Self-priming hydraulic free-piston linear engine

An engine and self-priming technology, which is applied in the field of power devices and piston engines, can solve the problems that the system does not have self-priming oil function, the engine fuel utilization rate is poor, and the complexity of the system increases, so as to improve efficiency and reliability, Good transient response, good economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0027] This embodiment provides a hydraulic free-piston linear engine with self-priming ability, which can solve the problems of low efficiency, poor fuel rate and complex structure of the existing linear engine.

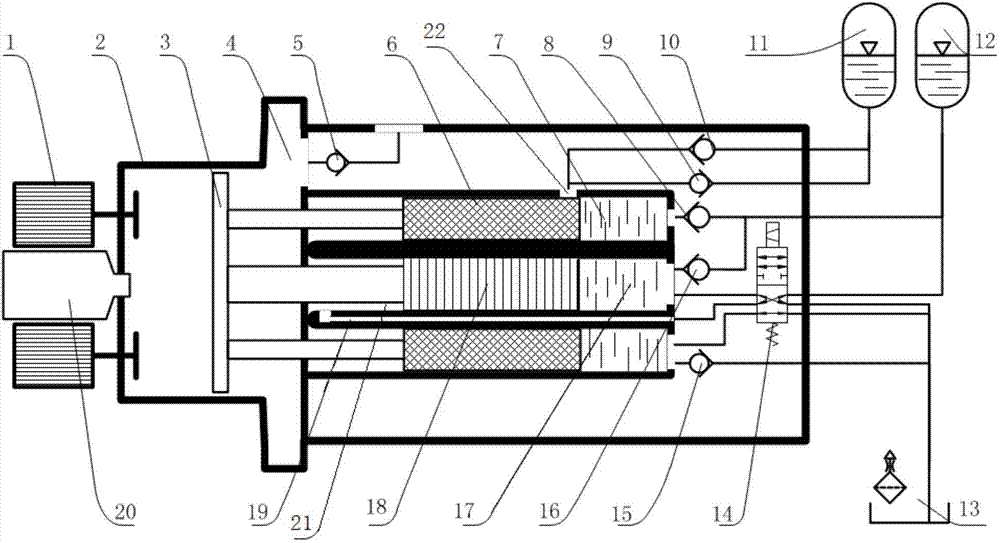

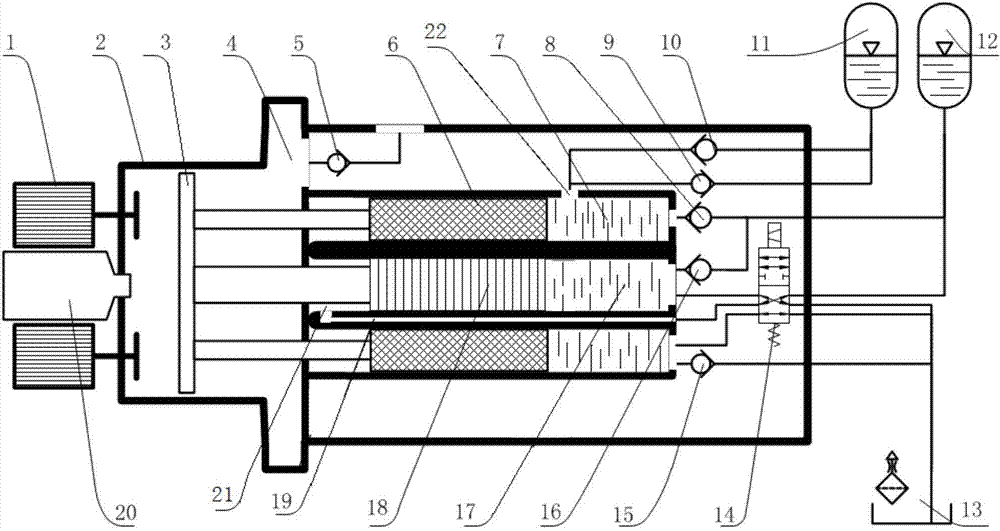

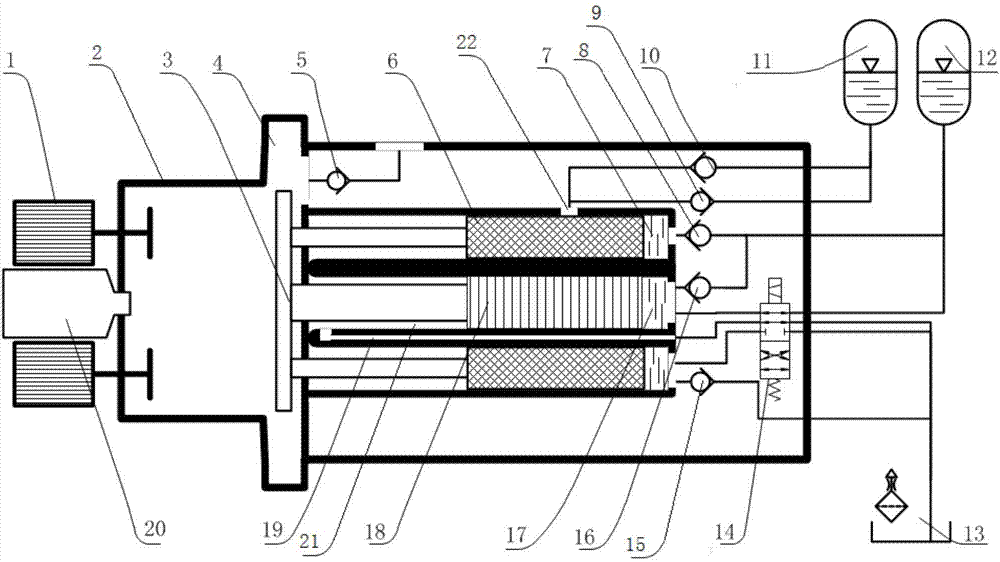

[0028] The linear engine includes: a cylinder block 2, a piston assembly, a low pressure accumulator 11, a high pressure accumulator 12, a pressure oil tank 13, a pneumatic control valve 14 and a fuel injector 20. Wherein the cylinder body 2 is the body, the high-pressure accumulator 12 and the low-pressure accumulator 11 are energy storage devices, and the piston assembly includes a cylinder piston 3 , a pump piston 6 and a compression piston 18 .

[0029] Its overall connection relationship is as follows figure 1 As shown: the cylinder block 2 is a hollow cylindrical structure, providing a mounting cavity for the piston assembly. The cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com