Synthetic crosstie and manufacturing method for the same

A manufacturing method and technology for sleepers, which can be applied to devices, roads, tracks and other directions for coating liquid on the surface, can solve the problems of increased manufacturing cost of sleepers 11, and achieve increased bonding area, good weather resistance, and strong peeling resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

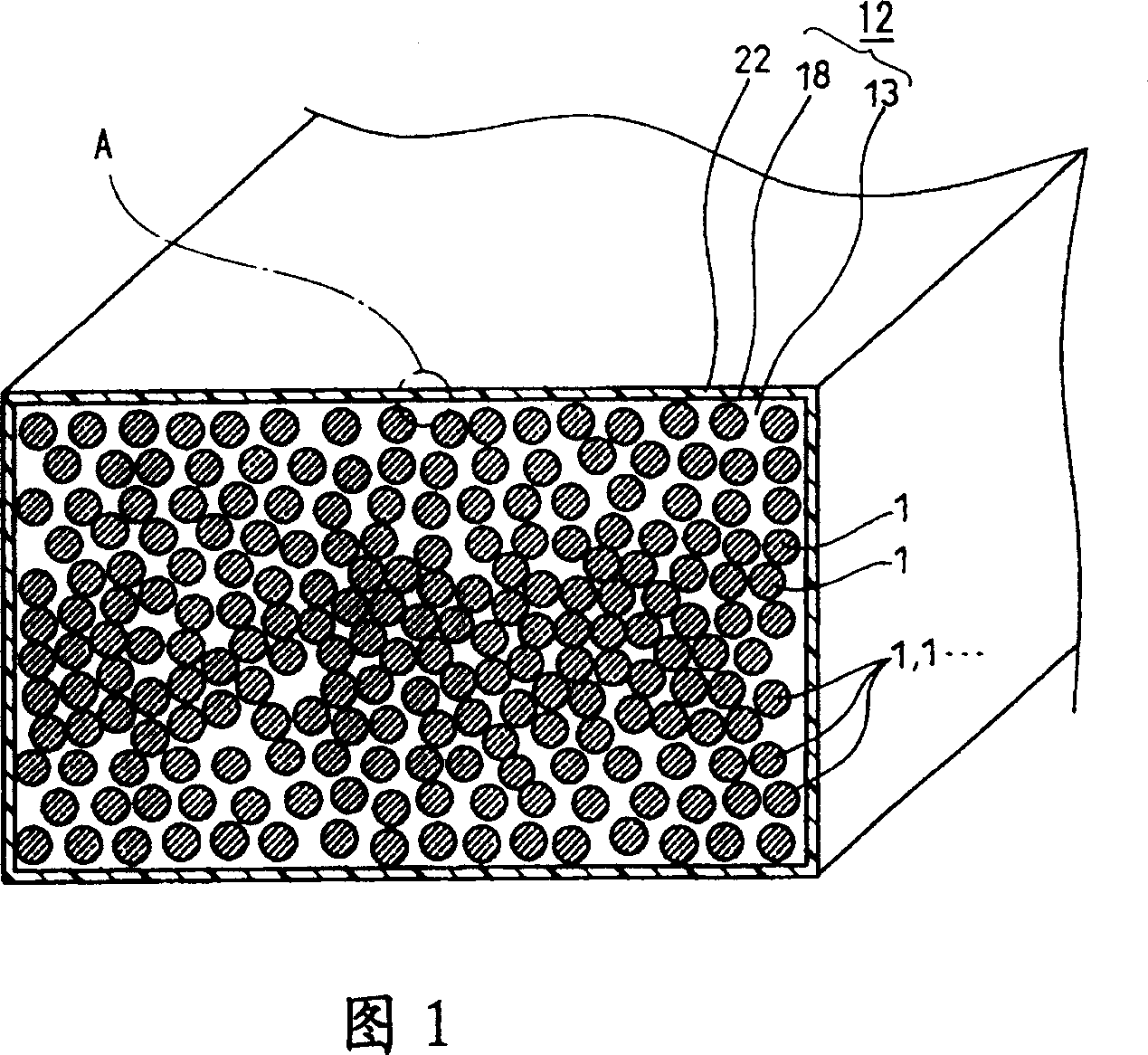

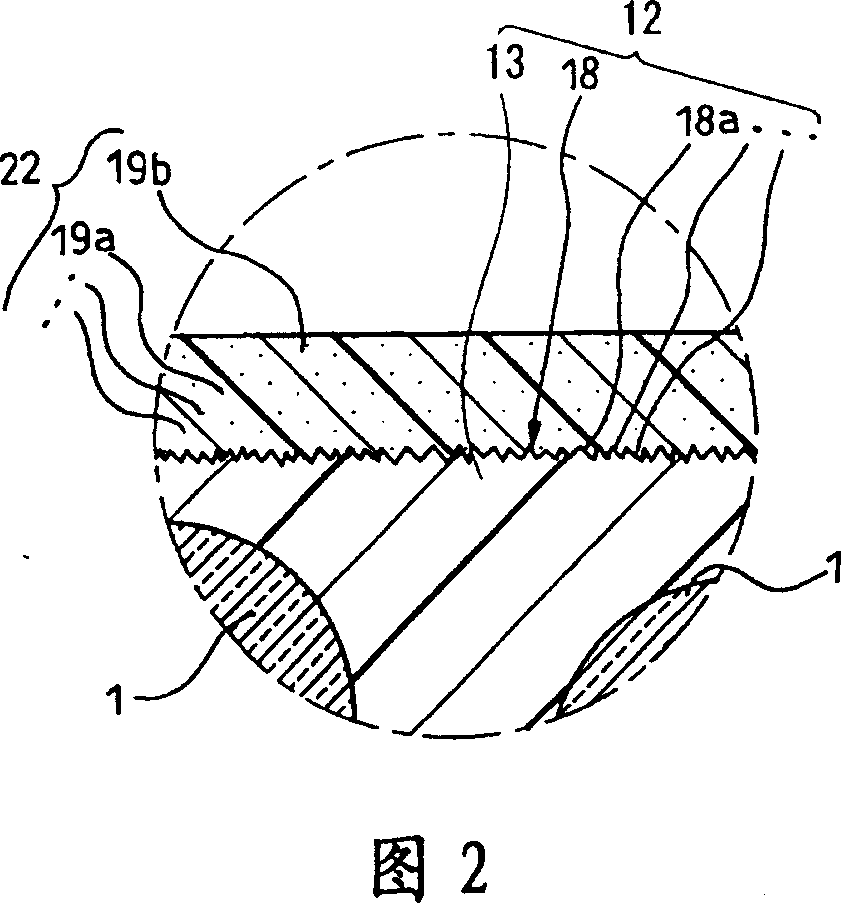

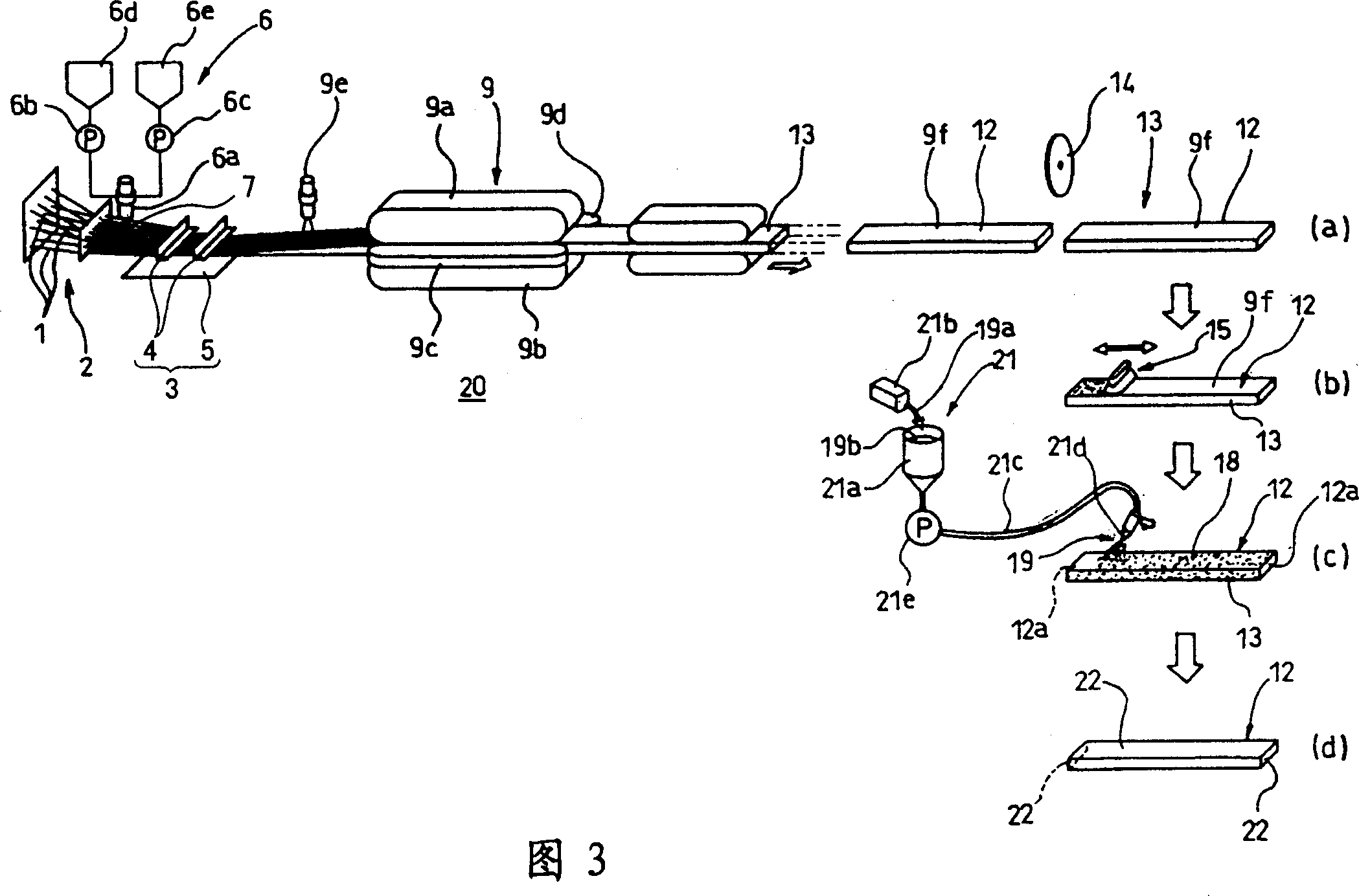

[0051] Next, a composite sleeper and a method of manufacturing the composite sleeper in the best mode for carrying out the present invention will be described with reference to FIGS. 1 to 6 . In addition, the same code|symbol is used and the same code|symbol is used about the part which is the same as or equivalent to the said previous example.

[0052] As shown in Fig. 1 and Fig. 2, the synthetic sleeper in Example 1 of this embodiment includes: a composite sleeper formed by a foam base material 13 and a plurality of long glass fibers 1 ... arranged in the foam base material 13. The sleeper body 12, and the flame retardant layer 22. In addition, the synthetic sleeper in this embodiment also includes an abrasive layer 18 disposed on the surface of the synthetic sleeper body 12 , and the flame retardant layer 22 is disposed on the surface of the abrasive layer 18 .

[0053] Hereinafter, the manufacturing process of the synthetic sleeper in this embodiment is demonstrated. In ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com