Four-stroke linear engine

An engine, four-stroke technology, applied in engine components, engine lubrication, machine/engine, etc., can solve the problems of reduced efficiency, many frictional contacts, inconvenient setting of the lubrication system, etc., and achieve the effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

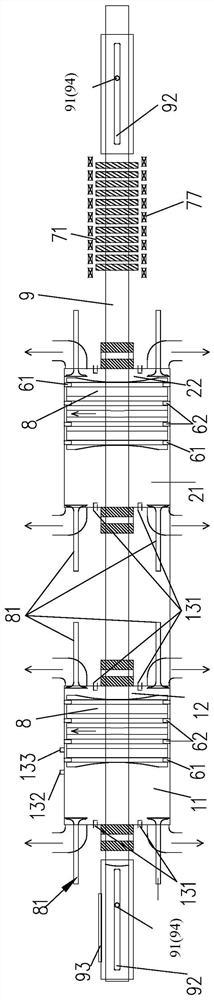

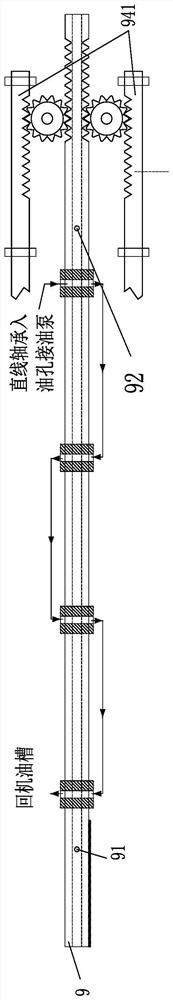

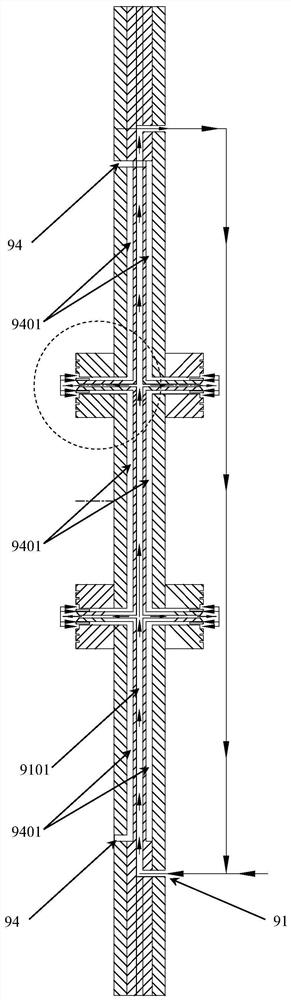

[0027] Such as Figure 1 to Figure 8 As shown, the four-stroke linear engine of the present invention at least includes: a first piston chamber and a second piston chamber arranged coaxially in an airtight manner, a piston 8 is arranged in each piston chamber, and the left side piston chamber is divided into Left and right two combustion chambers 11,12. The right side piston divides the right side piston cavity into two left and right combustion chambers 21 , 22 . A power output shaft 9 passes through the piston cavity and is connected with two pistons; each combustion chamber is provided with a controlled electromagnetic valve 81 for controlling the intake (oil) gas and exhaust of each combustion chamber.

[0028] Among them, each piston reciprocates in the piston cavity, so that each combustion chamber performs in sequence: suction (intake) stroke, compression stro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com