Focusing structural

一种传动机构、成像模组的技术,应用在对焦结构领域,能够解决影响对焦结构寿命、不方便对焦、易阻挡采光孔1224入射光线等问题,达到寿命长、操作简单的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

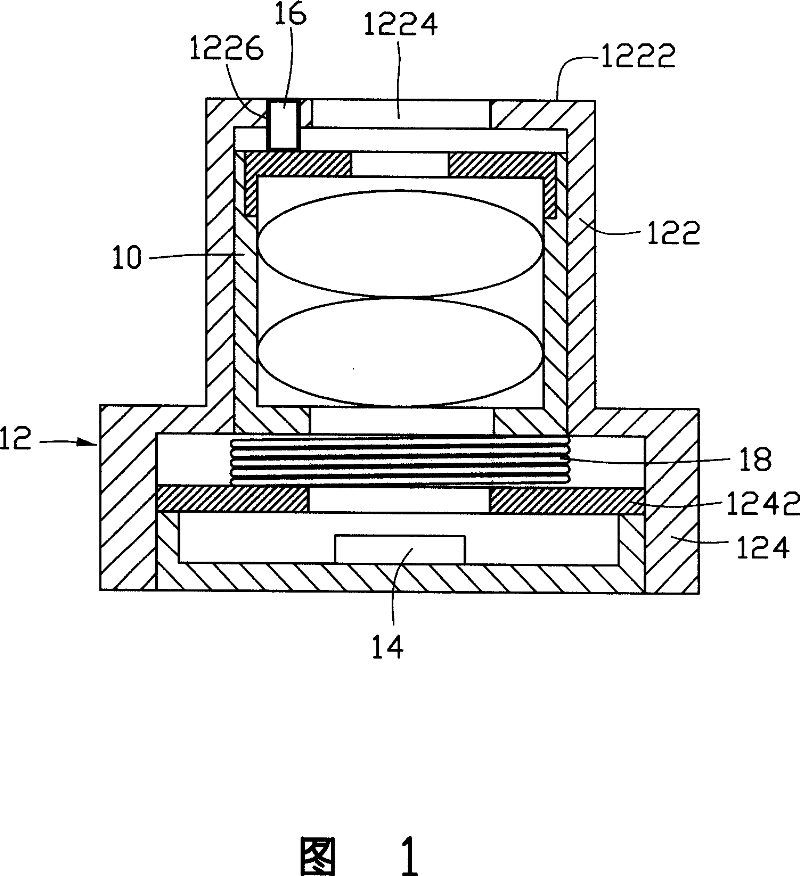

[0014] The focusing structure of the preferred embodiment of the present invention is applied to a portable electronic device. This embodiment takes a digital camera as an example for illustration.

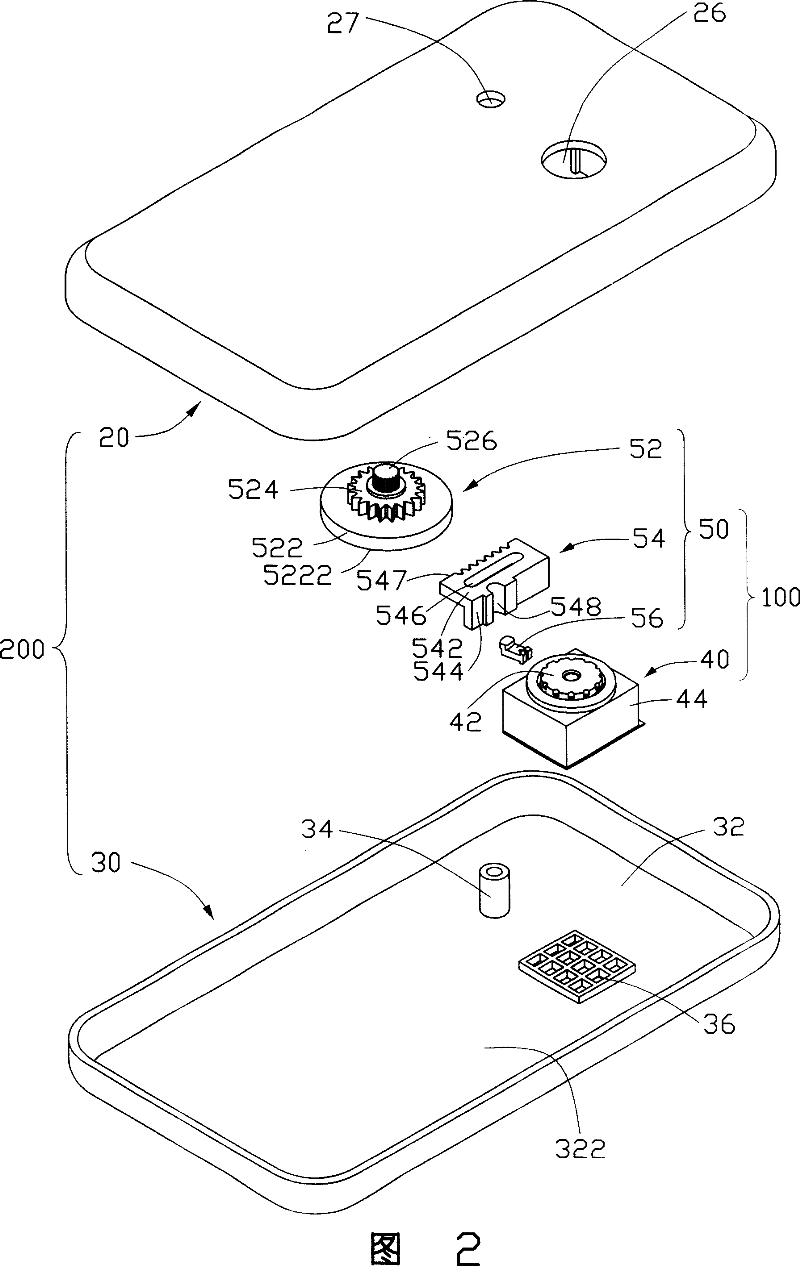

[0015] Referring to FIG. 2 , the focusing structure 100 of the preferred embodiment of the present invention is applied to a digital camera 200 , and the focusing structure 100 includes an imaging module 40 and a transmission mechanism 50 .

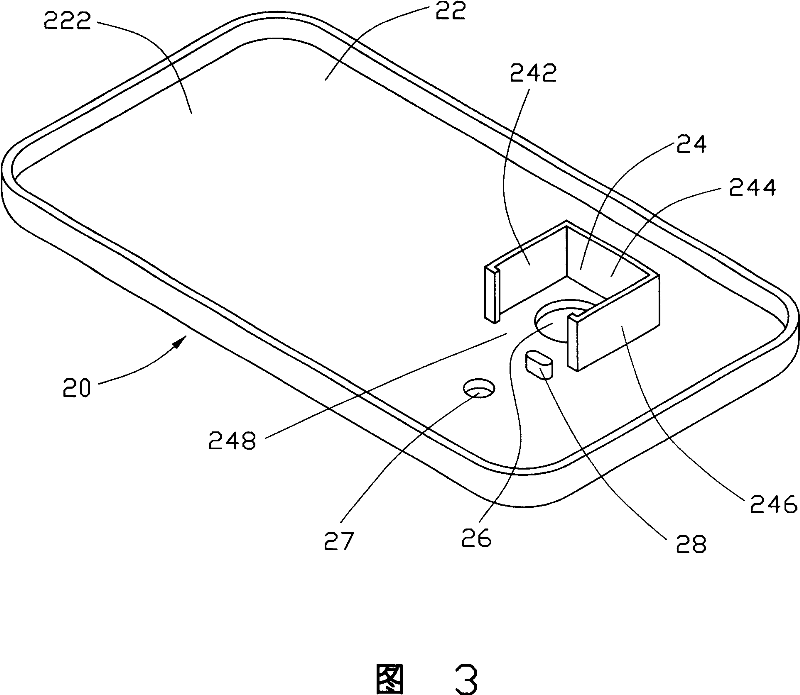

[0016] Please refer to FIG. 3 , the digital camera 200 includes a first casing 20 and a second casing 30 .

[0017] The first housing 20 is in the shape of a cover and has an upper cavity 22 . The upper cavity 22 has a bottom surface 222 , and one side of the bottom surface 222 is provided with an accommodating portion 24 for fixing the imaging module 40 and preventing it from moving. The accommodating portion 24 is surrounded by a bottom surface 222 and three side walls 242, 244, 246 extending from the bottom surface 222, wherein the two en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com