Straight shank linear engine

An engine and straight shank technology, applied in the field of straight shank linear engines, can solve the problems of low thermal efficiency utilization rate and power consumption of the engine, and achieve the effects of increasing power, reducing fuel consumption and high utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

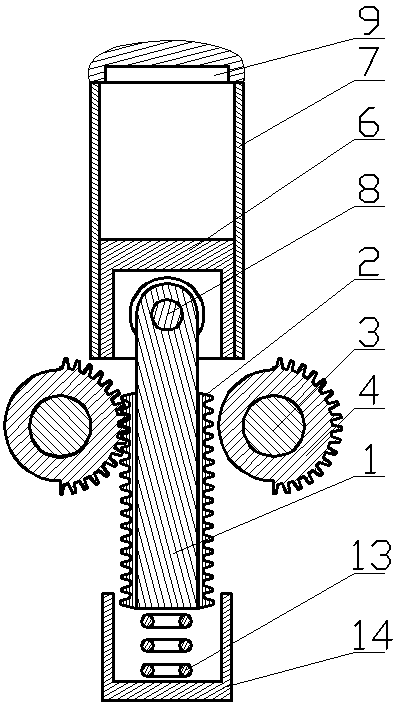

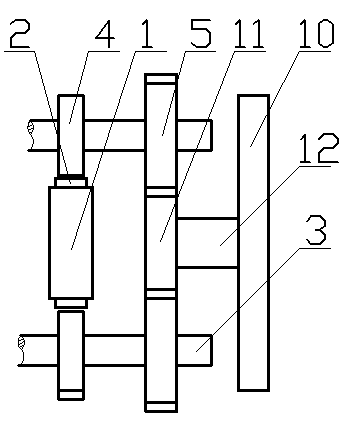

[0013] The two major mechanisms of the straight shank linear engine of the present invention are composed of a straight shank connecting rod mechanism and a gas distribution mechanism; one end of the connecting rod 1 of the straight shank connecting rod mechanism is connected with the piston 6 through a piston pin 8, and a rack is fixed on the connecting rod 1 2. When the piston is at the bottom dead center, the other end of the connecting rod 1 is pressed on the spring 13, and the spring 13 is installed in the internal combustion engine through the spring seat 14; in a straight handle engine, there are two rotating shafts 3 installed on the cylinder body and can be Rotate, the connecting rod 1 passes through the semicircular gear 4 on the two rotating shafts 3, each rotating shaft 3 is fixed with a transmission gear 5 and a semicircular gear 4, the transmission gear 5 meshes with the intermediate gear 11, Semicircular gear 4 can be meshed or separated with rack 2; Intermediate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com