Air-cooled coil unit of a linear motor

A linear motor, coil unit technology, applied in electrical components, electrical components, cooling/ventilation devices, etc., can solve the problem of loss of magnetic flux in cooling channels, and achieve the effect of high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

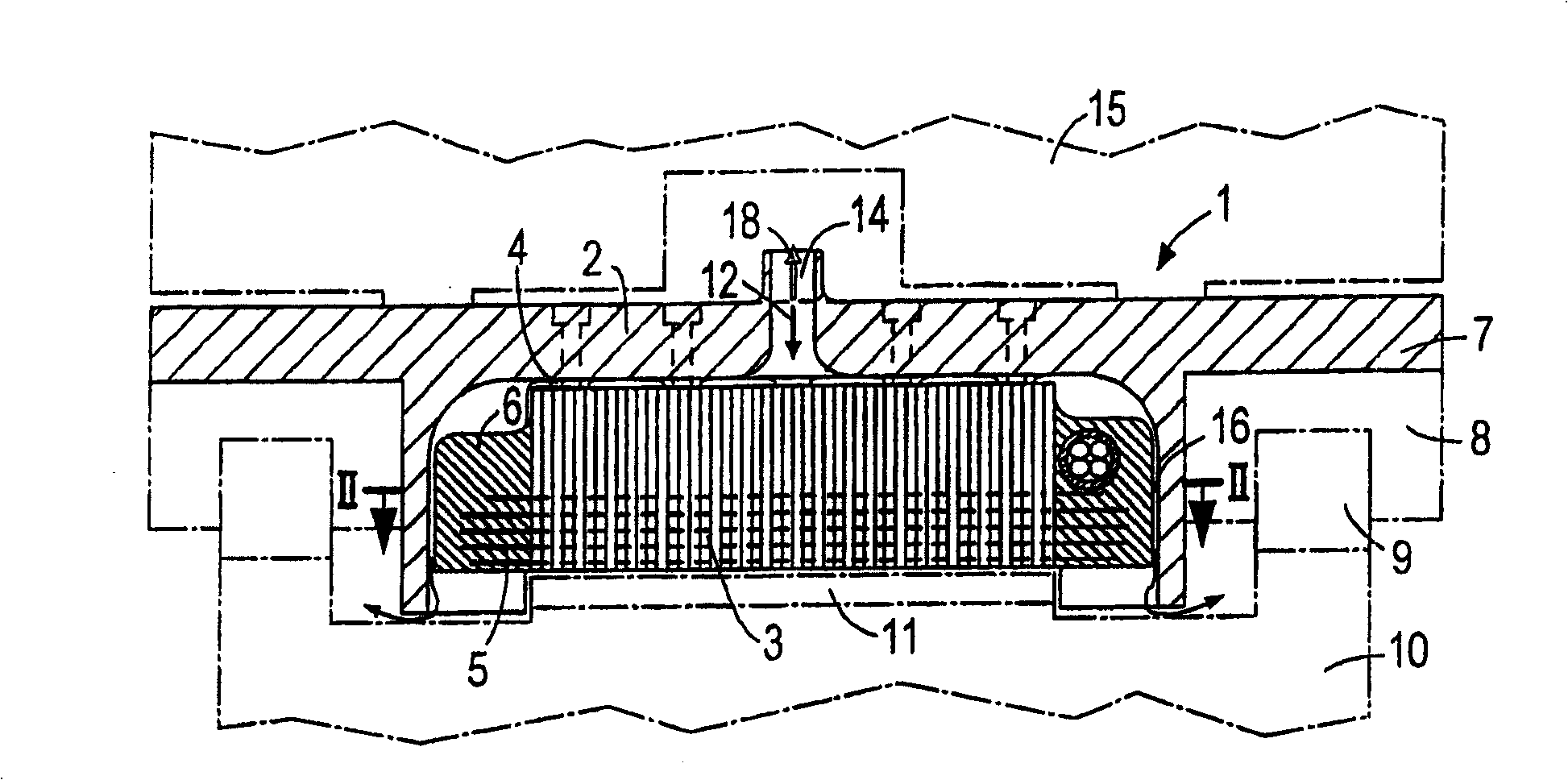

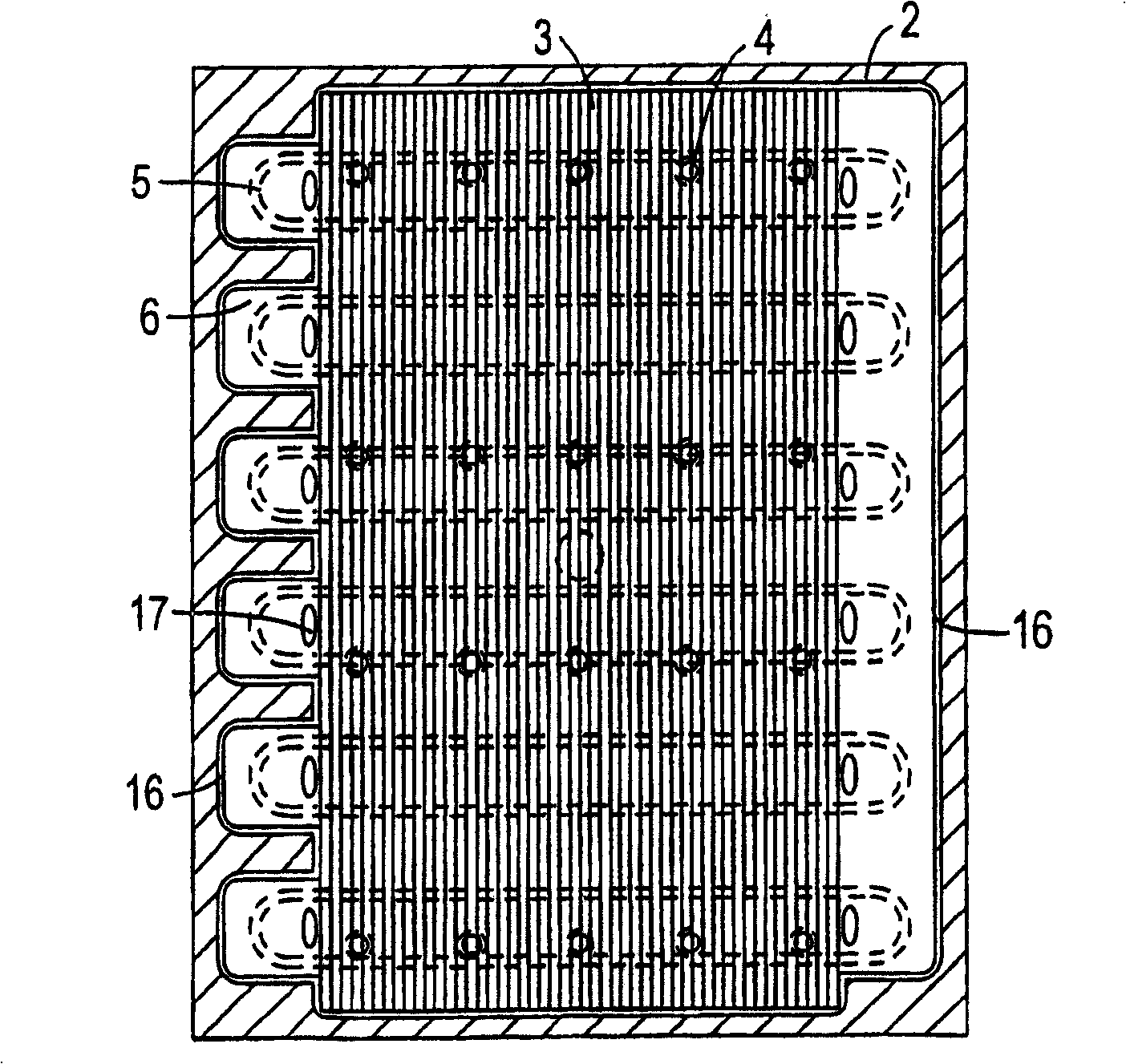

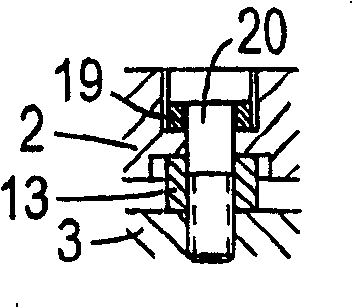

[0021] according to figure 1 and 2 A coil unit 1 has a housing 2 on which a core 3 made of laminations is fastened via a support element 4 which is designed as a support projection integrally formed on the housing 2 . The iron core 3 is fixedly connected to the winding of the electrical coil 5 via a casting compound 6 . The housing 2 has a laterally protruding flange-shaped projection 7 for fastening a linear guide element 8 . This guide element cooperates with a corresponding guide rail 9 of a fixed guide rail 10 . Between the guide rails 9, the guide rail 10 has a magnetic rail 11 made of permanent magnets arranged next to each other in the direction of movement.

[0022] The housing 2 is open on the side facing the magnetic track 11 and surrounds the core 3 with the coil 5 at a narrow distance on the other side. This distance serves as a surrounding slot 16 whose width is reduced to a fraction of a half millimeter. The core 3 and the coil 5 together with the potting co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com