Patents

Literature

35 results about "Linear engine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

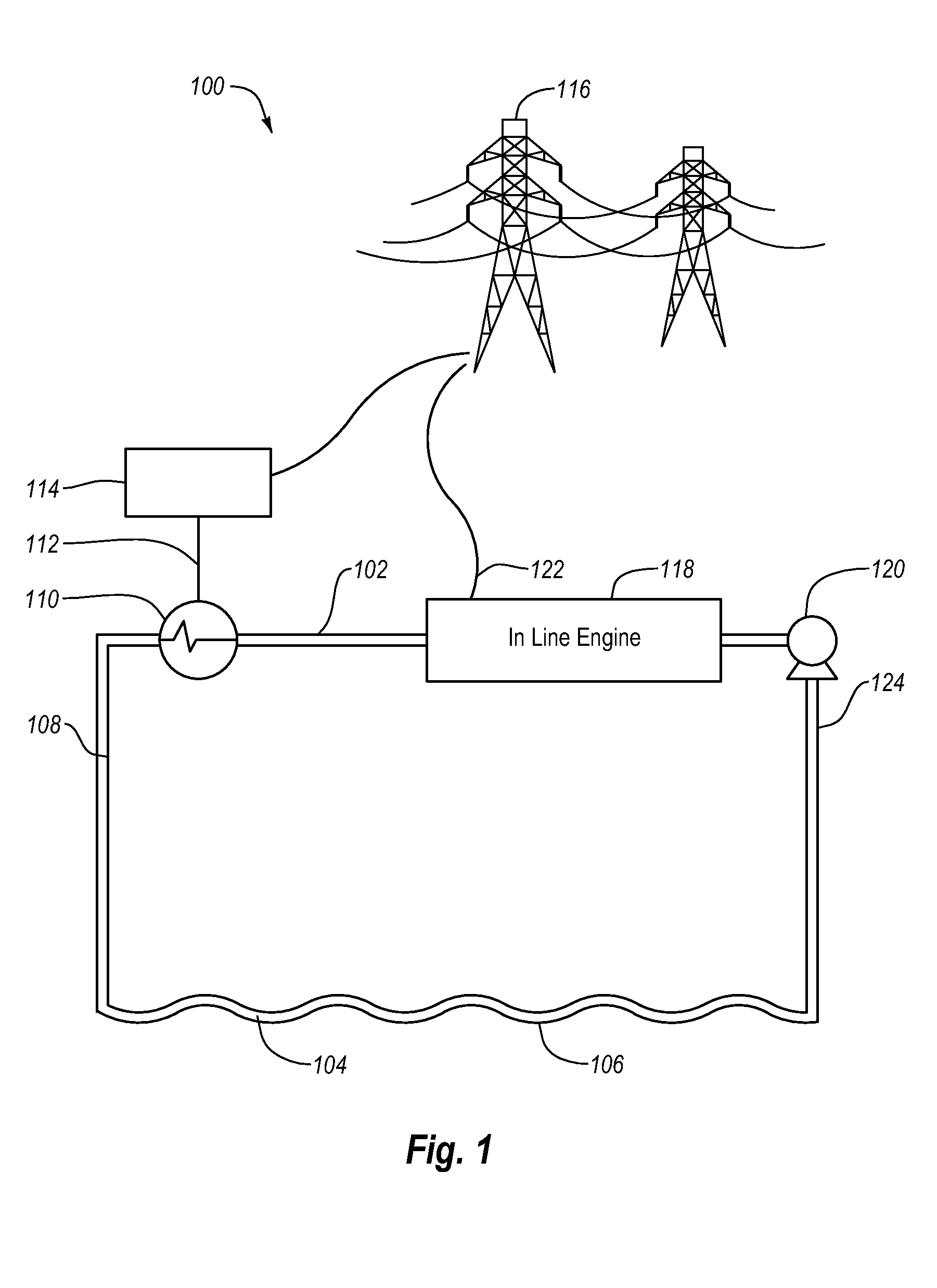

Process to obtain thermal and kinetic energy from a geothermal heat source using supercritical co2

InactiveUS20110100002A1Easy to useProduce energyGeothermal energy generationMachines/enginesThermal energyLinear engine

Methods and systems for extracting geothermal energy from an underground hot dry rock reservoir using supercritical carbon dioxide are disclosed. In a first step, the methods and systems utilize a heat exchanger in a binary system to heat a secondary fluid that is used to perform work. In a second step, the supercritical carbon dioxide is transferred to a pseudo turbine (e.g., a free-piston linear engine) to perform additional work through expansion.

Owner:GREENFIRE PARTNERS

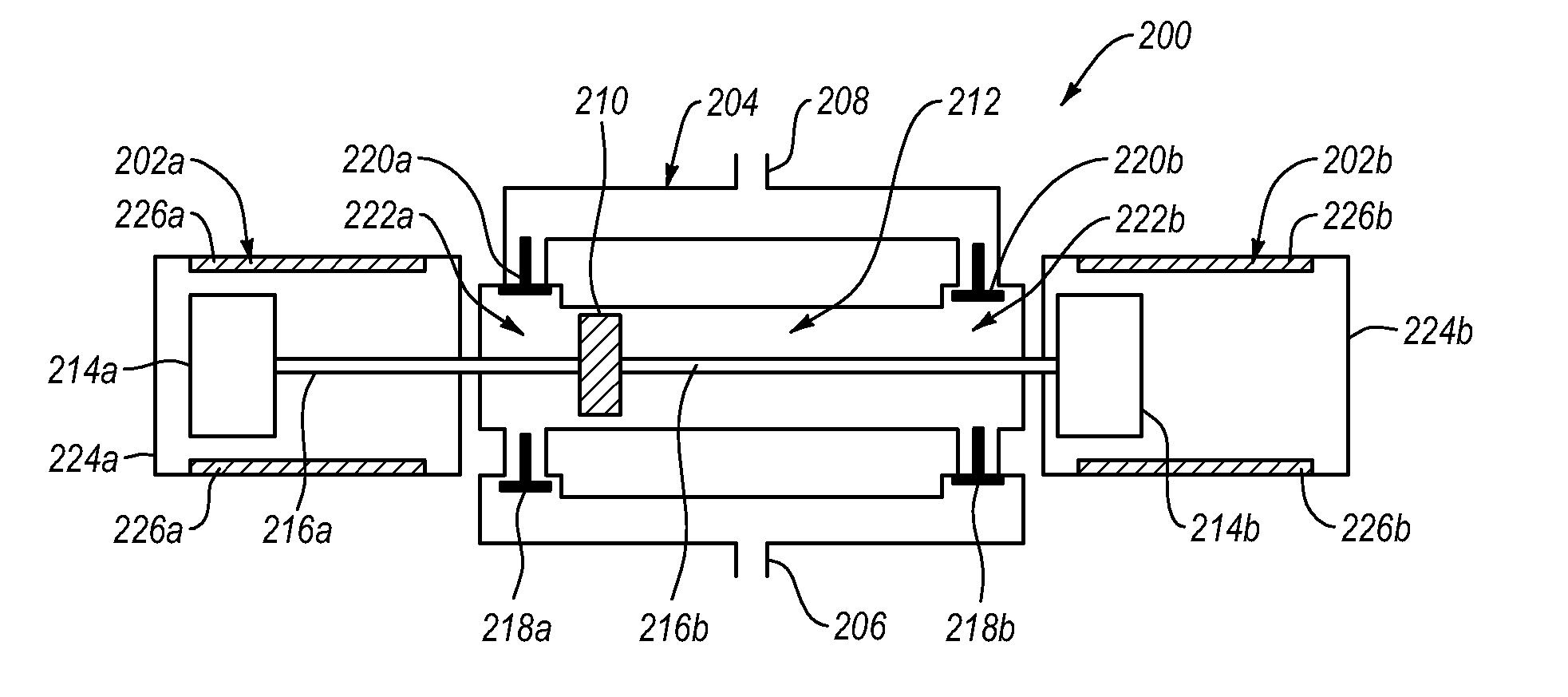

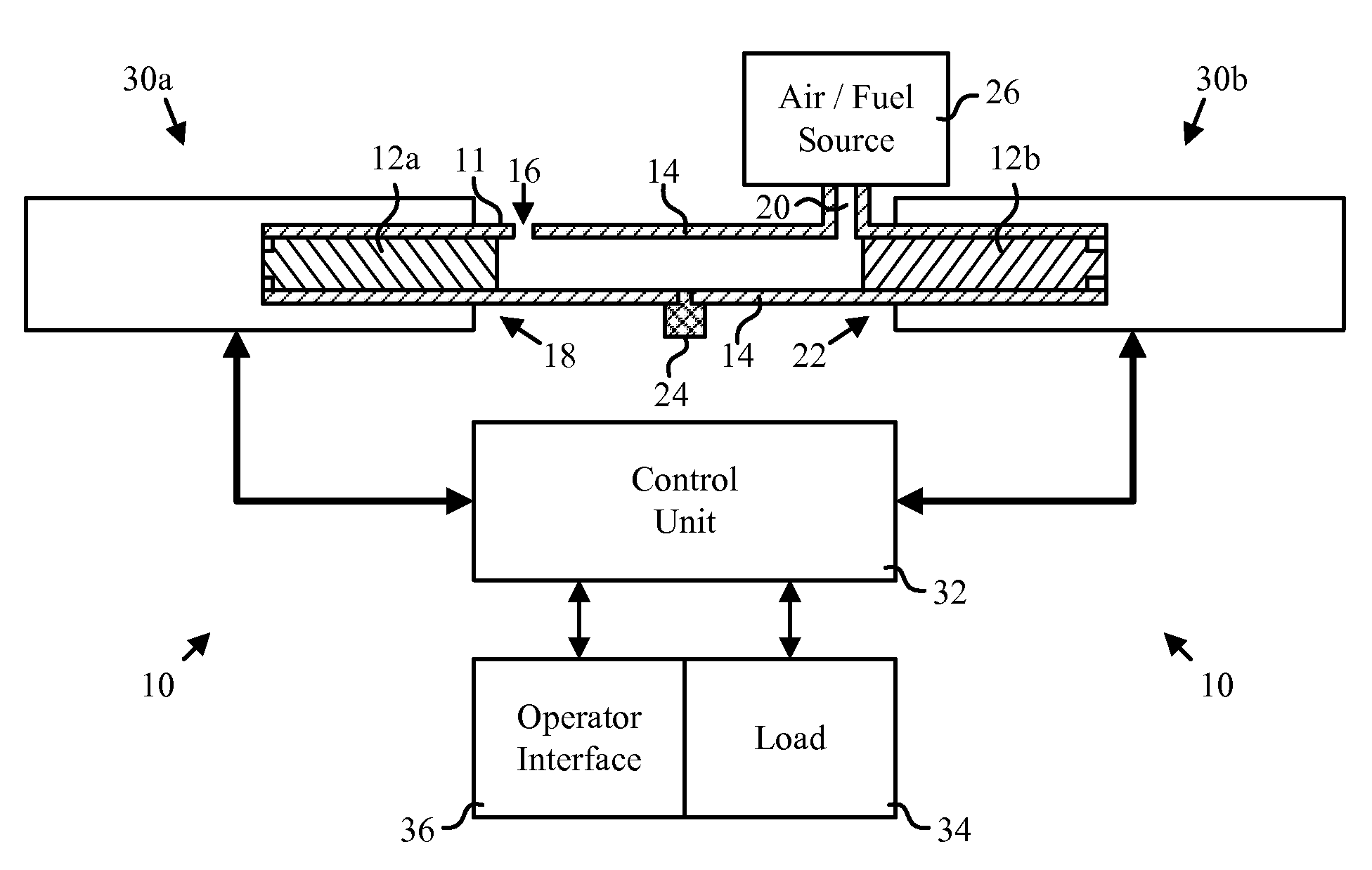

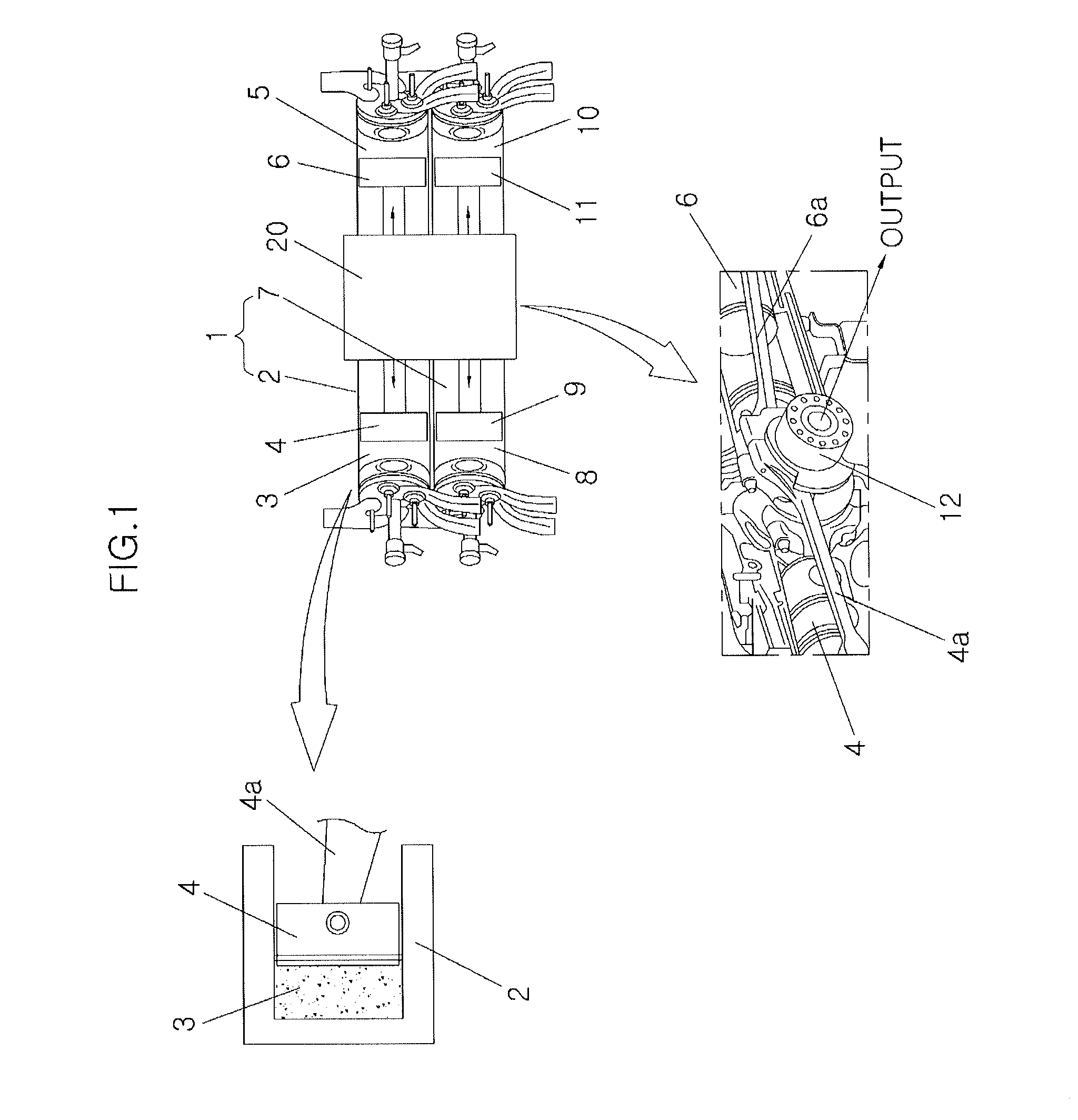

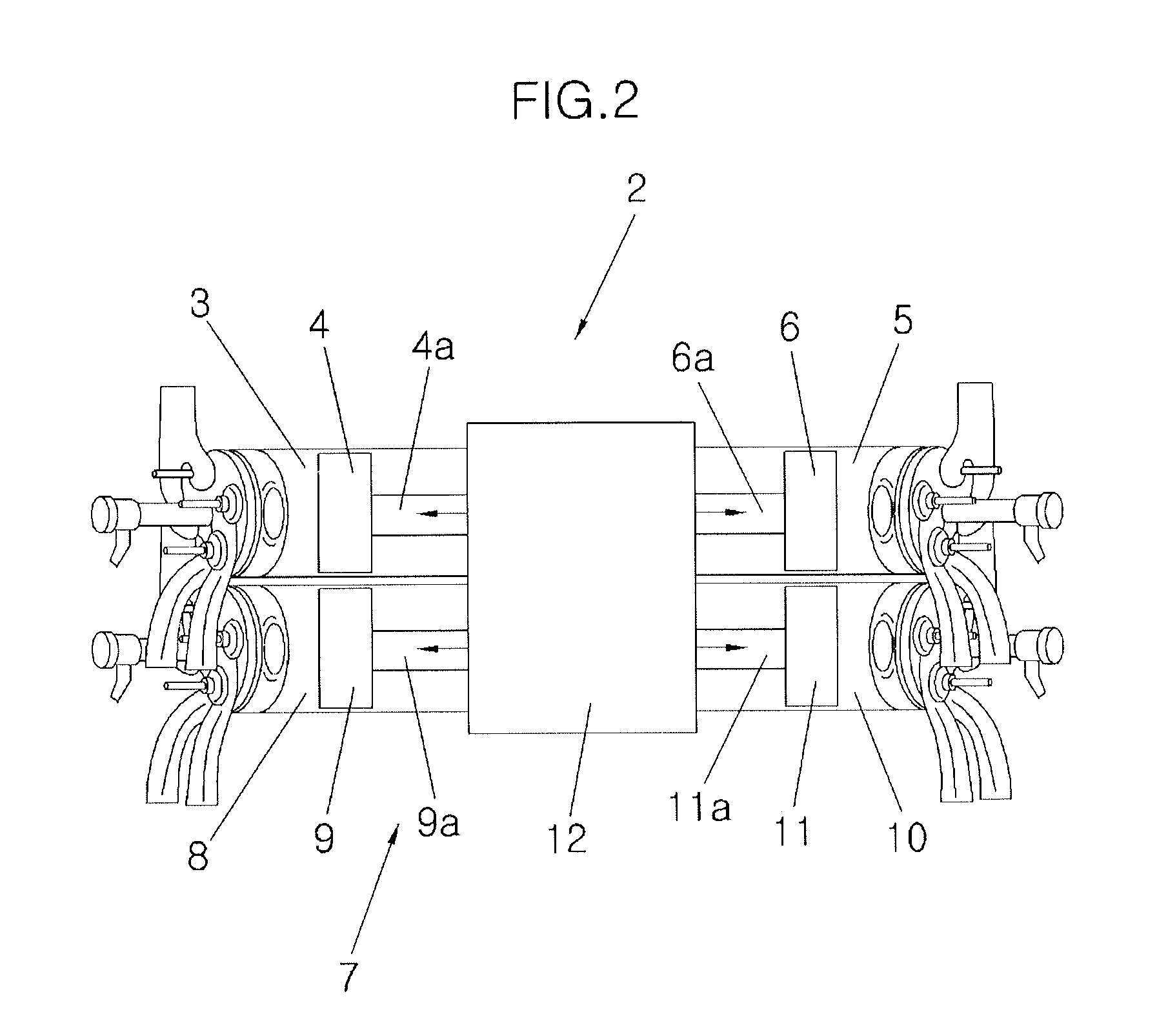

Paired-piston linear engine

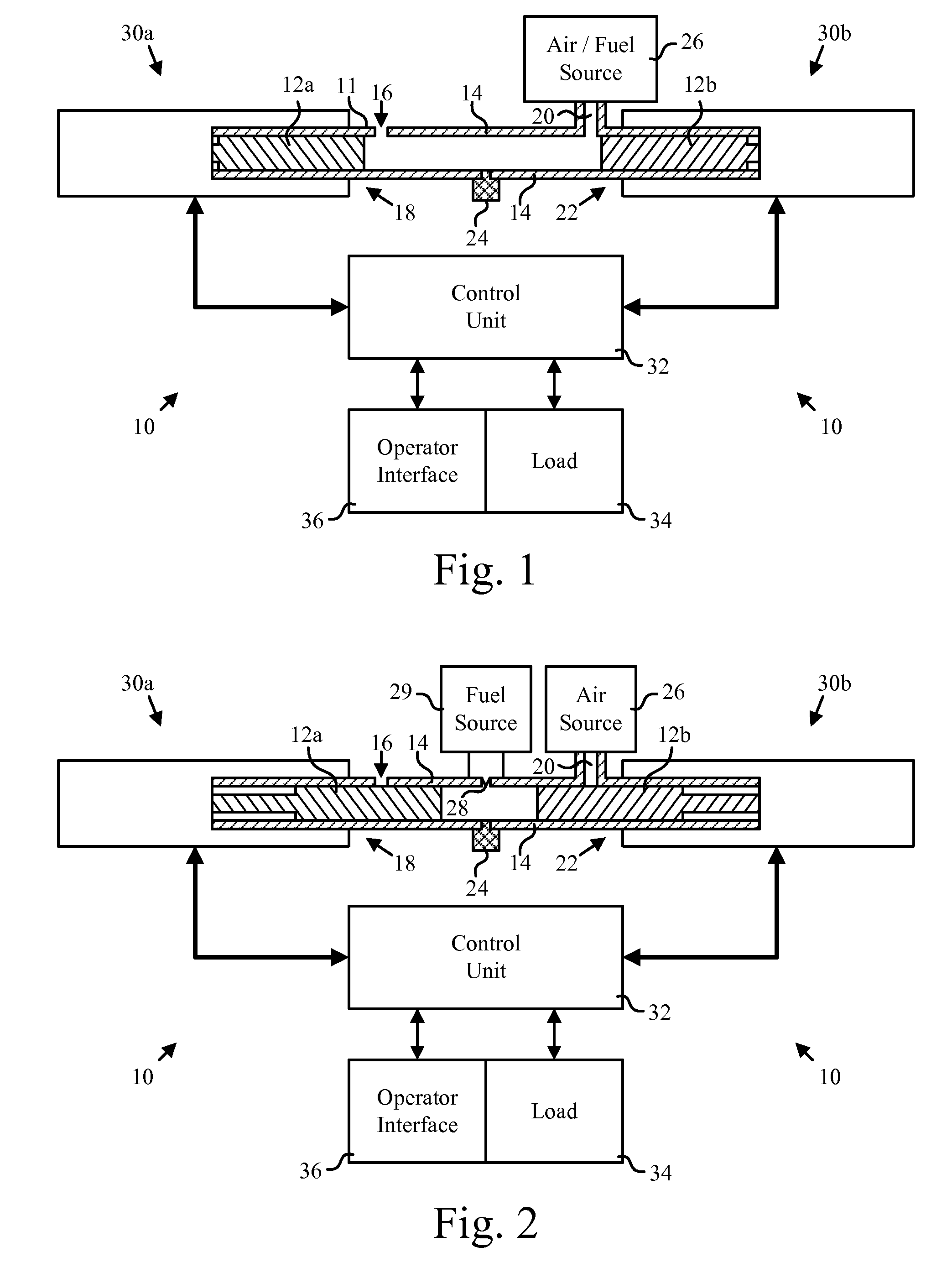

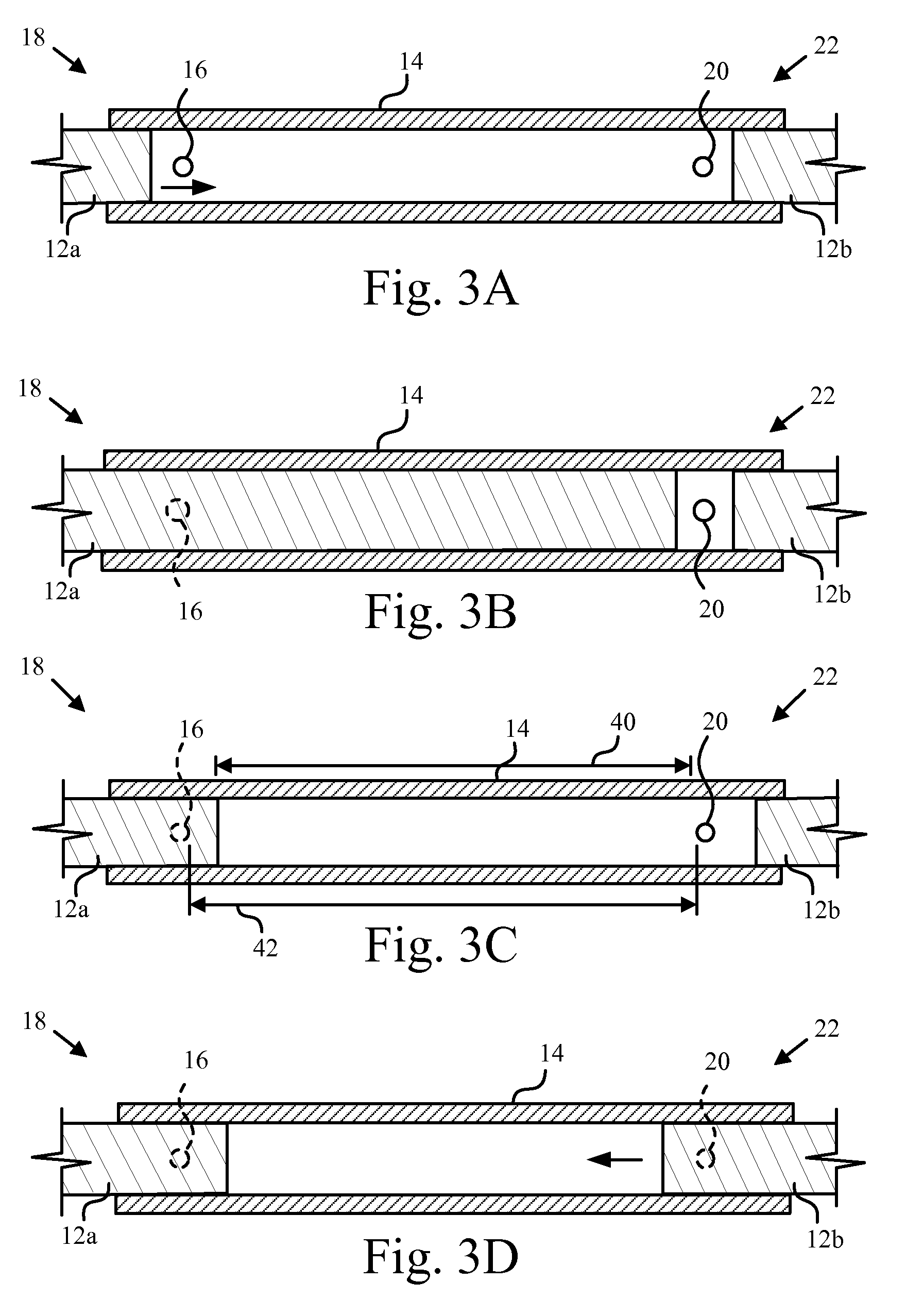

A linear internal combustion engine is disclosed having a cylinder defining an intake port proximate a first end thereof and an exhaust port proximate a second end thereof. First and second pistons insert into opposite ends of the cylinder. Each piston is coupled to an actuator / generator, such as a linear switched reluctance motor. The actuator / generators are coupled to a control unit which controls the actuator / generators and extracts energy therefrom. The control unit causes the actuators to move the pistons through a fluid handling process, such as pumping, compression, or a four cycle combustion process coupled with a recovery phase. The pistons are positioned over the intake and output ports to seal them off at proper times during the fluid handling process.

Owner:BENNION ROBERT F

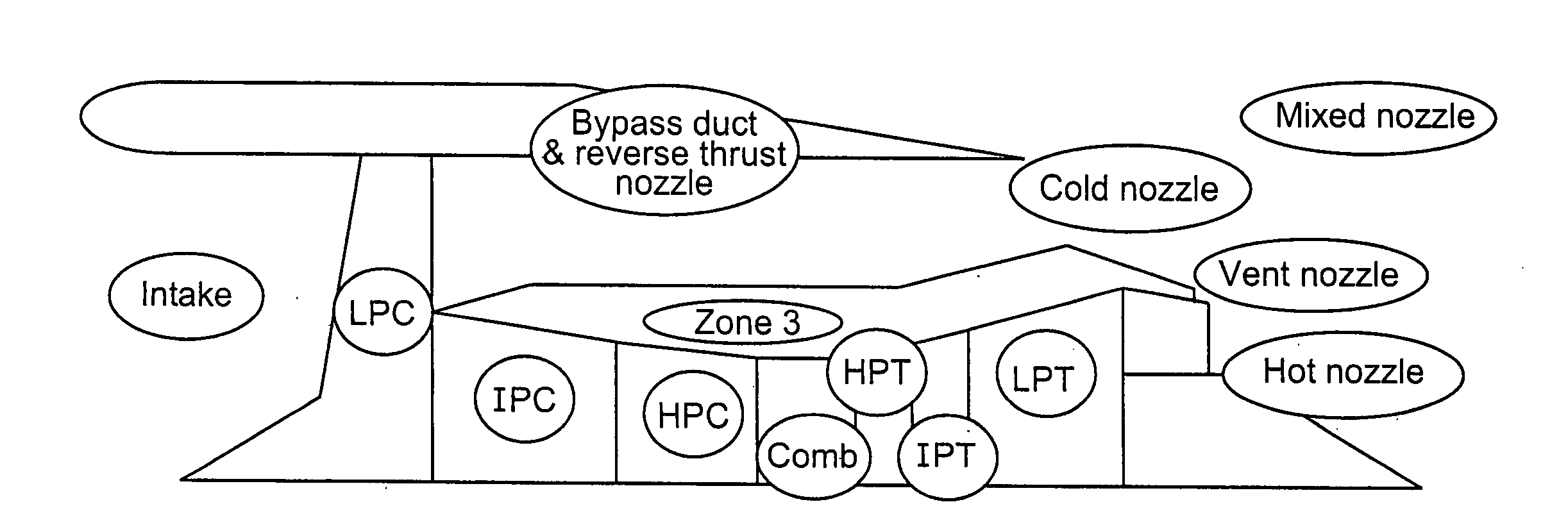

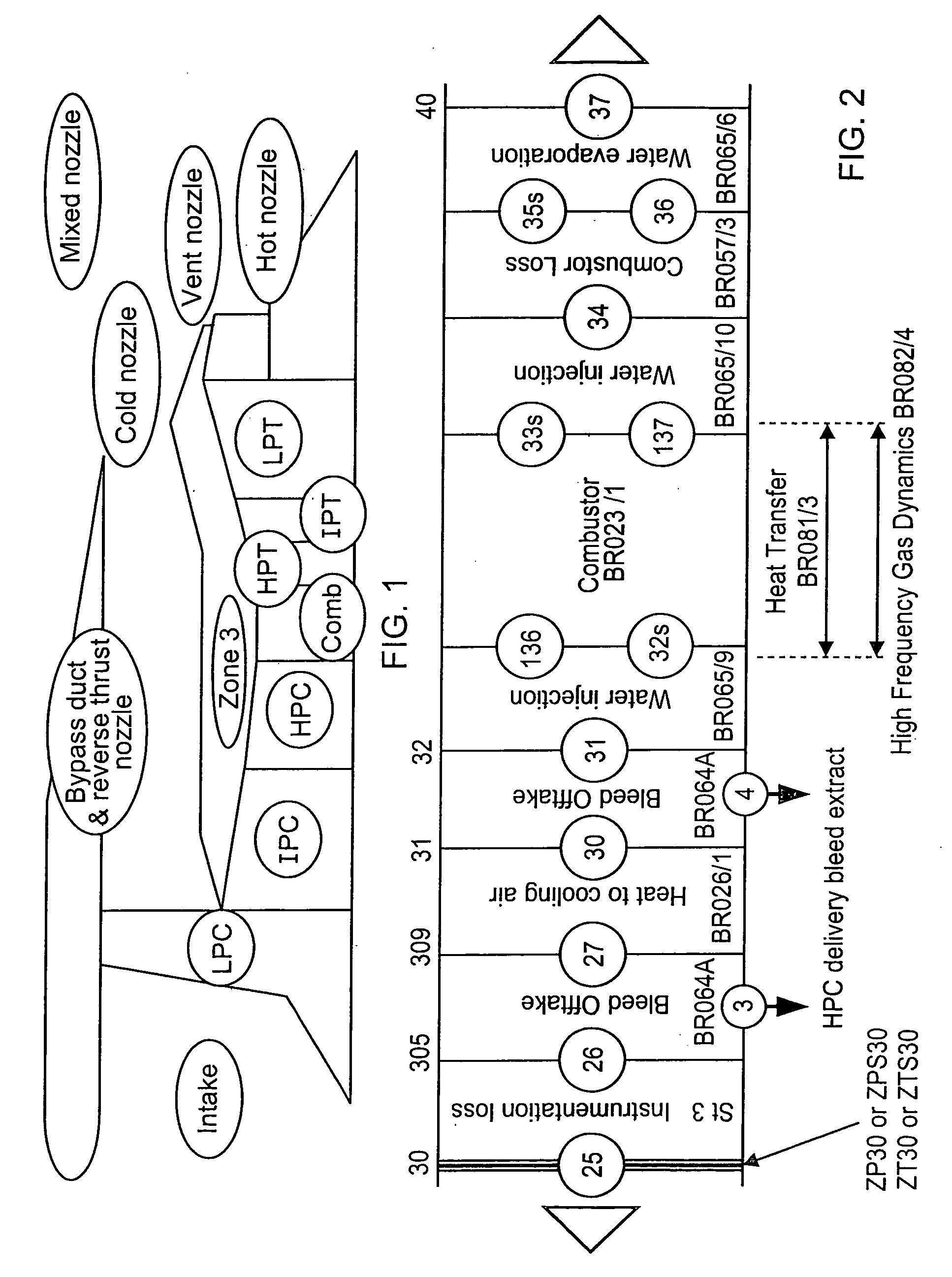

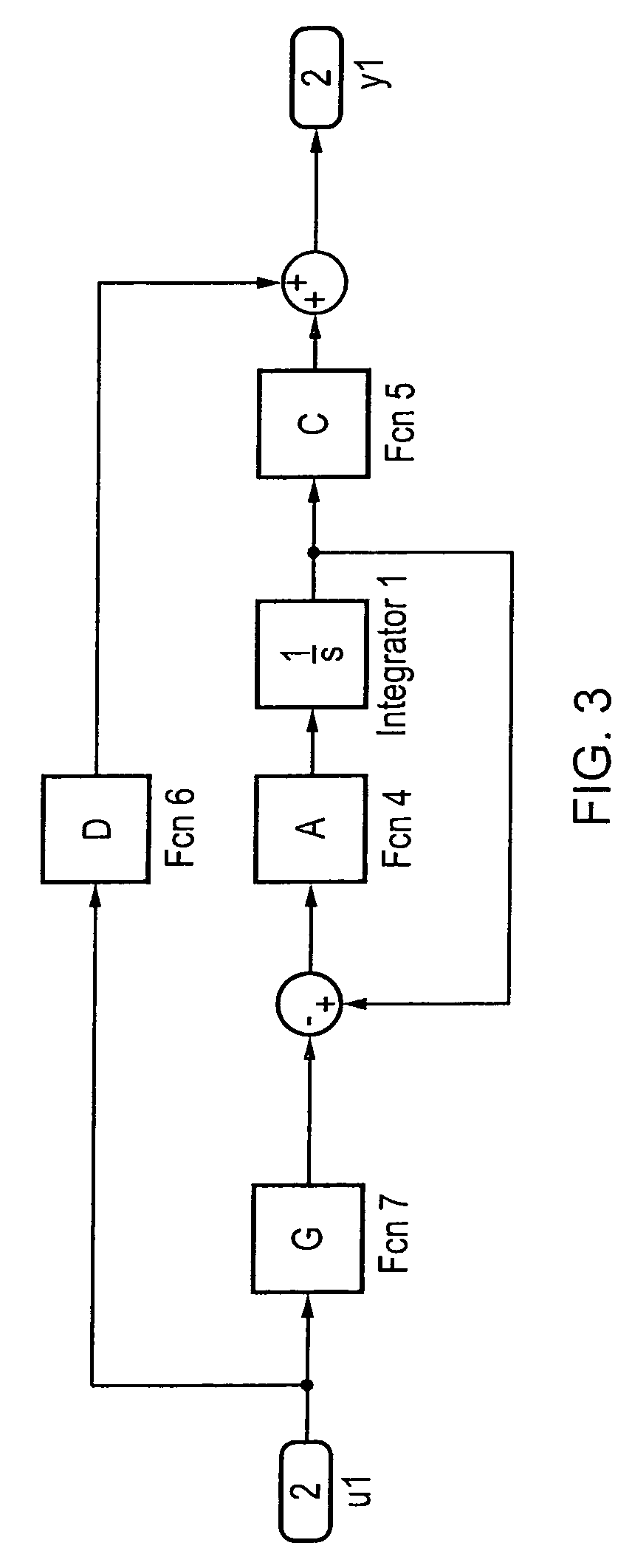

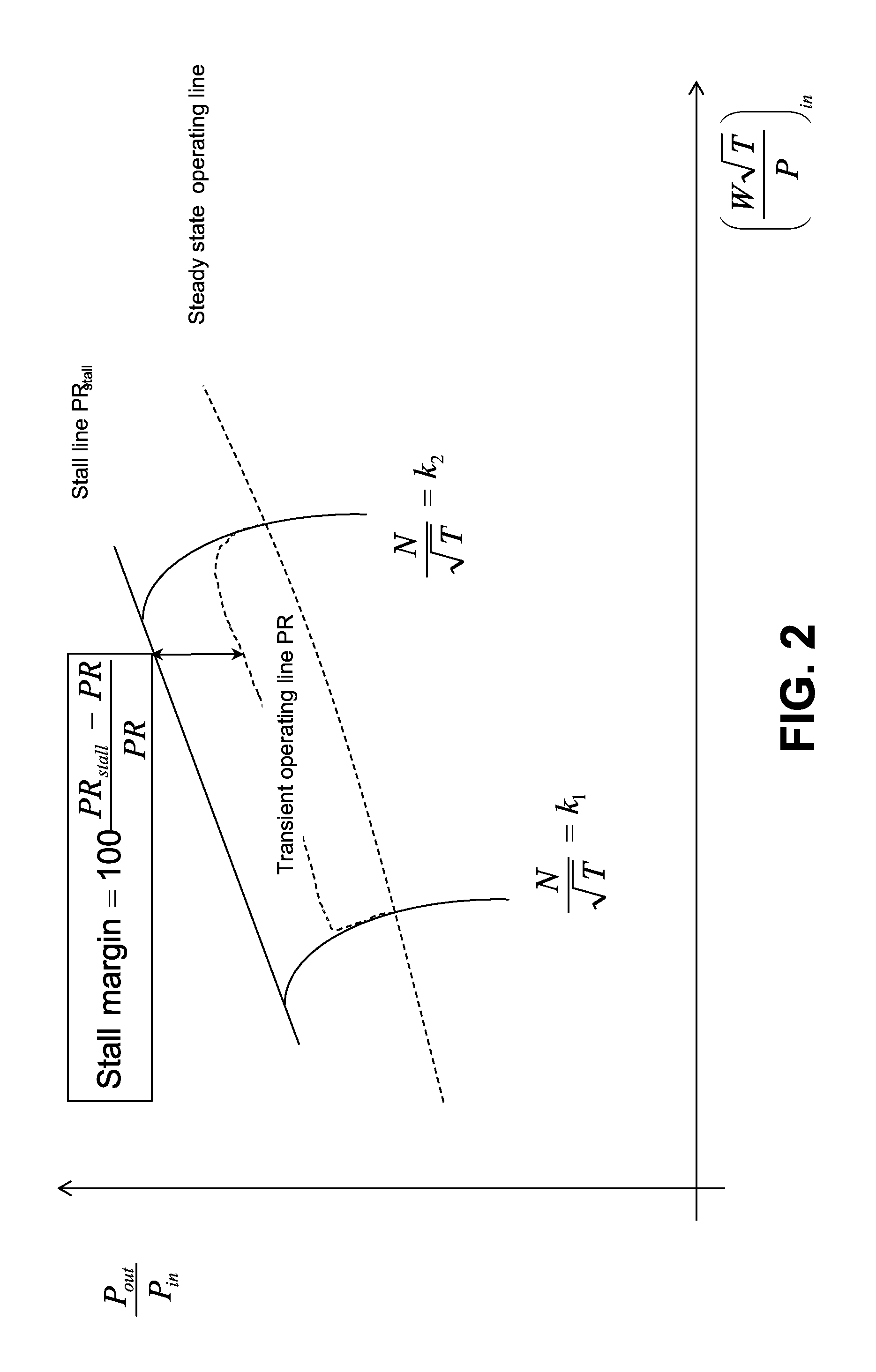

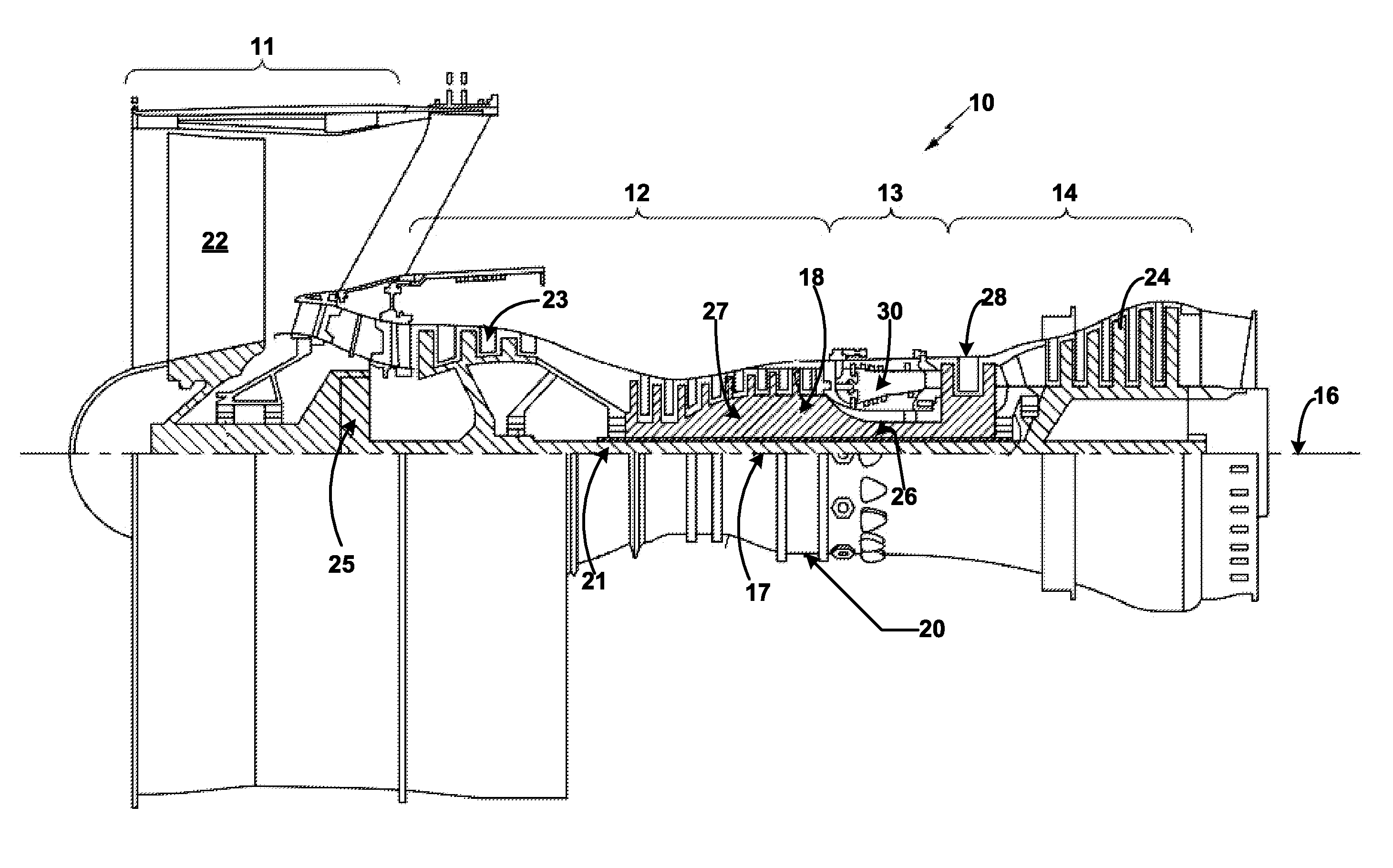

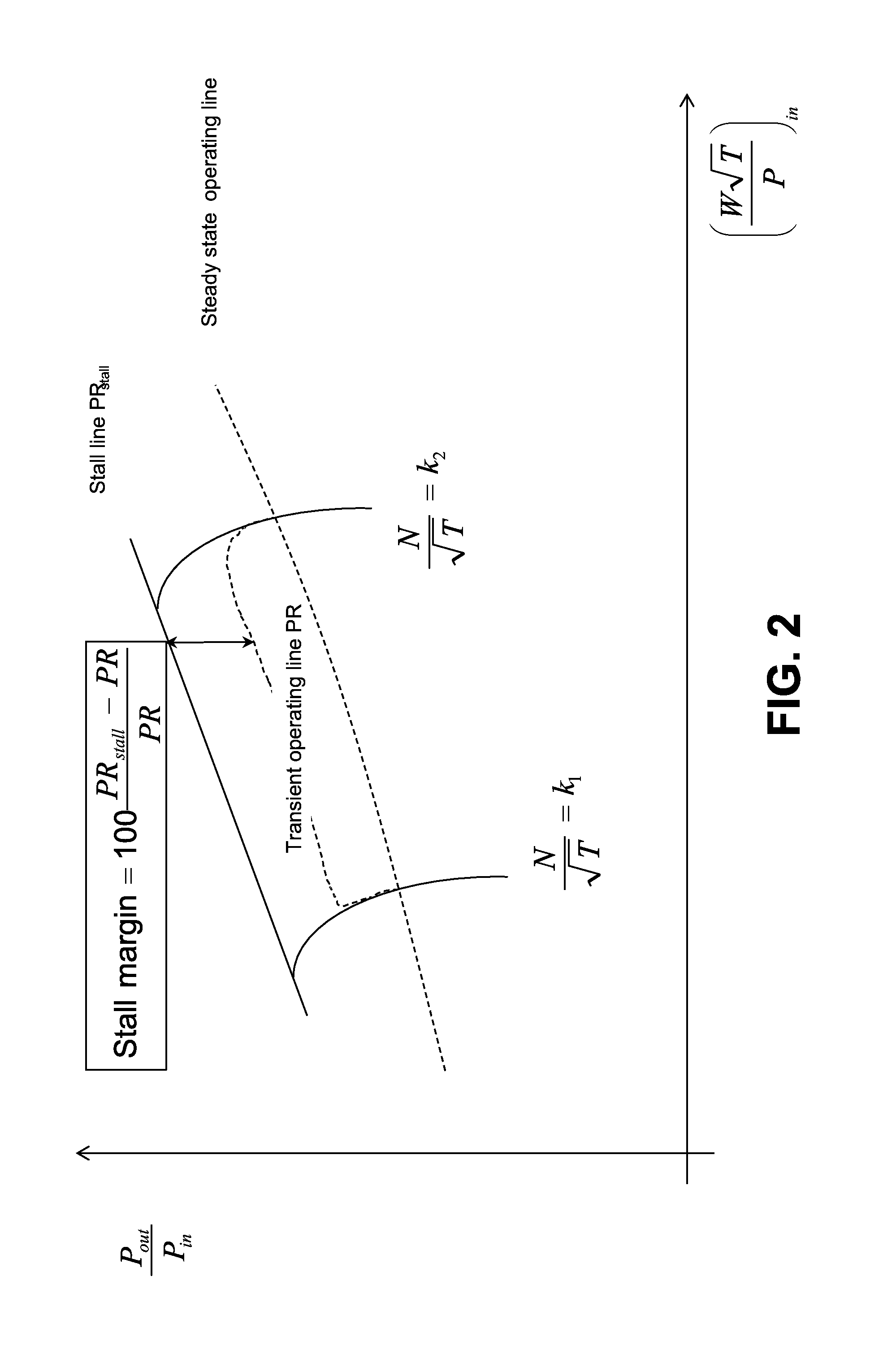

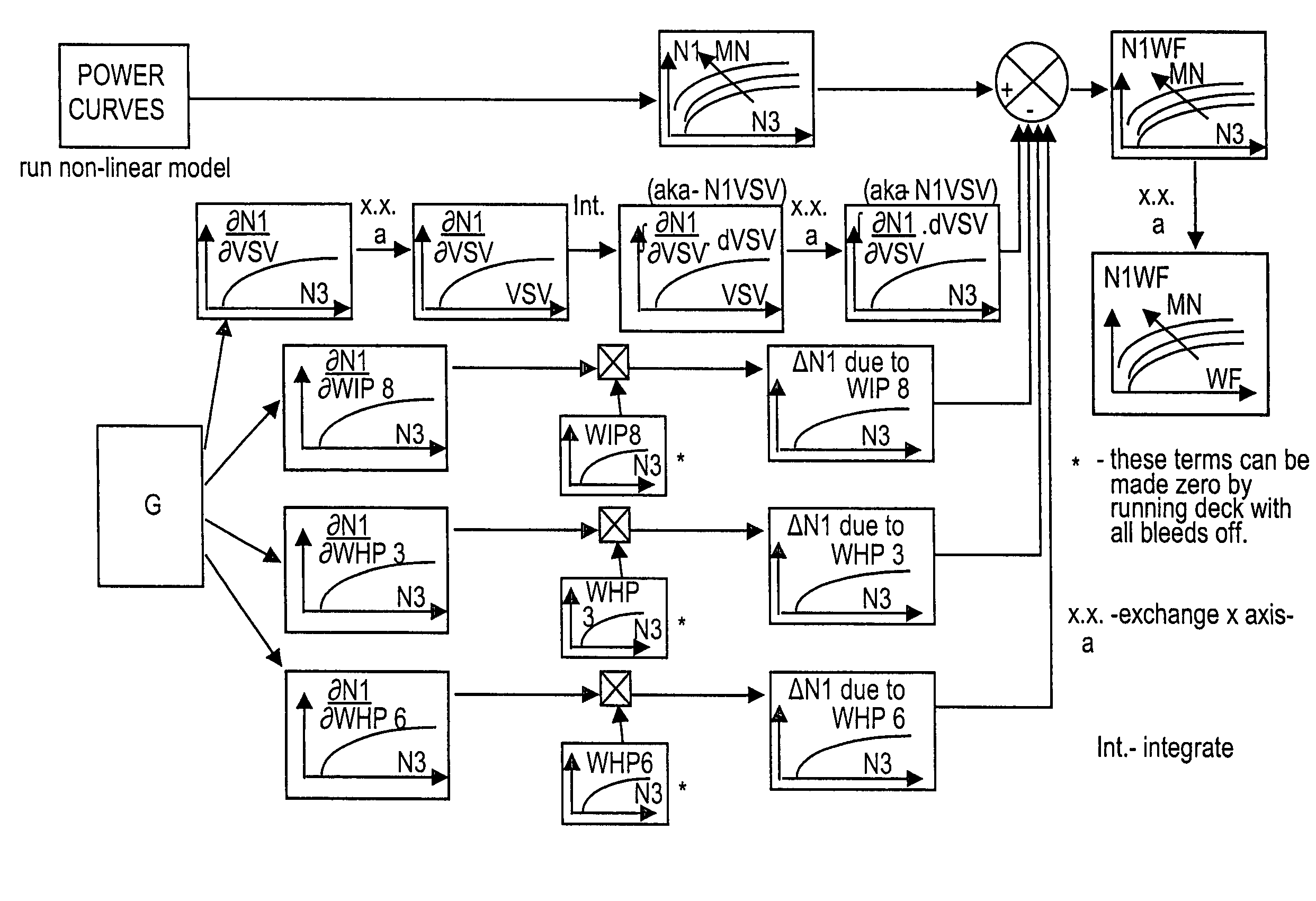

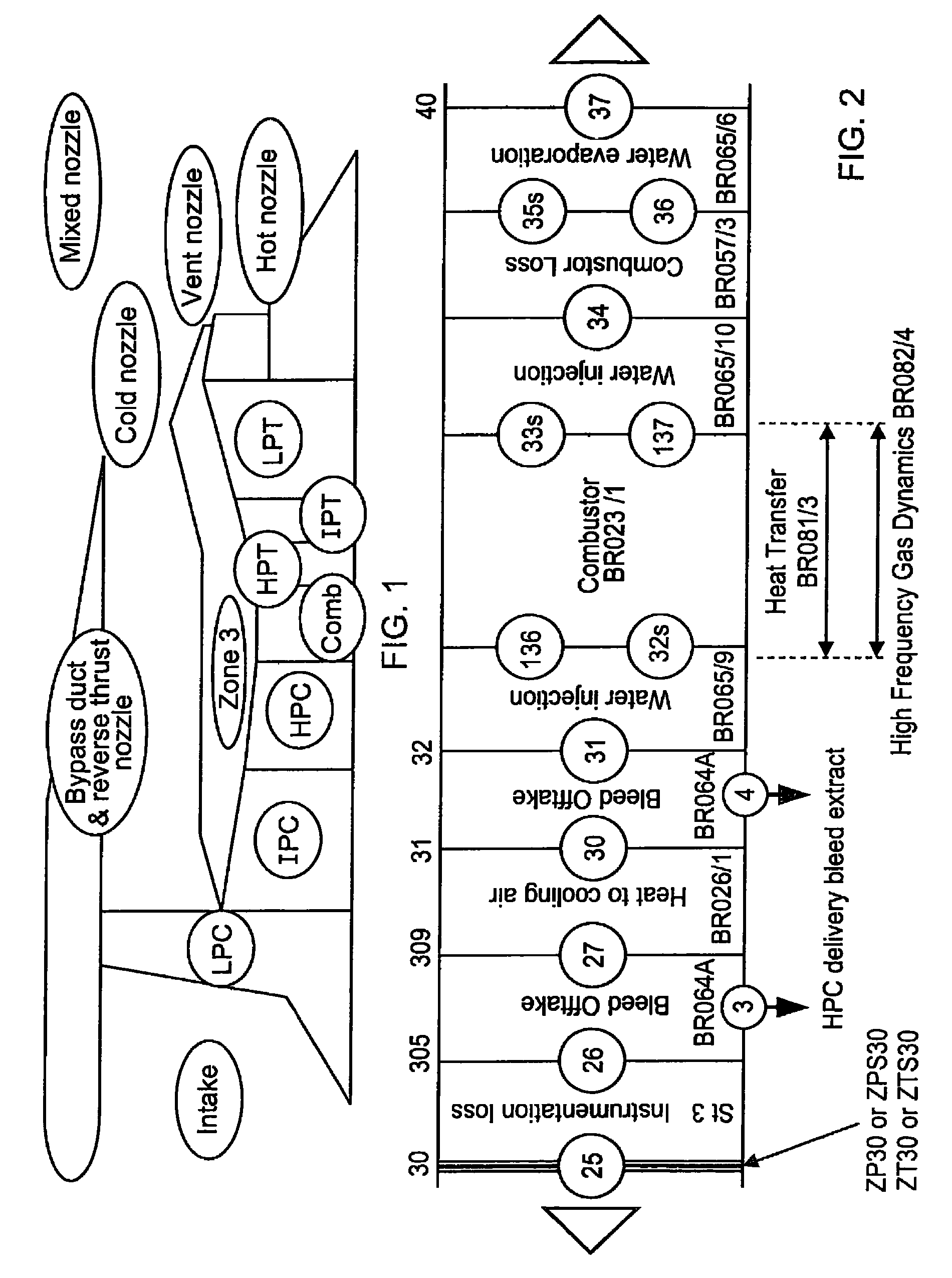

Engine performance model

InactiveUS20090012762A1Improve accuracyAnalogue computers for vehiclesSimulator controlLinear enginePiecewise linearization

A method of constructing a piecewise linear engine performance model, comprises the steps of:(a) providing a non-linear engine performance model which iteratively calculates engine performance variables y from a plurality of sub-models, each sub-model representing the performance of a component of the engine;(b) defining a plurality of engine power conditions, each engine power condition being defined by one or more engine state variables x;(c) for each of the engine power conditions, using the non-linear engine performance model to determine partial derivatives δy of the engine performance variables y with respect to engine control variables u and with respect to the engine state variables x, the values of the partial derivatives δy being determined so that, on integrating the partial derivatives δy, the error between steady state values for the engine performance variables y calculated by the non-linear engine performance model and steady state values for the engine performance variables y calculated from the integrated partial derivatives δy is reduced or eliminated; and(d) constructing a piecewise linearised engine performance model in which calculation of the engine performance variables y involves combining each of the engine control variables u and the engine state variables x with the respective partial derivative δy.

Owner:ROLLS ROYCE PLC

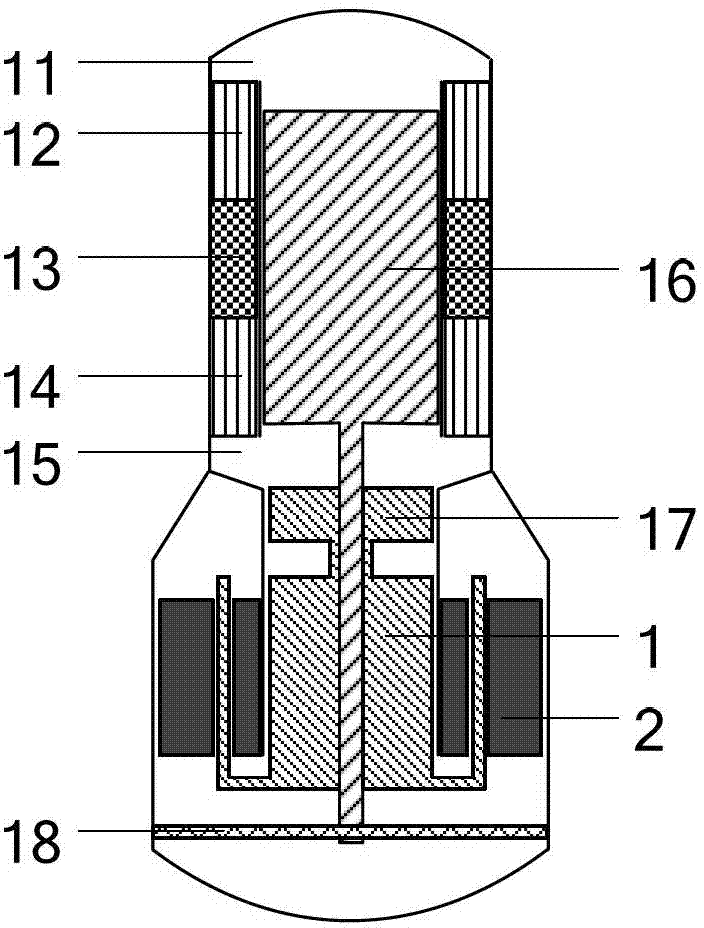

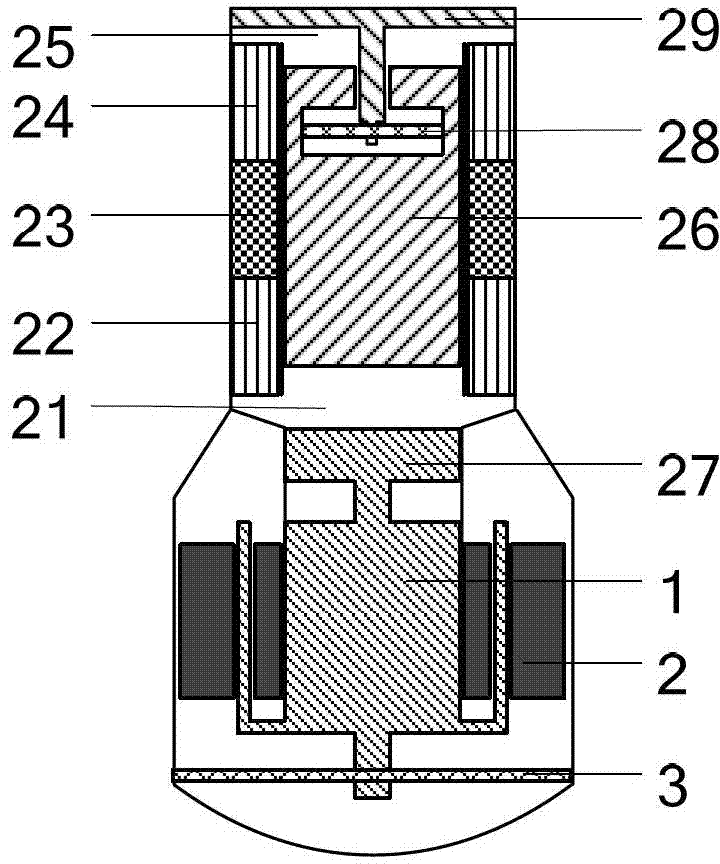

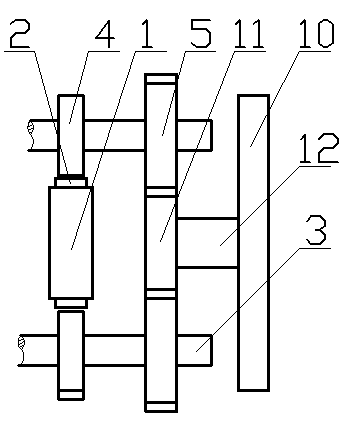

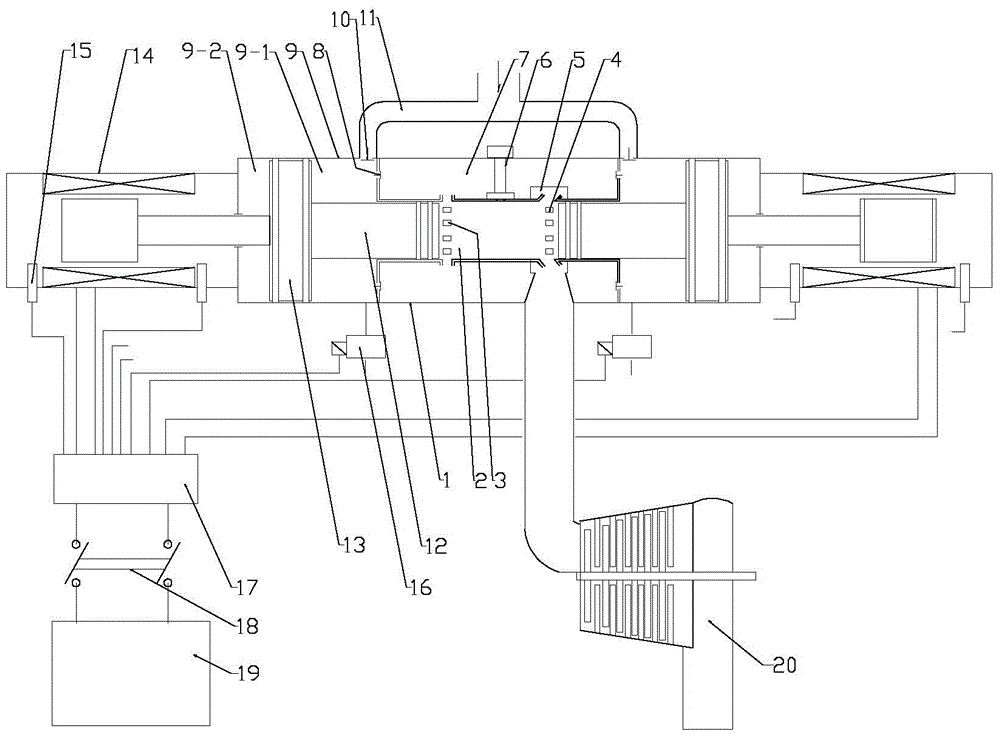

Free piston Stirling engine system utilizing high-low temperature heat sources meanwhile

ActiveCN103114941AAvoid adverse effects caused by sealingLow costHot gas positive displacement engine plantsLinear engineRoom temperature

A free piston Stirling engine system utilizing high-low temperature heat sources meanwhile is composed of a high-temperature heat source free piston Stirling engine, a low-temperature cold source free piston Stirling engine and a linear engine, wherein the high-temperature heat source free piston Stirling engine and the low-temperature cold source free piston Stirling engine drive the linear engine together, a structure and a arrangement method of the high-temperature heat source free piston Stirling engine are the same to that of a traditional free piston Stirling engine, a structure of the low-temperature cold source free piston Stirling engine and the structure of the traditional free piston Stirling engine are reversed, and therefore a power piston is enabled to work room-temperature environment. The free piston Stirling engine system utilizing the high-low temperature heat sources meanwhile utilizes a high-temperature heat source and a low-temperature heat source at the same time and has the advantages of being compacted in structure and low in cost. A high-temperature heat exchanger and a low-temperature heat exchanger are both arranged at the side far from the power piston, the power piston works at the room temperature, the temperature is prevented from having bad effect on sealing of the power piston, and high-efficient and stable operation of a system are guaranteed.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

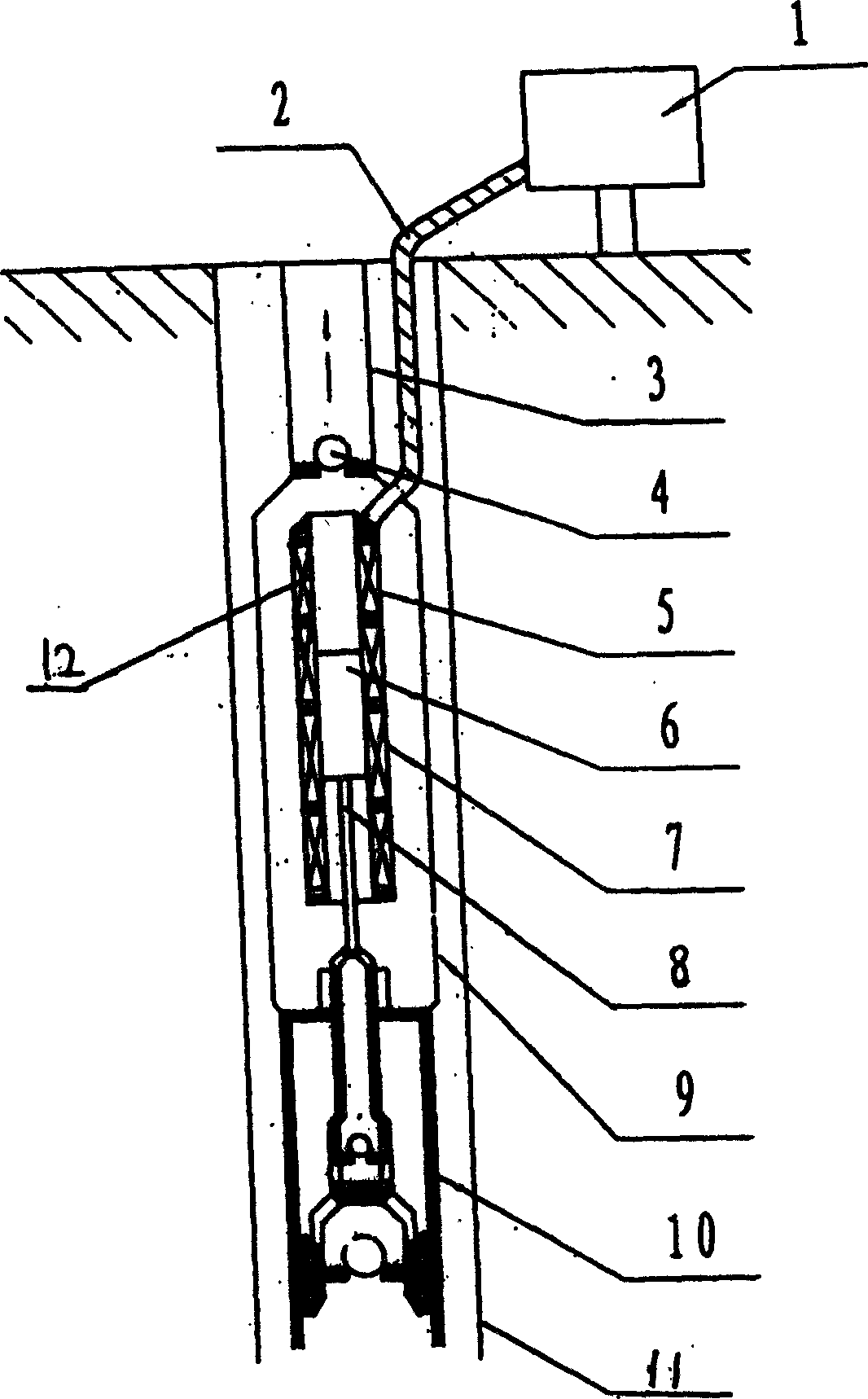

Electrical submersible, permanent-magnet straight reciprocating pump

InactiveCN1563715AReduce volumeReduce weightMagnetic circuit rotating partsPumpsPermanent magnet rotorLinear engine

The apparatus applis the combination of the lanthanon permanent magnet linear engine and plunger-style lanthanon permanent magnet electric pump set. In the sleeve pipe the electric pump and engine are installed, they are connected by the shaft, the permanent magnet rotor and stator coil combine the straight line engine, the engine shell and internal liner tube is sealed, on top of the assistant shell the liquid outlet valve and oil pipe are installed, the engine is connected with the switchboard on the ground.

Owner:王善政

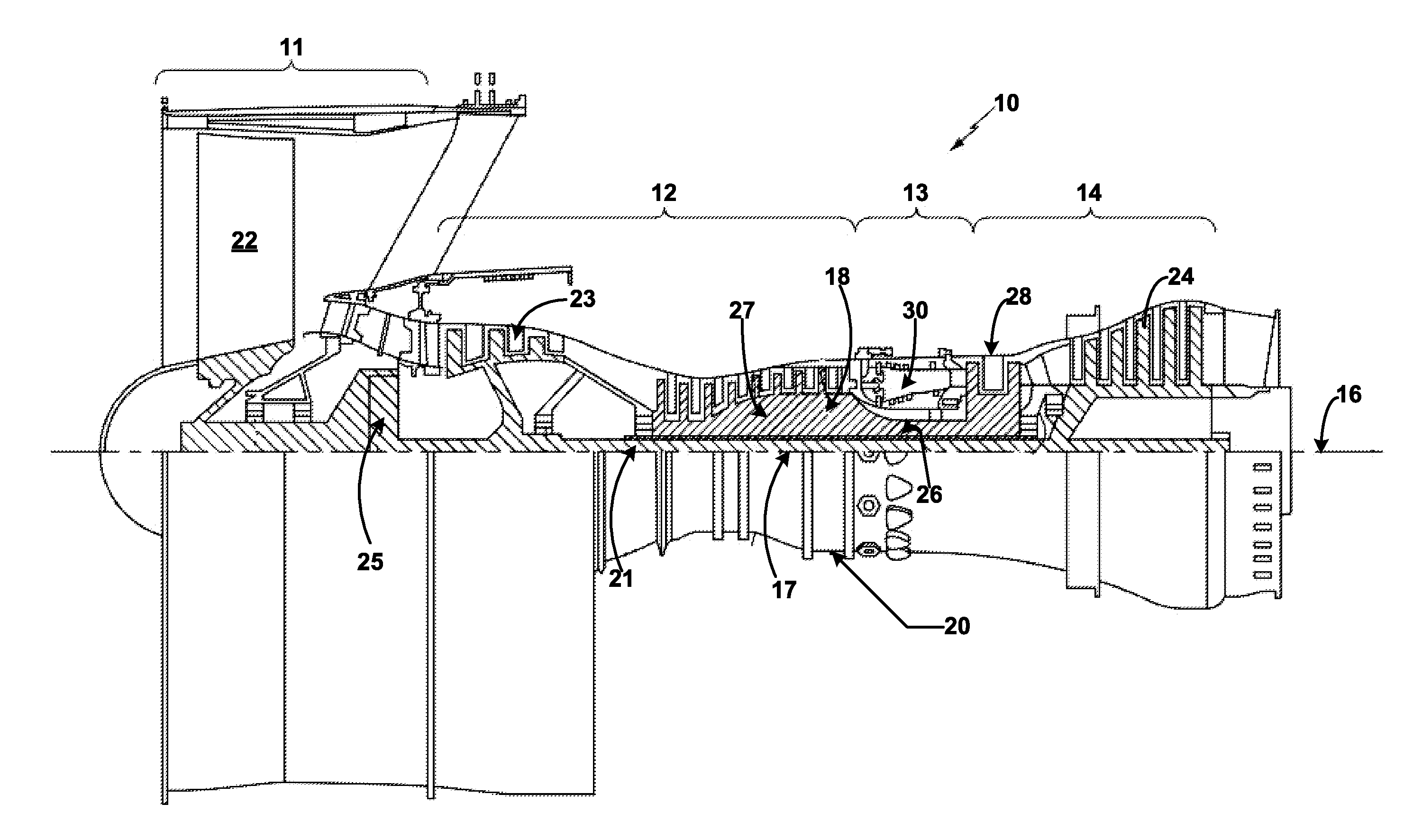

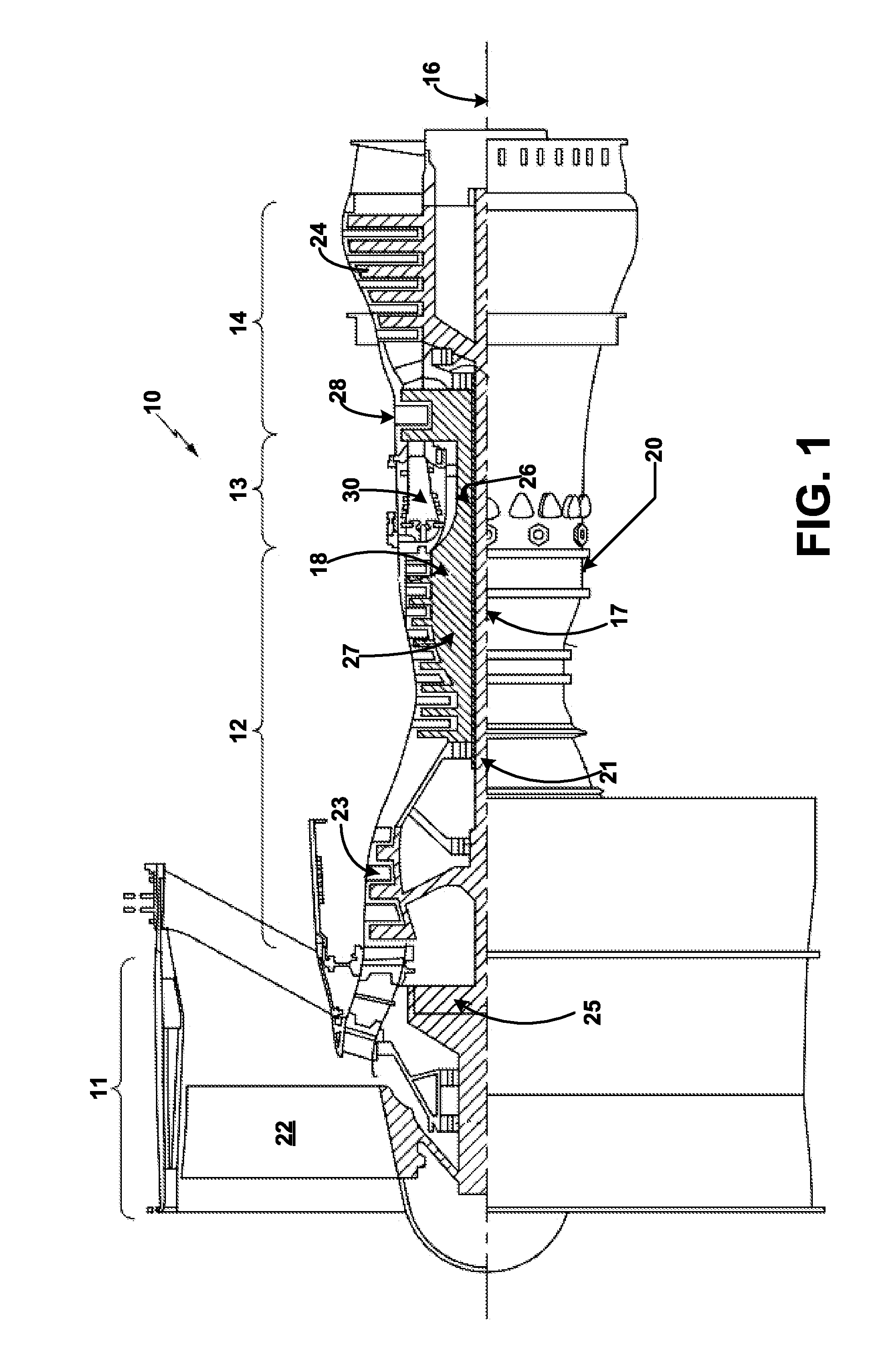

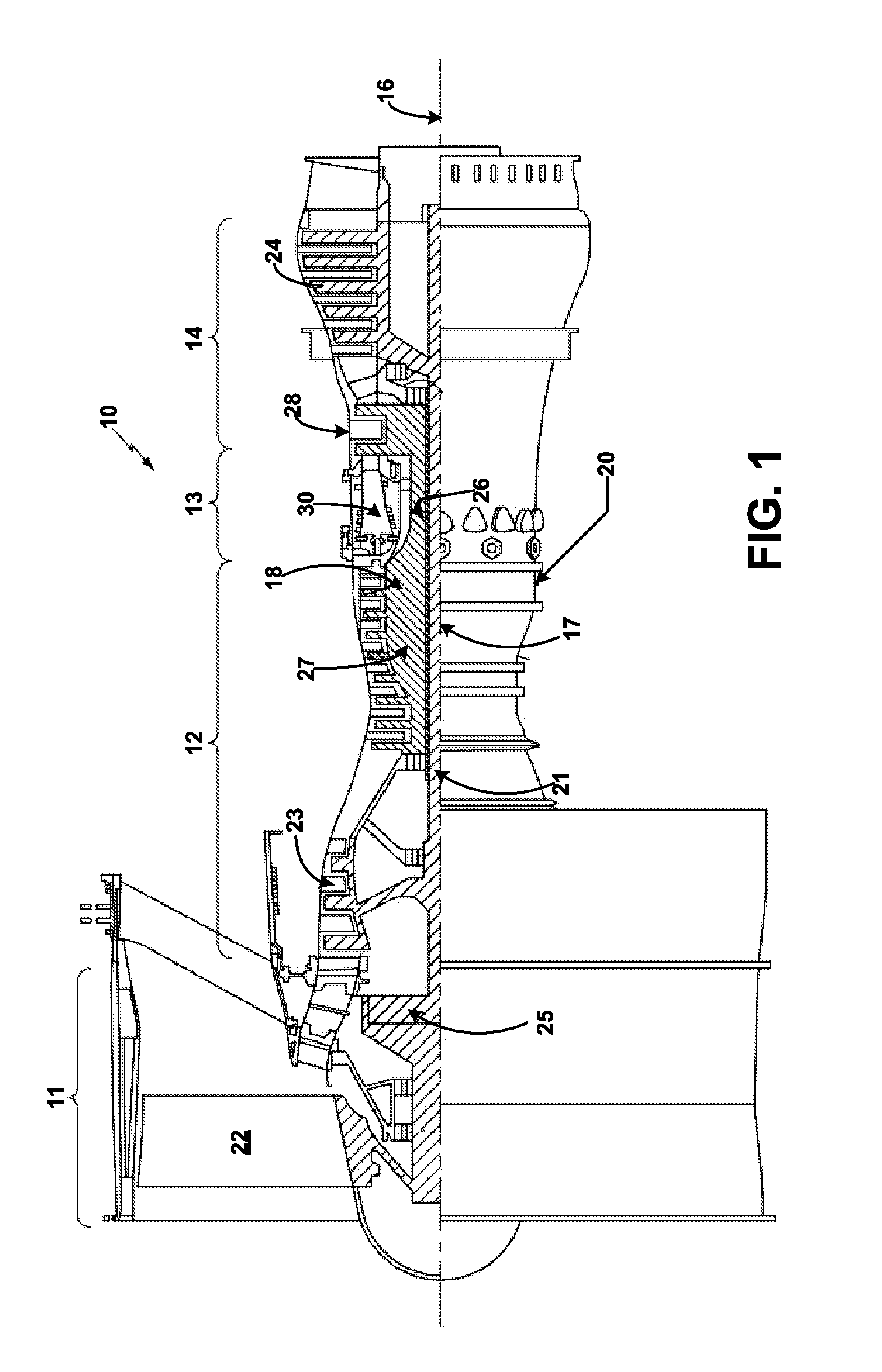

Model-Based Optimal Control For Stall Margin Limit Protection in an Aircraft Engine

A control system for a gas turbine engine, a method for controlling a gas turbine engine, and a gas turbine engine are disclosed. The control system may include a hybrid model predictive control (HMPC) module, the HMPC module receiving power goals and operability limits and determining a multi-variable control command for the gas turbine engine, the multi-variable control command determined using the power goals, the operability limits, actuator goals, sensor signals, and synthesis signals. The control system may further include system sensors for determining the sensor signals and a non-linear engine model for estimating corrected speed signals and synthesis signals using the sensor signals, the synthesis signals including an estimated stall margin remaining. The control system may further include a goal generation module for determining actuator goals for the HMPC module using the corrected speed signals and an actuator for controlling the gas turbine engine based on the multivariable control command.

Owner:RTX CORP

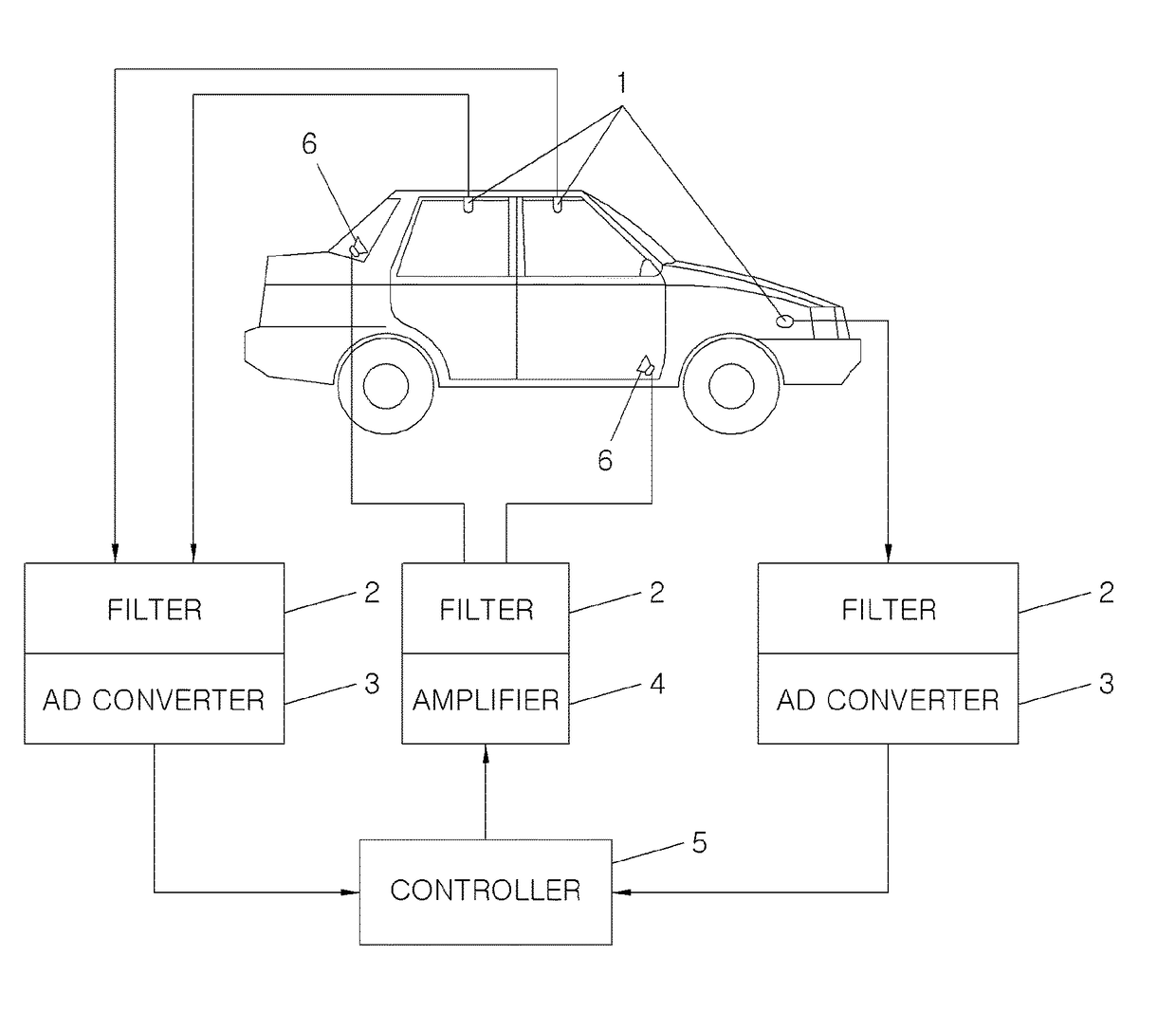

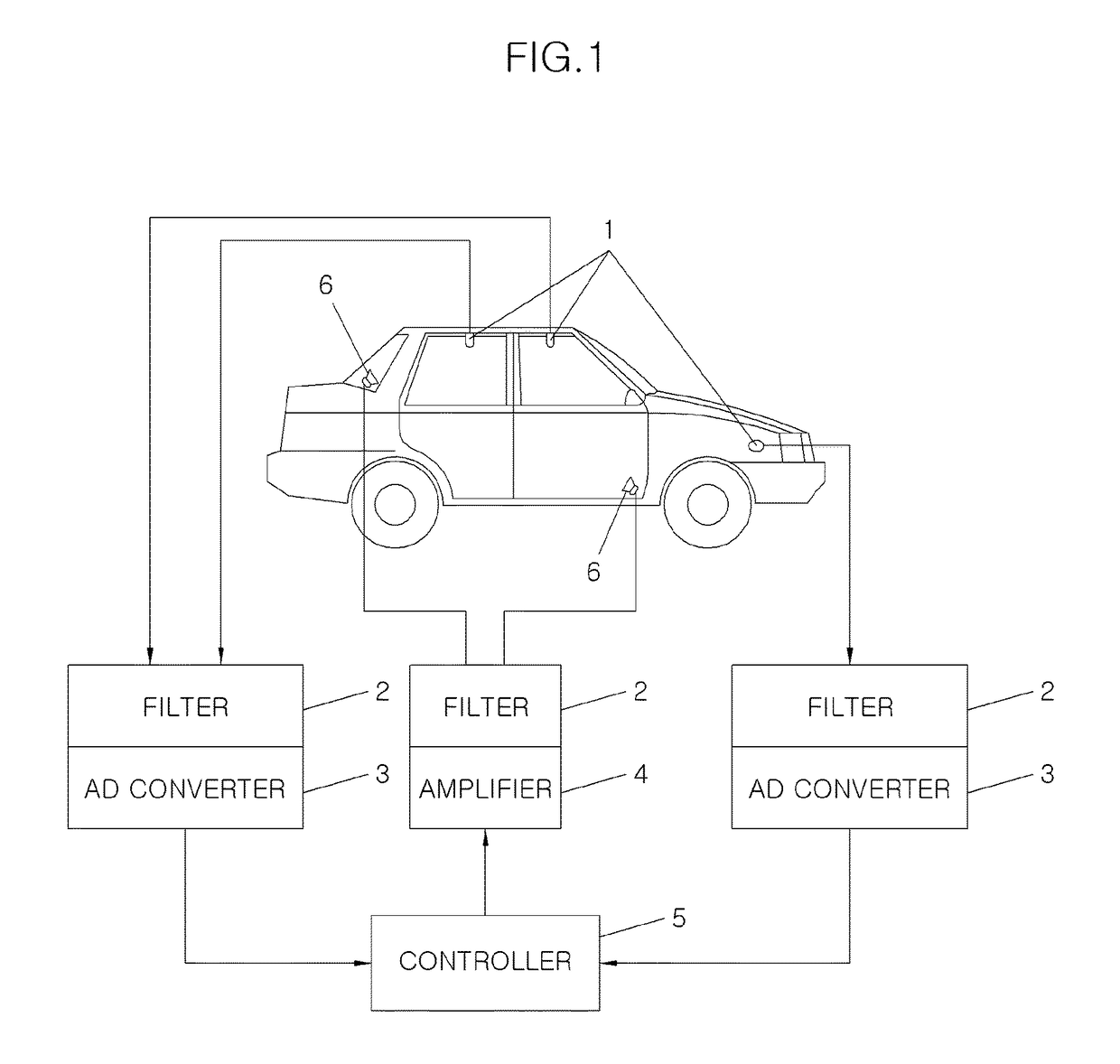

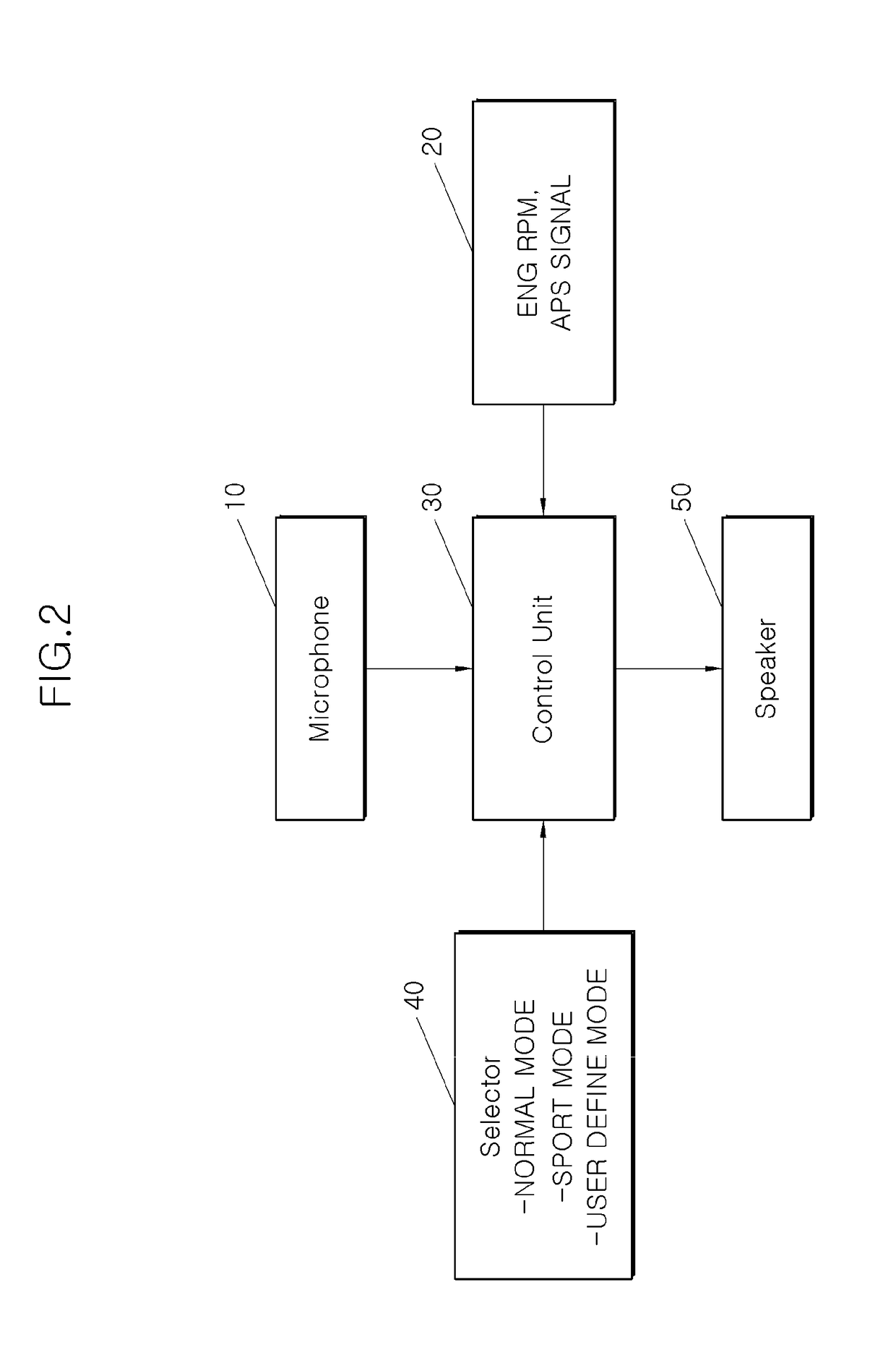

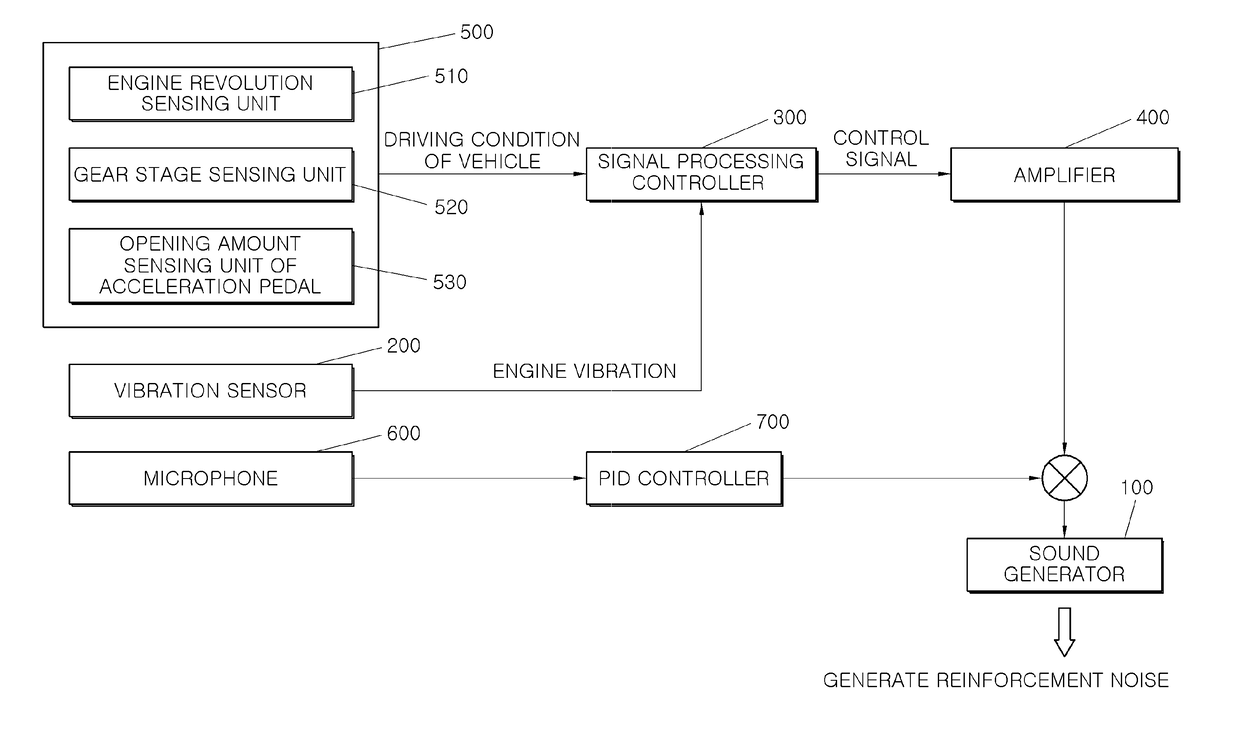

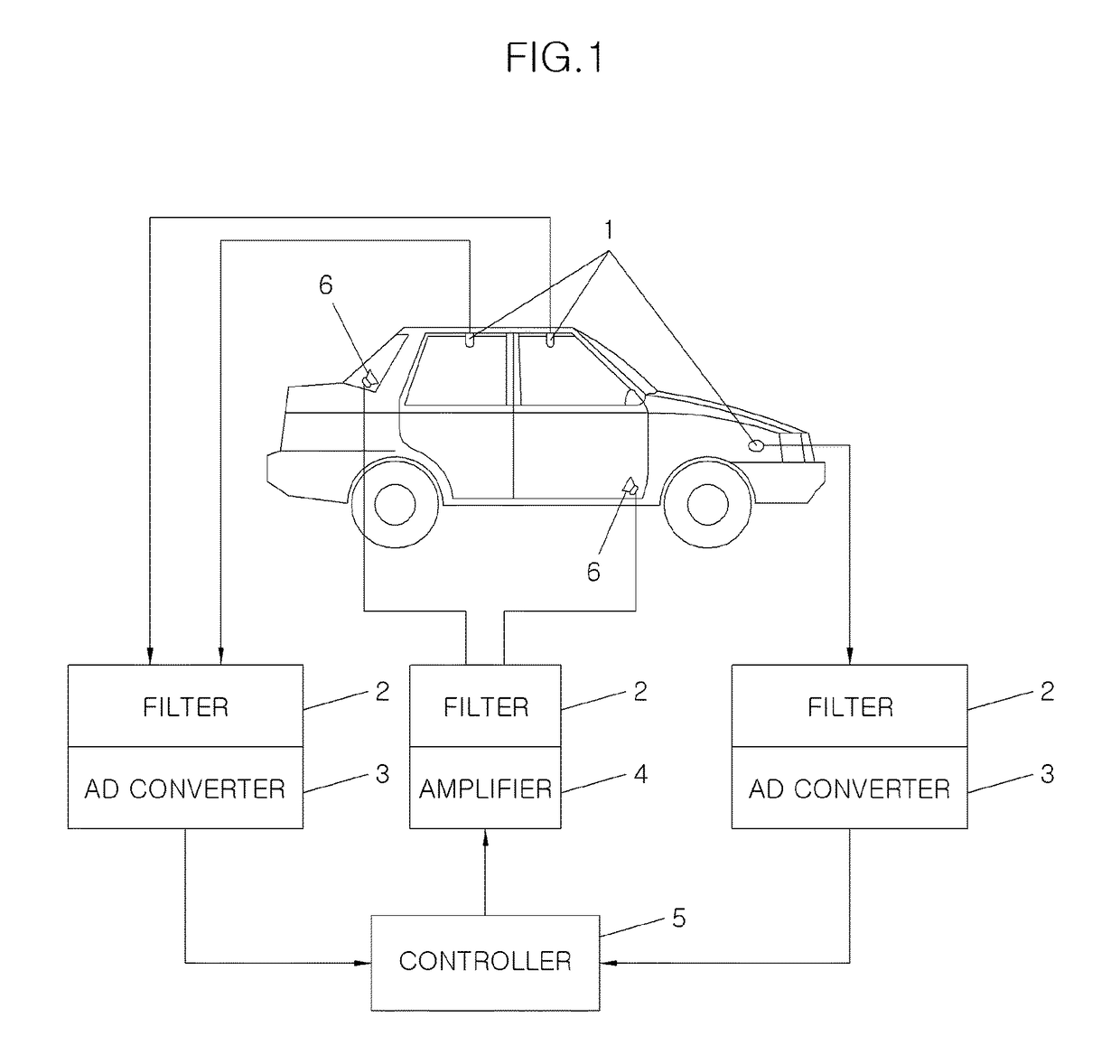

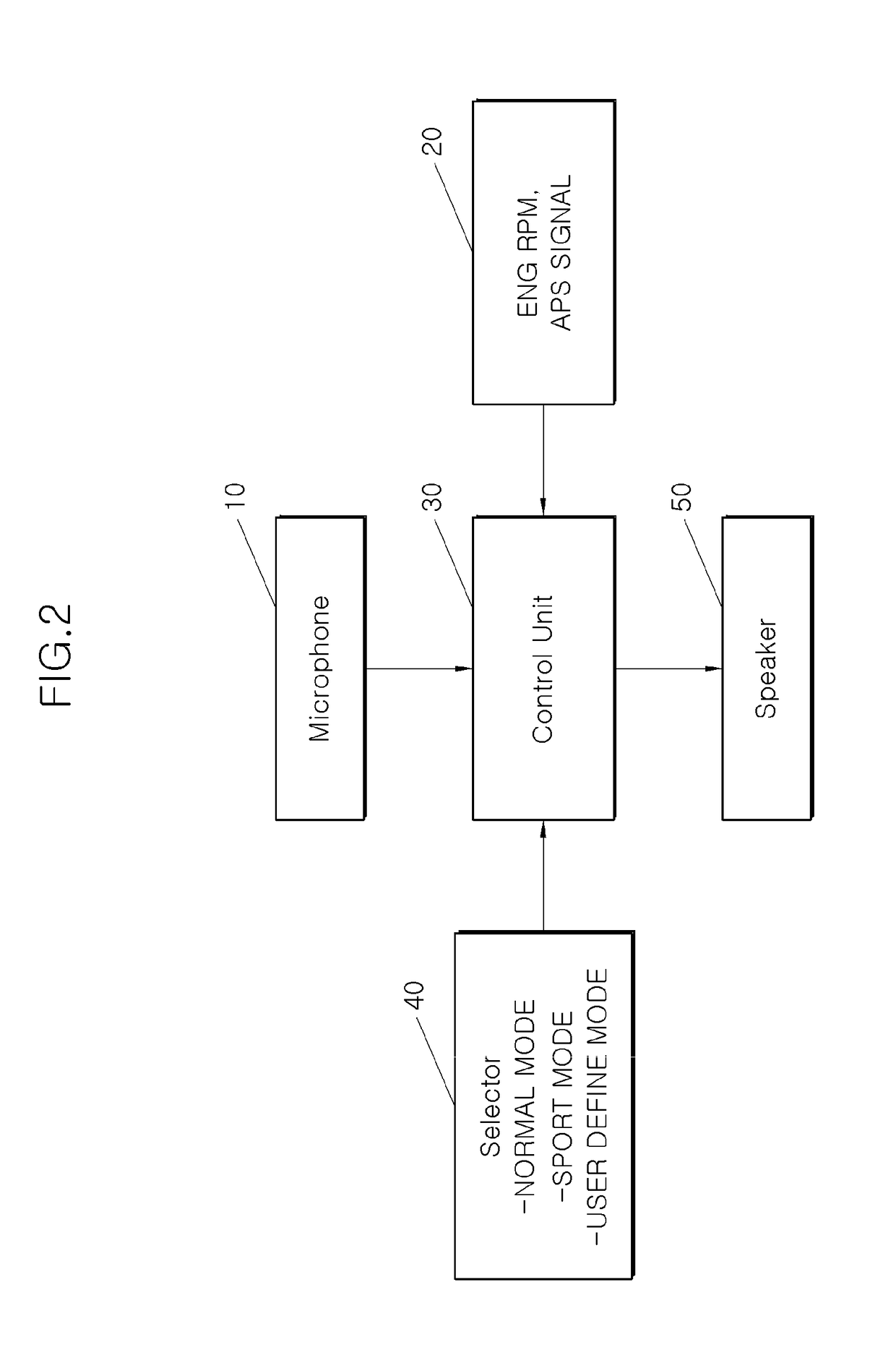

Apparatus for controlling engine noise reflecting engine vibration and driving conditions

ActiveUS20170330550A1Keep linearDetection characteristicElectrical controlMachines/enginesAudio power amplifierLinear engine

An apparatus for controlling engine noise reflecting engine vibration and driving conditions includes a sound generator that generates reinforcement noise in order to reinforce non-linear engine noise. The apparatus includes a vibration sensor measuring engine vibration as a noise source of the engine, a signal processing controller receiving the signal of the vibration sensor in real time and controlling the sound generator so that the engine noise may maintain linearity, and an amplifier receiving and then amplifying a control signal of the signal processing controller to transfer the amplified control signal to the sound generator.

Owner:HYUNDAI MOTOR CO LTD +1

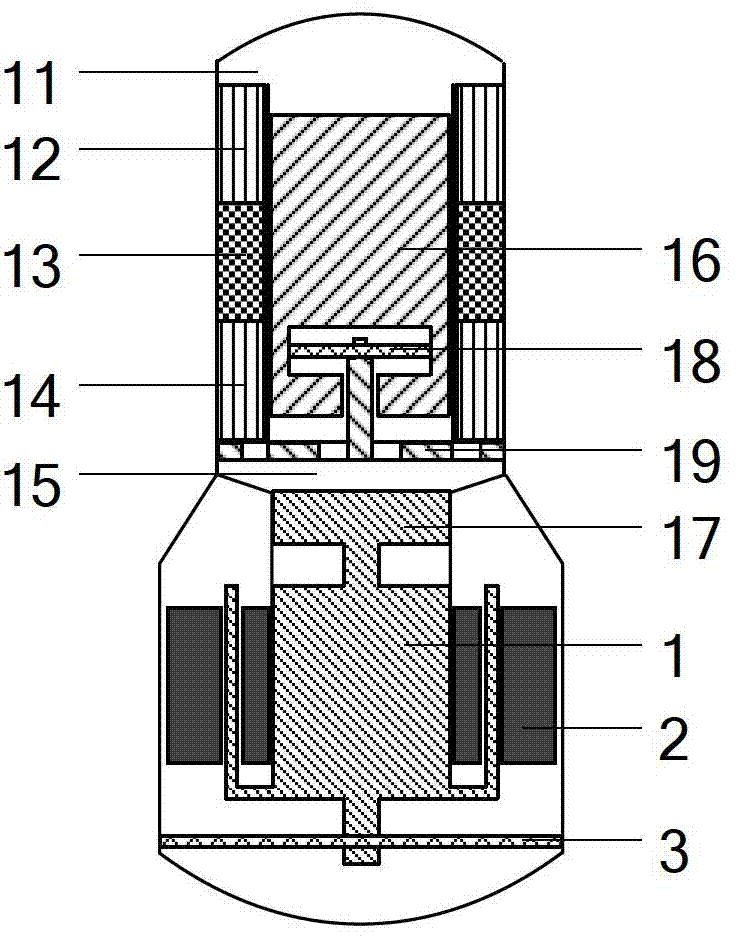

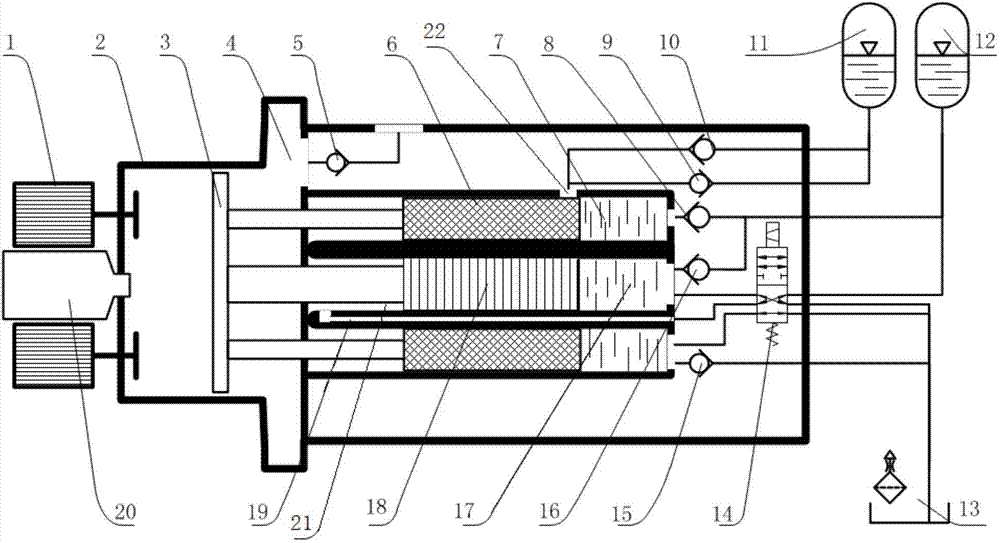

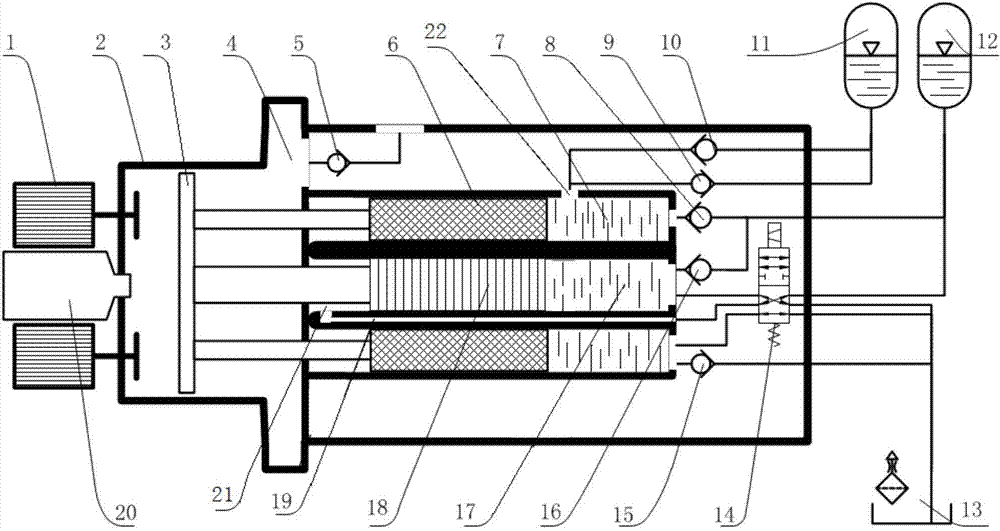

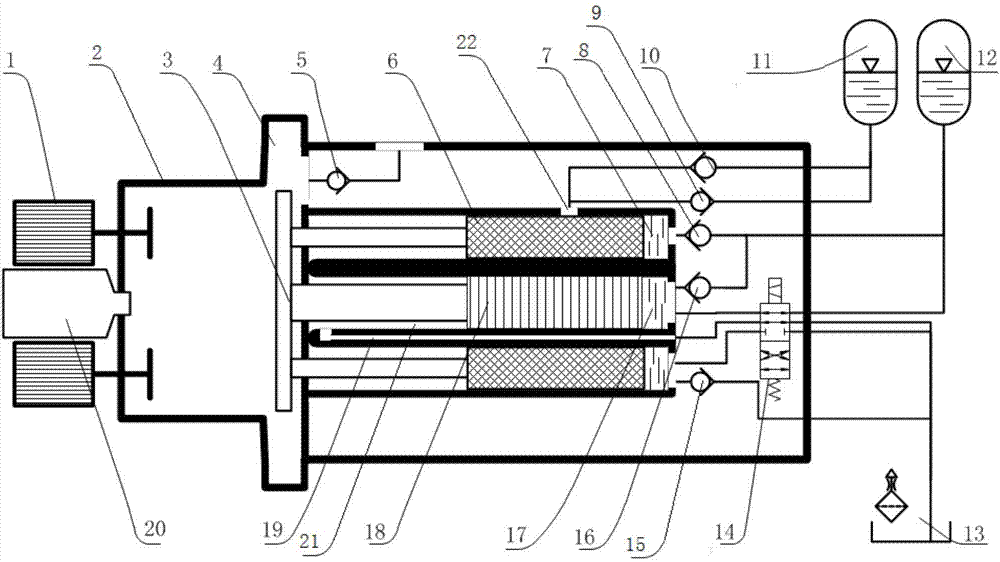

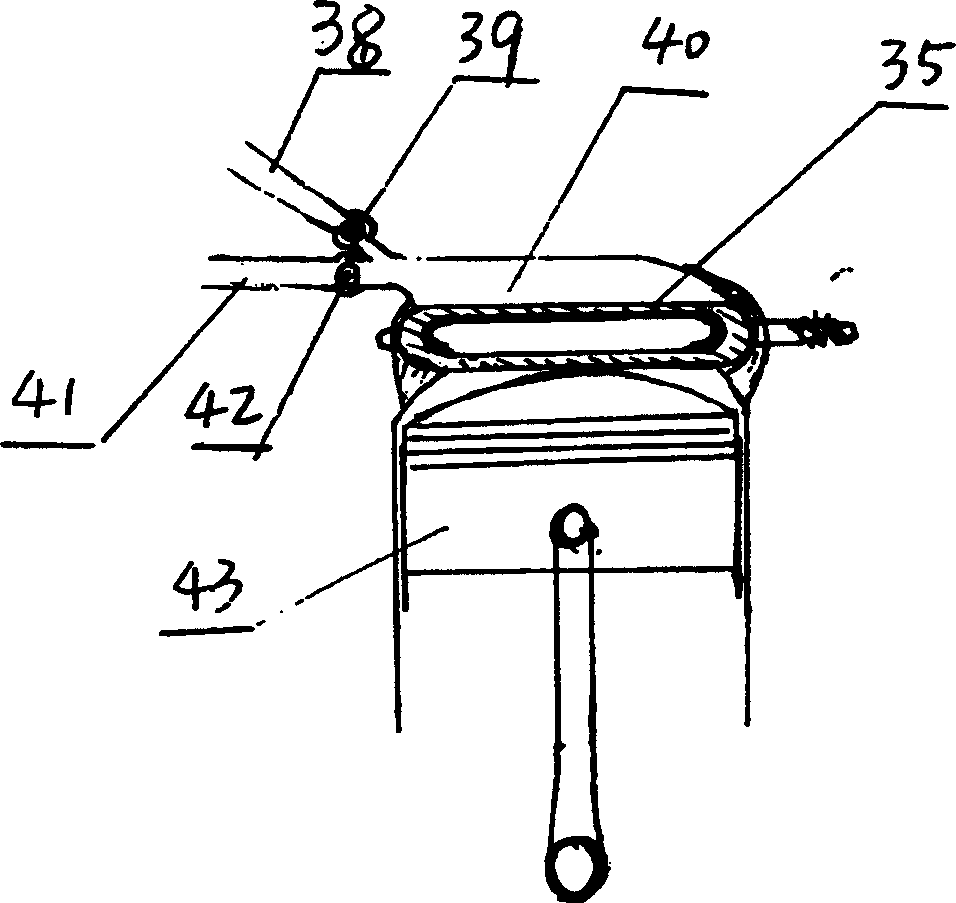

Self-priming hydraulic free-piston linear engine

ActiveCN104763525AImprove efficiencyImprove reliabilityFree piston enginesInternal combustion engineHigh pressure

The invention discloses a self-priming hydraulic free-piston linear engine. Pressure difference produced by a piston moving at high speed can be utilized to suck oil into a pump cavity, an independent oil supply pump can be omitted, accordingly energy loss is reduced, and the efficiency of the engine is improved. The linear engine comprises an internal combustion engine portion and a hydraulic portion, wherein the internal combustion engine portion applies a working principle of a two-stroke diesel engine and adopts a uniflow scavenging mode. The hydraulic portion provides energy for a compression stroke and meanwhile stores energy produced by an acting stroke in energy accumulators. The self-priming hydraulic free-piston linear engine comprises an air cylinder body, a piston module, a scavenging chamber, a low-pressure energy accumulator, a high-pressure energy accumulator, a pressure oil tank, a pneumatic control valve and an oil sprayer. The piston module comprises an air cylinder piston, a pump piston and a compression piston which are fixedly connected together. The piston module performs circulating reciprocating linear motion, and the pump piston suck low-pressure oil through a low-pressure oil way in the compression stroke. In an expansion stroke, the compression piston converts the low-pressure oil into high-pressure oil to complete power output.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

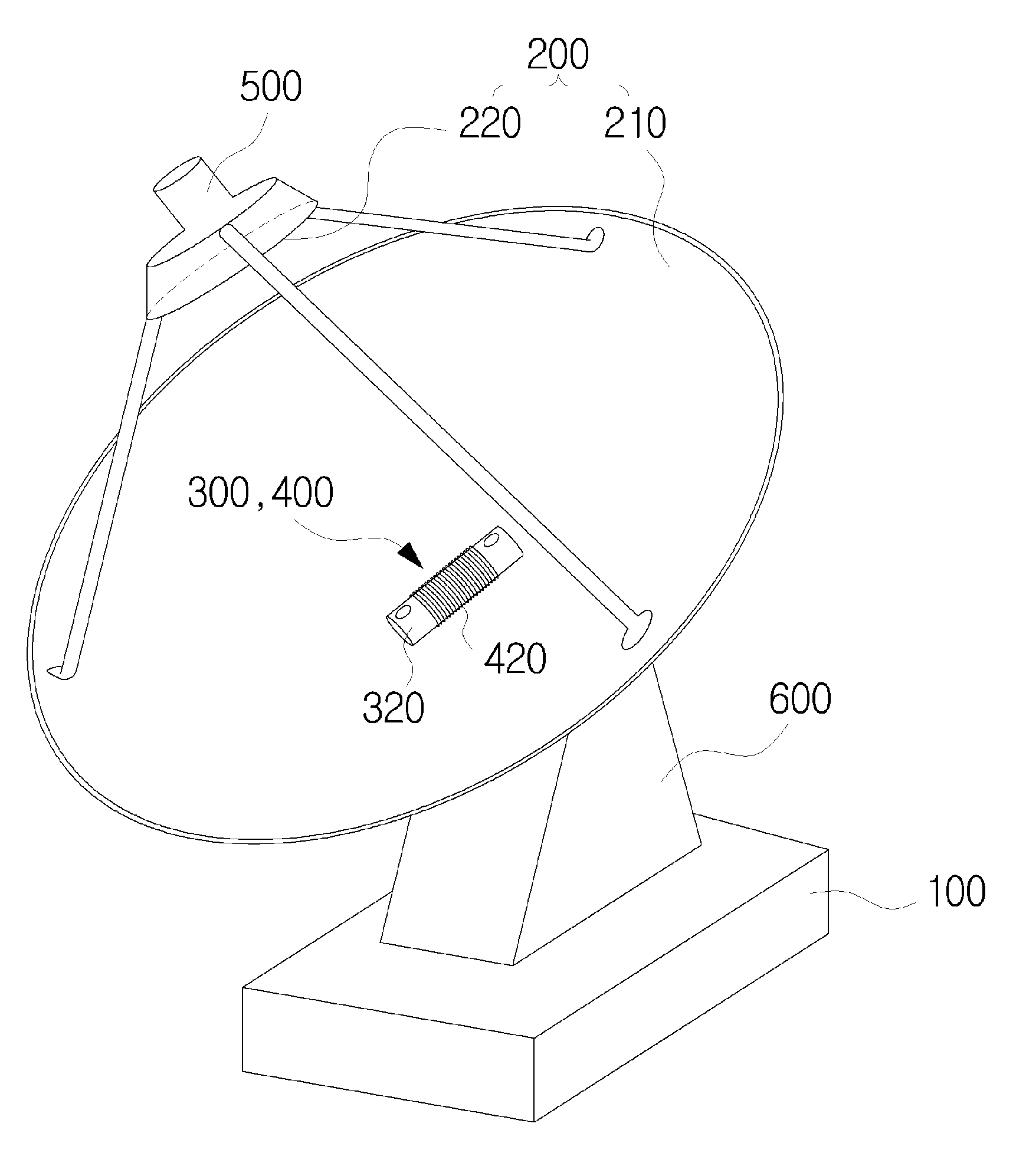

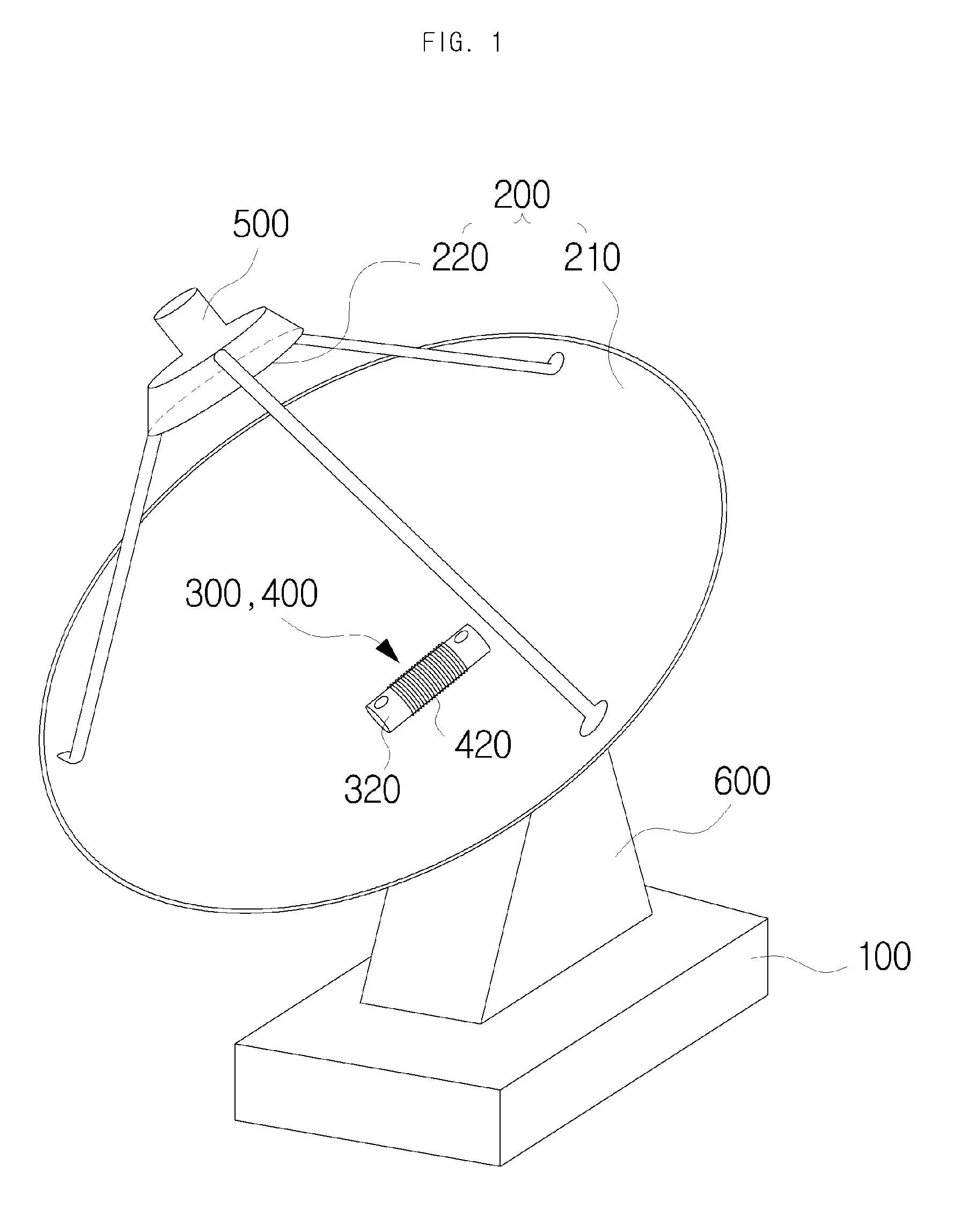

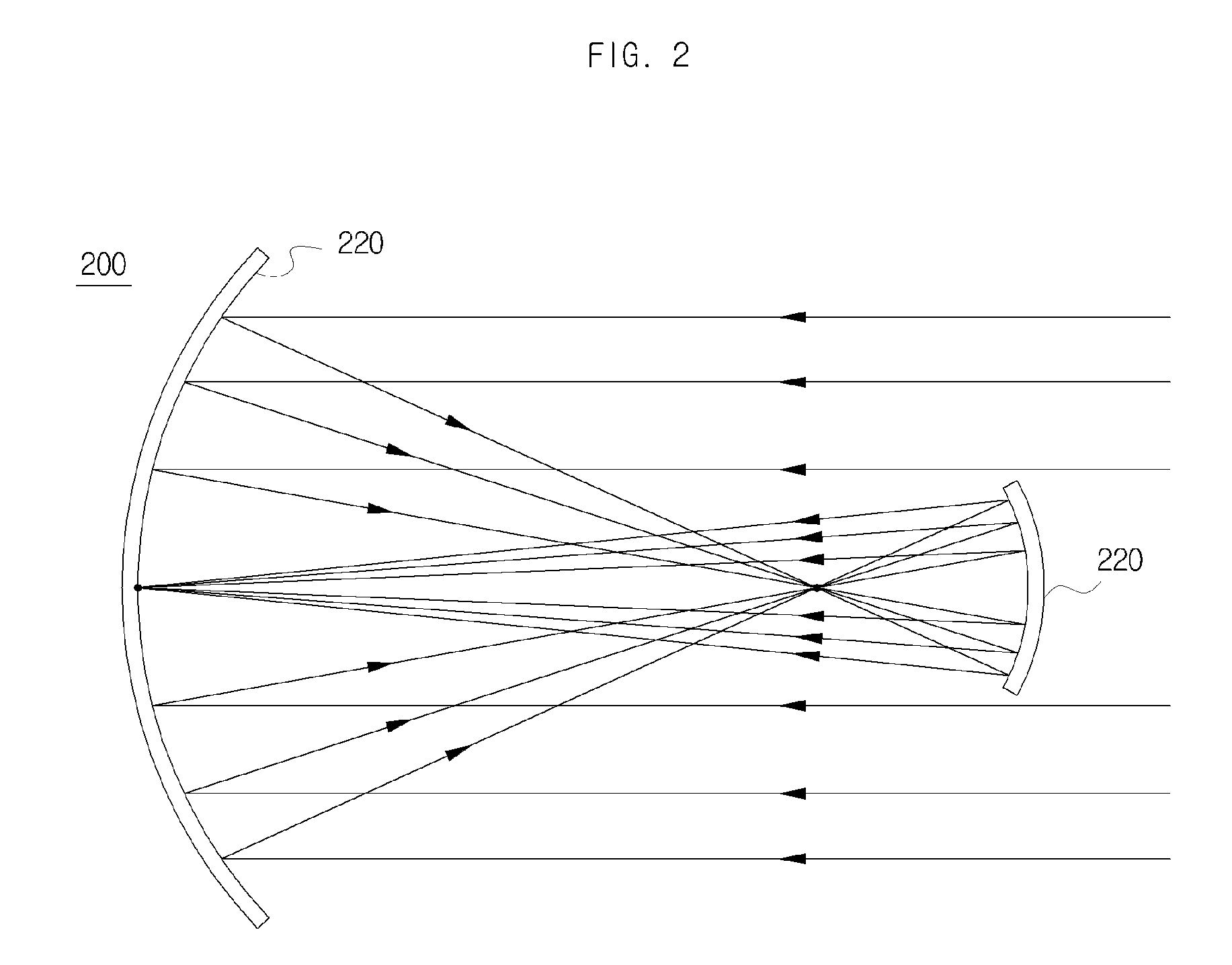

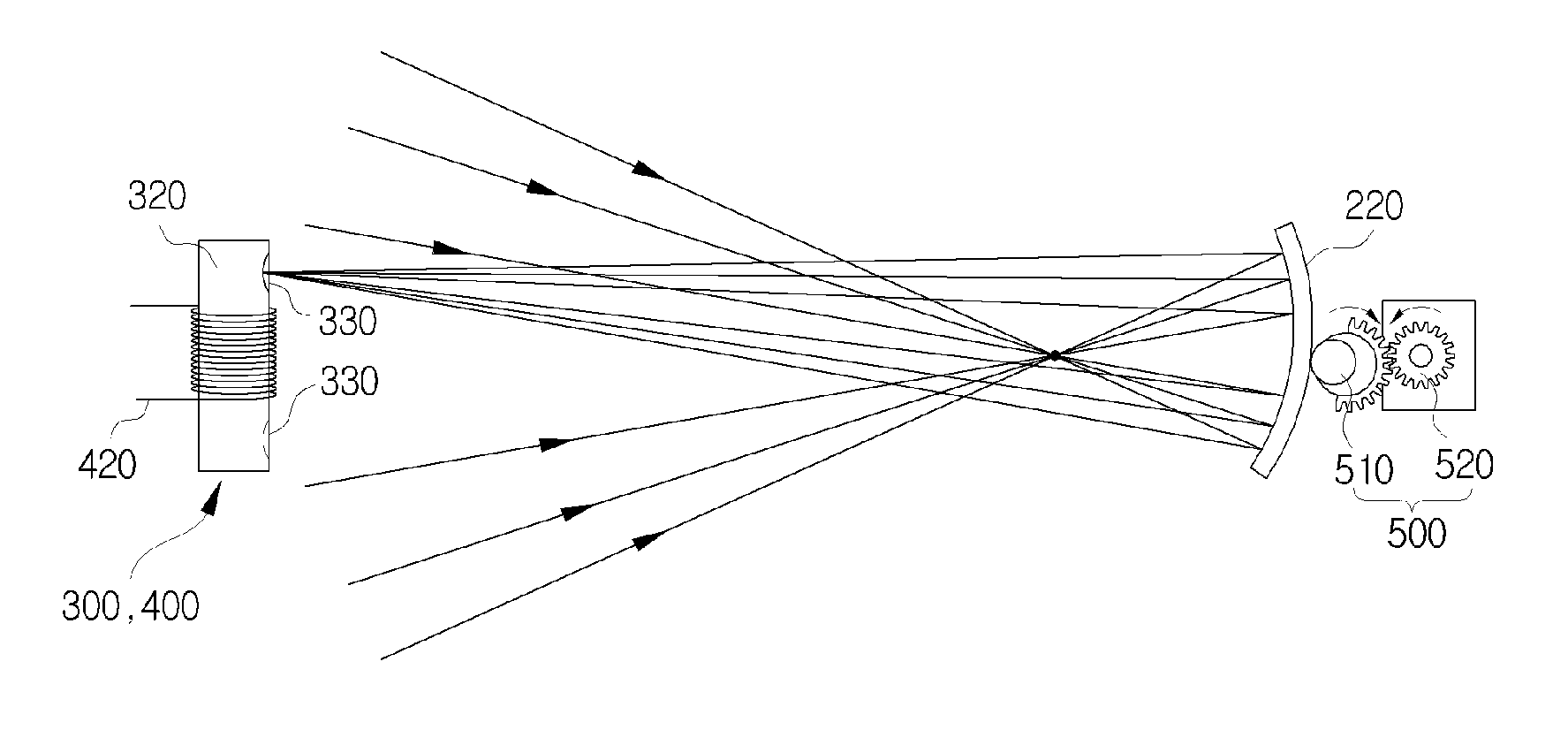

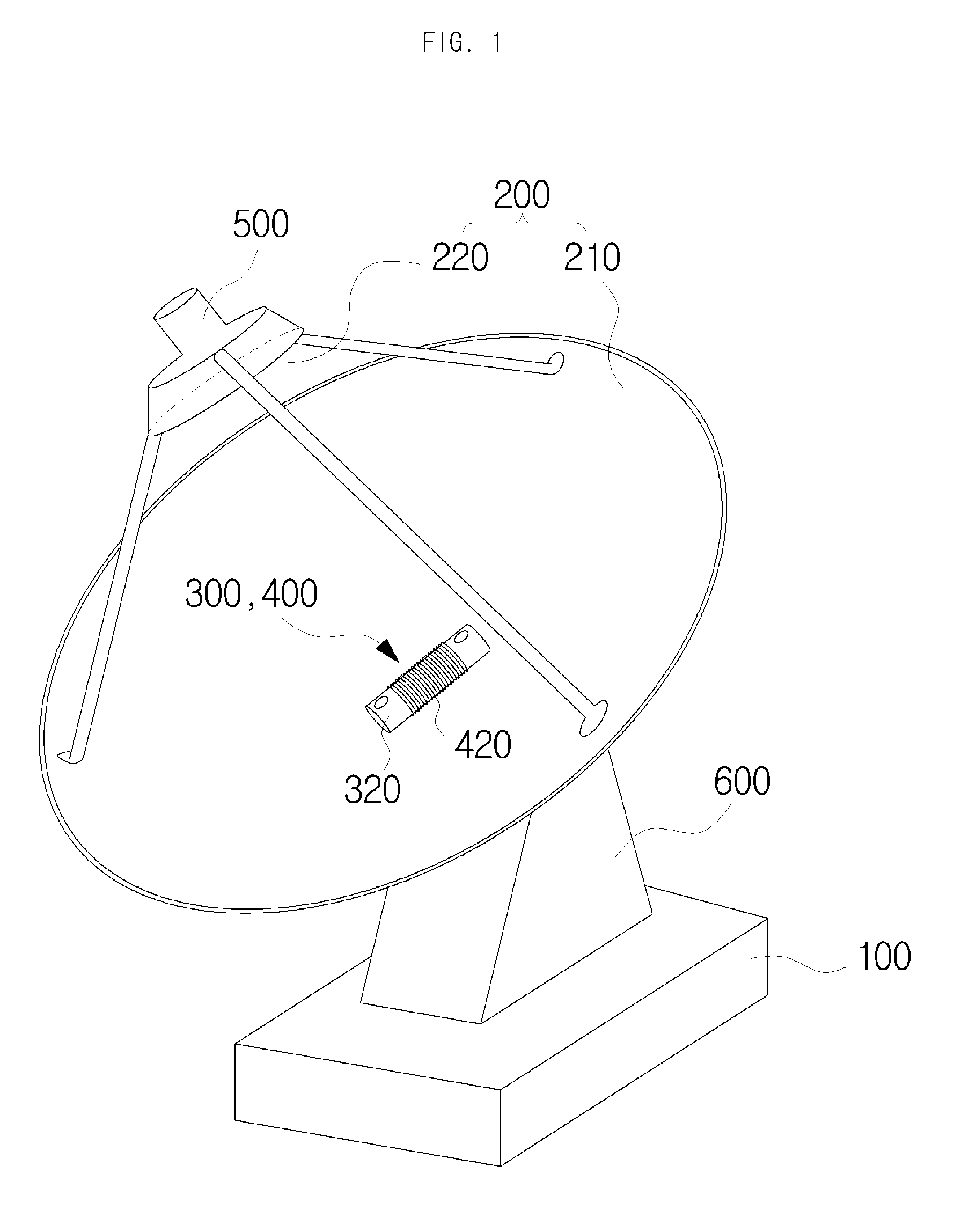

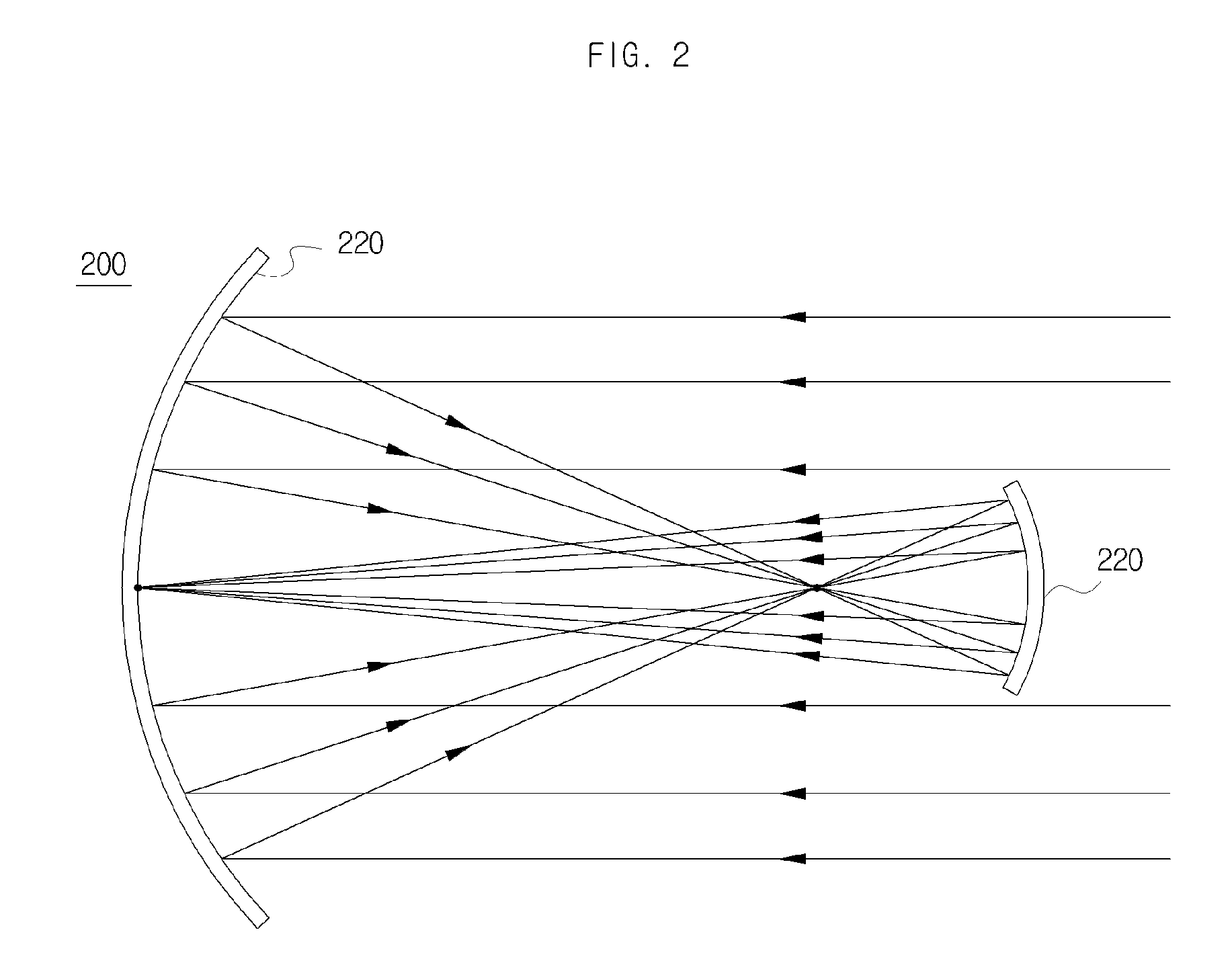

Linear solar heat generating system

InactiveUS20110209476A1Easy to installEasy maintenanceSolar heating energyFrom solar energyLinear engineEngineering

An eco-friendly linear solar heat generating system may employ a linear engine with a simple structure using solar heat is employed in place of a conventional Stirling engine with a complicated structure. Magnets and a coil are arranged in a piston and a cylinder, respectively, to thereby generate power in a highly efficient matter, improve installation stability, and enable easy maintenance and repair.

Owner:CHAE SOO JOH

Model-based optimal control for stall margin limit protection in an aircraft engine

A control system for a gas turbine engine, a method for controlling a gas turbine engine, and a gas turbine engine are disclosed. The control system may include a hybrid model predictive control (HMPC) module, the HMPC module receiving power goals and operability limits and determining a multi-variable control command for the gas turbine engine, the multi-variable control command determined using the power goals, the operability limits, actuator goals, sensor signals, and synthesis signals. The control system may further include system sensors for determining the sensor signals and a non-linear engine model for estimating corrected speed signals and synthesis signals using the sensor signals, the synthesis signals including an estimated stall margin remaining. The control system may further include a goal generation module for determining actuator goals for the HMPC module using the corrected speed signals and an actuator for controlling the gas turbine engine based on the multivariable control command.

Owner:RTX CORP

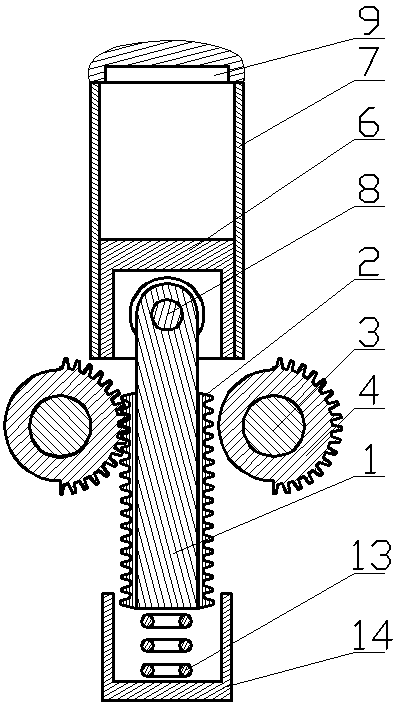

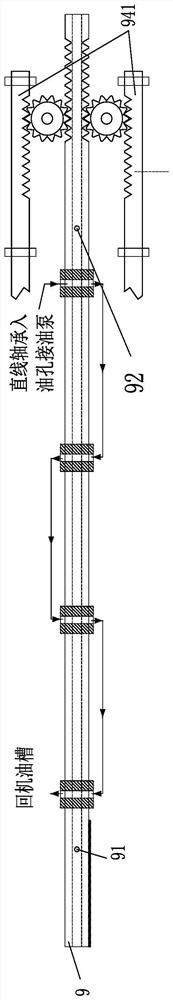

Straight shank linear engine

InactiveCN102996246AReasonable structureIncrease profitMachines/enginesLinear engineExternal combustion engine

The invention discloses a straight shank linear engine. The linear engine comprises a straight shank connecting rod mechanism and a gas distribution mechanism, wherein one end of a connecting rod of the straight shank connecting rod mechanism is connected with a piston via a piston pin; racks are fixed on the connecting rod; when the piston is positioned at a lower dead point, the connecting rod presses a spring on a spring seat; in one engine, two rotating shafts are installed on a cylinder body; the connecting rod passes through semicircular gears on the two rotating shafts; a transmission gear and a semicircular gear are fixed on each rotating shaft; an intermediate gear is meshed with the transmission gears; the semicircular gears can be meshed with or separated from the racks; the intermediate gear is arranged in the cylinder body fixed on an intermediate shaft on the cylinder body; a flywheel is arranged outside the cylinder body; a timing gear is fixed on the intermediate shaft or one of the two rotating shafts; and the movable center line of the piston is vertical to a line connecting the axes of the two rotating shafts. After a straight shank internal combustion engine with reasonable structure, high utilization rate of heat efficiency and strong practicability is adopted, the power of the internal combustion engine is improved and the fuel consumption is reduced.

Owner:CHONGQING SHIZHAN TECH DEV CENT

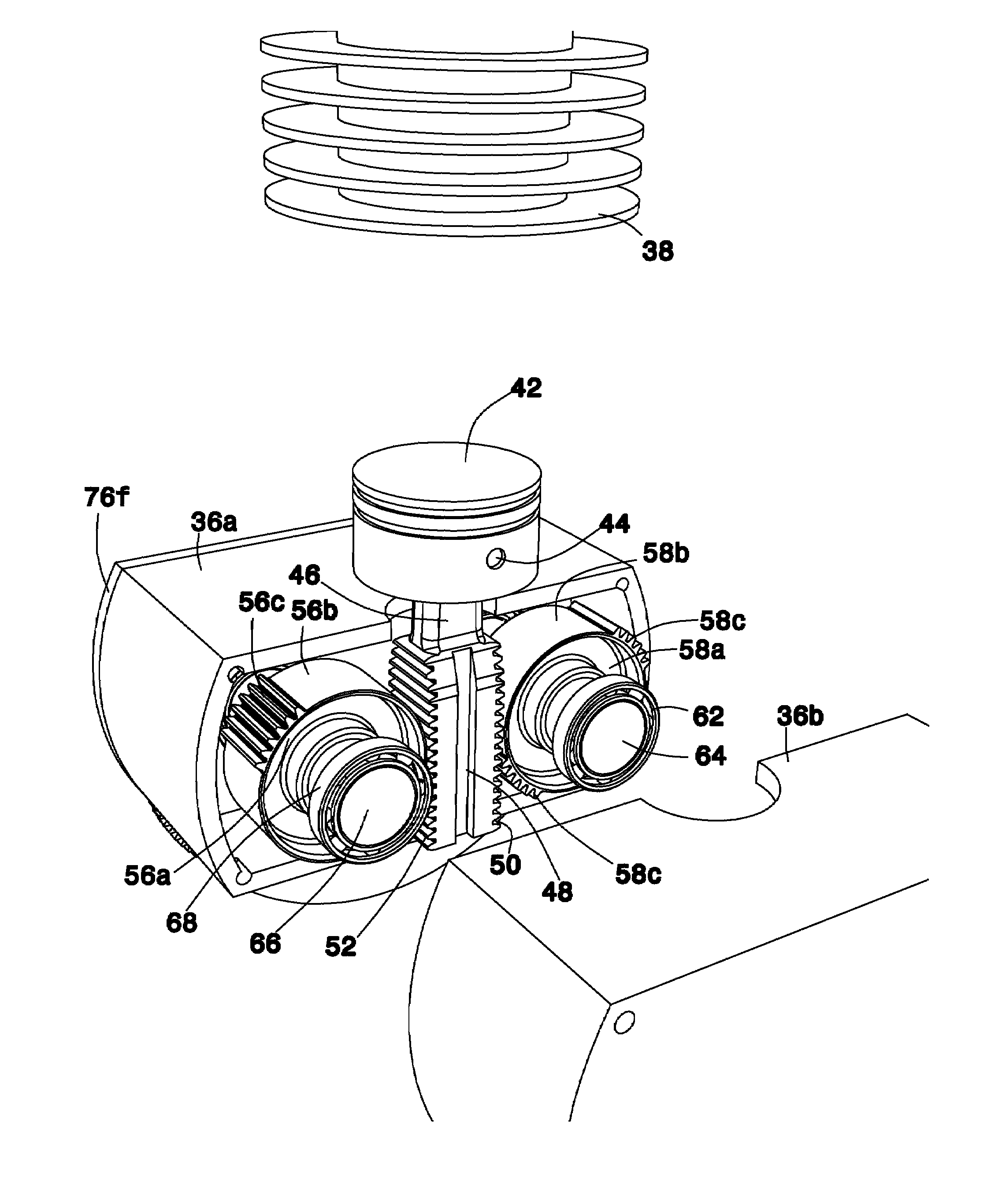

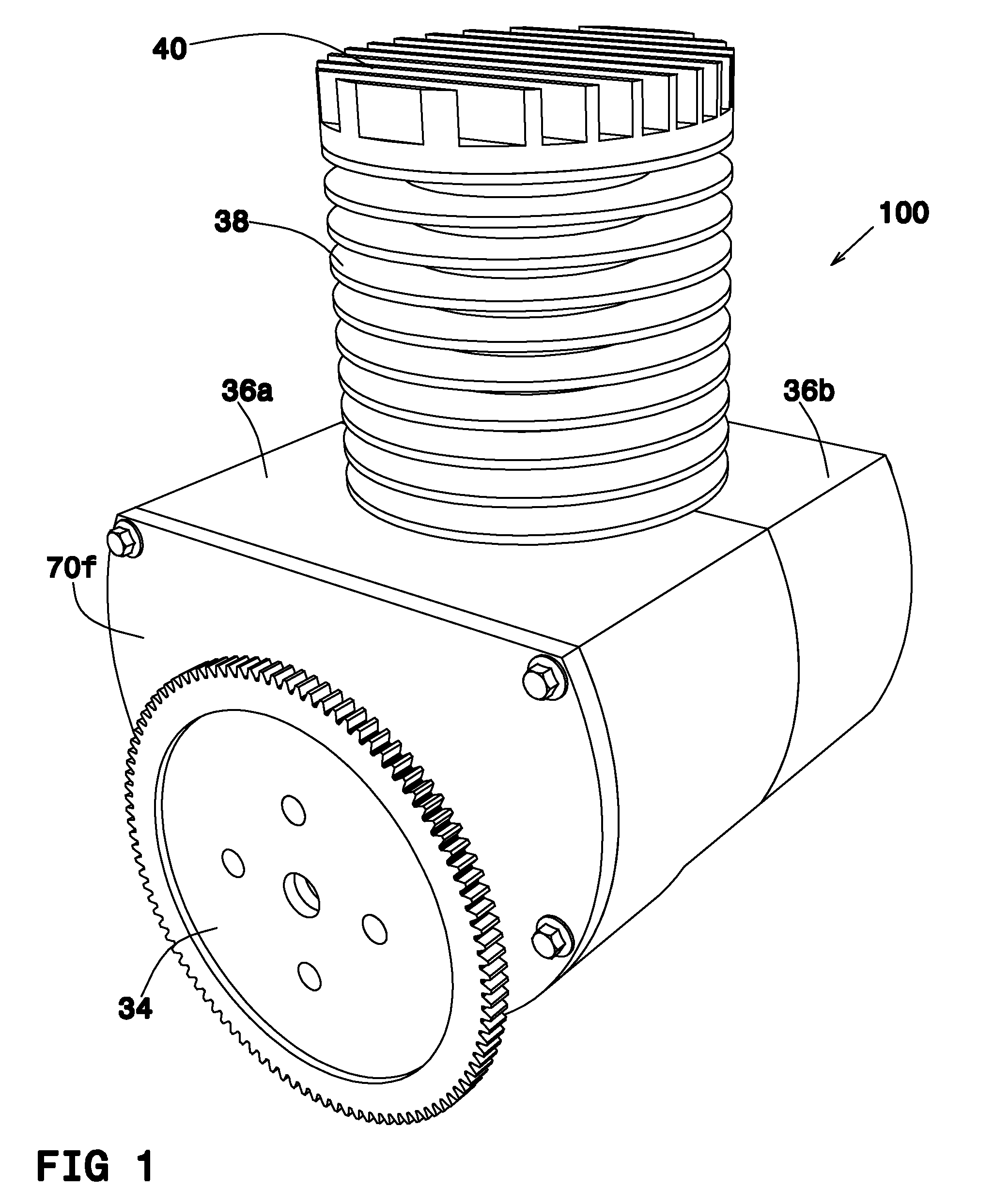

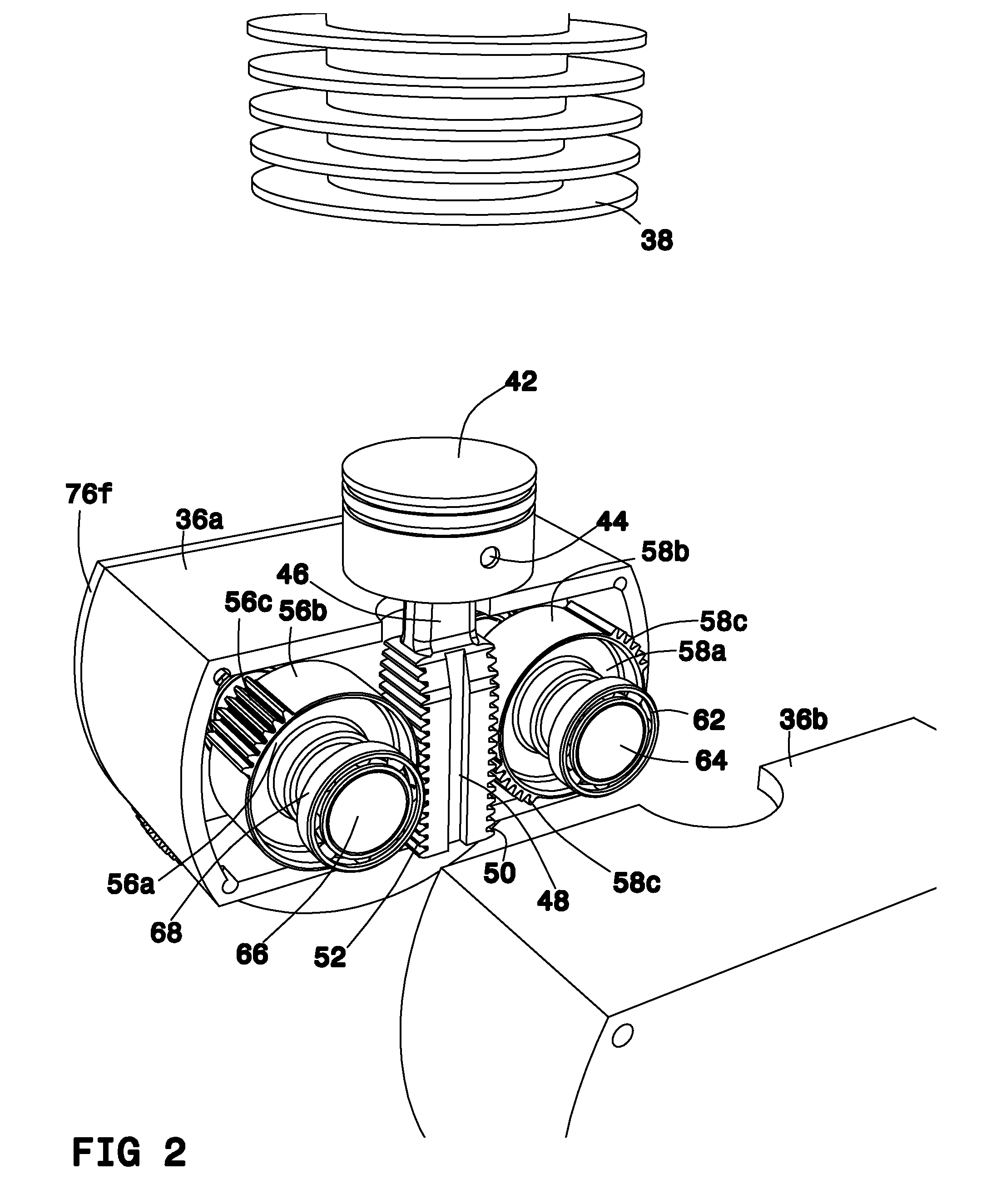

Linear Engine

In one embodiment, the present invention is directed to a linear engine comprising: a piston; a linear piston leg comprising two opposite cogged edges including: lowering cogs and raising cogs; at least one lowering segmental cogwheel, the cogs of which correspond to said cogs of one edge of said linear piston leg; at least one raising segmental cogwheel, the cogs of which correspond to said cogs of one edge of said linear piston leg; and a transmission system connecting said cogwheels to a driveshaft; wherein each of said segmental cogwheels comprising at least two opposite cogged segments and two opposite cogless segments.

Owner:BEN SHABAT MORRIS +1

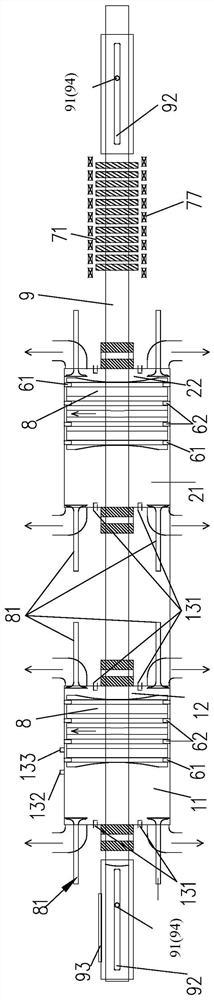

Electric-started free piston engine

InactiveCN105569838AEasy to startSynchronization correctionFree piston enginesFree-piston engineElectric generator

The invention discloses an electric-started free piston linear engine. Two power pistons are oppositely positioned in a cylinder of the engine, and are separately connected with a pressure air piston and a rotor of a linear motor. The linear motors serve as starting motors of the engine; and after the engine is started, a controller switches to a working state of a generator to charge an accumulator. When the engine is started, the left and right linear motors pull the left and right power pistons to perform a reciprocating motion in a range of inner and outer stop points to perform air suction, compression and fuel injection by a fuel injection nozzle to generate combustion and expansion; after the engine is started, air in left and right air cushion chambers is compressed and stored as energy of enabling the pistons to move to the inner stop points; and when the expansion is finished, the right power piston opens an exhaust hole, so that a lot of fuel gas flows into a gas turbine to continuously expand to output power. As the linear motors are used as the starting motors, the engine is conveniently started, and the linear motors also can serve as generators; the engine is not liable to generate flameout; and the two power pistons can be synchronously corrected.

Owner:徐建宁

Apparatus for controlling engine noise reflecting engine vibration and driving conditions

ActiveUS9911405B2Keep linearDetection characteristicElectrical controlMachines/enginesAudio power amplifierLinear engine

An apparatus for controlling engine noise reflecting engine vibration and driving conditions includes a sound generator that generates reinforcement noise in order to reinforce non-linear engine noise. The apparatus includes a vibration sensor measuring engine vibration as a noise source of the engine, a signal processing controller receiving the signal of the vibration sensor in real time and controlling the sound generator so that the engine noise may maintain linearity, and an amplifier receiving and then amplifying a control signal of the signal processing controller to transfer the amplified control signal to the sound generator.

Owner:HYUNDAI MOTOR CO LTD +1

Engine performance model

InactiveUS8117017B2Improve accuracyAnalogue computers for vehiclesSimulator controlLinear engineState variable

A method of constructing a piecewise linear engine performance model, comprises the steps of:(a) providing a non-linear engine performance model which iteratively calculates engine performance variables y from a plurality of sub-models, each sub-model representing the performance of a component of the engine;(b) defining a plurality of engine power conditions, each engine power condition being defined by one or more engine state variables x;(c) for each of the engine power conditions, using the non-linear engine performance model to determine partial derivatives δy of the engine performance variables y with respect to engine control variables u and with respect to the engine state variables x, the values of the partial derivatives δy being determined so that, on integrating the partial derivatives δy, the error between steady state values for the engine performance variables y calculated by the non-linear engine performance model and steady state values for the engine performance variables y calculated from the integrated partial derivatives δy is reduced or eliminated; and(d) constructing a piecewise linearised engine performance model in which calculation of the engine performance variables y involves combining each of the engine control variables u and the engine state variables x with the respective partial derivative δy.

Owner:ROLLS ROYCE PLC

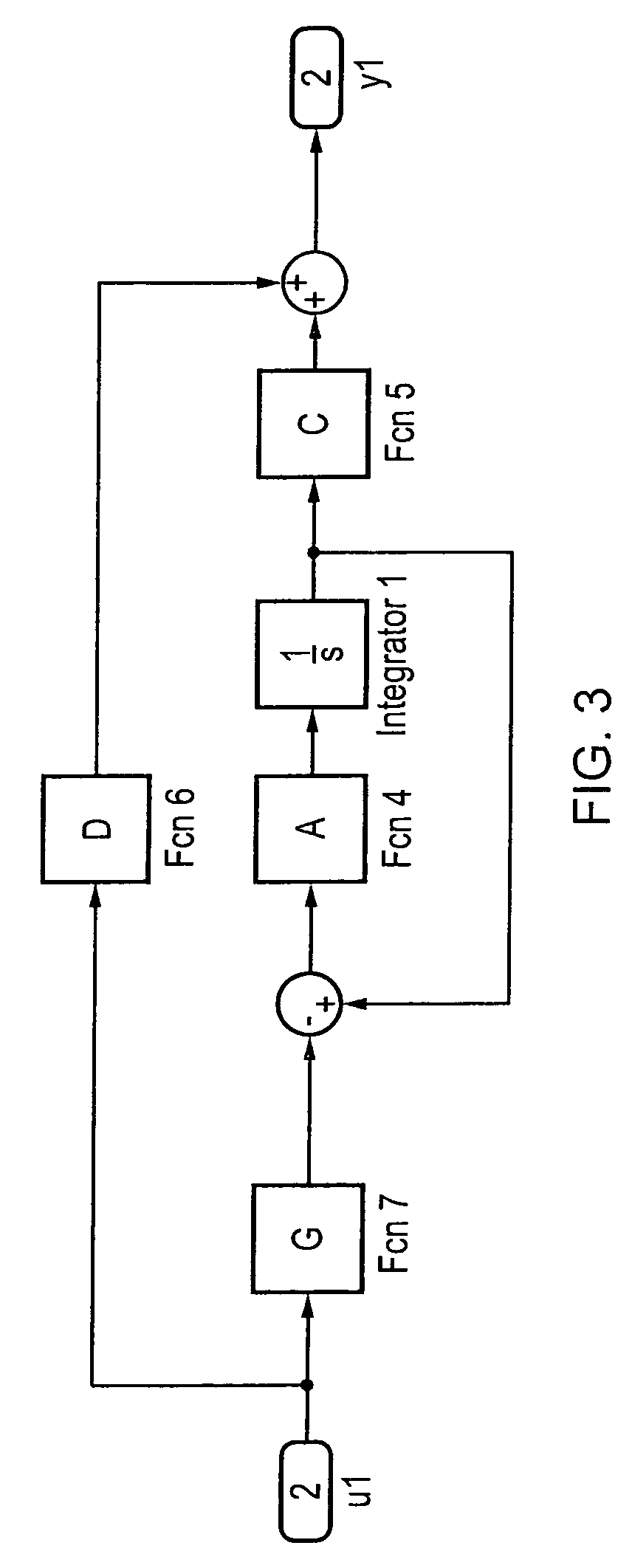

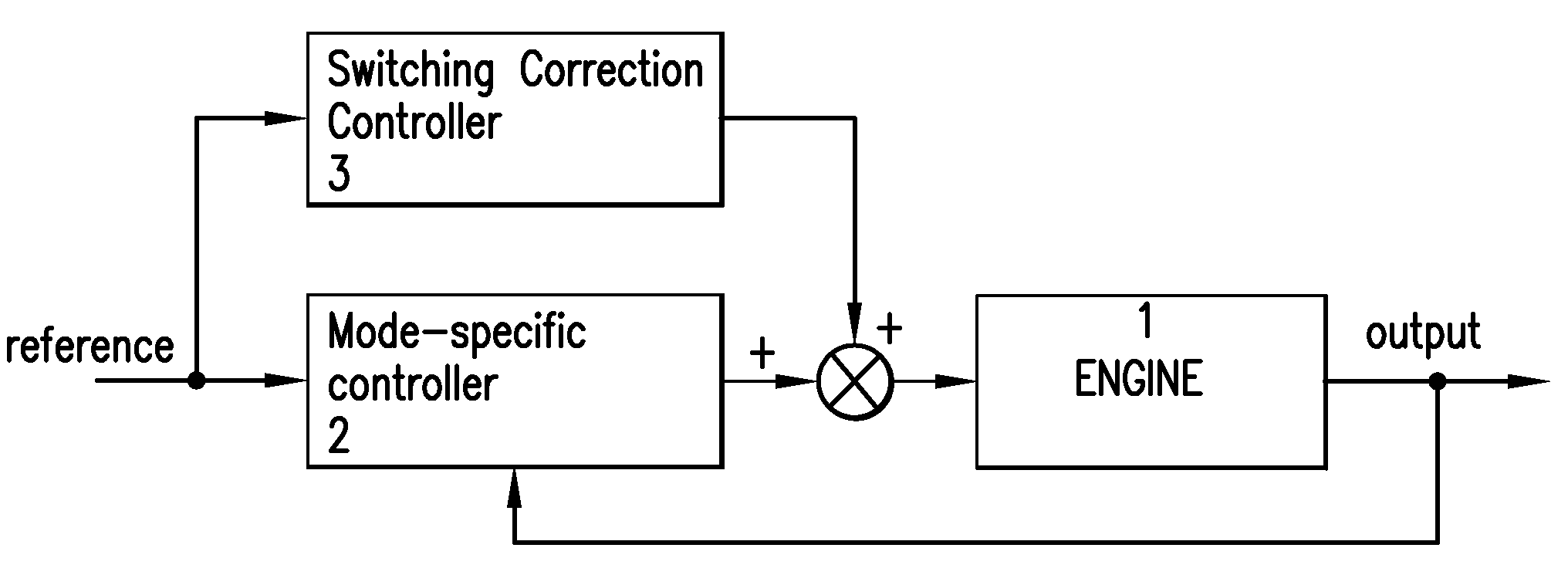

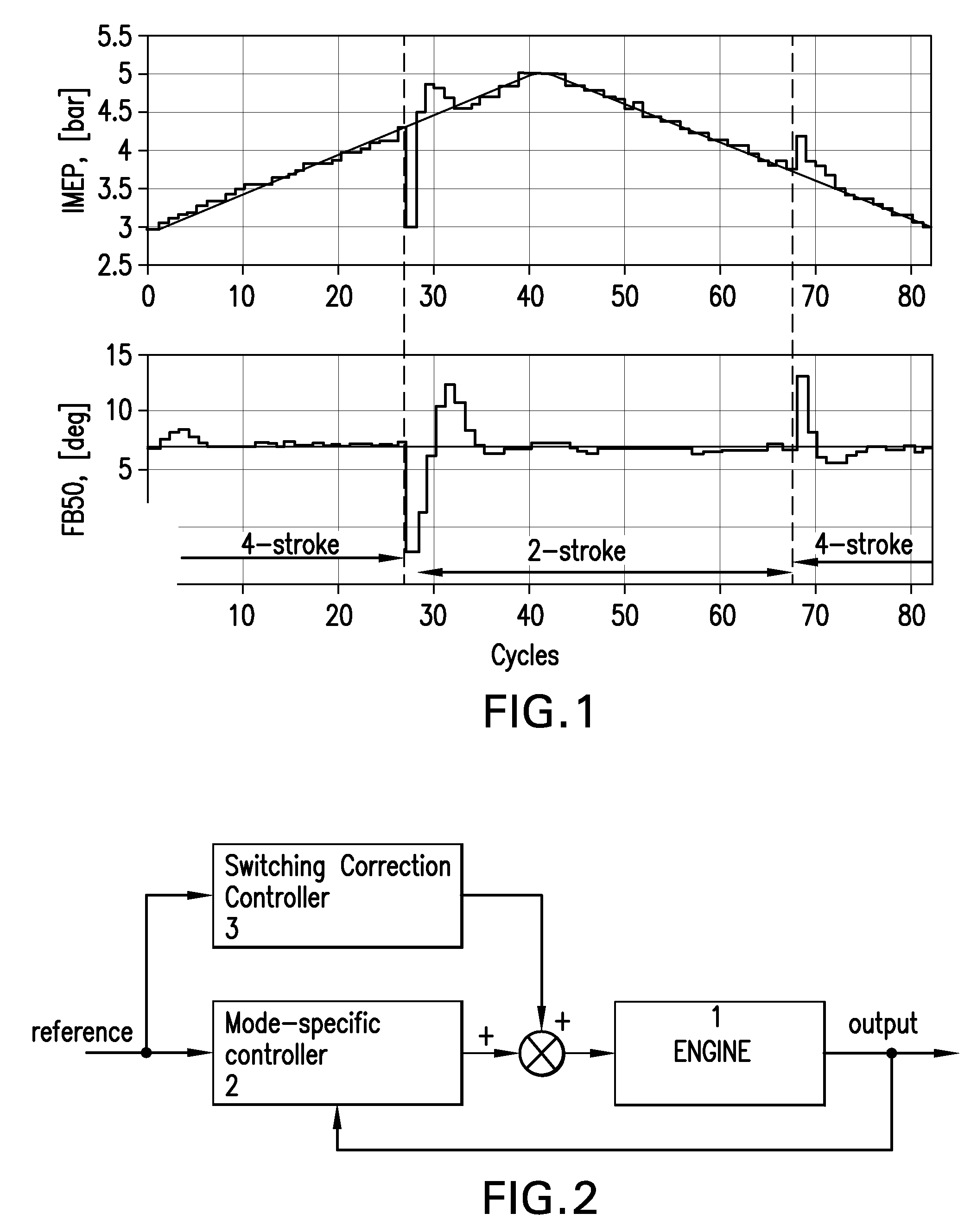

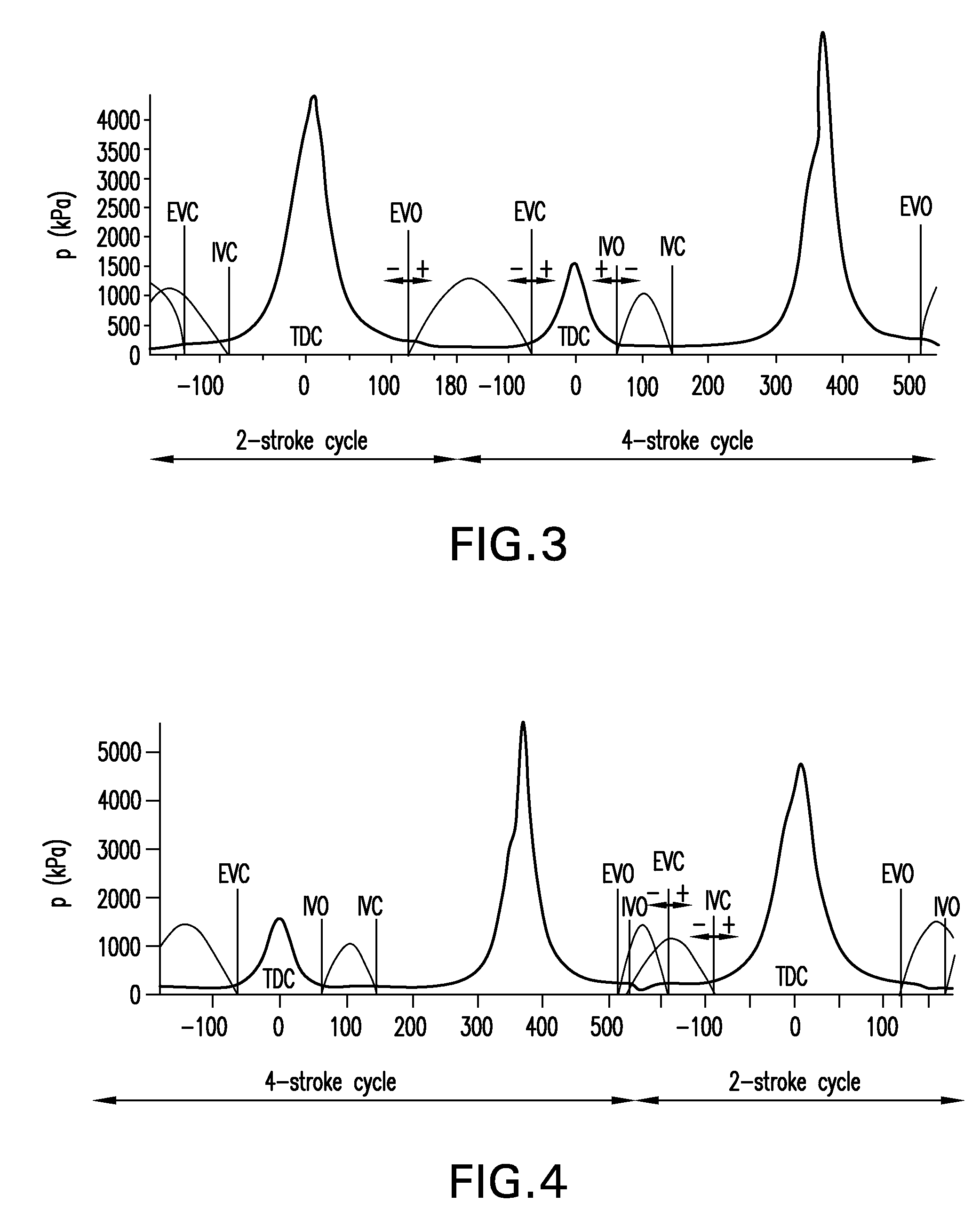

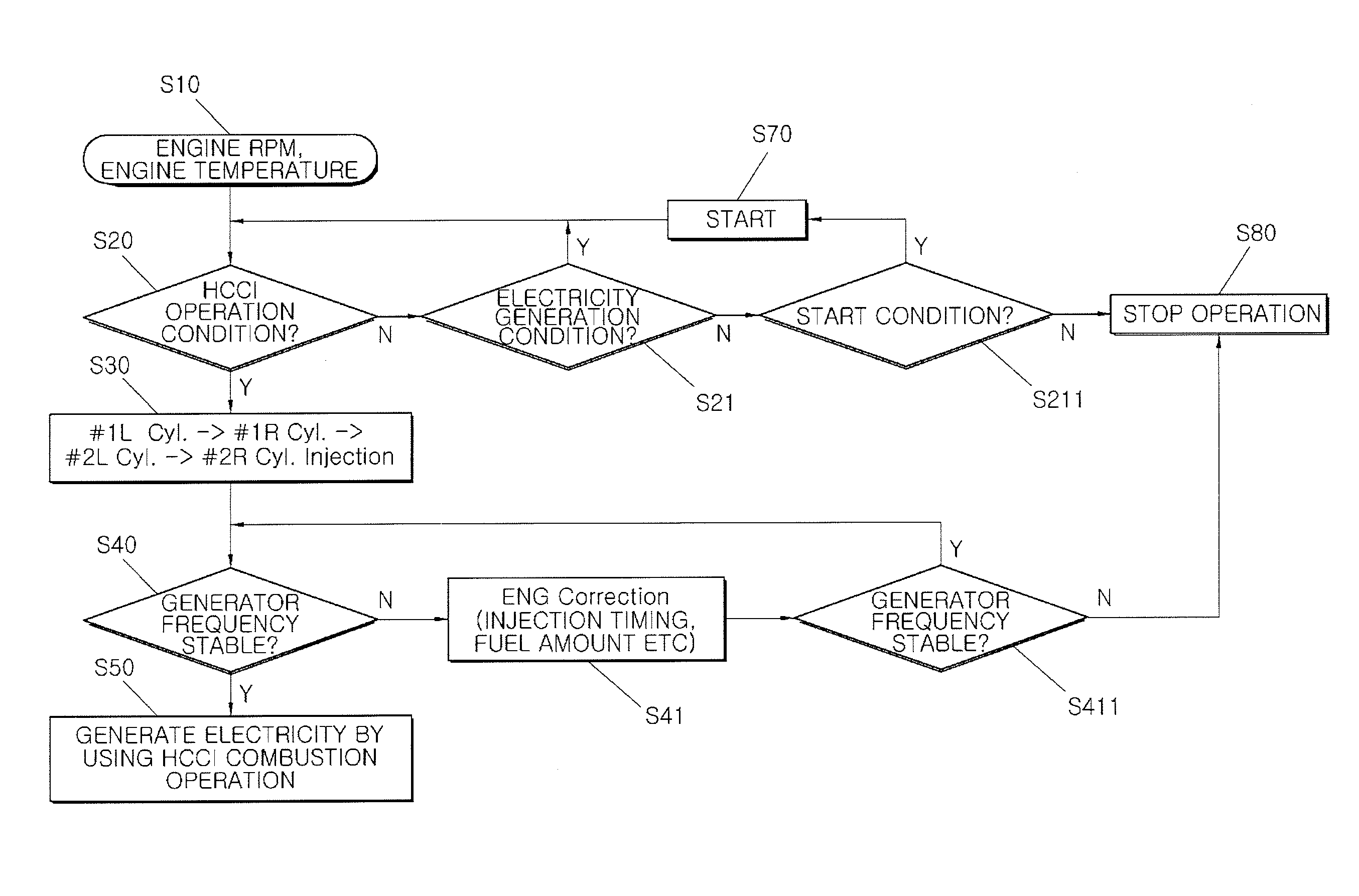

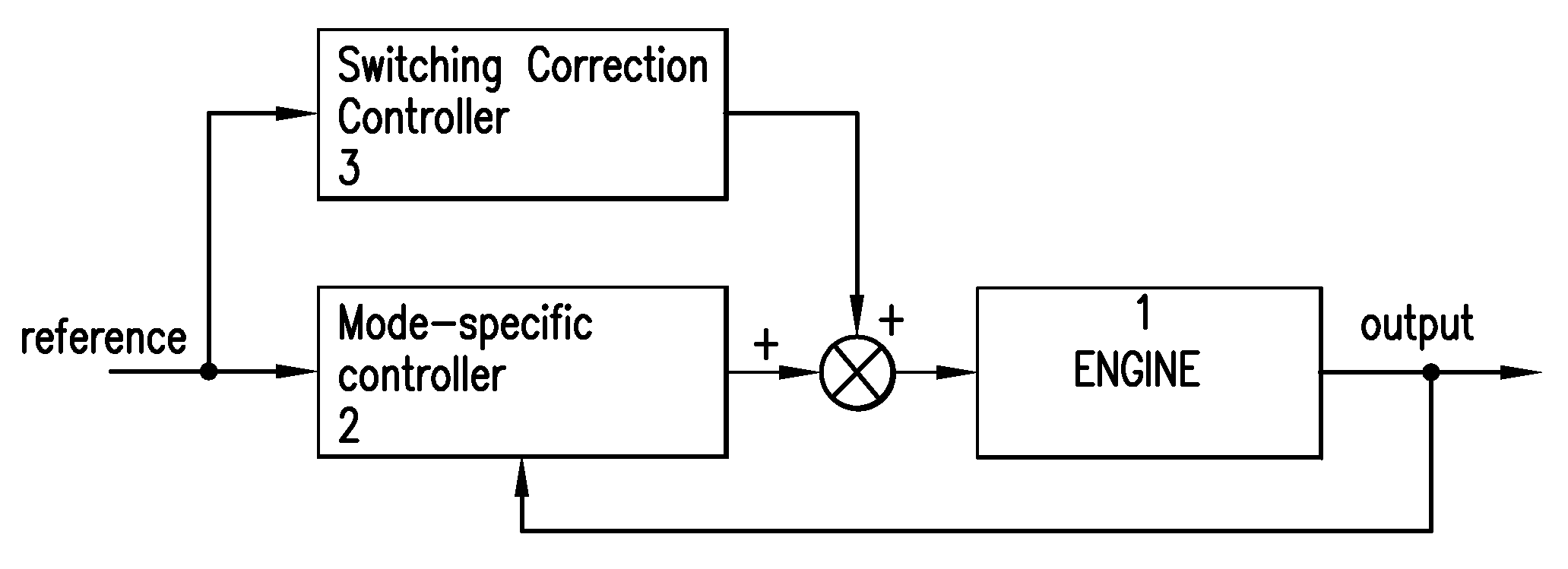

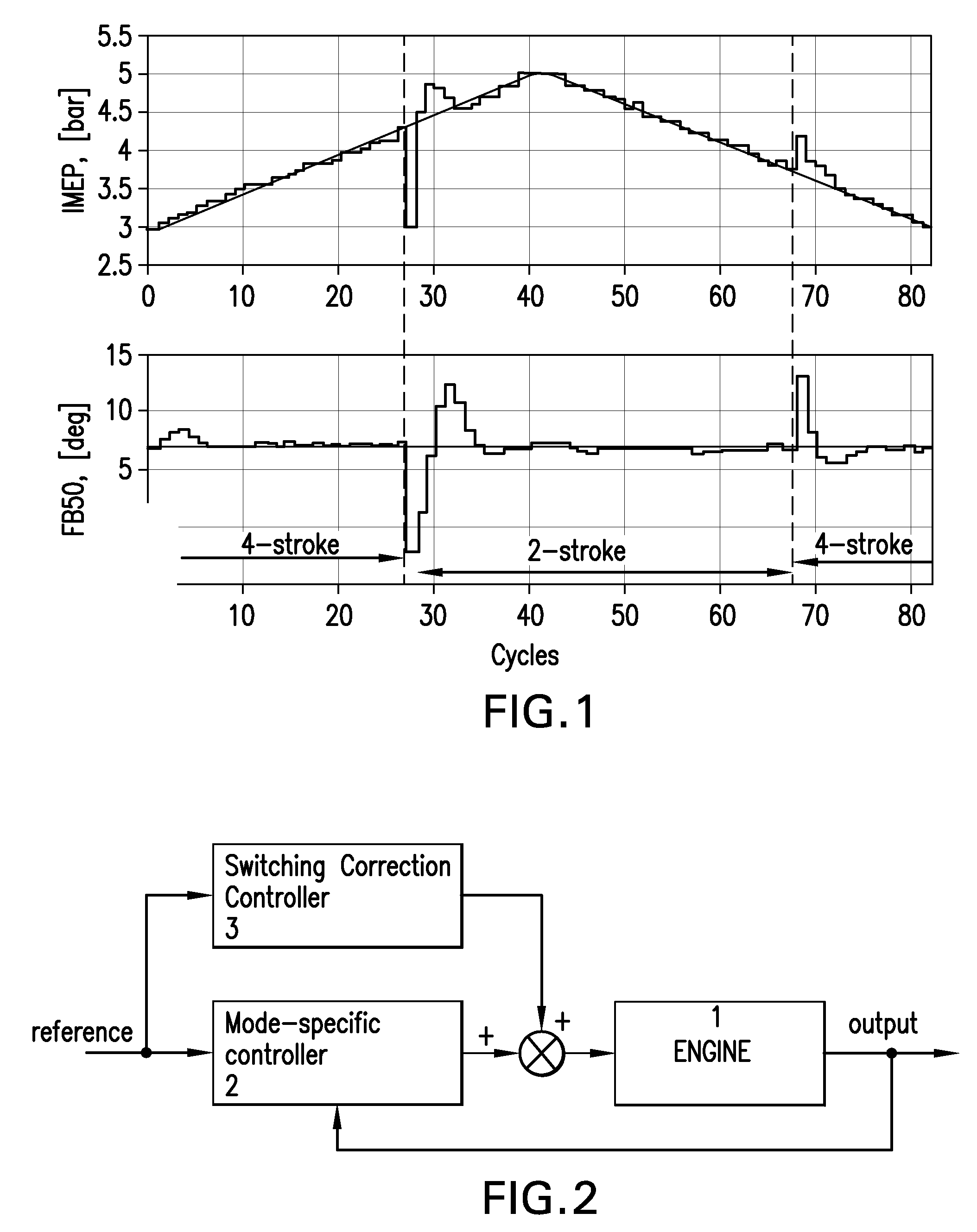

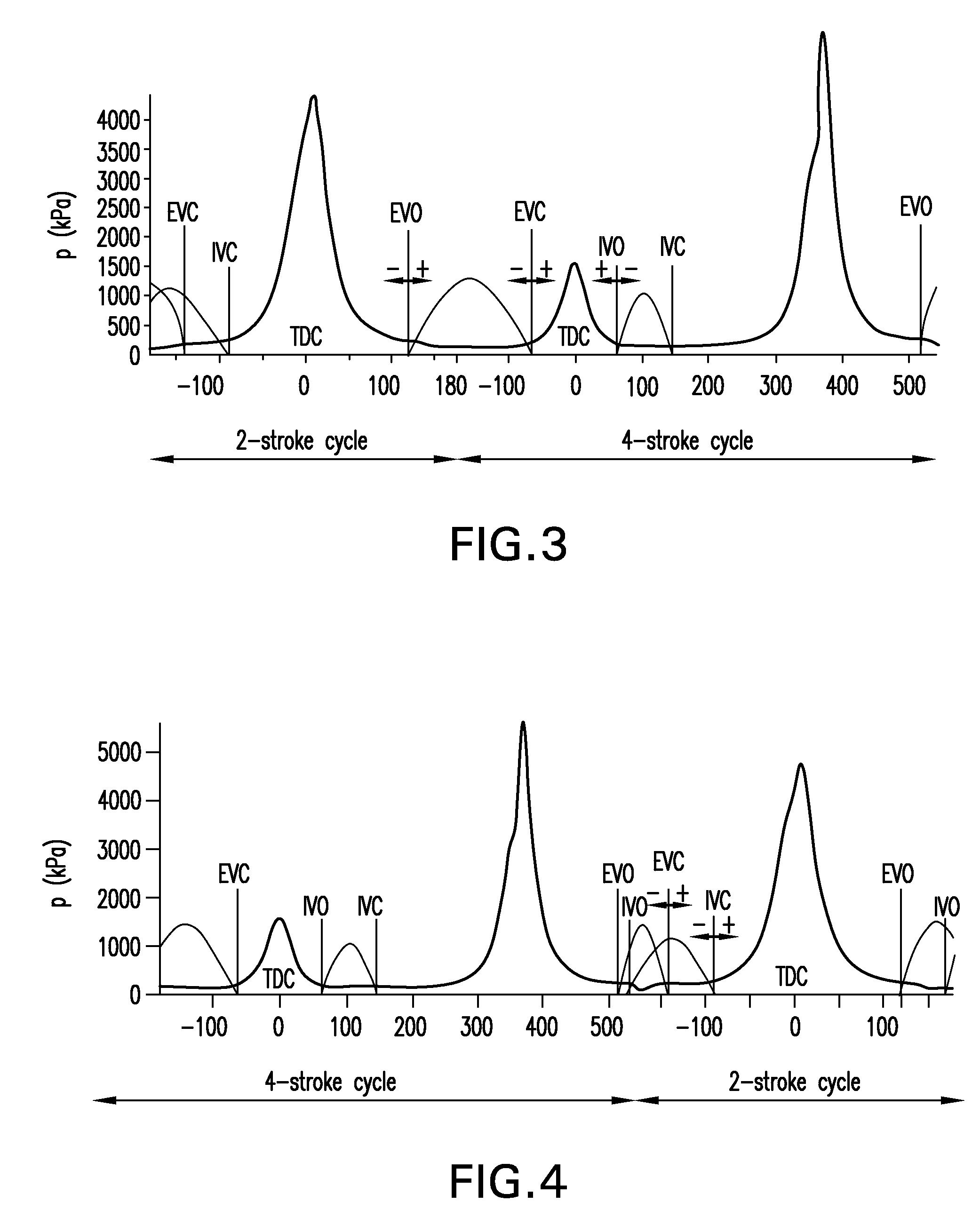

Control architecture and optimal strategy for switching between 2-stroke and 4-stroke modes of HCCI operation

ActiveUS20100275860A1Smooth transitionAnalogue computers for vehiclesElectrical controlLinear engineSystem model

Engine correction inputs to control oscillation in an engine output in a transition between 2-stroke and 4-stroke engine cycle modes of an HCCI engine are determined as follows: for each mode, valve timings which modify the engine output the most upon switching are determined, and a linear engine system model is defined at least partially based on the determined valve timings, which model provides mappings relating initial conditions of the engine and the engine correction inputs to outputs of the engine; initial conditions of the engine corresponding to a switching point for switching between the two modes are determined; desired engine output conditions upon switching between the two modes are specified; and the engine correction inputs are determined by using the determined initial conditions, the desired engine output conditions, and the linear engine system model corresponding to the engine cycle mode in effect upon switching.

Owner:ROBERT BOSCH GMBH

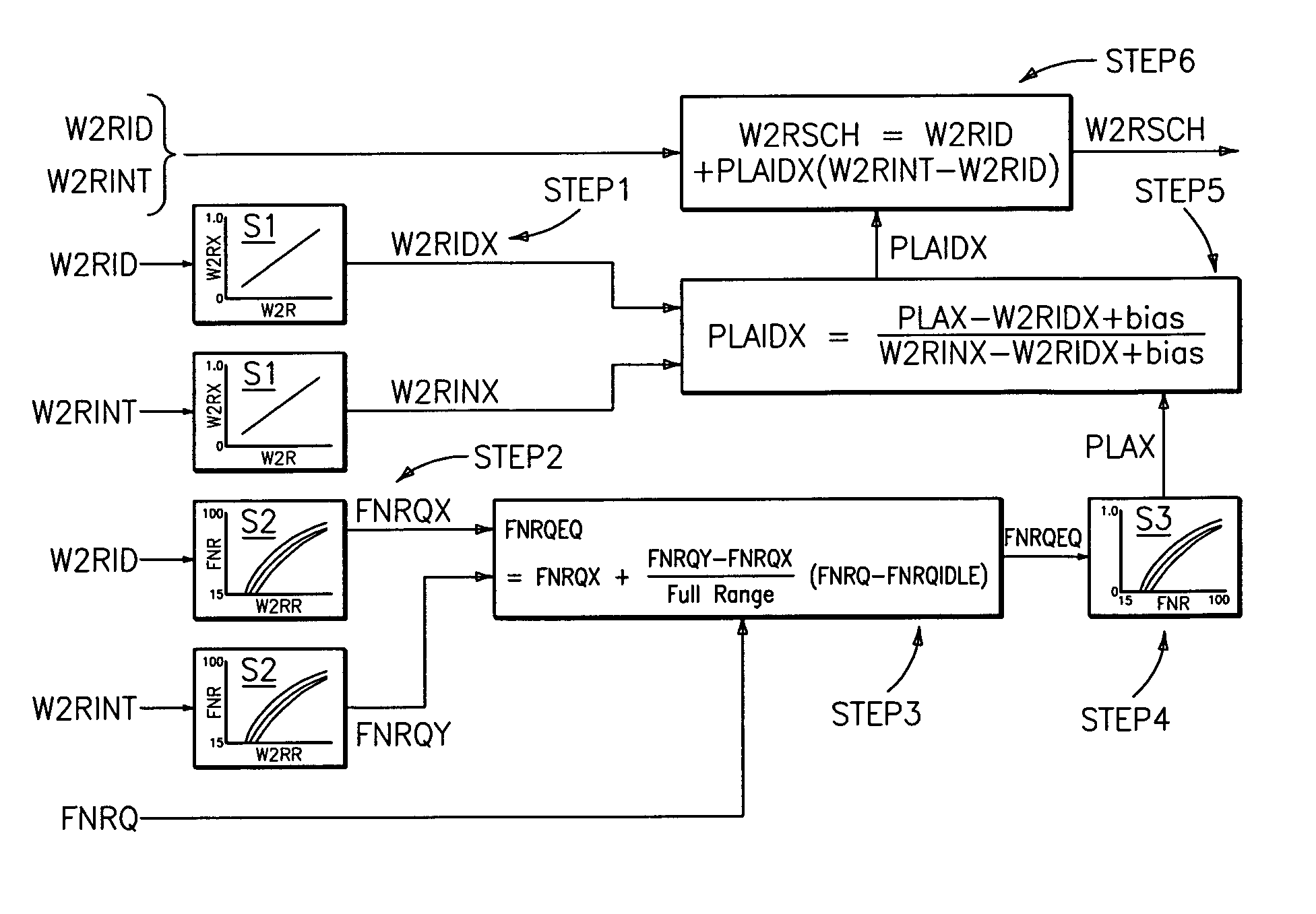

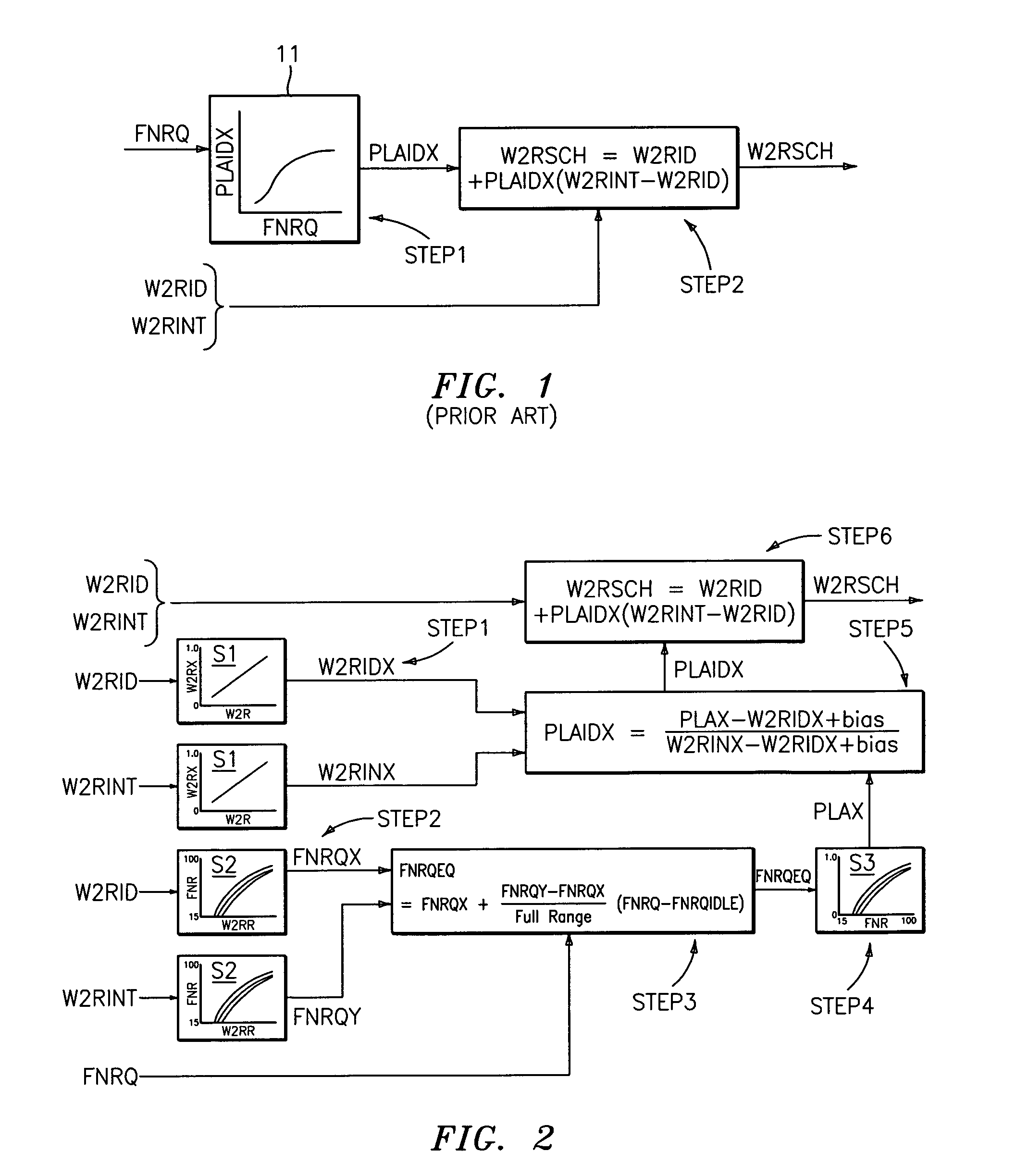

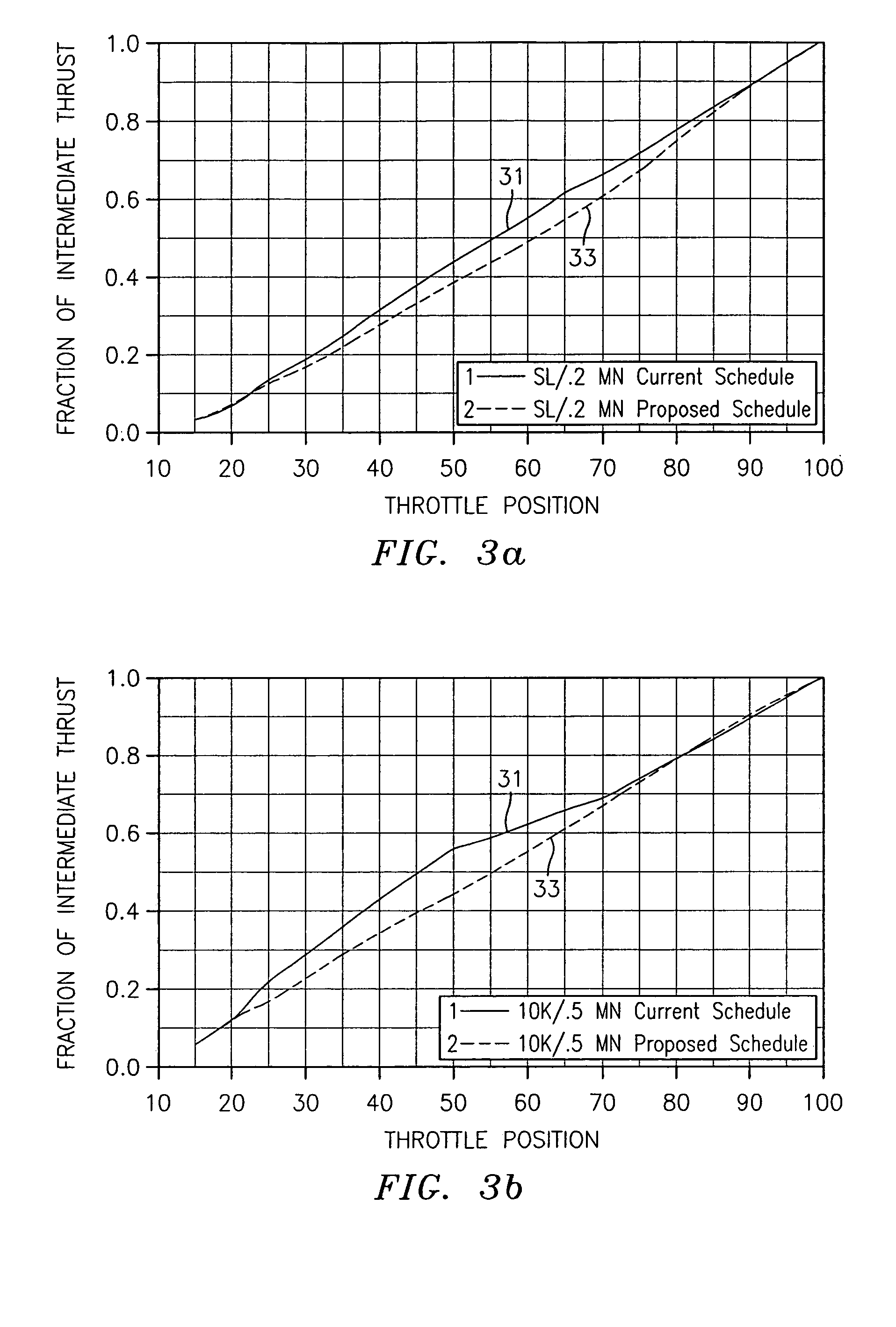

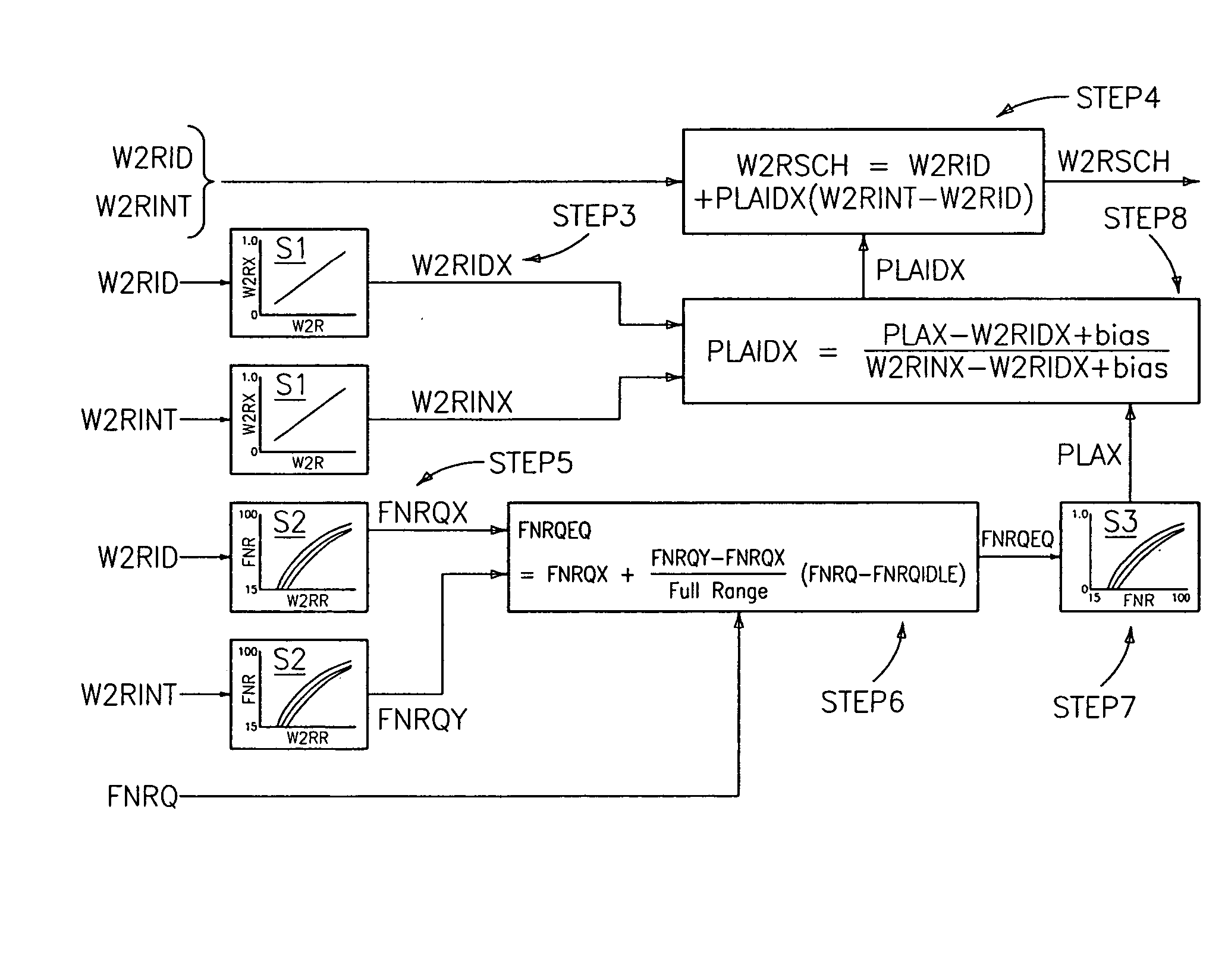

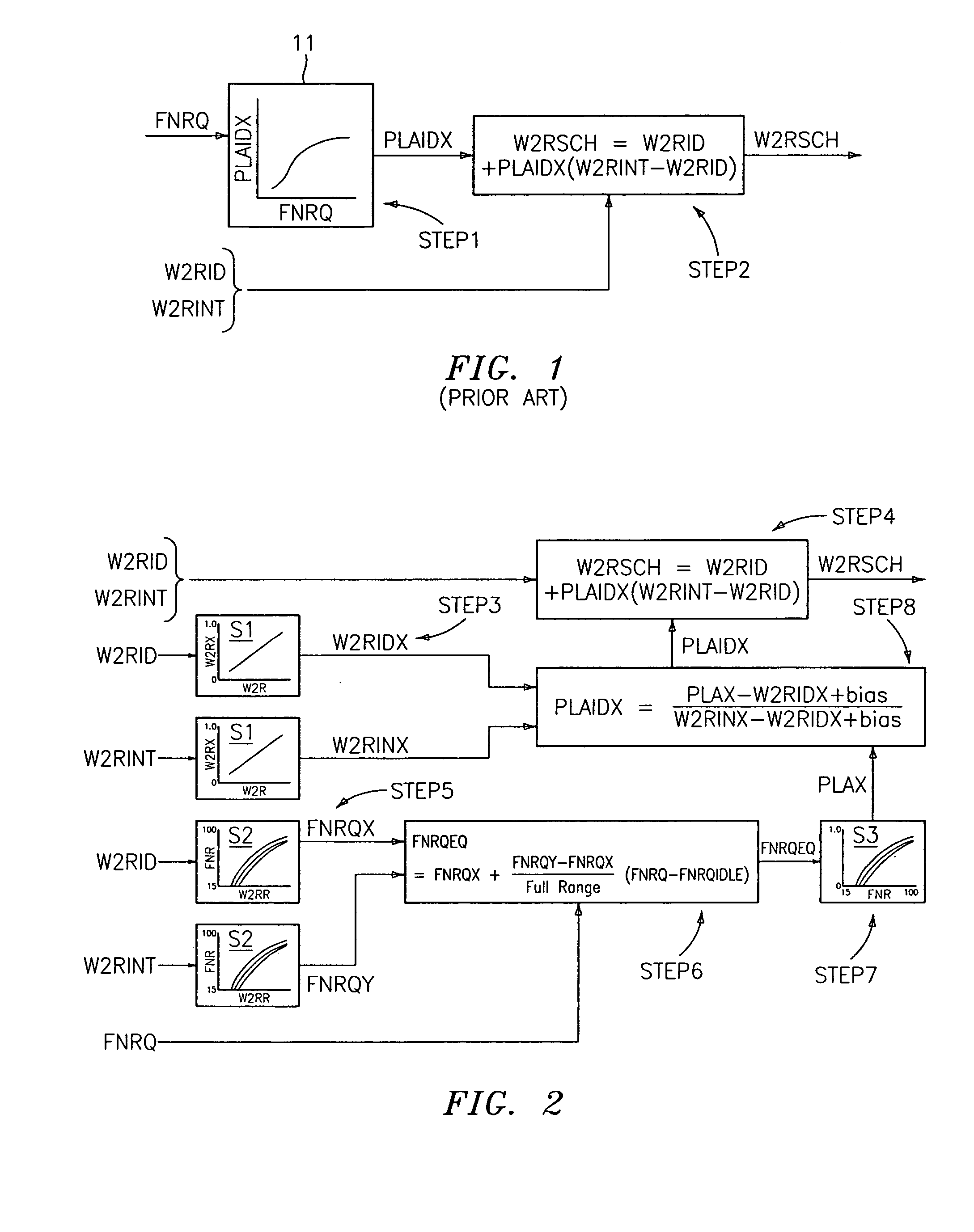

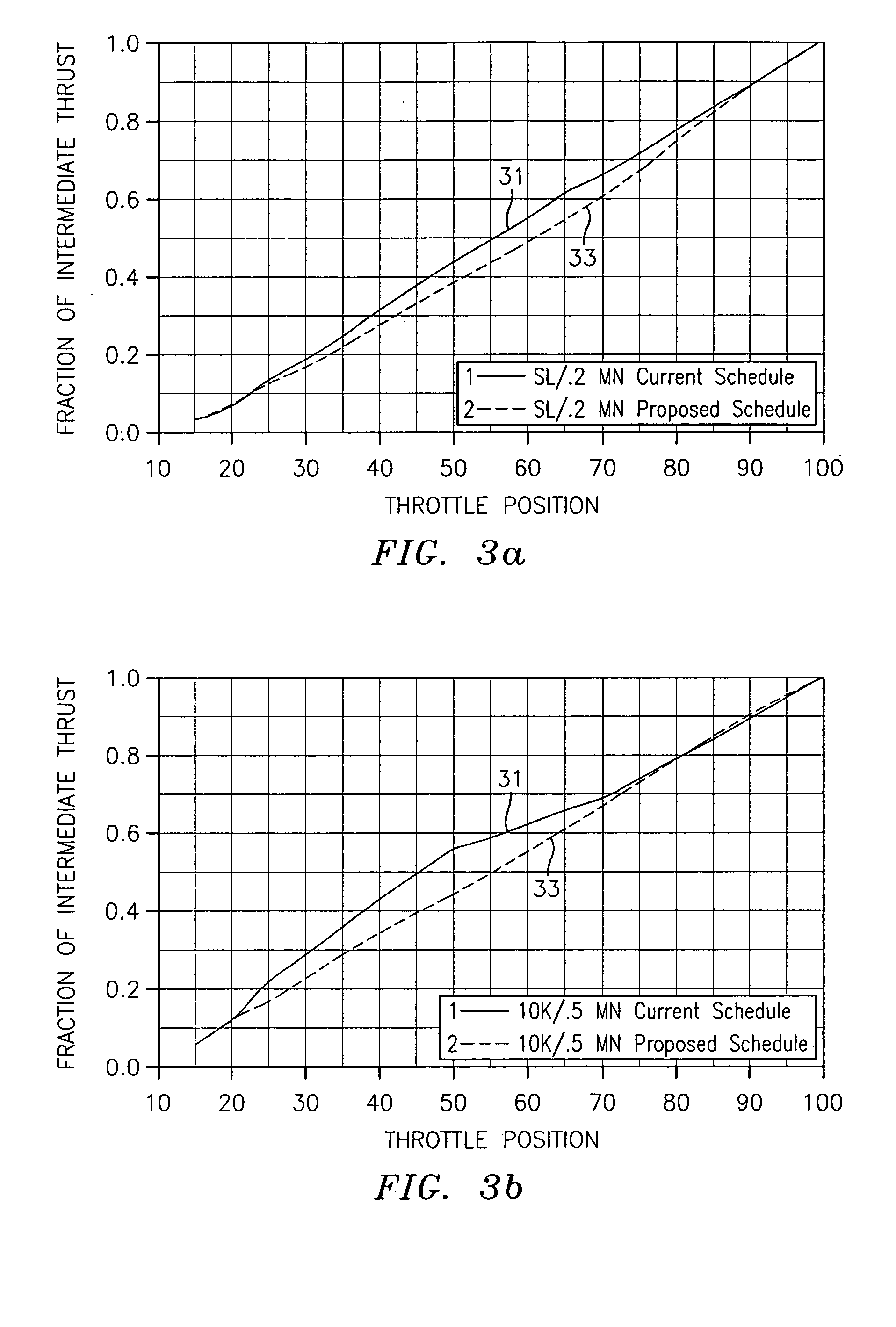

Method for control scheduling to achieve linear thrust response

A method for achieving linear engine thrust response comprising the steps of measuring a throttle position (FNRQ), measuring a plurality of engine parameters, inputting the plurality of engine parameters and the throttle position into a plurality of schedules to produce a plurality of outputs, combining the plurality of outputs to produce a part power scheduled airflow (W2RSCH), and using the W2RSCH to produce a near linear thrust response of the engine.

Owner:UNITED TECH CORP

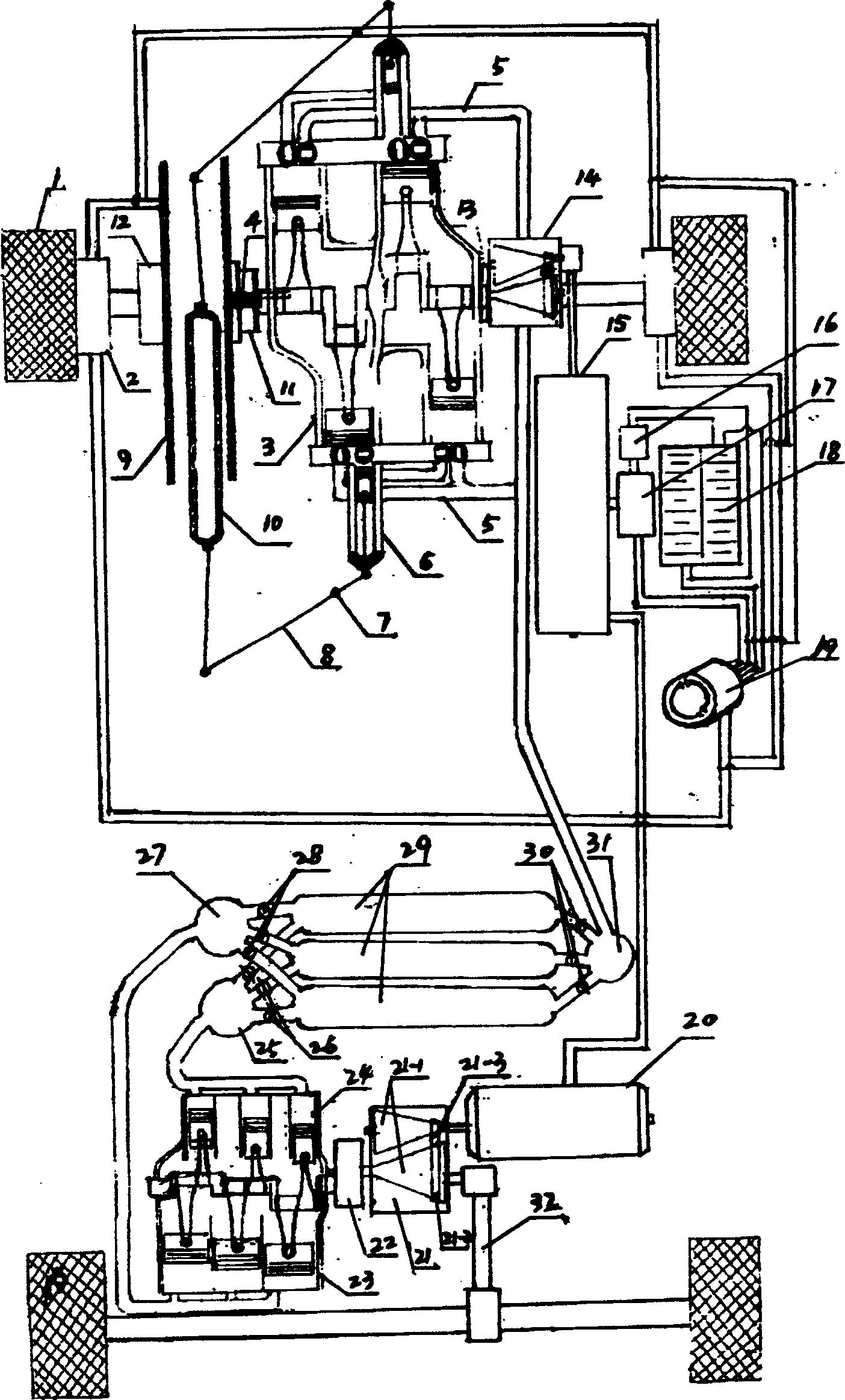

Gas, electricity and petroleum hybrid power arrangement

InactiveCN1284684CImprove efficiencySimple structureHybrid vehiclesInternal combustion piston enginesGas compressorAir compressor

The invention refers to a kind of gas, electricity, oil compound power device. It includes oil and gas dual-purpose electric engine, clutch, gearbox, hub electric engine, converter, charger, battery, air compressor, air collecting ball, air storage pot; the engine also includes cylinder engine, the original engine is mother-cylinder engine, the son-cylinder engine is connected with the linear engine, the gas inlet and outlet valve includes an upper piece, a subjacent piece, cylinder trestles, the gearbox includes two tower wheels, gearing chain, shifting yoke, the merits of the invention are: it sets an air energy saving device, reclaims residue energy in brake and no-load, it provides compressed air for engine, upgrades the efficiency of the engine, it uses charging and discharging valves with shifting yoke structure, the structure is simple, the volume is small, the airtightness is good, it is easy to be checked and manufactured, it uses son-cylinder engine and linear engine, the son-cylinder can work singly, it can save oil, the combustion is good.

Owner:田晓虹

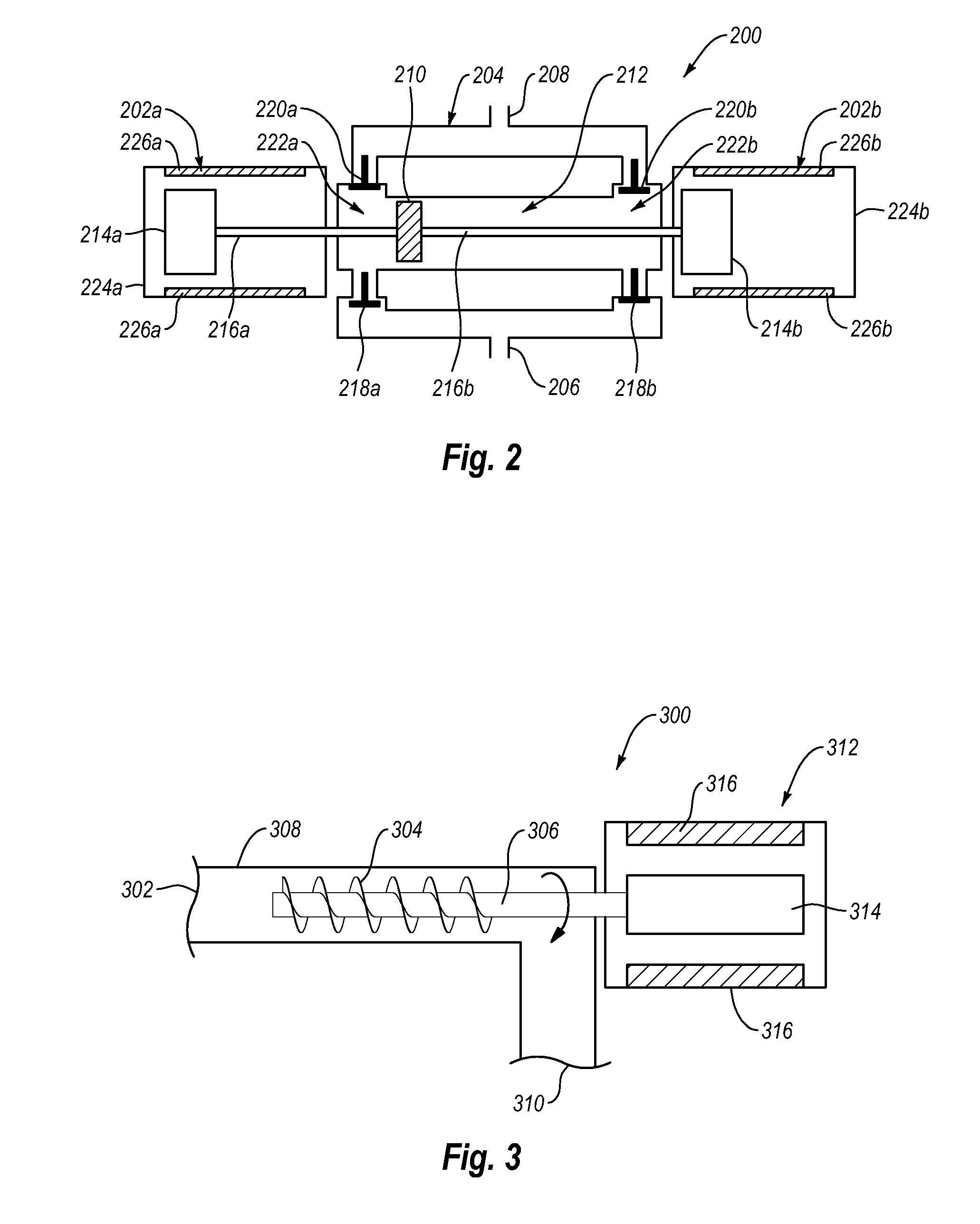

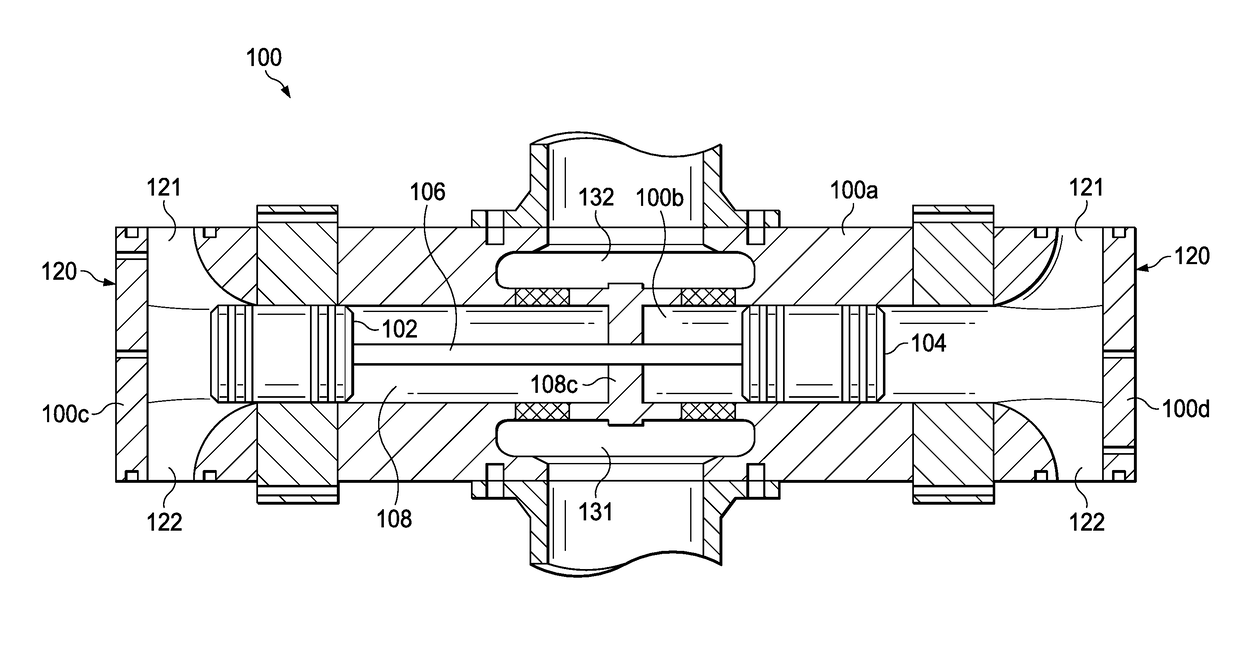

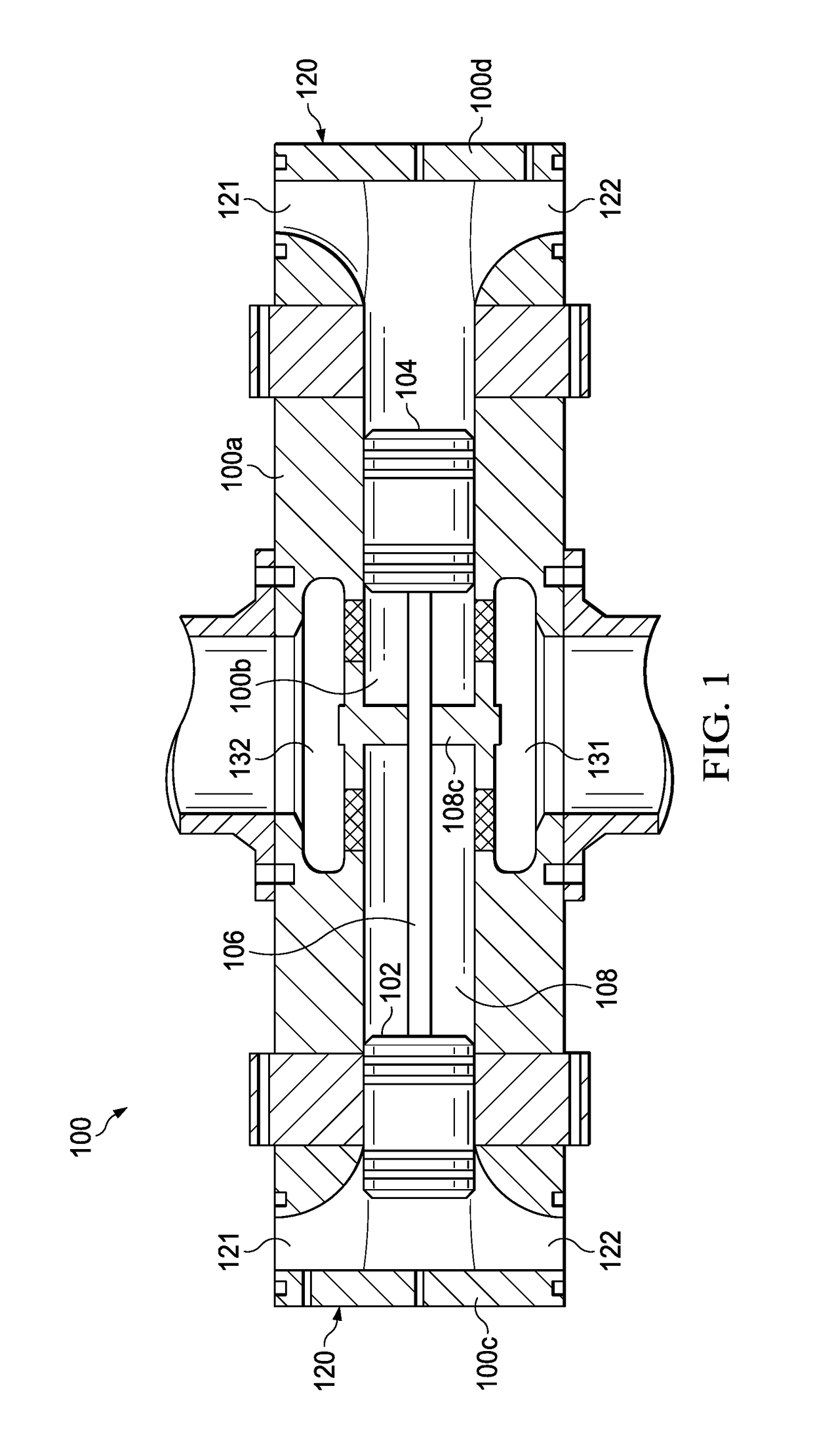

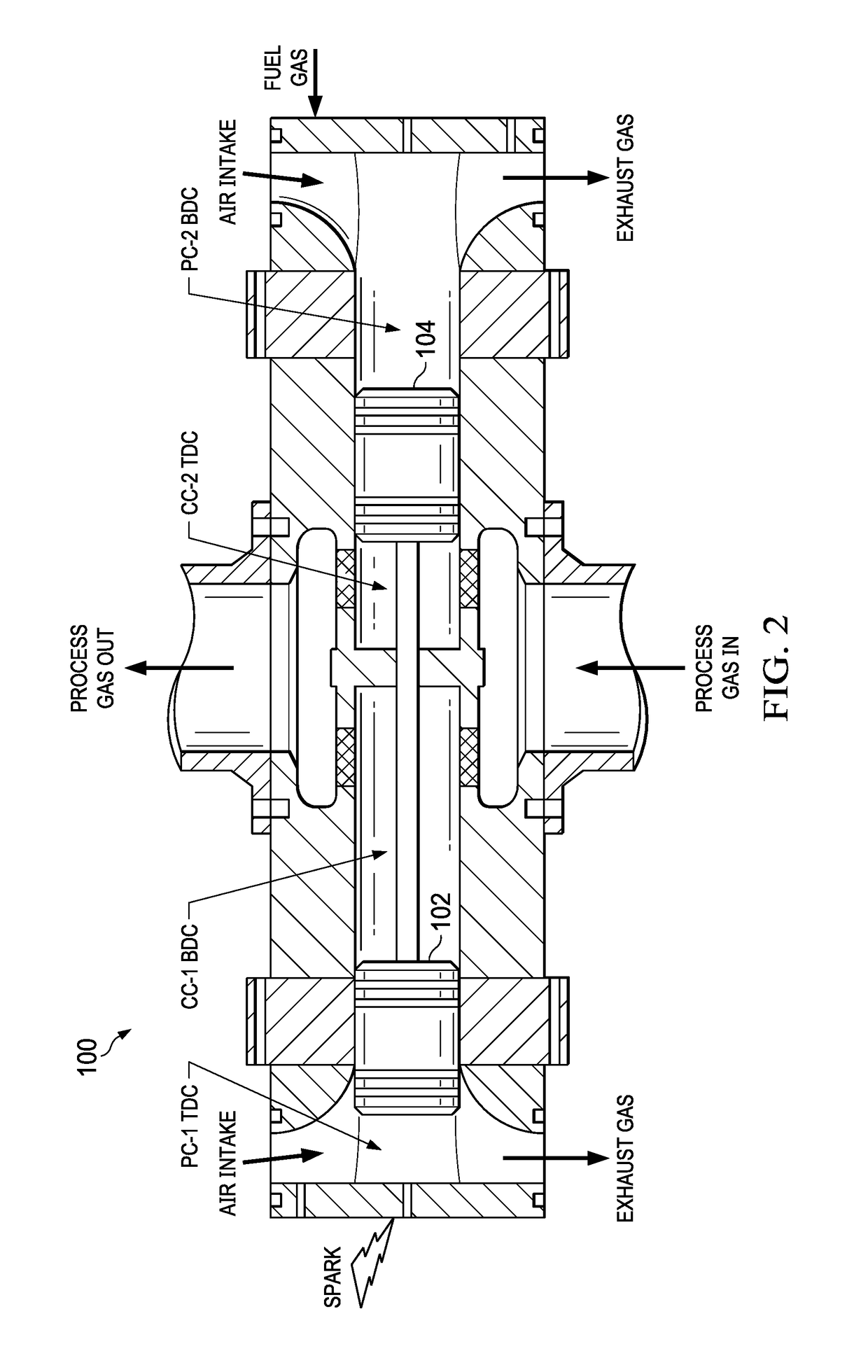

Reciprocating integral linear engine compressor

ActiveUS9957958B2Internal combustion piston enginesPositive displacement pump componentsLinear engineEngineering

Owner:SOUTHWEST RES INST

Linear solar heat generating system

InactiveUS8418464B2Easy to installEasy maintenanceSolar heating energyFrom solar energyLinear engineEngineering

An eco-friendly linear solar heat generating system may employ a linear engine with a simple structure using solar heat is employed in place of a conventional Stirling engine with a complicated structure. Magnets and a coil are arranged in a piston and a cylinder, respectively, to thereby generate power in a highly efficient matter, improve installation stability, and enable easy maintenance and repair.

Owner:CHAE SOO JOH

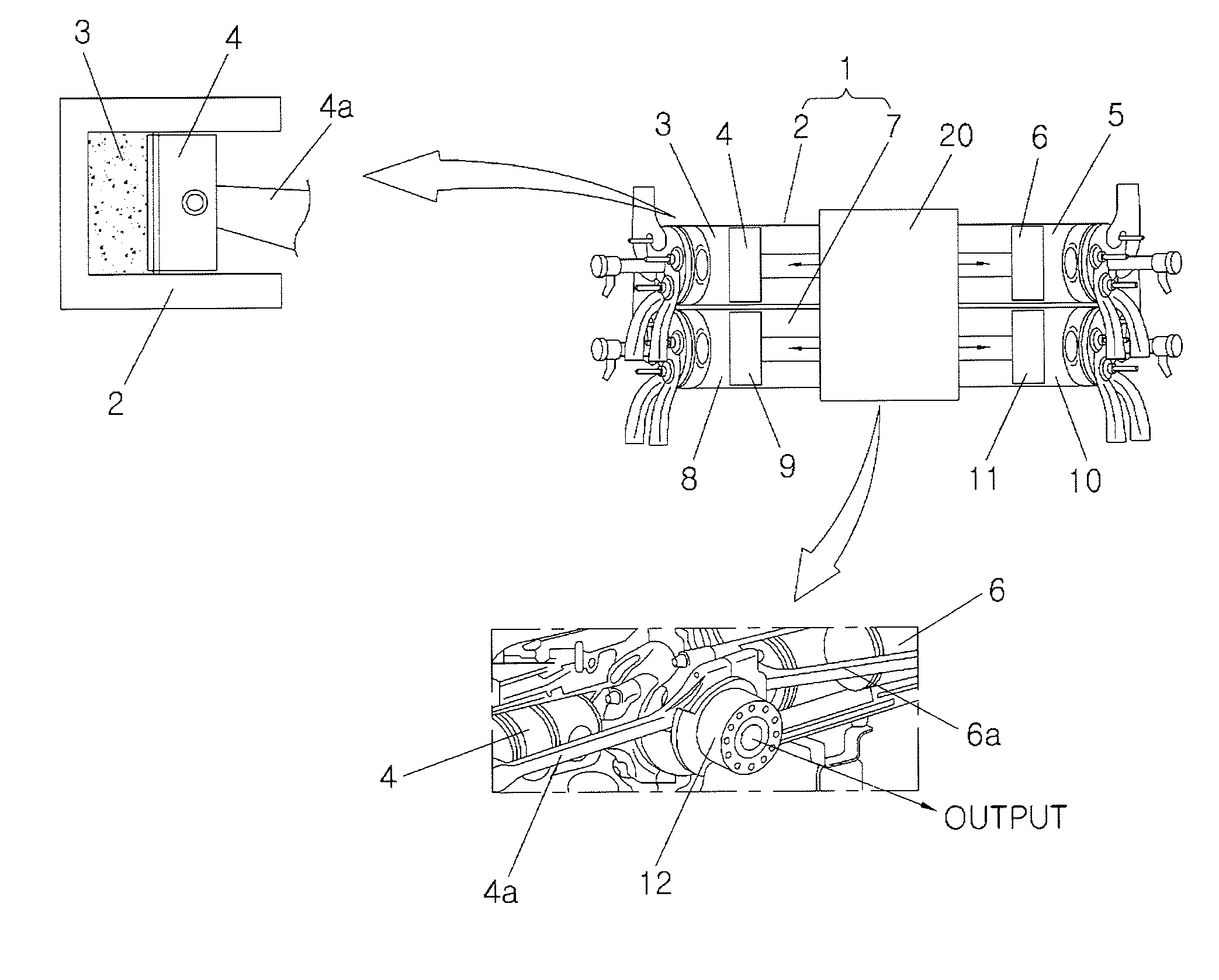

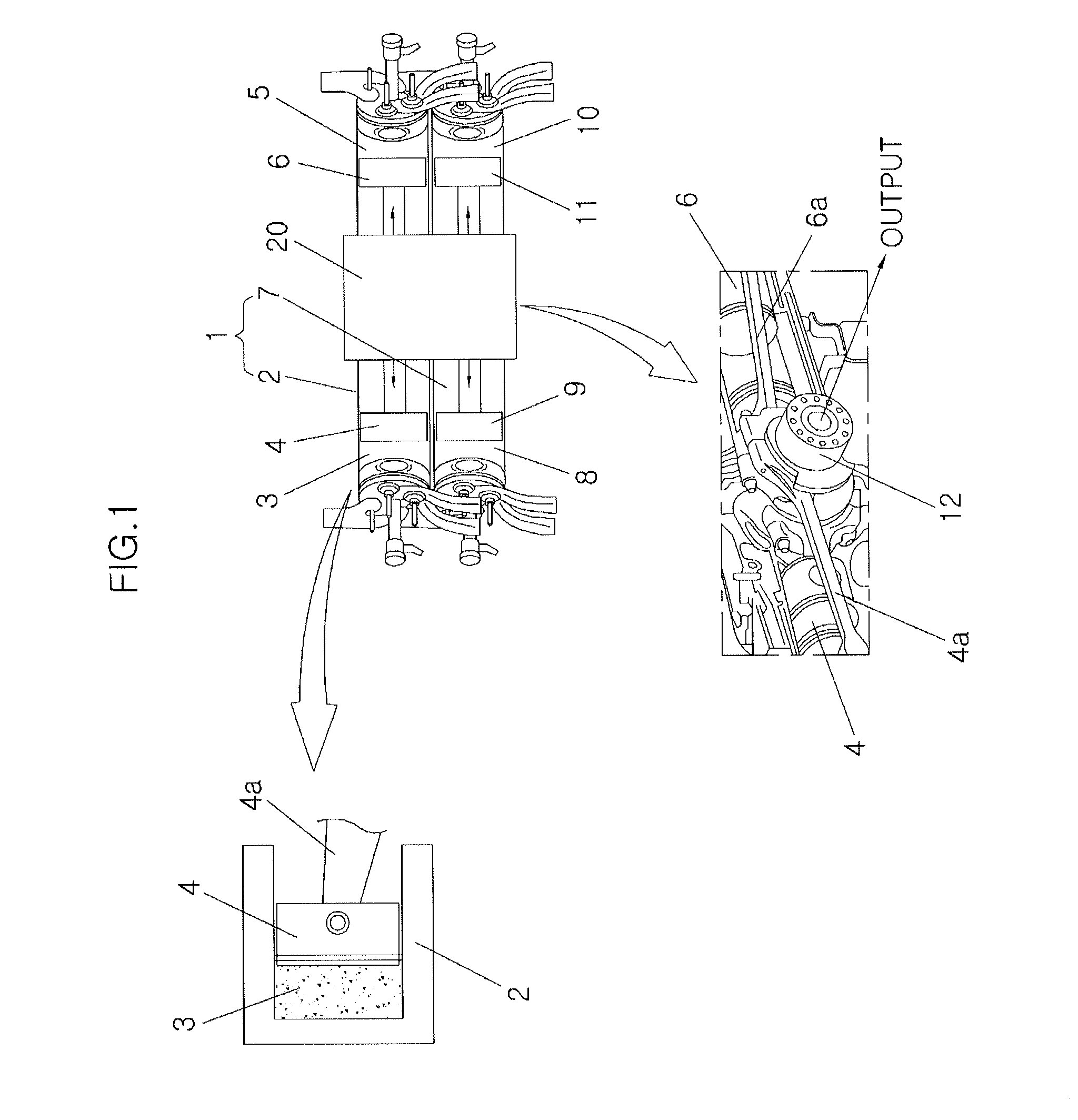

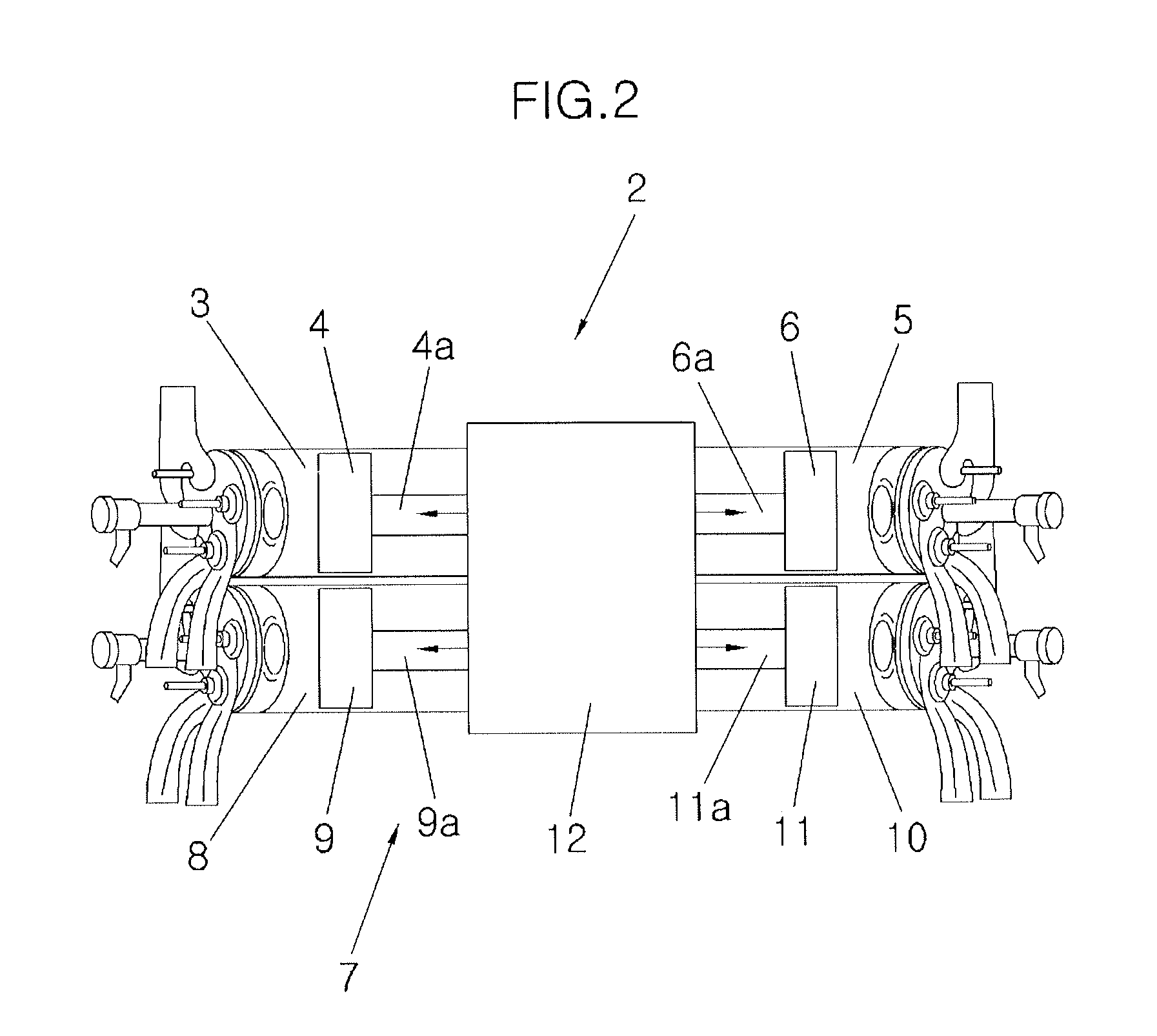

Hybrid vehicle and method of operating engine of the same

ActiveUS20130096750A1Improve vehicle performanceIncrease commercial qualityBatteries circuit arrangementsElectrical controlHcci combustionElectricity

A hybrid vehicle may include a linear engine controlled by HCCI (Homogeneous Charge Compression Ignition) combustion in an operation section where an engine power may be used for generating electricity after being started and reaching up to a predetermined RPM, and a motor-combined generator engaged to the liner engine and starting the linear engine and charging a battery by converting an entire engine power of the linear engine generated by the HCCI combustion into electricity generation power.

Owner:HYUNDAI MOTOR CO LTD

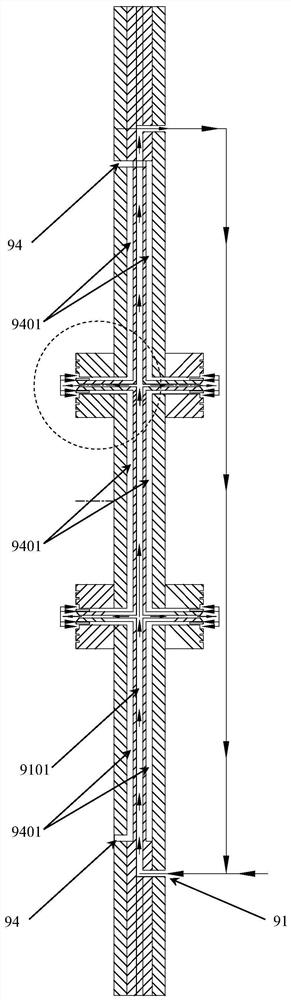

Four-stroke linear engine

PendingCN112049723ASimple structureCompact structureShaftsElectric motor startersCombustion chamberLinear engine

The invention discloses a four-stroke linear engine. The four-stroke linear engine at least comprises a first piston cavity and a second piston cavity which are sealed and coaxially arranged, whereinpistons are arranged in the piston cavities, piston cavities are divided into left combustion chambers and right combustion chambers by the corresponding pistons, an oil outlet hole and an oil returnhole are formed in the radial surface of the piston, a piston oil outlet channel corresponding to the oil outlet hole is arranged on the piston, a piston oil return channel corresponding to the oil return hole is arranged on the piston, a shaft oil inlet channel communicating with the piston oil outlet channel and a shaft oil return channel communicating with the piston oil return channel are axially arranged in a power output shaft, and the shaft oil inlet channel and the shaft oil return channel communicate with an oil inlet and an oil outlet close to the two ends of the power output shaft.According to the four-stroke linear engine, four engines are linearly arranged on a linear shaft to sequentially execute four strokes and complete reciprocating motion, the piston is directly installed on the power output shaft, a lubricating oil path is arranged on the power output shaft, gasoline gas enters the combustion chamber, combustion is more sufficient, and the whole structure is simpleand compact, cost is low, friction is little, and efficiency is high.

Owner:王芳华

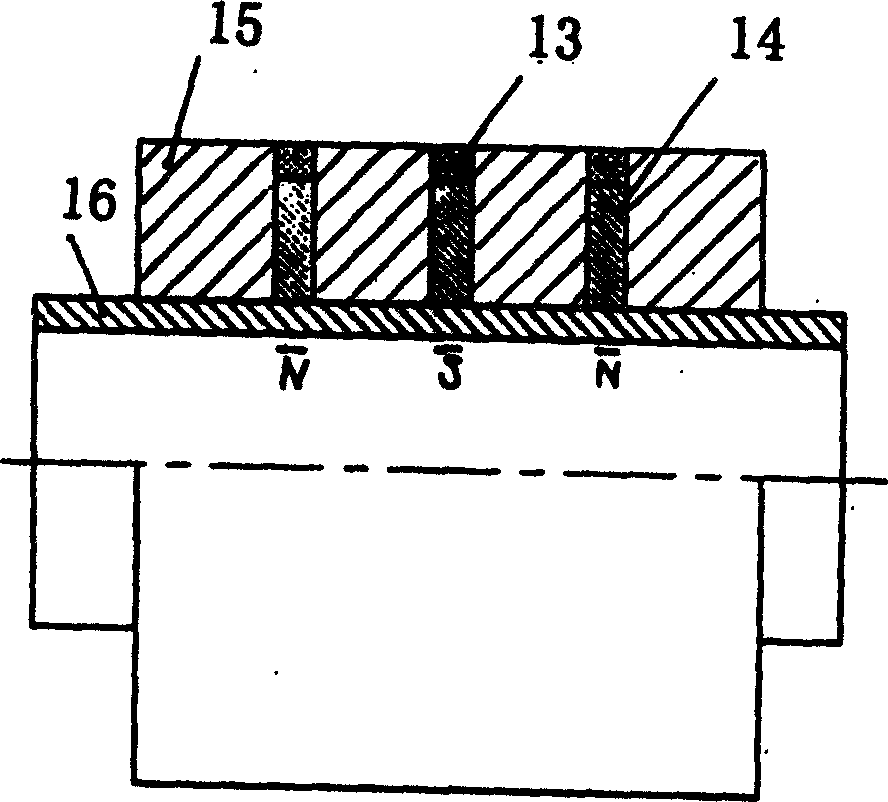

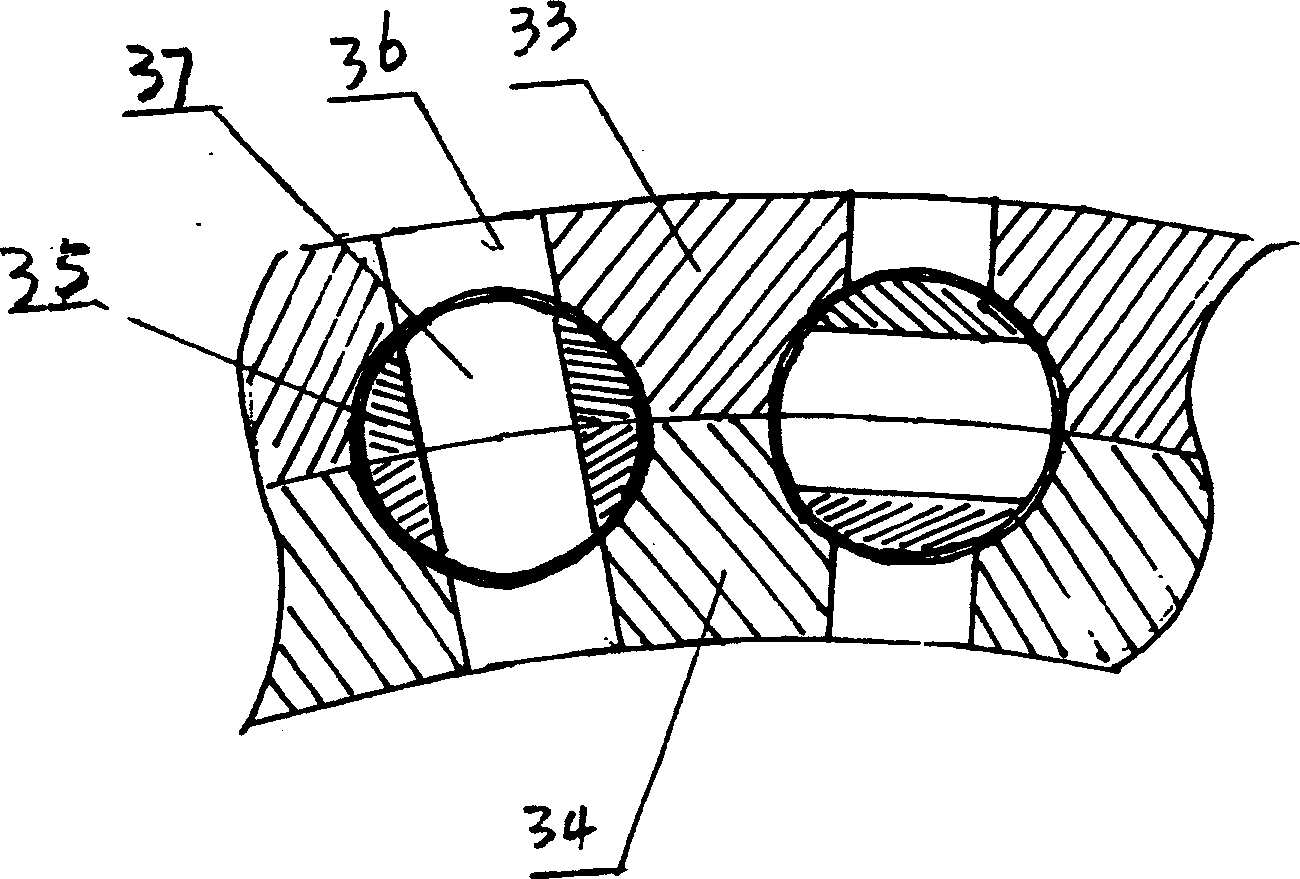

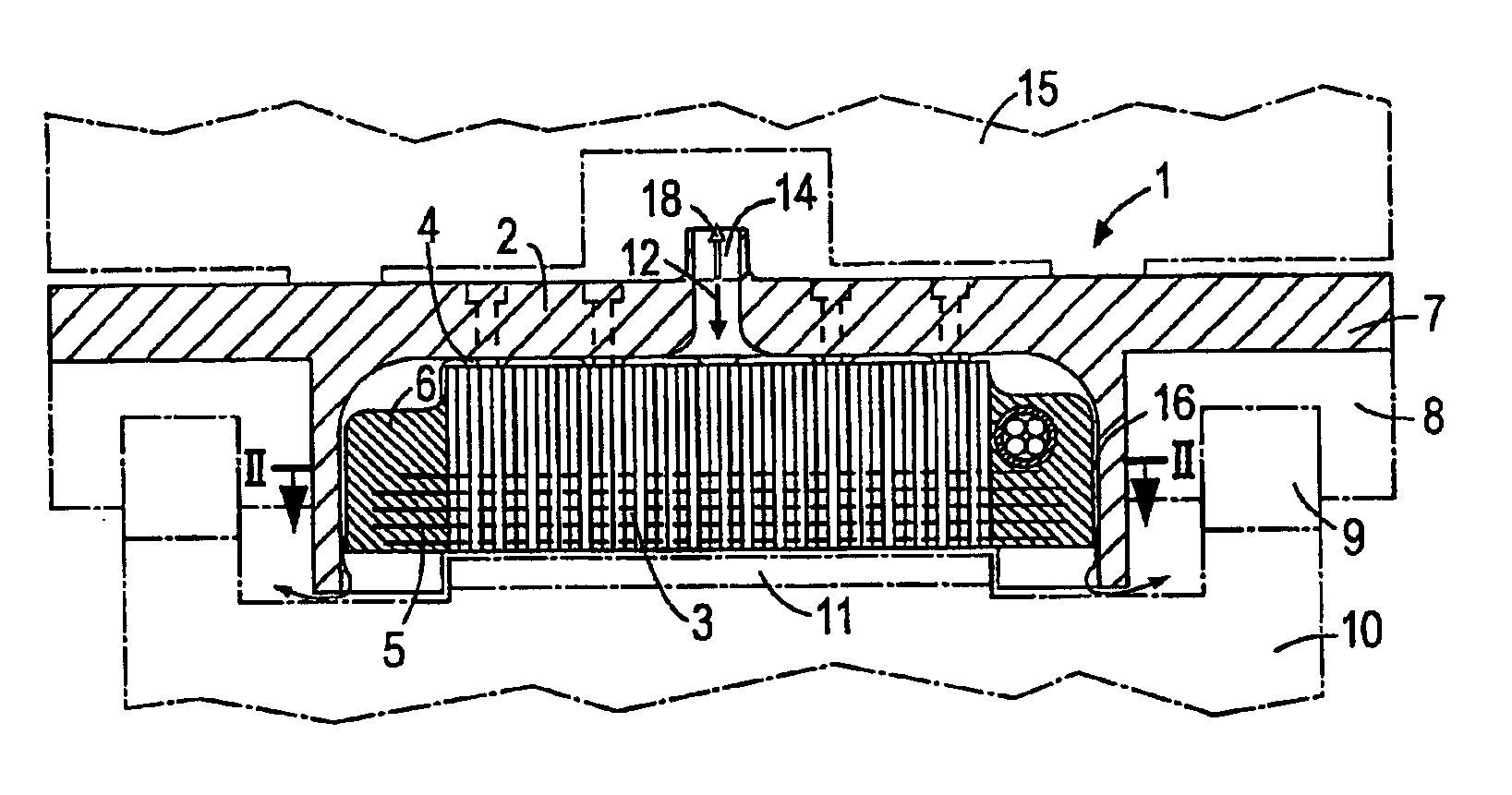

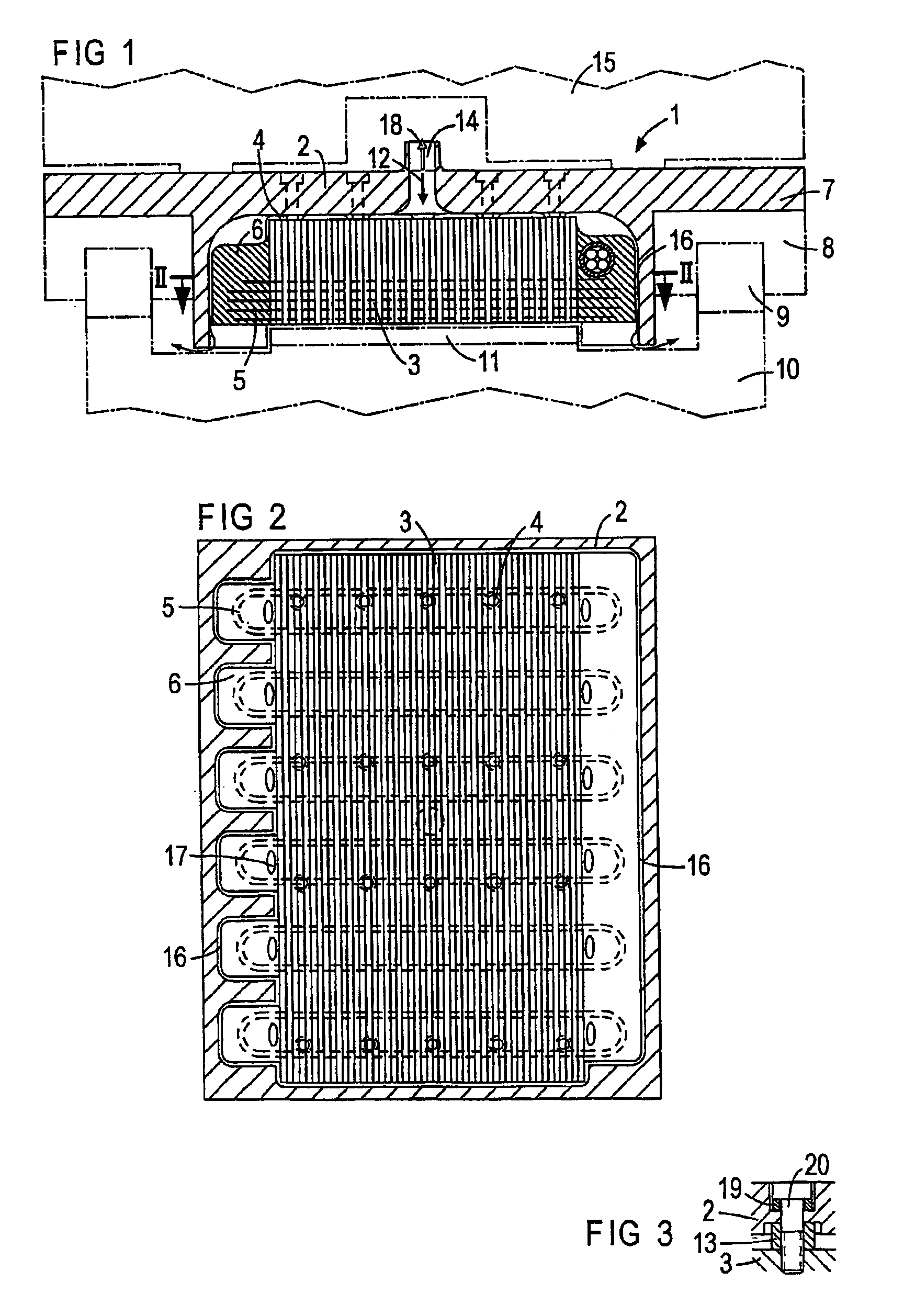

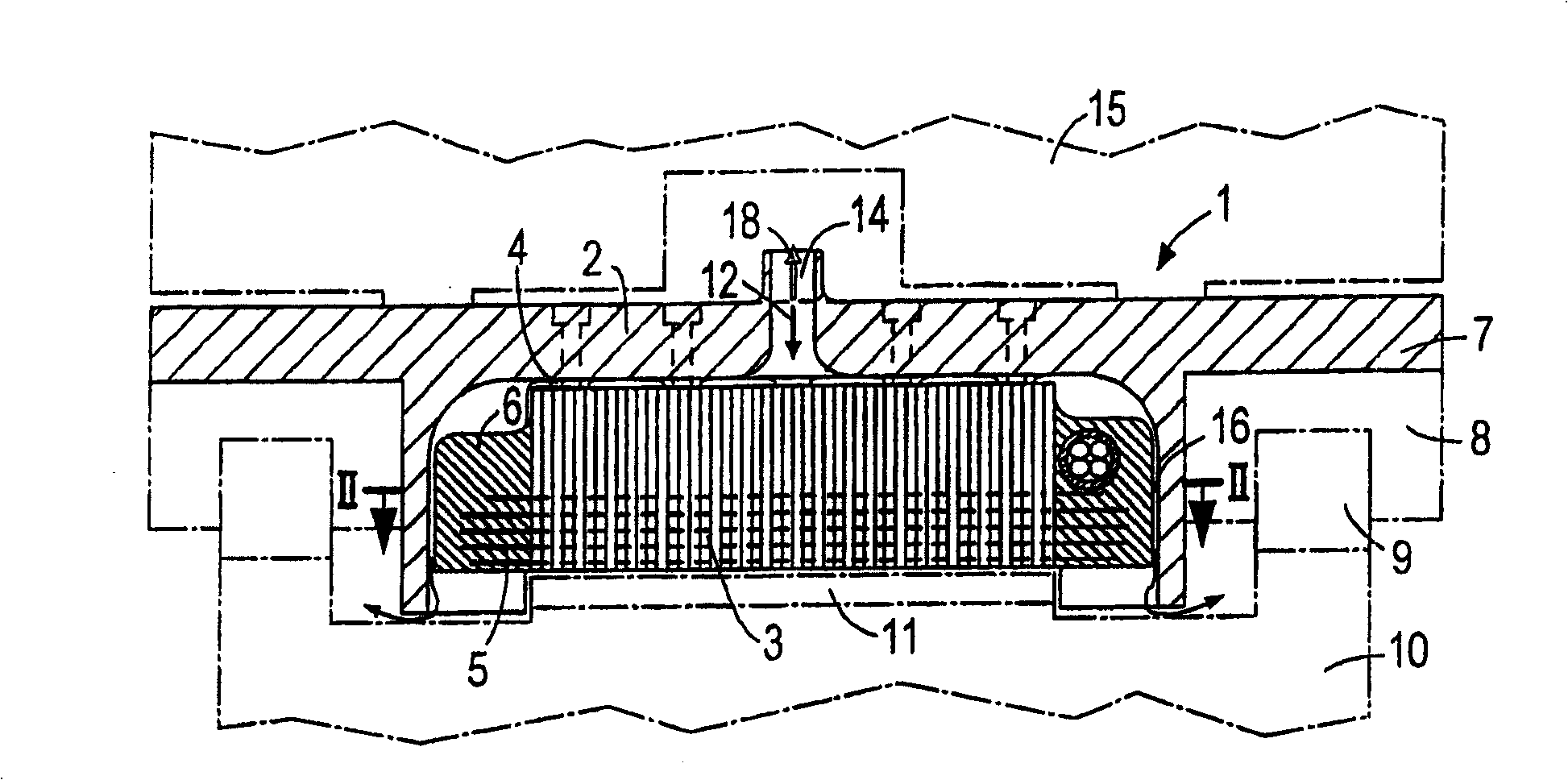

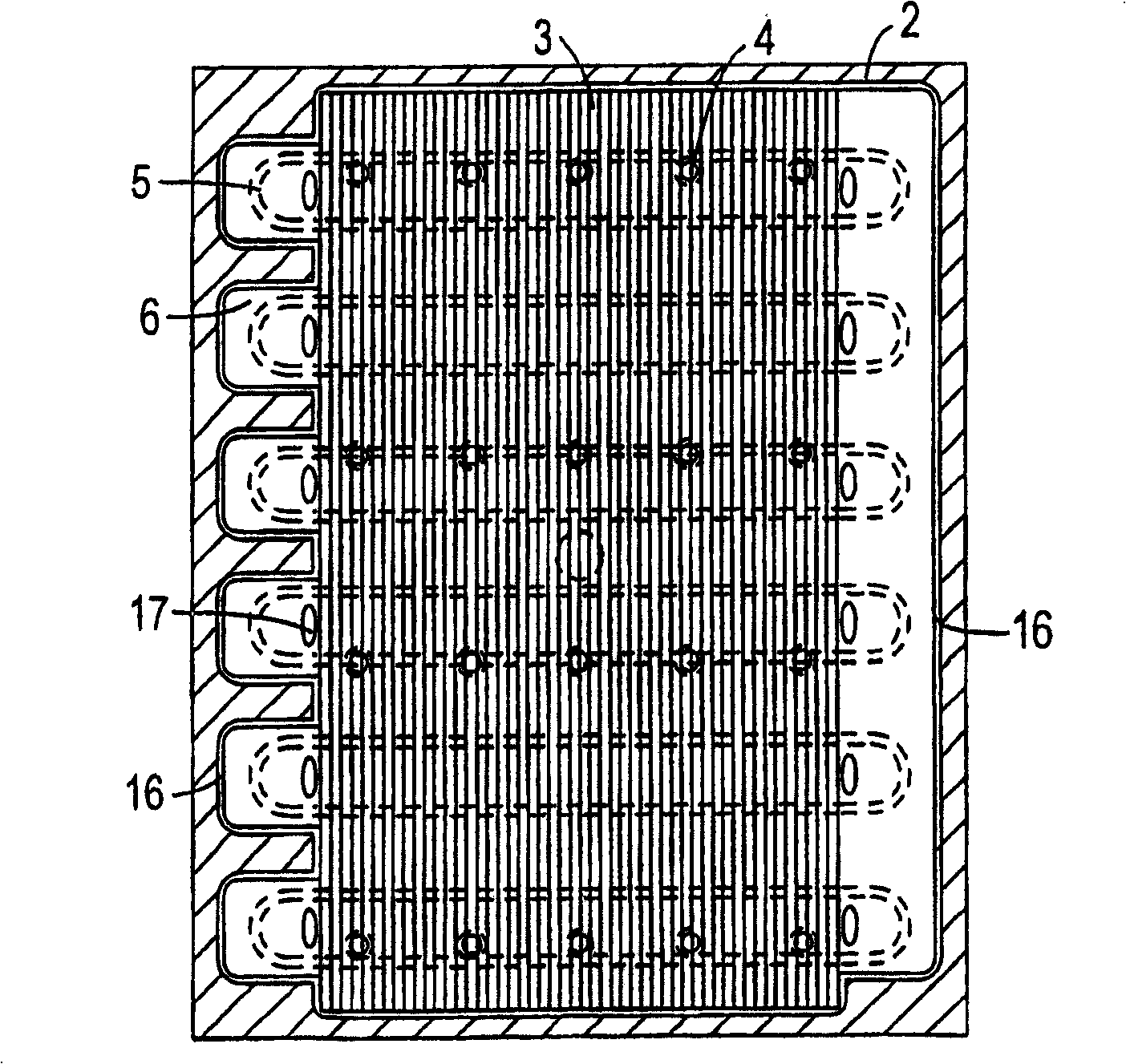

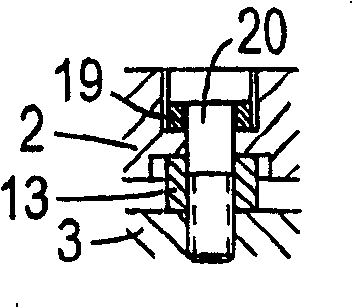

Air-cooled coil unit of a linear motor

InactiveUS6921991B2Improve thermal conditionsReduce positioning accuracyMotor/generator/converter stoppersDC motor speed/torque controlLinear engineCooling coil

The present invention is directed to a coil unit of a single-acting linear engine. The coil unit includes an iron core with coils that are linked with the iron core by way of a cast compound thereby forming a molded part. The molded part is enclosed by a housing having a narrow circumferential gap formed between the housing and the molded part. Through the gap, cooling air may flow or be blasted. The air extensively cools the iron core with the coils and thermally insulates the housing from the iron core and the coils.

Owner:SIEMENS AG

Air-cooled coil unit of a linear motor

InactiveCN100452625CImprove cooling effectImprove power densityCooling/ventillation arrangementPropulsion systemsLinear engineCooling coil

A coil unit (1) of a single-sided linear motor has an iron core (3) with a coil (5), which is connected to the iron core (3) via a casting compound (6) to form a molded part. The molded part is surrounded by a housing (2), wherein a narrow gap (16) is formed between the housing and the molded part, through which cooling air can blow through. As a result, the core (3) with the coil (5) is cooled over a large area and the housing (2) is thermally insulated from the core (3) and the coil (5).

Owner:ASM ASSEMBLY SYST GMBH & CO

Hybrid vehicle and method of operating engine of the same

ActiveUS8793043B2Improve engine performanceIncrease the number ofAnalogue computers for vehiclesBatteries circuit arrangementsElectricityHcci combustion

A hybrid vehicle may include a linear engine controlled by HCCI (Homogeneous Charge Compression Ignition) combustion in an operation section where an engine power may be used for generating electricity after being started and reaching up to a predetermined RPM, and a motor-combined generator engaged to the liner engine and starting the linear engine and charging a battery by converting an entire engine power of the linear engine generated by the HCCI combustion into electricity generation power.

Owner:HYUNDAI MOTOR CO LTD

Method for control scheduling to achieve linear thrust response

A method for achieving linear engine thrust response comprising the steps of measuring a throttle position (FNRQ), measuring a plurality of engine parameters, inputting the plurality of engine parameters and the throttle position into a plurality of schedules to produce a plurality of outputs, combining the plurality of outputs to produce a part power scheduled airflow (W2RSCH), and using the W2RSCH to produce a near linear thrust response of the engine.

Owner:UNITED TECH CORP

Control architecture and optimal strategy for switching between 2-stroke and 4-stroke modes of HCCI operation

Engine correction inputs to control oscillation in an engine output in a transition between 2-stroke and 4-stroke engine cycle modes of an HCCI engine are determined as follows: for each mode, valve timings which modify the engine output the most upon switching are determined, and a linear engine system model is defined at least partially based on the determined valve timings, which model provides mappings relating initial conditions of the engine and the engine correction inputs to outputs of the engine; initial conditions of the engine corresponding to a switching point for switching between the two modes are determined; desired engine output conditions upon switching between the two modes are specified; and the engine correction inputs are determined by using the determined initial conditions, the desired engine output conditions, and the linear engine system model corresponding to the engine cycle mode in effect upon switching.

Owner:ROBERT BOSCH GMBH

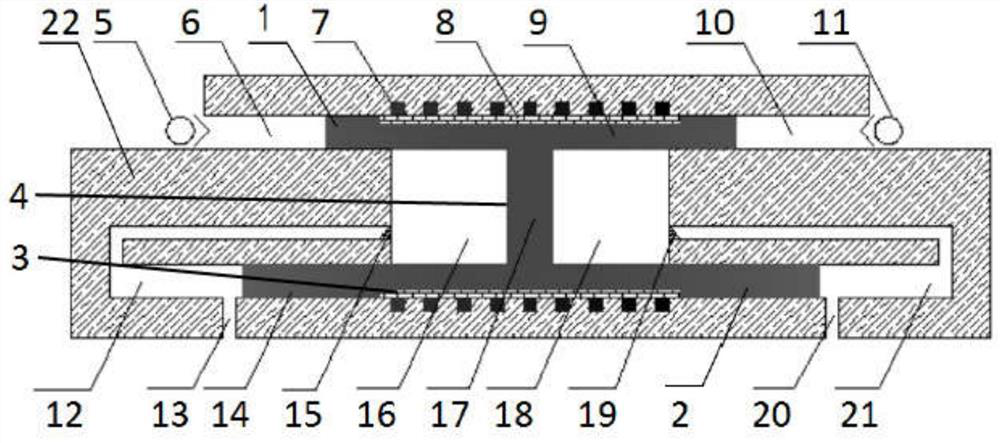

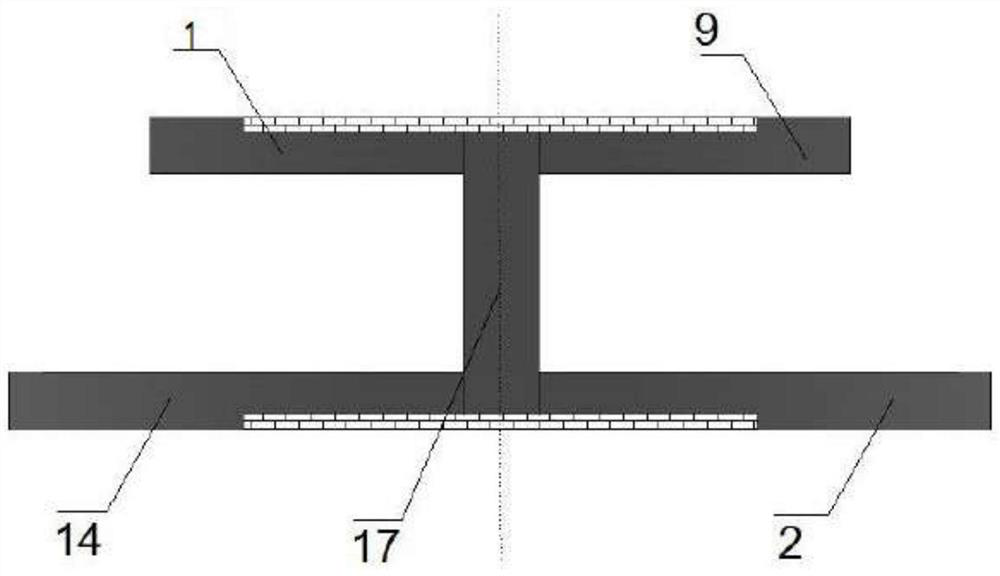

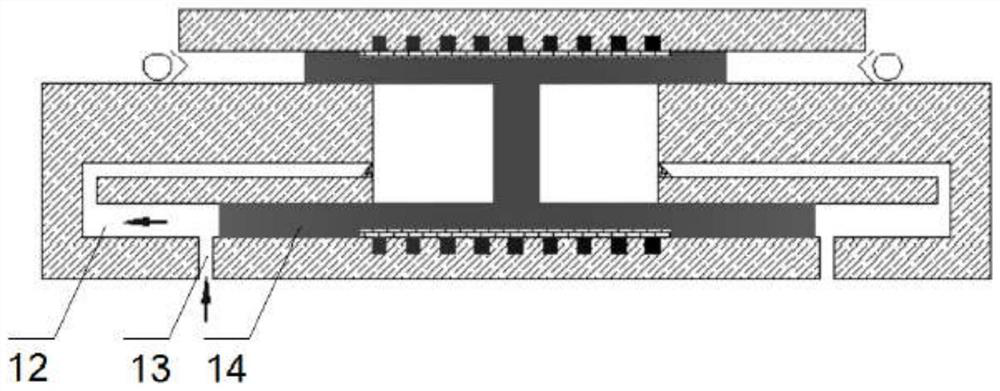

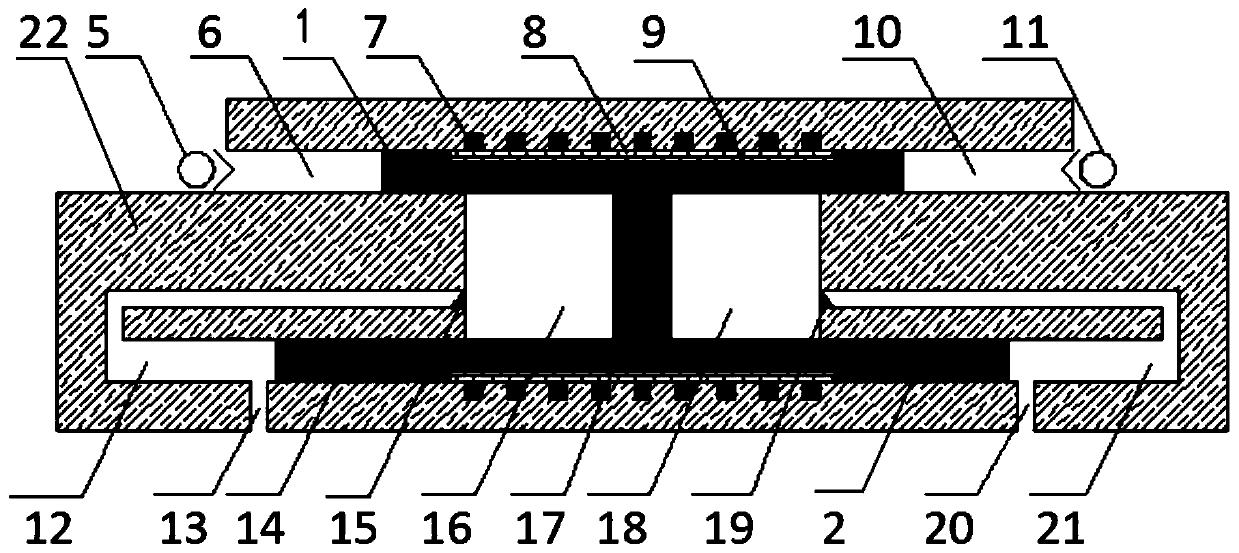

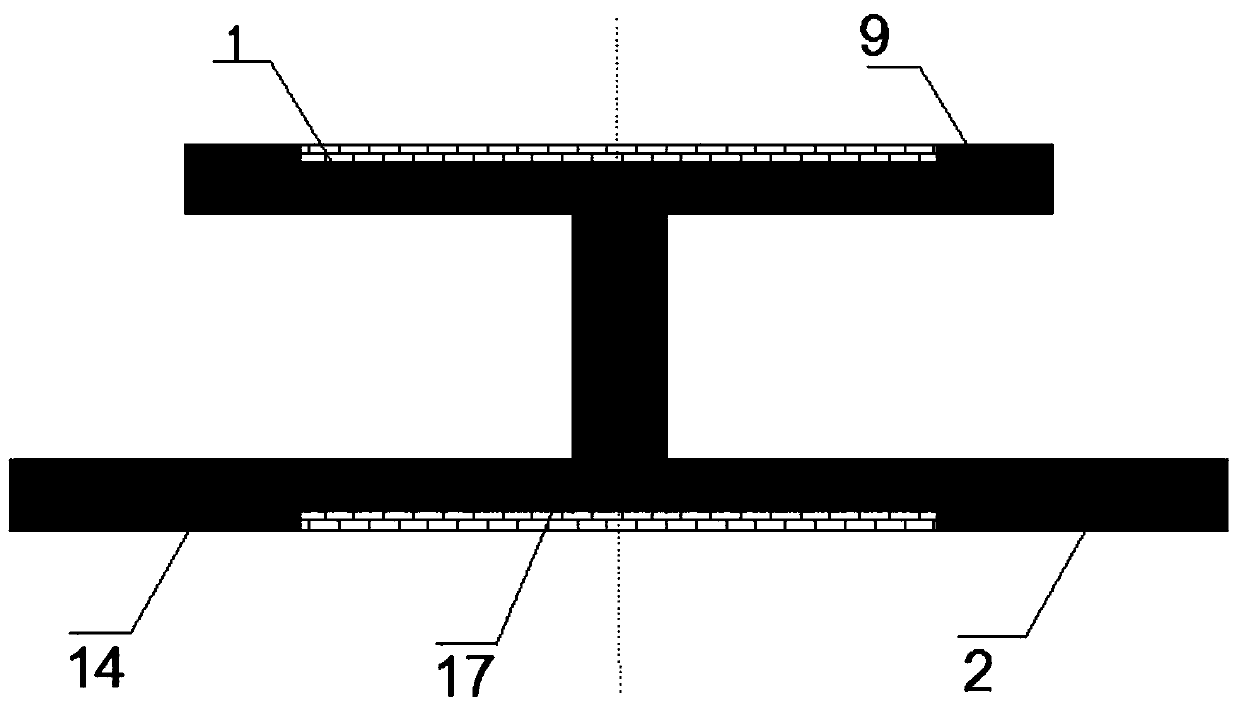

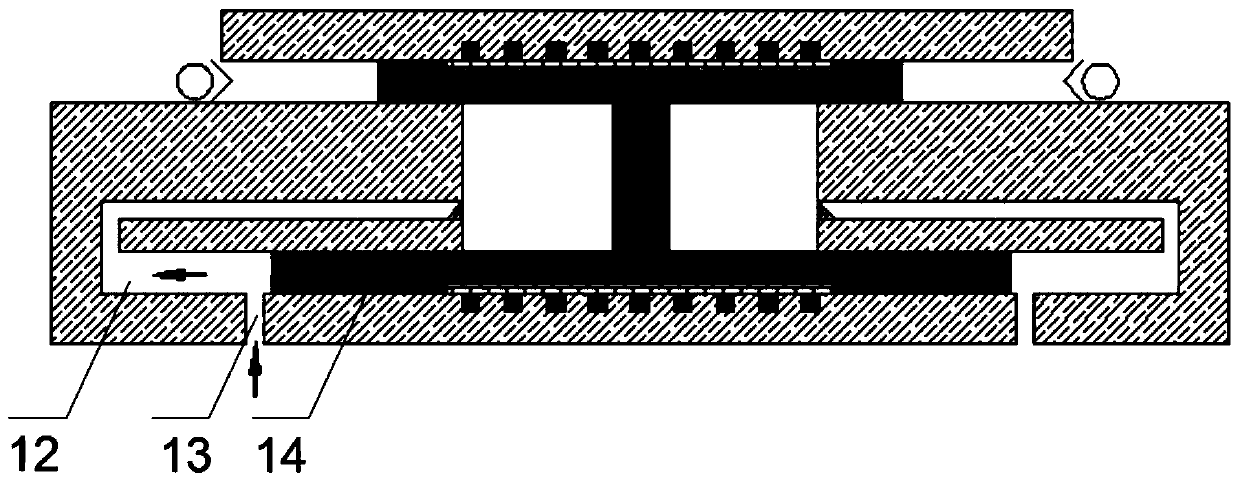

A gas type free piston linear engine

ActiveCN110454283BSimple structureGuaranteed fillingFree piston enginesLinear engineReciprocating motion

The invention relates to a gas-fired free piston linear generator, which includes an I-shaped piston and a cylinder body; the cylinder body is respectively symmetrically provided with a left air intake cavity, a right air intake cavity, a left exhaust gas cavity, and a right exhaust gas cavity; The I-shape includes a compression piston, a left intake piston, a right intake piston, a left exhaust piston and a right exhaust piston; the I-shaped piston is installed in the cylinder; the pressure difference is used to ensure the filling of the intake air , using differential pressure exhaust to ensure the adequacy of exhaust. The process of air intake, compression, combustion and expansion is continuously and alternately realized. The magnet fixed on the piston reciprocates horizontally with the I-shaped piston, and realizes the magnetic force line cutting between the power generation coil to realize power generation. The design, layout and structure of the device are simple, and are suitable for the development of miniaturization and portability.

Owner:JIANGSU UNIV

Fuel gas type free piston linear engine

ActiveCN110454283ASimple structureSuitable for miniaturizationFree piston enginesForce linesLinear engine

The invention relates to a fuel gas type free piston linear engine. The fuel gas type free piston linear engine comprises an I-shaped piston and a cylinder body, wherein the cylinder body is symmetrically provided with a left air inlet cavity and a right air inlet cavity as well as a left exhaust gas cavity and a right exhaust gas cavity; the I-shaped piston comprises a compression piston, a leftair inlet piston, a right air inlet piston, a left exhaust piston and a right exhaust piston; and the I-shaped piston is arranged in the cylinder body; the full air intake is guaranteed through differential pressure air intake, and the sufficient air exhaust is guaranteed through differential pressure air exhaust; the air intake, compression, combustion and expansion process is continuously and alternately realized, a magnet fixed on the piston performs horizontal reciprocating motion along with the I-shaped piston, magnetic force line cutting is realized between the magnet and a power generation coil, and power generation is realized. The fuel gas type free piston linear engine is simple in design and layout structure and is suitable for miniaturized and portable development.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com