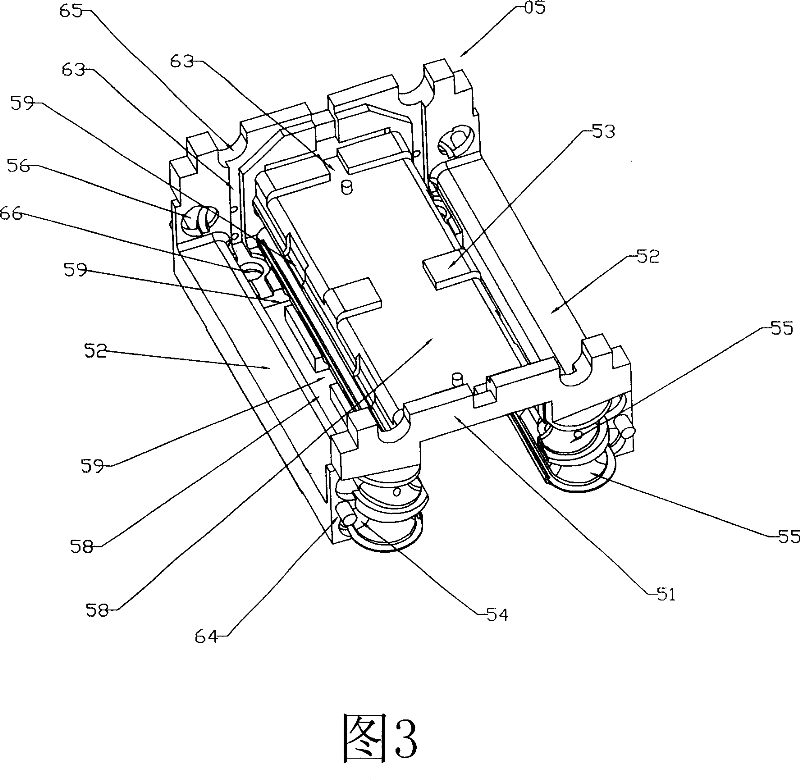

[0017]A linear slide rail includes a slide rail 01 and a slide seat 02 as shown in FIG. 1 . The slide 02 is composed of a rigid body 03, front and rear end covers 04, a base 05, reinforcement sheets 08 and multiple rows of rolling elements 100 as shown in Figure 2; Figure 2 is an exploded view of the parts of a slide 02. A rigid body 03 consists of a flat plate 31 and two legs 32 extending downwards; the inner sides of the two legs respectively have two tracks 33, 34 up and down, and a through hole 35 is arranged on the outer side of the upper track 33 as the return channel of the upper track 33. Hole 36. A base 05 includes an upper plate 53, which is combined with the inner sides of the two legs 32 of the rigid body and the bottom of the flat plate 31; The plate 51 is combined with the outer side of the end face of the rigid body and provides the inner edge 55 of the rolling track; the base 05 is combined with the rigid body 03 from bottom to top. The two end covers 04 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com